Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

170results about How to "High acid value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

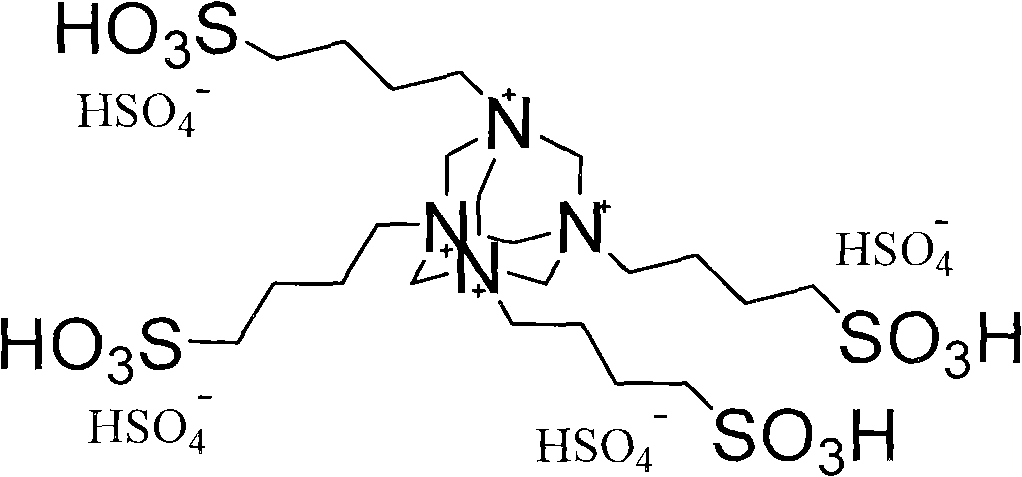

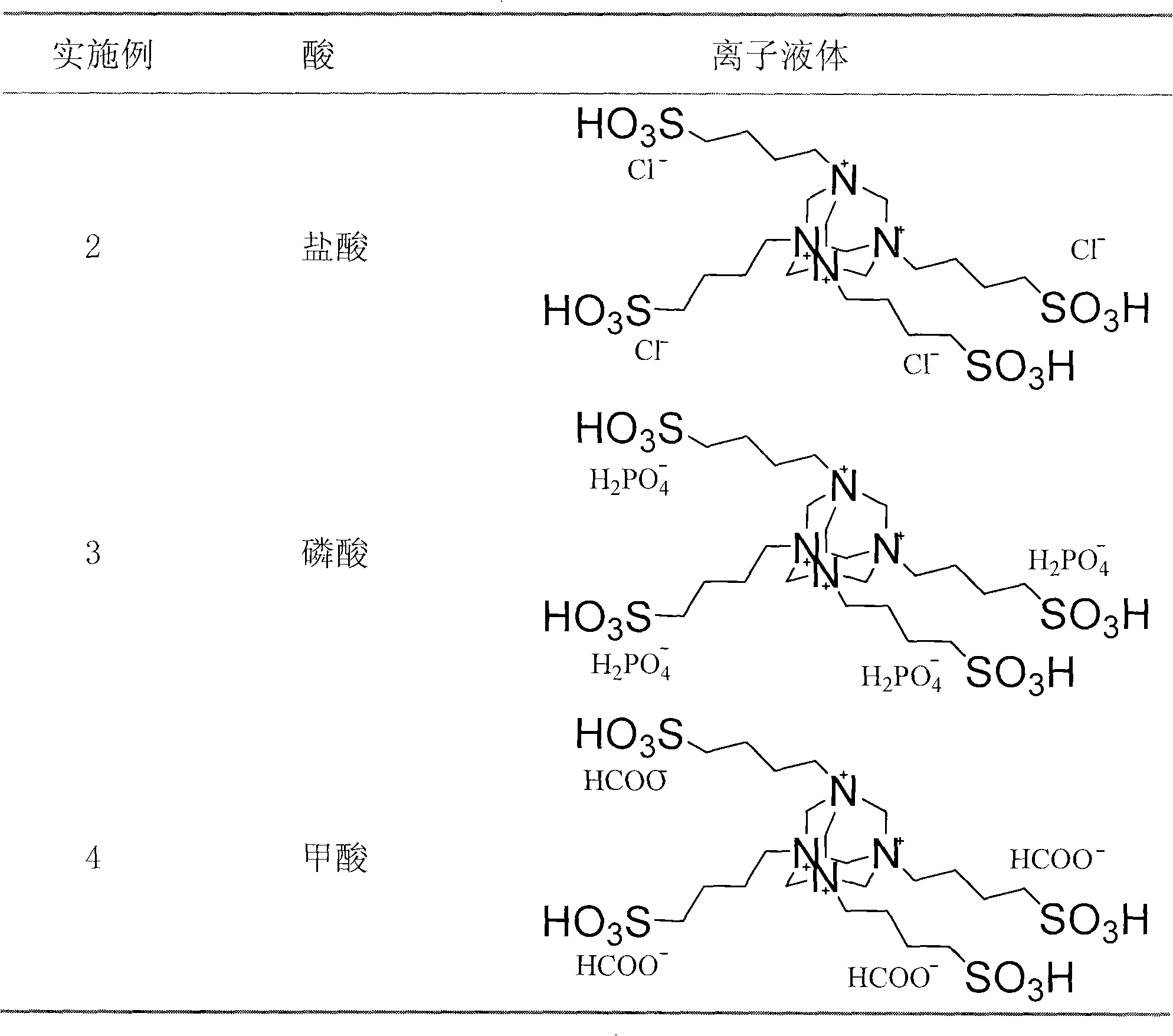

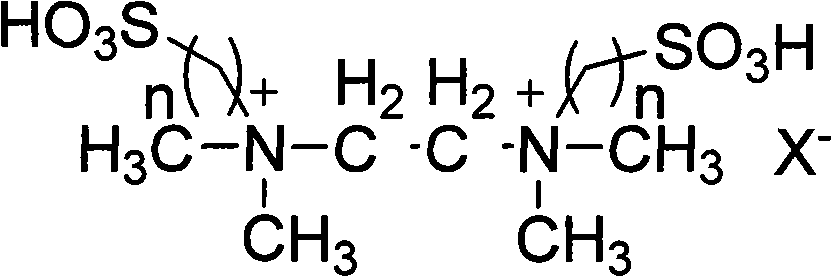

Preparation of multi-sulfonic functional ion liquid

InactiveCN101348487AHigh acid valueLow costOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsBetaineAcid value

The invention discloses a method for preparing a multi-sulfonic acid group functionalized ionic liquid. In the method, a poly-nitrogen tertiary amine reacts with a sultone to an obtain multi-sulfonic acid radical betaine, and the obtained betaine is subjected to acidification by an acid to obtain the multi-sulfonic acid group functionalized ionic liquid. The ionic liquid prepared by the invention has the characteristics of high thermal stability, high acid value, low synthesis cost and good catalytic effect, etc.

Owner:EAST CHINA NORMAL UNIV

Method of drying an absorbent polymer with a surfactant

InactiveUS20070123624A1Improved pumpability and spreadabilityImprove drying efficiencyTransportation and packagingMixingPolymer scienceAcid value

A method of drying an absorbent polymer includes providing the absorbent polymer. A surfactant having a C10 to C24 ester group is incorporated with the absorbent polymer. An acid value of the surfactant is increased to further increase drying efficiency of the absorbent polymer. More specifically, after increasing the acid value of the surfactant, the absorbent polymer exhibits improved pumpability and spreadability, as compared to absorbent polymers including the surfactant without having the acid value of the surfactant increased.

Owner:OTTEN JAY +2

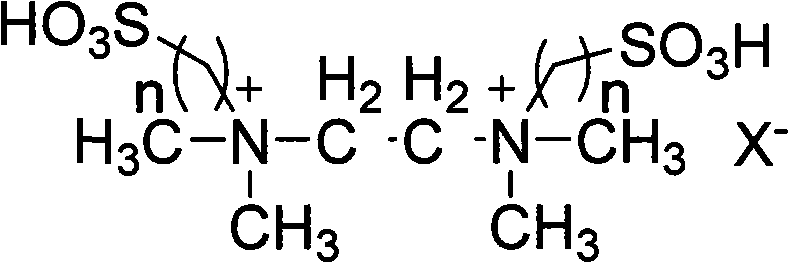

N,N,N,N-tetramethylethylenediamine sulphonate ionic liquid and preparation method thereof

InactiveCN101648894AHigh acid valueHigh catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsSulfonic acid preparationChemical synthesisOrganic reaction

The invention provides N,N,N,N-tetramethylethylenediamine sulphonate ionic liquid and a preparation method thereof, belonging to the technical field of organic chemical synthesis. The preparation method of the ionic liquid comprises the following steps: using N,N,N,N-tetramethylethylenediamine and sultone to react at room temperature in the presence of acetone and absolute ethanol to obtain N,N,N,N-tetramethylethylenediamine sulphonate inner salt, and then using N,N,N,N-tetramethylethylenediamine sulphonate inner salt to react with inorganic acid or organic acid to obtain disulfonic acid groupacidic ionic liquid with N,N,N,N-tetramethylethylenediamine cationic group. The prepared ionic liquid can be used as the catalyst or solvent of organic reactions, in particular to the catalytic reaction of inorganic acid or organic acid; compared with the existing monosulfonic group acidic ionic liquid used as catalyst, the N,N,N,N-tetramethylethylenediamine sulphonate ionic liquid has higher catalytic activity, less dosage, less loss in cycle use, higher product yield and more environmentally friendly.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

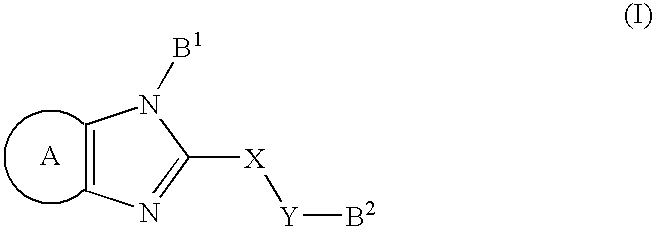

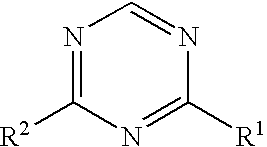

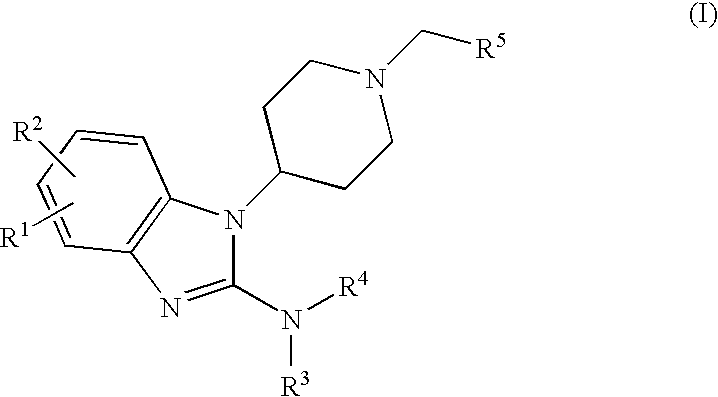

Receptor Function Regulating Agent

InactiveUS20080021069A1Use agentSuperior GPR4 receptor antagonist activityBiocideSenses disorderHyperinsulinemiaObesity

The present invention relates to a GPR40 receptor function regulator comprising a fused imidazole compound represented by the formula: wherein each symbol is as defined in the specification, or a salt thereof or a prodrug thereof. The GPR40 receptor function regulator is useful as an agent for the prophylaxis or treatment of obesity, hyperinsulinemia, type 2 diabetes and the like.

Owner:TAKEDA PHARMA CO LTD

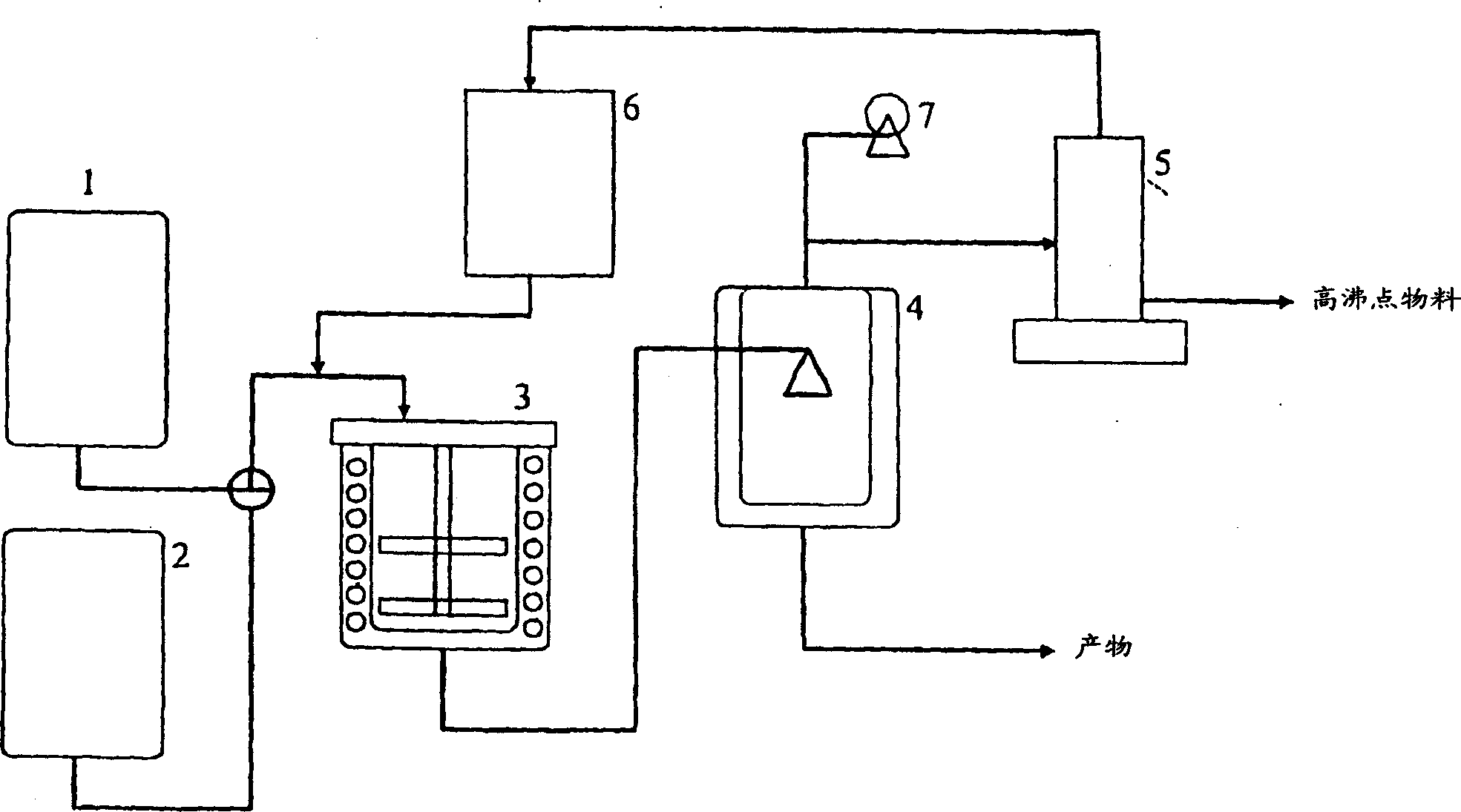

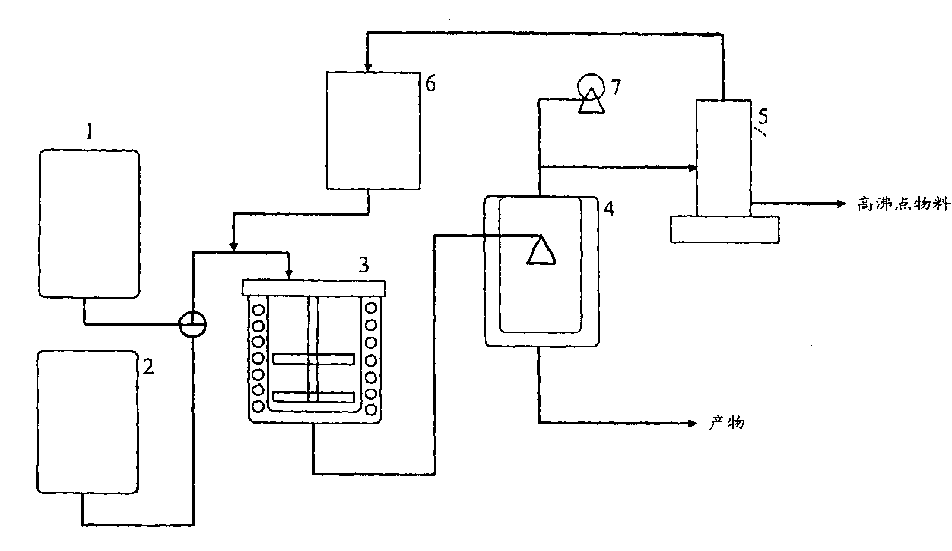

Process for preparing water-soluble styrenelacrylic resins by continuous bulk polymerization

The invention relates to a bulk polymerization process for preparing water-soluble styrene / acrylic resins, in which styrene and acryl monomers are polymerized in a solvent mixture of dipropylene glycol methyl ether and water in a temperature-controllable reactor equipped externally with an oil jacket containing a cooling coil therein and the resulting polymers are deprived of volatile contents in a falling-strand type devolatilizer. The water-soluble styrene / acrylic resins take industrial advantages over conventional resins because the resins, if polymerized at lower temperatures, show lower molecular weights, narrower molecular weight distributions, higher acid values and lower volatile content.

Owner:HANWHA CHEMICAL CORPORATION

Proton conducting membrane for fuel cells

InactiveUS6977122B2High number of acid siteControl contentSemi-permeable membranesIon-exchanger regenerationFuel cellsCoupling

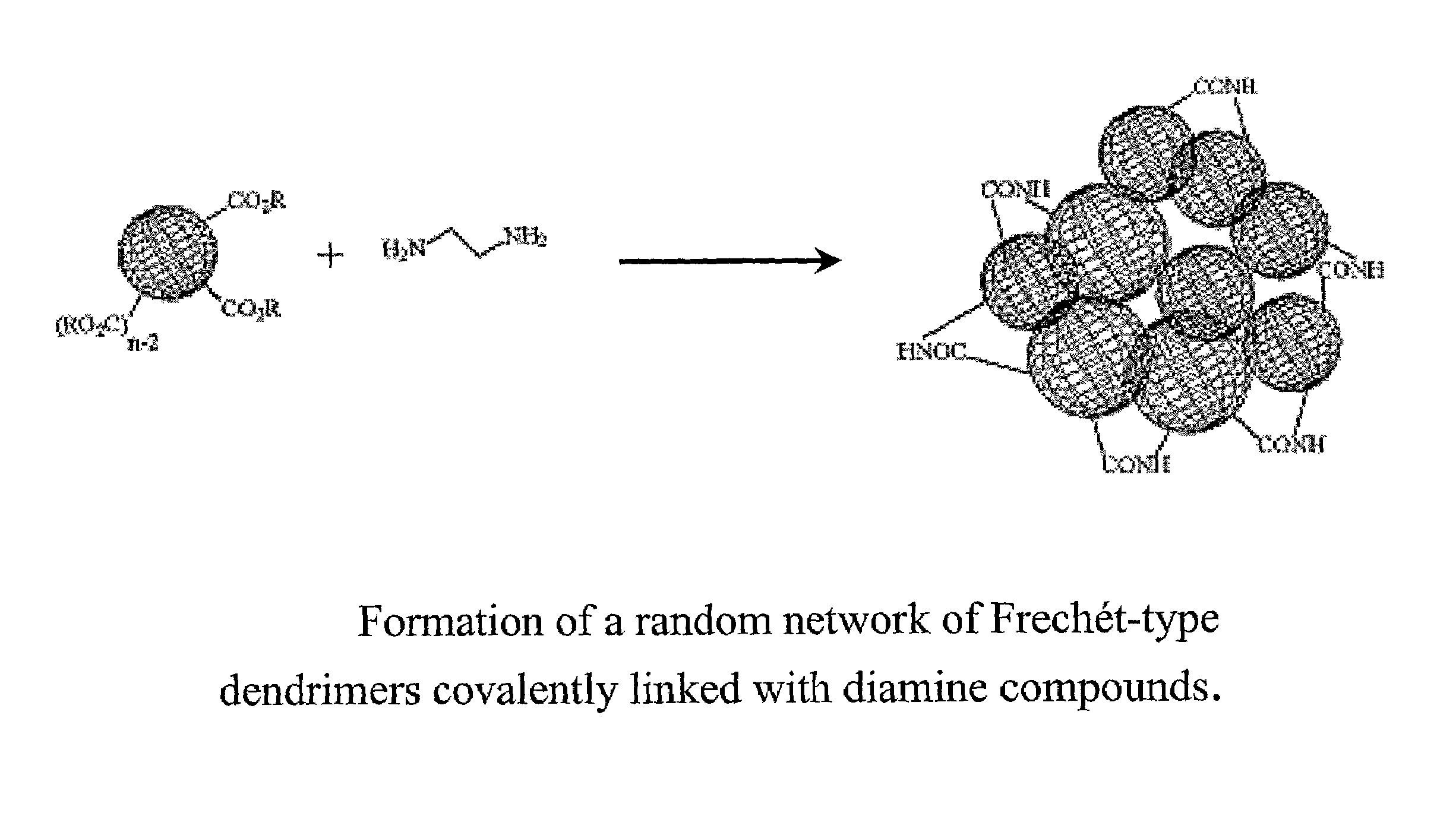

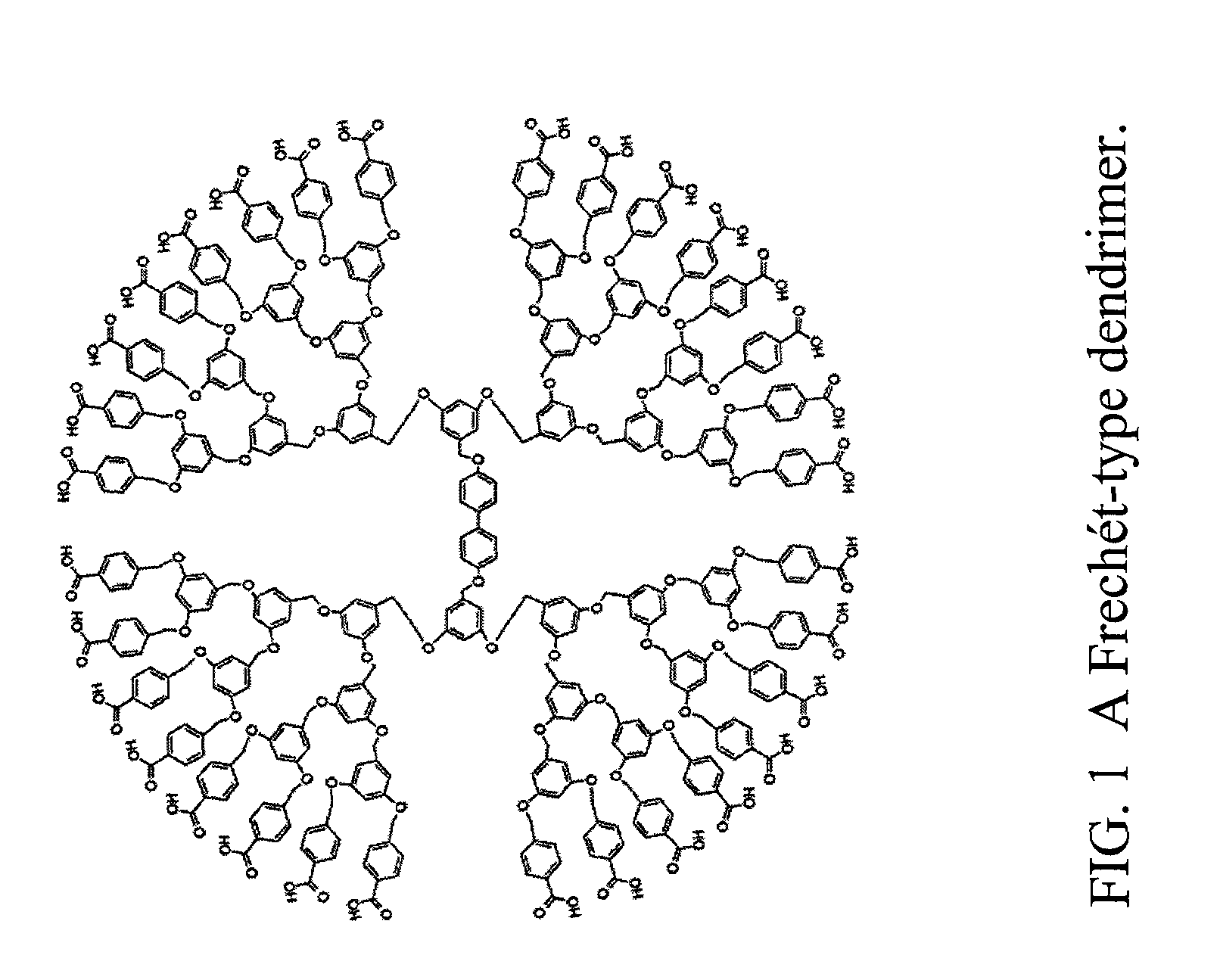

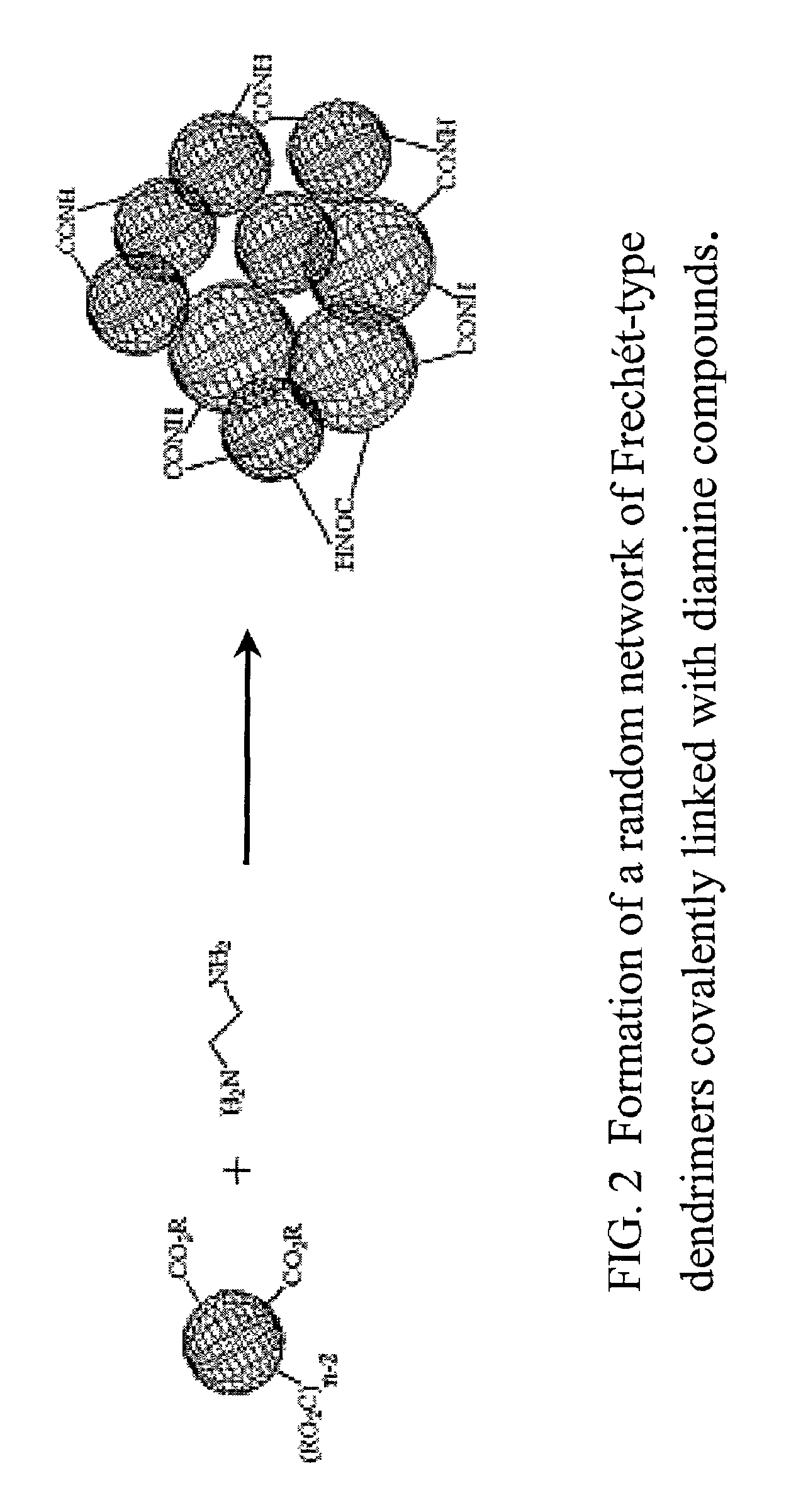

An ion conducting membrane comprising dendrimeric polymers covalently linked into a network structure. The dendrimeric polymers have acid functional terminal groups and may be covalently linked via linking compounds, cross-coupling reactions, or copolymerization reactions. The ion conducting membranes may be produced by various methods and used in fuel cells.

Owner:UCHICAGO ARGONNE LLC +1

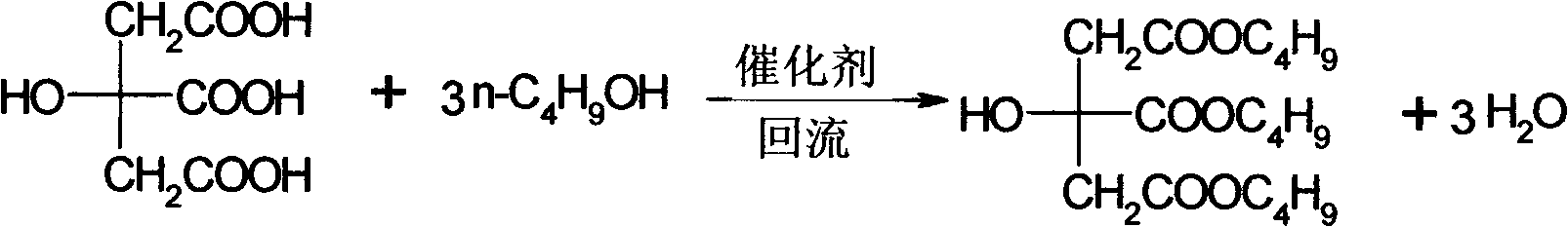

Method for synthesizing tributyl citrate

InactiveCN102070450AHigh yieldReduce dosageOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsChemical synthesisSolid acid

The invention discloses a method for synthesizing tributyl citrate, in particular relates to a method for synthesizing the tributyl citrate through the catalysis of gel starch-based carbon-based solid acid, and belongs to the technical field of organic chemical synthesis. The method is characterized by comprising the following steps of: performing ester synthesis by taking the gel starch-based carbon-based solid acid as a catalyst; filtering the catalyst out of the reaction mixture after the reaction is finished; and performing water-washing and alkali-washing, distilling and the like to obtain the tributyl citrate. The method has the advantages of high yield, small using amount of catalyst, mild reaction condition, short reaction time, environmental friendliness and the like.

Owner:SHAOXING UNIVERSITY

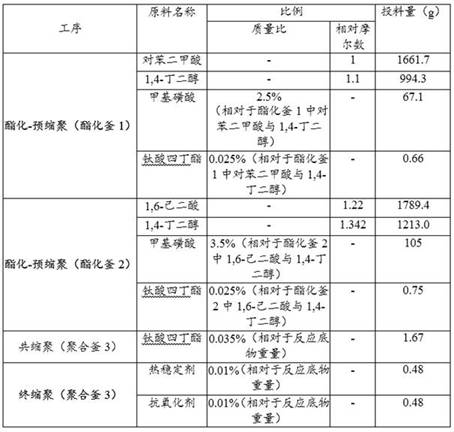

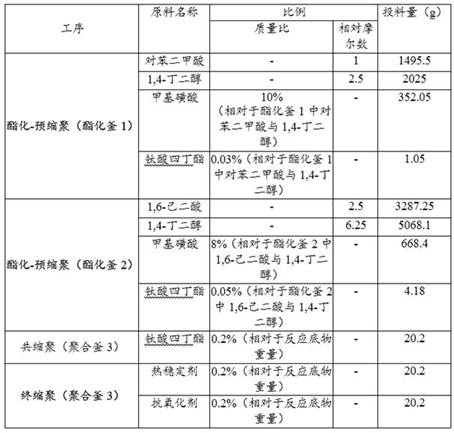

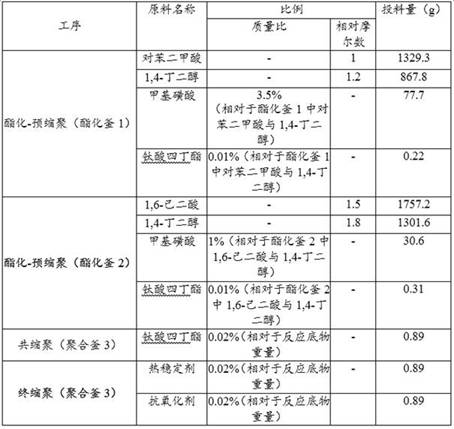

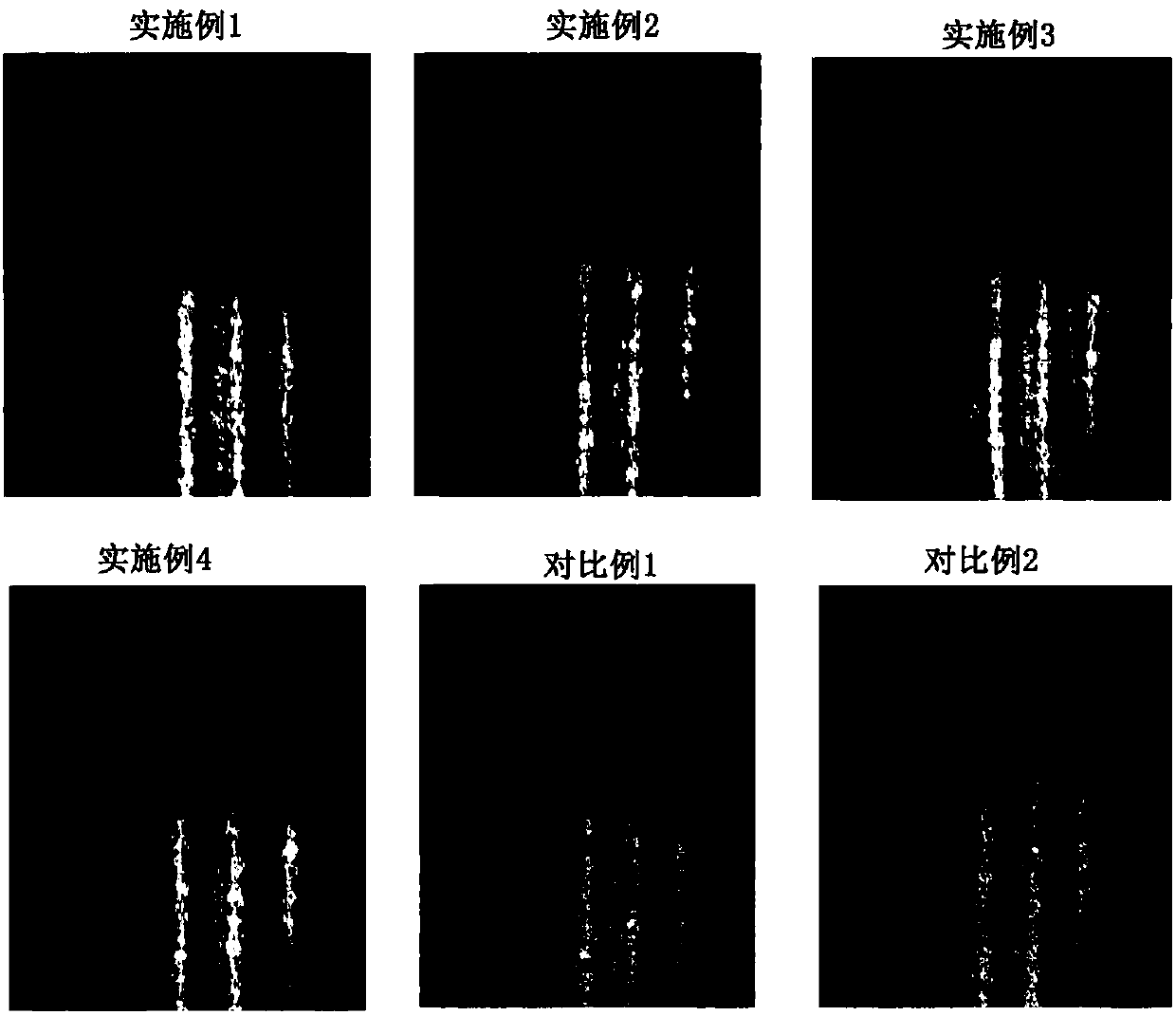

Biodegradable polyester and preparation method thereof

ActiveCN112521592ASuppress thermal degradation side reactionsRapid and thorough thermal degradation side reactionsOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsMethyl palmoxirateChain segment

The invention discloses biodegradable polyester and a preparation method thereof, and relates to the technical field of biodegradable materials. According to the method, methanesulfonic acid replacestitanate which is easy to hydrolyze to serve as the catalyst in the esterification reaction stage for generating a large amount of water, then the titanate catalyst is added in batches during pre-polycondensation and copolycondensation reaction without generating water, catalyst hydrolysis is avoided, the use amount of the catalyst is reduced, and therefore PBAT thermal degradation reaction is effectively inhibited, the acid value of the product is reduced, and the acid value of the prepared PBAT is smaller than 15mol / t. The block copolymer with a longer BHBT and BHBA chain segment structure can be obtained by firstly carrying out pre-polycondensation after esterification and then carrying out co-polycondensation, the regularity of the molecular chain structure is higher than that of PBATprepared by a traditional random copolymerization method, and the mechanical property of PBAT resin is better due to the BHBT chain segment with a longer hard segment structure in the molecular structure.

Owner:FUHAI (DONGYING) ADVANCED MATERIAL TECH CO LTD

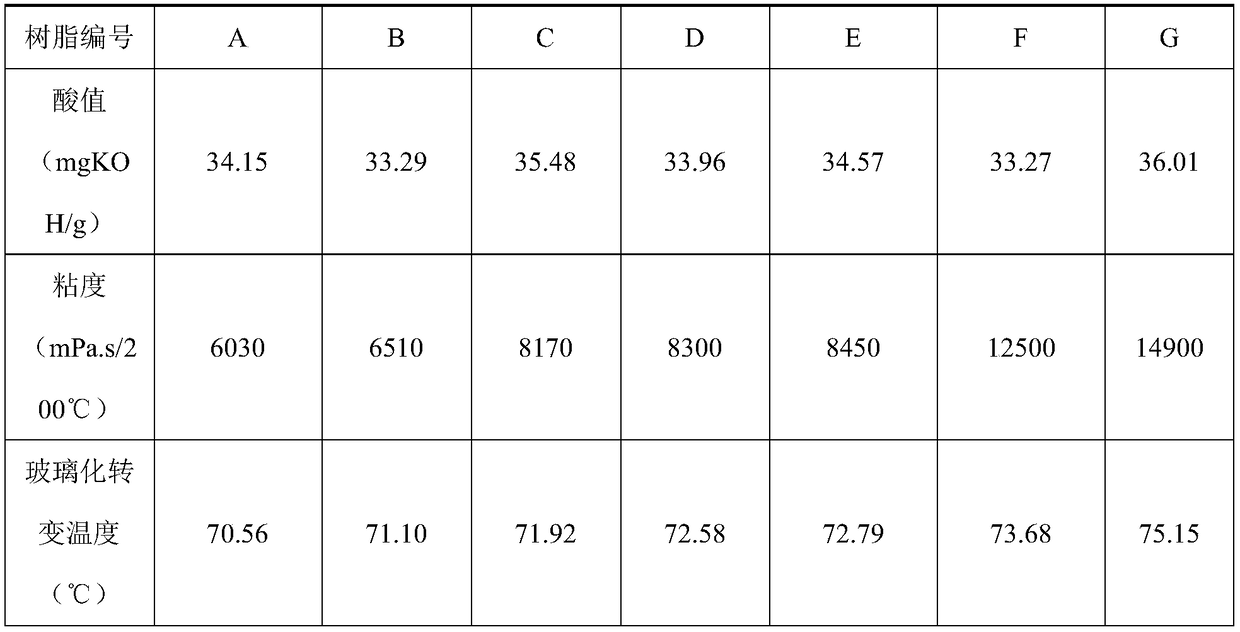

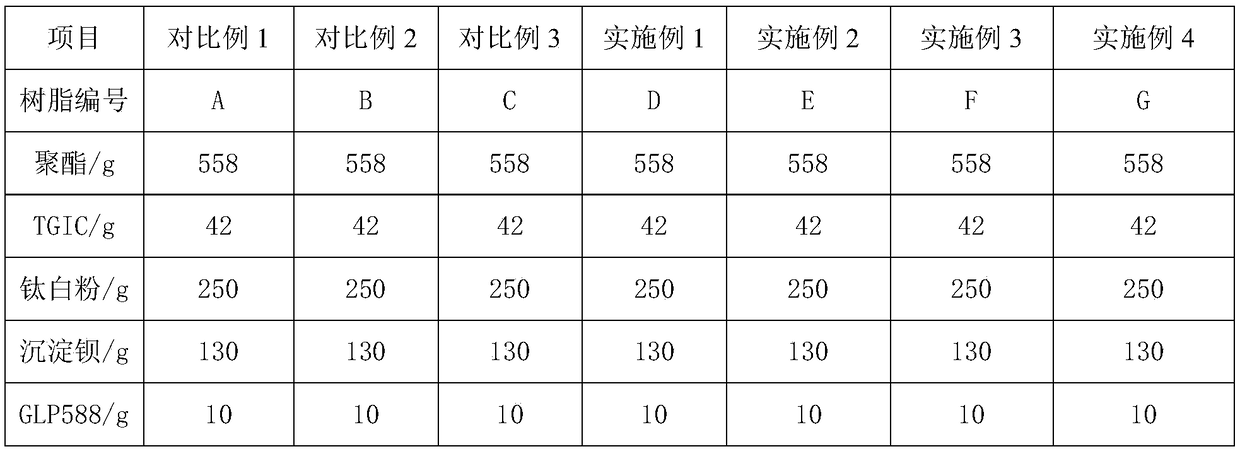

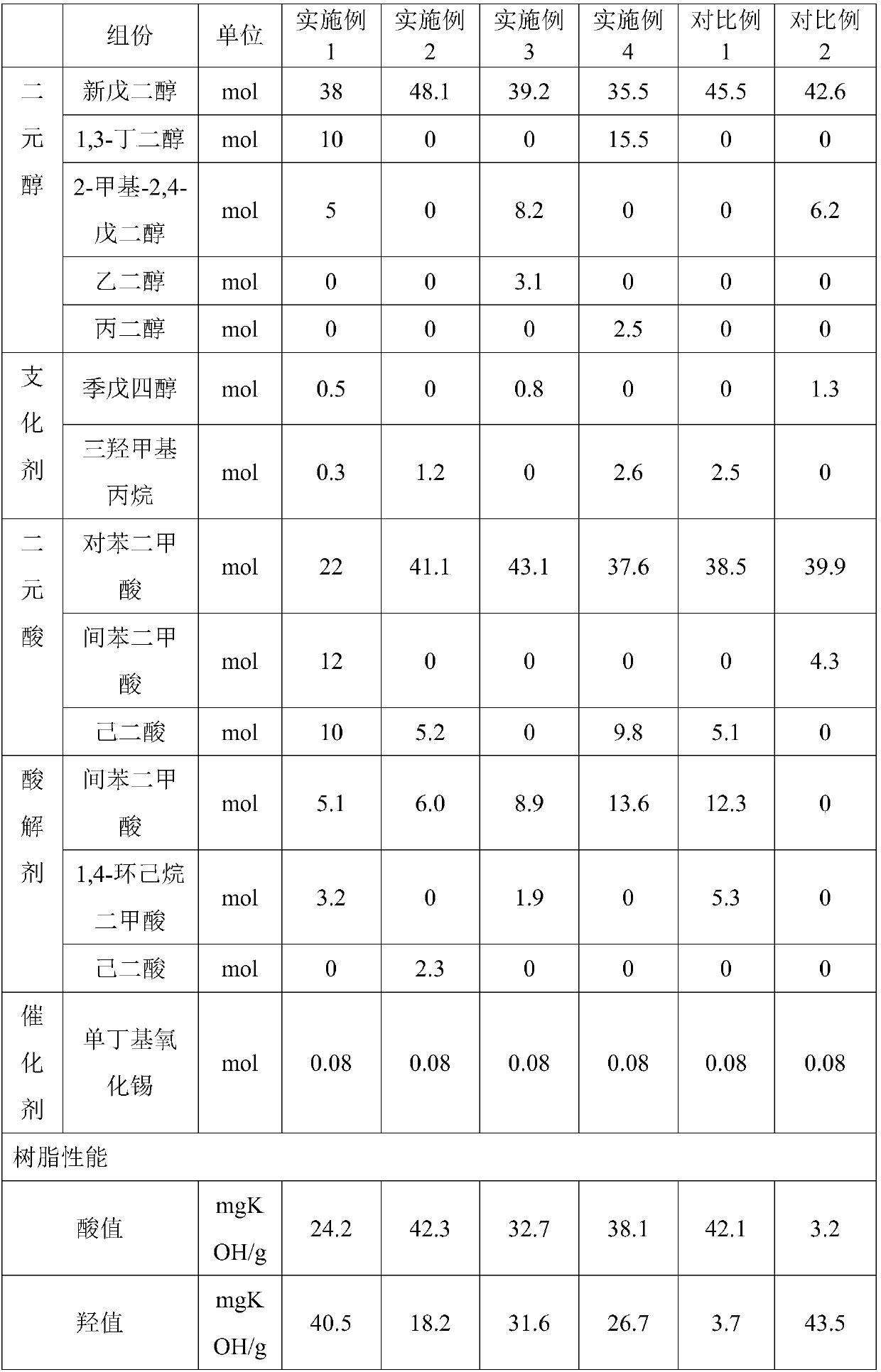

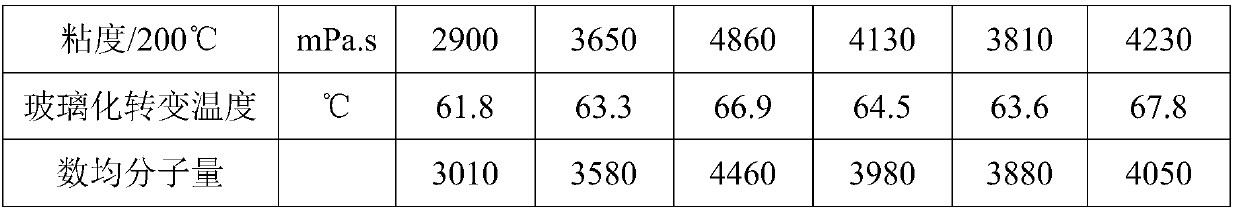

Bifunctional polyester resin for powder coating and preparation method of polyester resin

InactiveCN107868235ASimple structureImprove performancePowdery paintsPolyester coatingsSolventGlass transition

The invention discloses bifunctional polyester resin for a powder coating. The polyester resin has two functional groups including a terminal carboxyl group and a terminal hydroxyl group and has the acid value of 20-45 mgKOH / g, the hydroxyl value of 15-45 mgKOH / g, the viscosity of 2,600-5,200 mPa.s at the temperature of 200 DEG C, the number-average molecular weight of 3,000-4,500 and the glass transition temperature of 61-69 DEG C; the polyester resin is mainly prepared from components in mole percent as follows: 44mol%-55mol% of dibasic alcohol, 40mol%-46mol% of binary acid, 0.1mol%-3.0mol%of a branching agent, 4mol%-15mol% of an acidulate agent and 0.01mol%-0.10mol% of an esterification catalyst through melt polymerization. The polyester resin has outstanding comprehensive properties in the aspects of leveling performance, mechanical property, weather fastness, boiling resistance, heat resistance, solvent resistance, heat transfer printing property and the like. The invention alsodiscloses a preparation method of the bifunctional polyester resin for the powder coating.

Owner:GUANGZHOU KINTE IND

Method for synthesizing ethylene sulfate

The invention relates to a method for synthesizing ethylene sulfate, and belongs to the technical field of chemical power supplies. The method comprises the following steps: A, carrying out a contactreaction on sulfur dioxide with ethylene oxide in the presence of a composite catalyst, controlling the reaction temperature to be 120-160 DEG C, introducing sulfur dioxide gas to keep the pressure ofthe reaction system at 5-12 MPa, and controlling the reaction time at 1-2.5 hours to obtain ethylene sulfite for standby use; B, adding an aqueous solution of sodium hydrogen carbonate into the ethylene sulfite obtained in the step A, carrying out cooling to a temperature ranging from -5 DEG C to 5 DEG C, dropwise adding a mixed solution of sodium periodate and ruthenium trichloride under a condition with a temperature ranging from -5 DEG C to 5 DEG C, keeping the temperature for 1-1.5 hours after the adding is completed so as to obtain a reaction solution with co-existed water phase and organic phase, carrying out standing for layering, and separating out the water phase to obtain the organic phase, namely a crude product of the ethylene sulfate; and C, carrying out molecular distillation on the crude product of the ethylene sulfate obtained in the step B under the condition with a temperature of 70-80 DEG C to obtain the ethylene sulfate. The ethylene sulfate prepared by the methodhas high purity and high yield, and when the ethylene sulfate is added into a battery, the performance of the battery is better.

Owner:SHIJIAZHUANG SAN TAI CHEM CO LTD

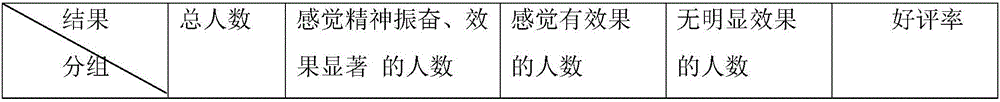

Oat and linolenic acid composite beverage and preparation method thereof

ActiveCN106721789AReduce heart diseasePrevent puffinessFood ingredient functionsEmulsionOmega 3 fatty acid

The invention relates to an oat and linolenic acid composite beverage, relates to a preparation method of the beverage, and belongs to the technical field of processing of other beverages. The oat and linolenic acid composite beverage is mainly prepared from the following raw materials in percentage by mass: 1-6% of oat, 1-8% of linseed oil, 2-3% of maltose, 0.2-0.6% of fructo-oligosaccharide, 1-3% of xylitol, 1-4% of cane sugar or starch syrup, 2-6% of coconut milk, 0.1-0.3% of a composite emulsion stabilizer, 0.005-0.01% of edible essence and 0.1-1% of sodium ascorbate. According to the oat and linolenic acid composite beverage disclosed by the invention, the oat is used as a main raw material, the linseed oil and the coconut milk are added, the specific composite emulsion stabilizer is matched, and a specific technology is used, so that the oat and linolenic acid composite beverage is prepared. High omega-3 fatty acid content of the oat beverage is guaranteed, and besides, a good stabilizing effect can be achieved. Under normal temperature, after being subjected to standing for 3 months, the oat and linolenic acid composite beverage does not generate precipitates, and is free of a layering phenomenon and the phenomenon that fat floats upwards.

Owner:蔡密林

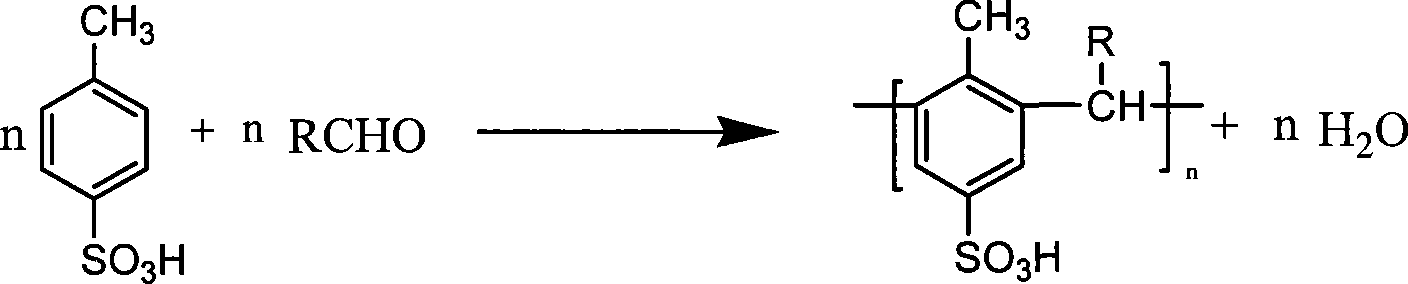

A preparation method of carbon base solid acid catalyst

InactiveCN101157052AImprove thermal stabilityHigh acid valueOrganic-compounds/hydrides/coordination-complexes catalystsFiltrationSolid acid

The invention discloses a preparation method for novel carbon-based solid acid catalyst. The invention is characterized in that aroma sulfonic acid compound is taken as raw material, aldehyde compound is taken as coupling agent, inorganic strong acid is taken as catalyst, to perform the condensation reaction, after the reaction is finished, hot water is added to perform the cleaning and the filtration, to remove inorganic strong acid, and the drying is performed in a baking oven, thereby obtaining objective resultant. The obtained resultant of the invention has the advantages that the thermal stability is high, the acid value is high, the synthetic cost is low, the catalytic effect is good, and the catalyst can be repeatedly used time after time, etc.

Owner:EAST CHINA NORMAL UNIV

Method for hydrothermal synthesis of carbon-silicon composite solid acid catalyst

InactiveCN101773840AEmission reductionSynthetic method greenCatalyst activation/preparationChemical synthesisLiquid waste

The invention discloses a method for hydrothermal synthesis of a carbon-silicon composite solid acid catalyst, which belongs to the technical field of chemical synthesis. The method comprises the following steps: preparing aqueous solution with sugar compounds easy to be carbonated, adjusting the pH value of the solution to be 3-4, dropping ethyl orthosilicate, hydrolyzing for 15 minutes under the stirring condition, transferring the solution into a high-pressure reactor, heating for 4 hours in a baking oven of 150-200 DEG C, cooling the solution to the room temperature, opening the high-pressure reactor, filtering, washing and drying, thereby obtaining a carbon-silicon composite material, and then sulfonating the obtained carbon-silicon composite material and concentrated sulfuric acid, thereby completing the preparation of the novel carbon-silicon composite solid acid catalyst. The solid acid has the advantages that: the synthesis is green, the emissions of waste solution and waste gas are low; the acid value is high; the specific surface of the synthesized material is large; the synthesis cost is low; the catalytic effect is good; and the catalyst can be used repeatedly.

Owner:SHAOXING UNIVERSITY

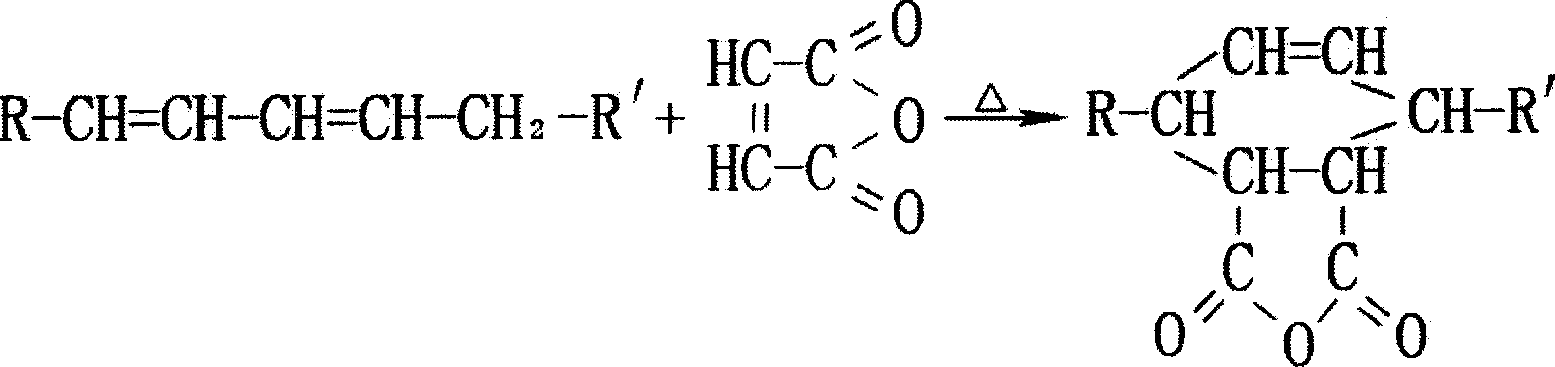

Method for producing 4-propyl-[1,3,2]dioxathiolane-2,2-dioxide

A method for producing 4-propyl-[1,3,2]dioxathiolane-2,2-dioxide comprises an addition reaction, an oxidation reaction and a purifying process. The method concretely comprises the following steps: 1, carrying out the addition reaction: carrying out addition reaction on thionyl chloride and 1,2-pentanediol as reaction raw materials; 2, carrying out the oxidation reaction: adding a sodium hypochlorite and catalyst mixed solution, carrying out the oxidation reaction to obtain a water phase and organic phase co-existence reaction solution, standing the water phase and organic phase co-existence reaction solution for layering, and separating the obtained water phase to obtain the organic phase which is crude 4-propyl-[1,3,2]dioxathiolane-2,2-dioxide; and 3, purifying: carrying out molecular distillation to obtain 4-propyl-[1,3,2]dioxathiolane-2,2-dioxide. The purity of the prepared 4-propyl-[1,3,2]dioxathiolane-2,2-dioxide can be greater than 99.5%, the water content is not greater than 100PPM, the acid value is not greater than 100PPM, and 4-propyl-[1,3,2]dioxathiolane-2,2-dioxide can be added to a battery in order to improve the performances of the battery and prolong the life of the battery.

Owner:SHIJIAZHUANG SAN TAI CHEM CO LTD

Preparation method for synergistic polyhydric alcohol used for flame retardant polyurethane foaming plastic

The invention discloses a preparation method for synergistic polyhydric alcohol used for flame retardant polyurethane foaming plastic, and belongs to the technical field of high polymer chemistry, reactive flame retardants and building insulation materials. The polyhydric alcohol is prepared by catalytic reaction among triethyl phosphate, phosphorus pentoxide, pentaerythritol, Tetrabromophthalic anhydride and alkylene oxide.

Owner:UNIV OF JINAN

Ultrahigh-acid-value polyester resin for powder coating and preparation method of polyester resin

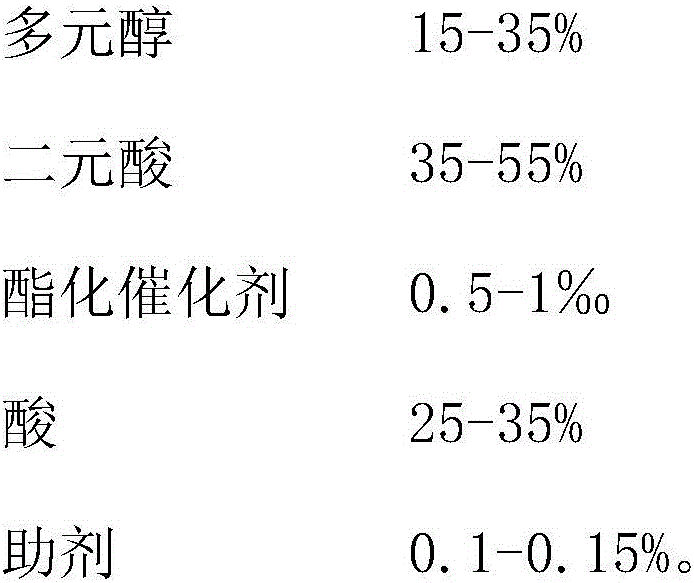

InactiveCN106752773AControl the phenomenon that the viscosity of the system rises sharplyHigh glass transition temperaturePowdery paintsPolyester coatingsVitrificationPolyol

The invention provides ultrahigh-acid-value polyester resin for a powder coating and a preparation method of the polyester resin. Use amount ratio of raw materials is regulated, organotin is taken as an esterification catalyst, polyacid and polyol have an esterification reaction organically under protection of nitrogen, and the polyester resin is prepared with a vacuum polycondensation method. The acid value of the prepared ultrahigh-acid-value polyester resin for the powder coating is 250-330 mgKOH / g, the viscosity is 500-2,500 mpa.s@200 DEG C, the glass transition temperature Tg is higher than or equal to 48 DEG C, and the number-average molecular weight is 800-2,500. The polyester resin has the characteristics of ultrahigh acid value and high glass transition temperature and solves the problem of poor storage stability.

Owner:ANHUI SHENJIAN NEW MATERIALS

Powder coating polyester resin for exhaust pipe of motor vehicle and preparation method thereof

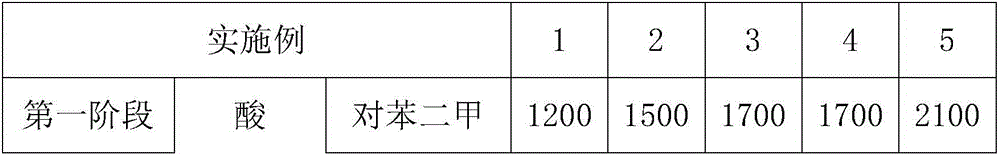

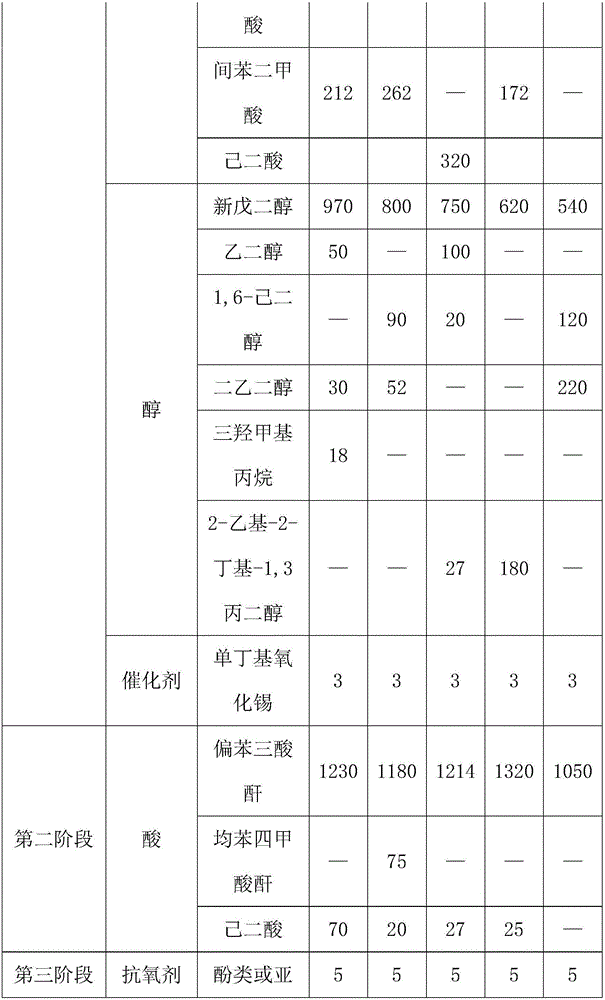

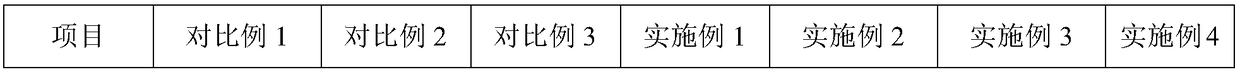

ActiveCN109306232AEfficient esterification combinationImprove the efficiency of esterification synthesisFireproof paintsPowdery paintsAntioxidantTemperature resistance

The invention provides powder coating polyester resin for an exhaust pipe of a motor vehicle. The powder coating polyester resin is prepared from the following raw materials: dicarboxylic acid, dihydric alcohol, a branching component, an esterification and polycondensation catalyst, an antioxidant and a curing accelerator. The powder coating polyester resin is prepared by carrying out feeding andstirring, carrying out heating and fusing, carrying out heating and esterifying, adding acid for end capping, carrying out vacuum polycondensation, carrying out cooling and adding the auxiliaries so as to obtain a finished product of the resin. According to the powder coating polyester resin, a powder coating prepared from the polyester resin has relatively high glass transition temperature, so that polyester and the powder coating have very excellent storage stability, the prepared polyester powder coating has excellent weather resistance and temperature resistance, temperature-resistant monomers of bis-hydroxyethyl hydantoin and 1,3,5-tris(2-hydroxyethyl)cyanuric acid with three functional groups are adopted, so that the temperature resistance and the weather resistance of the polyesterpowder coating are greatly improved through the synergistic effect of the two monomers, light lose is basically avoided at the temperature of 350 DEG C / 2 h, and relatively good adhesive force and impact performance are achieved.

Owner:ZHEJIANG GUANGHUA NEW MATERIALS

Preparation method of functionalized polyacid-type sulfonic ionic liquid

ActiveCN102442951AEasy to prepareHigh acid valueOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsSulfonateSulfate

The invention relates to a preparation method of functionalized polyacid-type sulfonic ionic liquid. According to the invention, a poly-nitrogen tertiary amine compound is subject to a reaction with sulfuric acid or sultone, such that lactone sulfate or lactone sulfonate is obtained; the obtained lactone sulfate or lactone sulfonate is acidified by using an acid, such that that the functionalized polyacid-type sulfonic ionic liquid is obtained. Compared to prior arts, no hydrogen peroxide is adopted. With effects such as complexation and oxidation, a maximal desulphurization rate reaches 55.7%. Therefore, the preparation method is advantaged in high desulphurization rate and mild reaction condition. According to the invention, a catalytic system can easily be separated, and can be recovered and reused.

Owner:上海欣年石化助剂有限公司

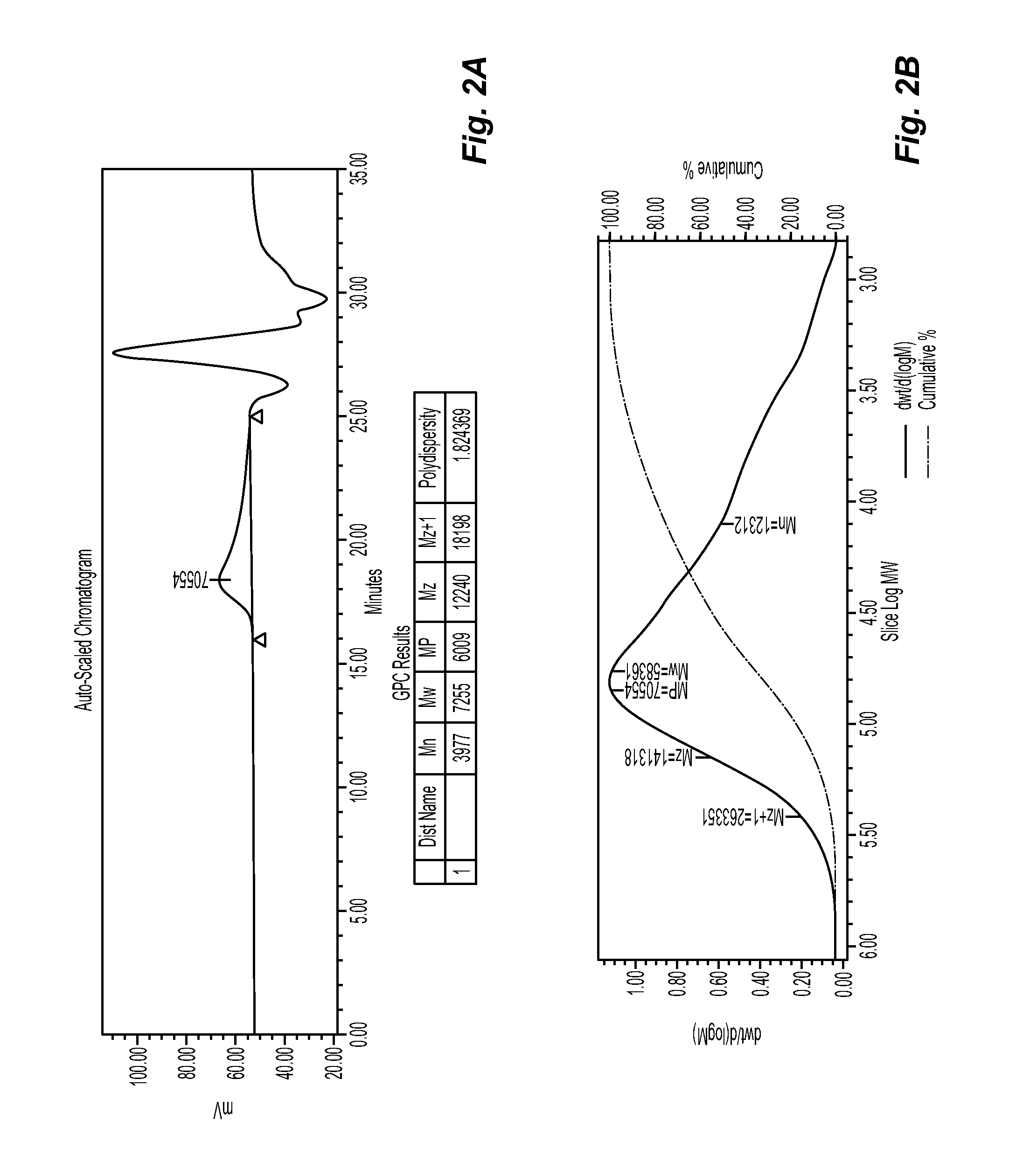

Grafted pigment dispersing polymeric additive and paint employing the same with improved hiding

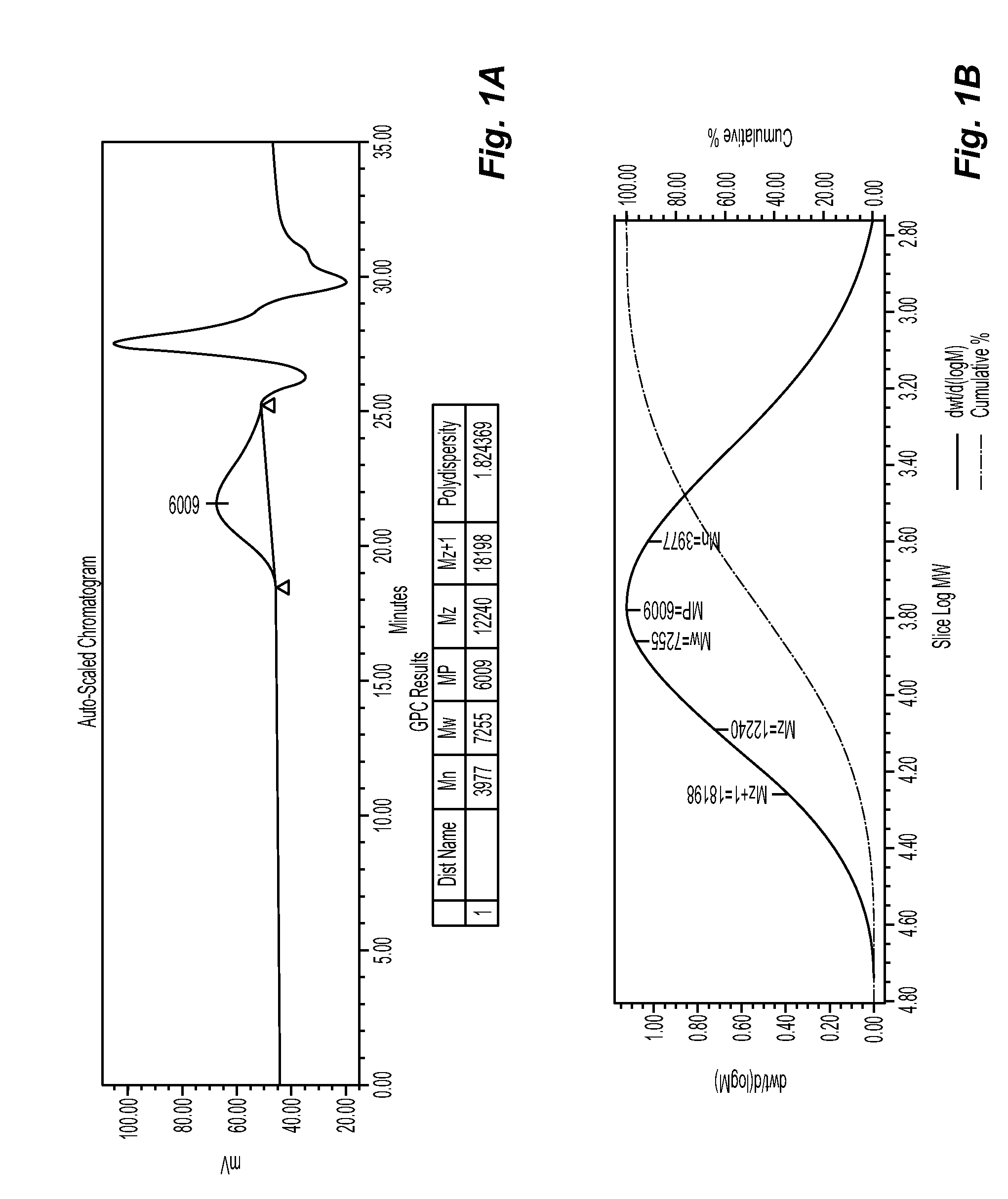

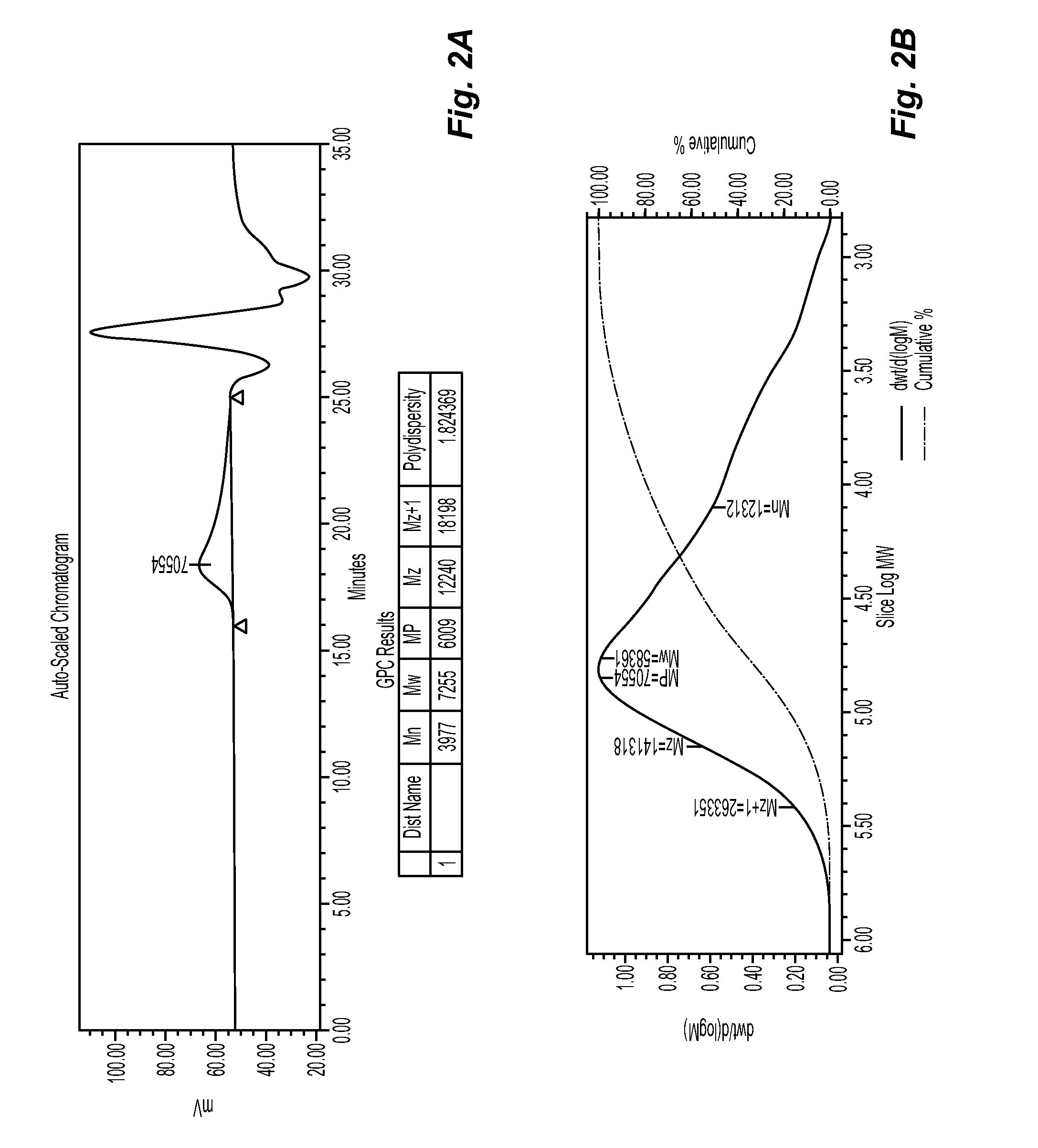

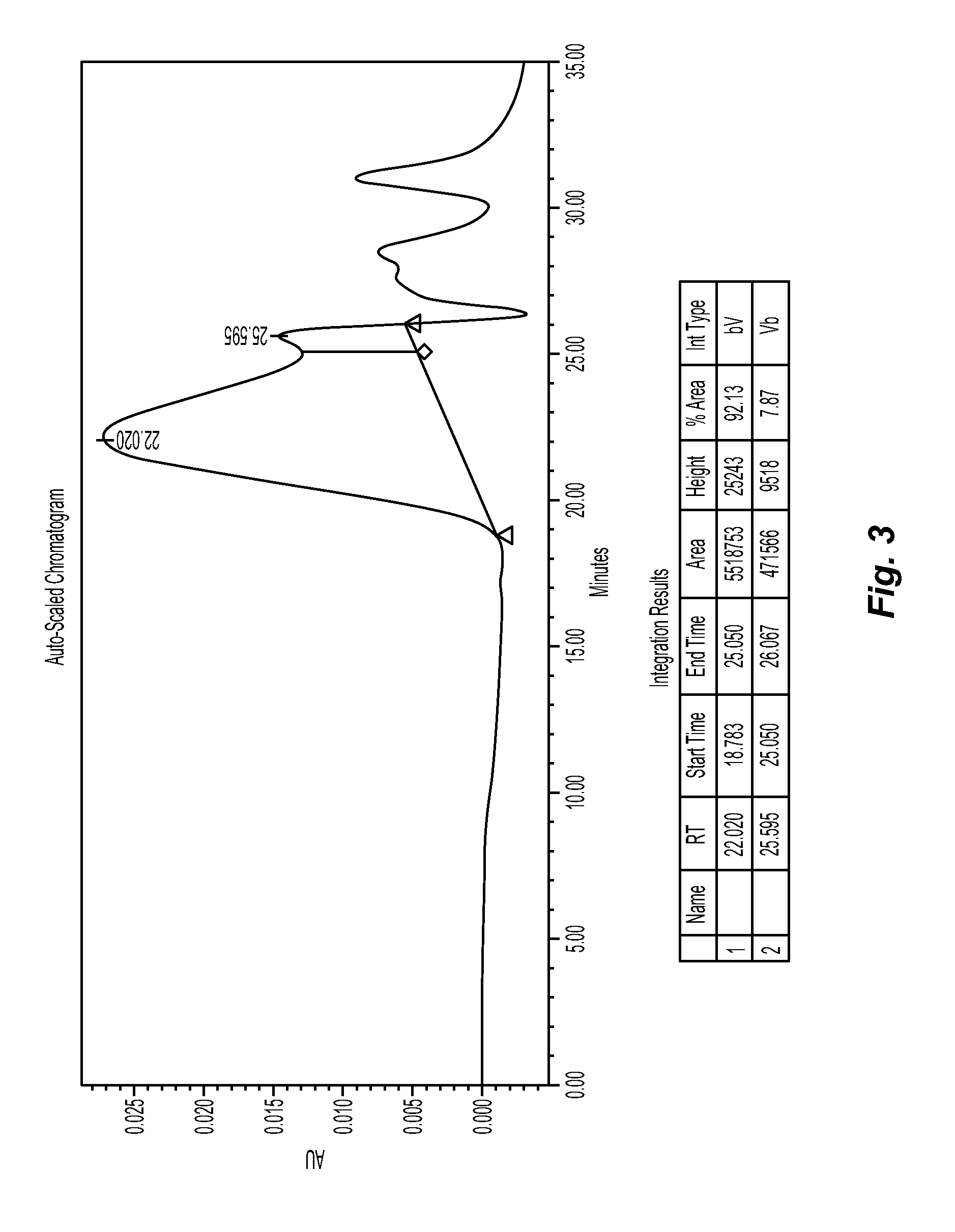

ActiveUS8895658B2Reduce molecular weightHigh total acid contentGroup 4/14 element organic compoundsSpecial tyresMonomerPigment

The present invention relates to a grafted pigment dispersing polymeric additive for opacifying pigments, prepared by polymerizing monomers in the presence of a polymeric pigment dispersant. The polymeric pigment dispersant has low molecular weight, high acid number and is dissolvable in alkali solution. When incorporated into paint compositions, hiding is improved with less opacifying pigments.

Owner:COLUMBIA INSURANCE CO

Grafted Pigment Dispersing Polymeric Additive and Paint Employing the Same with Improved Hiding

ActiveUS20140171585A1Reduce molecular weightHigh total acid contentOrganic dyesCoatingsPigment dispersionPigment

The present invention relates to a grafted pigment dispersing polymeric additive for opacifying pigments, prepared by polymerizing monomers in the presence of a polymeric pigment dispersant. The polymeric pigment dispersant has low molecular weight, high acid number and is dissolvable in alkali solution. When incorporated into paint compositions, hiding is improved with less opacifying pigments.

Owner:COLUMBIA INSURANCE CO

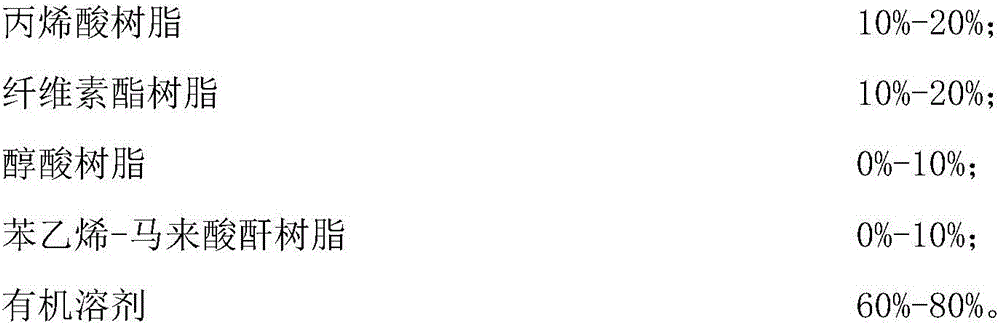

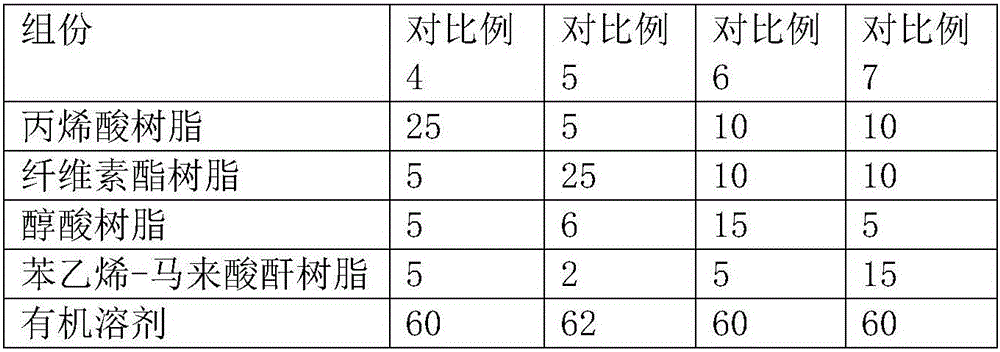

Low-VOC easy-to-offset-printing cold wave release layer coating and preparation method thereof

The invention provides a low-VOC easy-to-offset-printing cold wave release layer coating and a preparation method thereof. The coating is prepared from the following components in percentages by weight: 10% to 20% of acrylic resin, 10% to 20% of cellulose ester resin, 0% to 10% of alkyd resin, 0% to 10% of styrene-maleic anhydride resin and 60% to 80% of an organic solvent. Compared with the prior art, the coating has the advantages of adjustable and controllable stripping quality, excellent offset printing performance and low raw material cost; moreover, the coating adopts a benzene-free system, and has the characteristic of low VOC content.

Owner:SHANGHAI WEIKAI CHEM

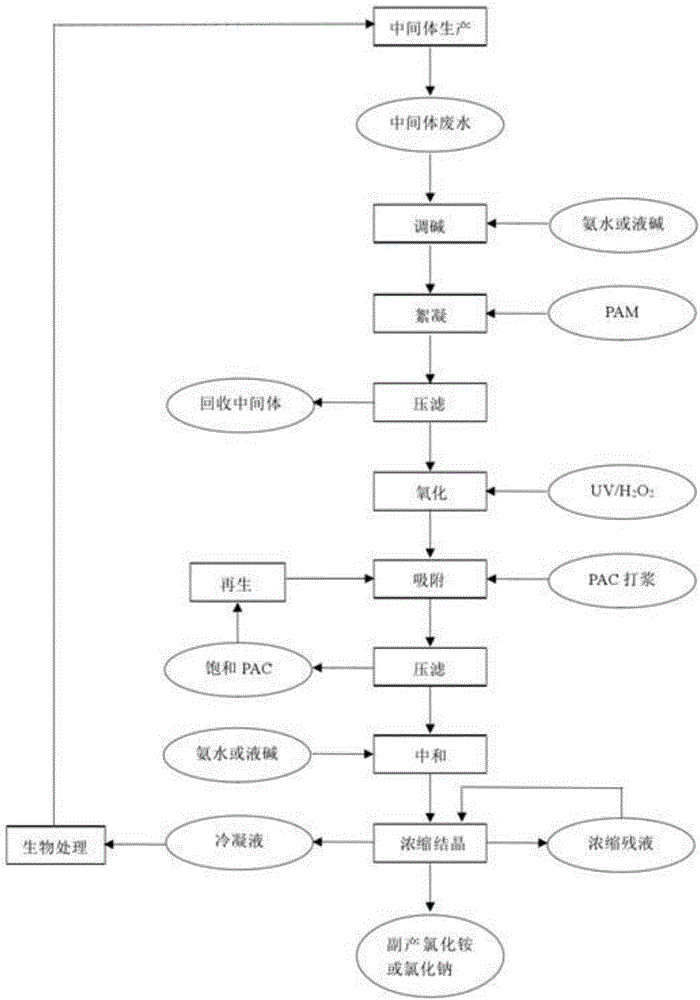

Recycling treatment method for anilines intermediate production wastewater

InactiveCN106167332AAchieve recyclingSimple processTreatment using aerobic processesWater/sewage treatment by irradiationFlocculationHydrogen

The invention provides a recycling treatment method for anilines intermediate production wastewater. The method includes the following steps of (1) flocculation: separately collecting and regulating the pH (potential of hydrogen) value of wastewater, adding flocculant for flocculation, and filtering to obtain precipitate I and treating fluid I; (2) oxidation: regulating the pH value of the treating fluid I, adding oxidizing agent, and performing adequate oxidation to obtain treating fluid II; (3) adsorption bleaching: regulating the pH value of the treating fluid II, adding adsorbent, and performing full adsorption prior to separation to obtain treating fluid III; (4) neutralization, concentration and crystallization: regulating pH value of the treating fluid III, entering a concentration device for concentration and crystallization, performing separation to obtain sodium chloride or ammonium chloride solid, returning mother fluid to the concentration device for continuous concentration and crystallization, and collecting condensate, namely treating fluid IV; (5) biological treatment: subjecting the treating fluid IV to treatment in a biological aerated filter to obtain treating fluid V, so as to finish treatment.

Owner:ZHEJIANG DIBANG CHEM

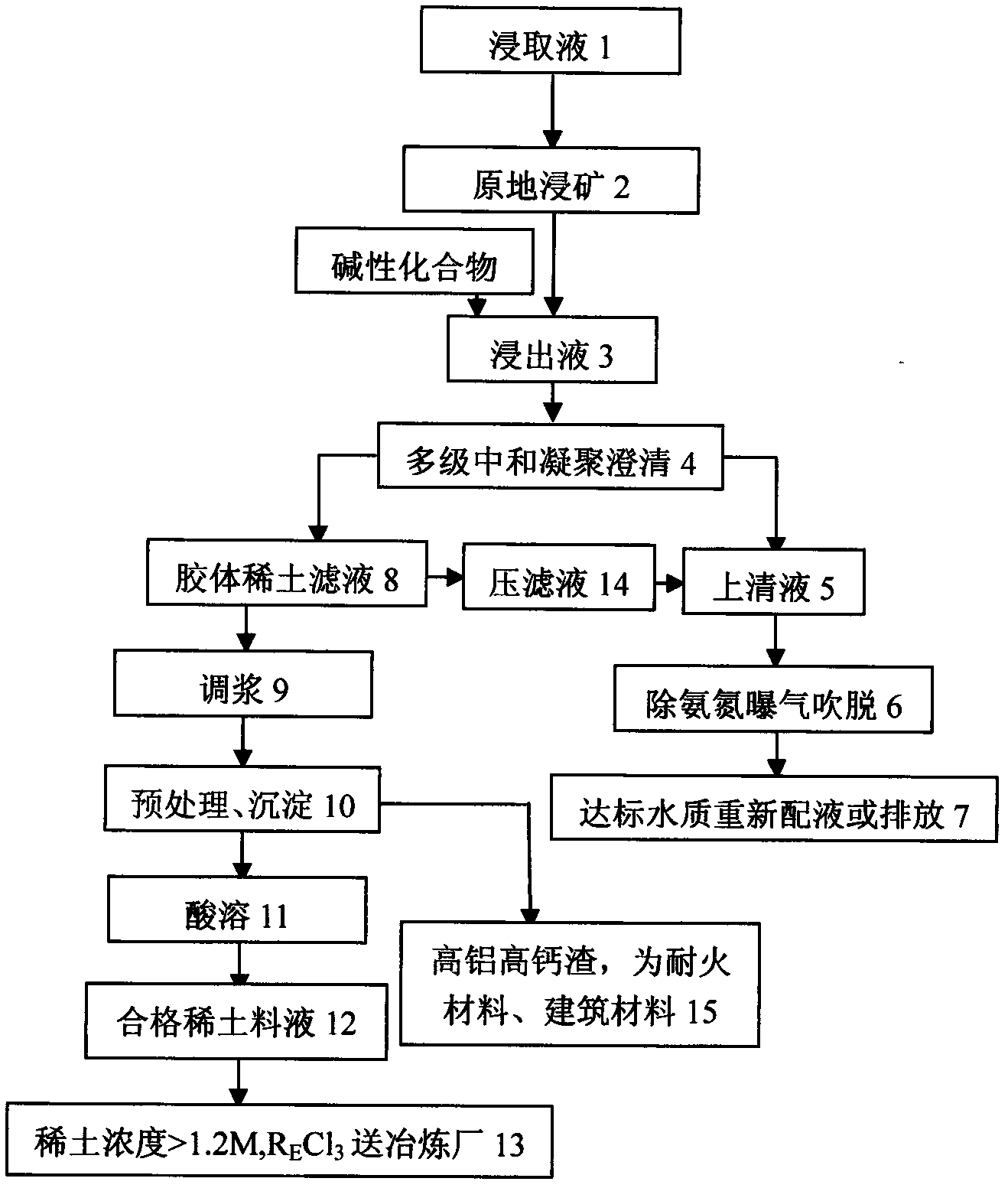

Method for preparing rare earth by reducing ammonia nitrogen oxygen demand (COD) and adjusting potential of hydrogen (pH) value from rare earth mine leach liquor

InactiveCN102643987AReduce secondary pollutionReduce ammonia nitrogen and acid valueProcess efficiency improvementContinuous operationChemistry

The invention relates to a method for preparing rare earth by reducing an ammonia nitrogen oxygen demand (COD) and adjusting a potential of hydrogen (pH) value from rare earth mine leach liquor, which is the method for preparing chloride rare earth products from the rare earth mine leach liquor by using lime milk or deposits and treats ammonia nitrogen, chemical oxygen demand (COD), the pH value and the like in dissolved ocyhydrate. The method can be used for environmental protection management, comprehensive utilization and the like, and has the advantages of being small in pollution, low in cost, free of secondary pollution, capable of achieving continuous operation and production and the like.

Owner:郑耀秋

Resorcinol formaldehyde resin base solid acid and preparation method and application thereof

InactiveCN102070758AImprove thermal stabilityHigh acid value of solid acidOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsCooking & bakingChemical synthesis

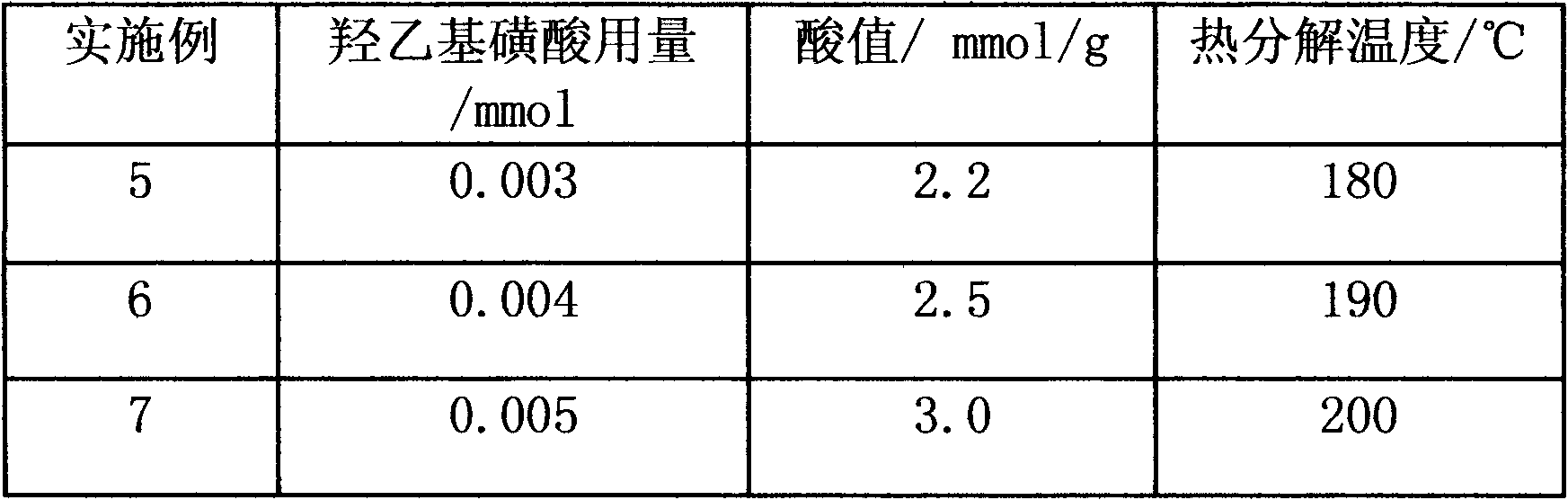

The invention discloses a resorcinol formaldehyde resin base solid acid and a preparation method and application thereof, belonging to the technical field of chemical synthesis. The invention is characterized in that the preparation method comprises the following steps: by using resorcinol as a raw material, a formaldehyde solution (the mol ratio of the raw material to the formaldehyde solution is (1:1)-(1:3)) as a crosslinking agent and hydroxy-ethyl sulfonic acid (the mol ratio of the raw material to the hydroxy-ethyl sulfonic acid is (1:0.1)-(1:1)) as an active molecule, adding water (the mass ratio of the resorcinol to the water is 1:5-1:20) to prepare a solution; carrying out condensation reaction at 65-95 DEG C for 60-120 hours, and drying by rotary evaporation to obtain the RF (resorcinol formaldehyde) resin; then, carrying out carbonization condensation reaction at 180-300 DEG C for 2-32 hours; and after the reaction, washing with hot water at the temperature higher than 80 DEG C, filtering to remove free acidic materials, and drying the product in a baking oven at 120 DEG C to obtain the resorcinol formaldehyde resin base solid acid. The resorcinol formaldehyde resin base solid acid disclosed by the invention has the advantages of high thermal stability, high acid value, favorable catalysis effect and the like, and can be repeatedly used.

Owner:SHAOXING UNIVERSITY

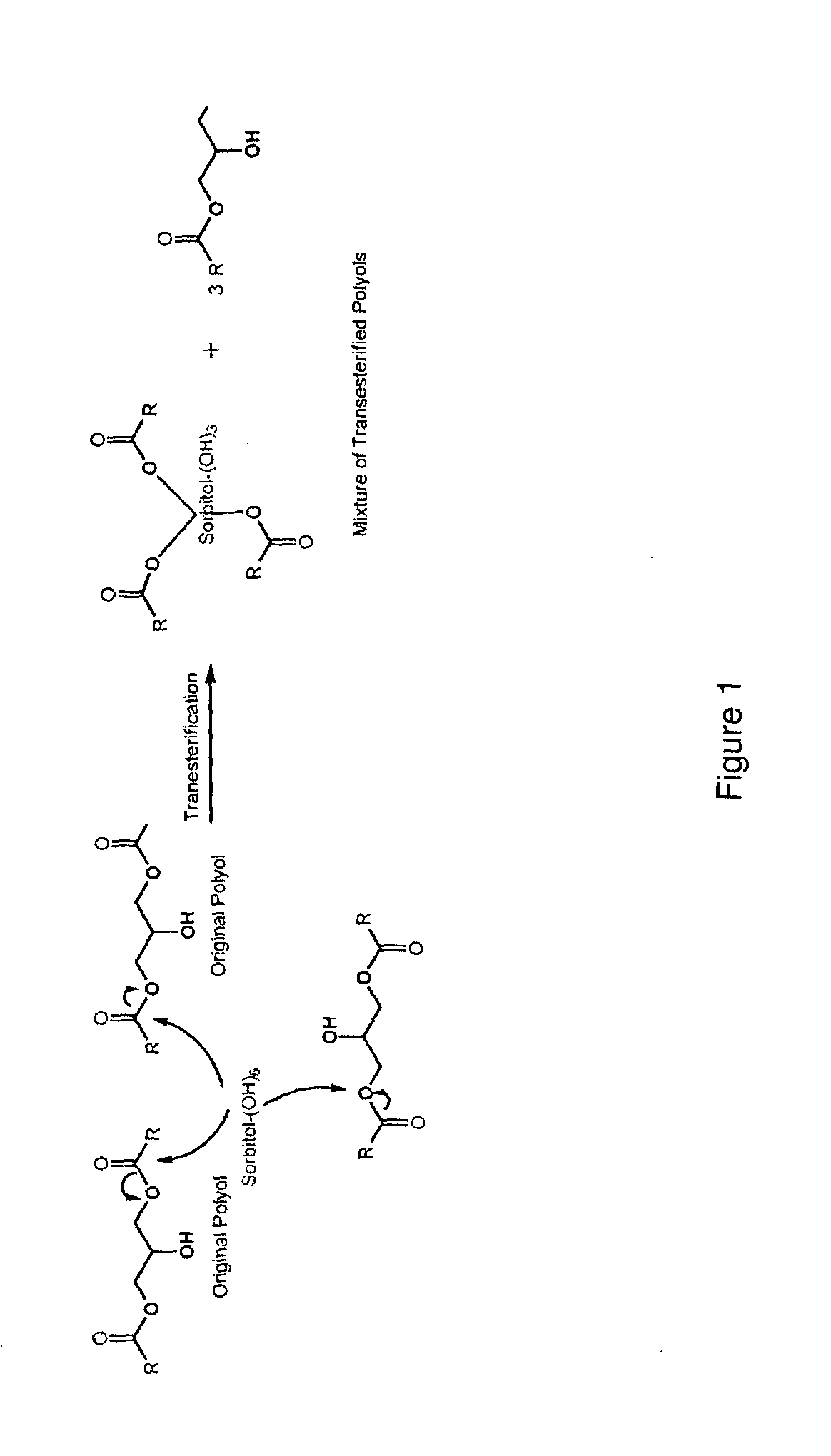

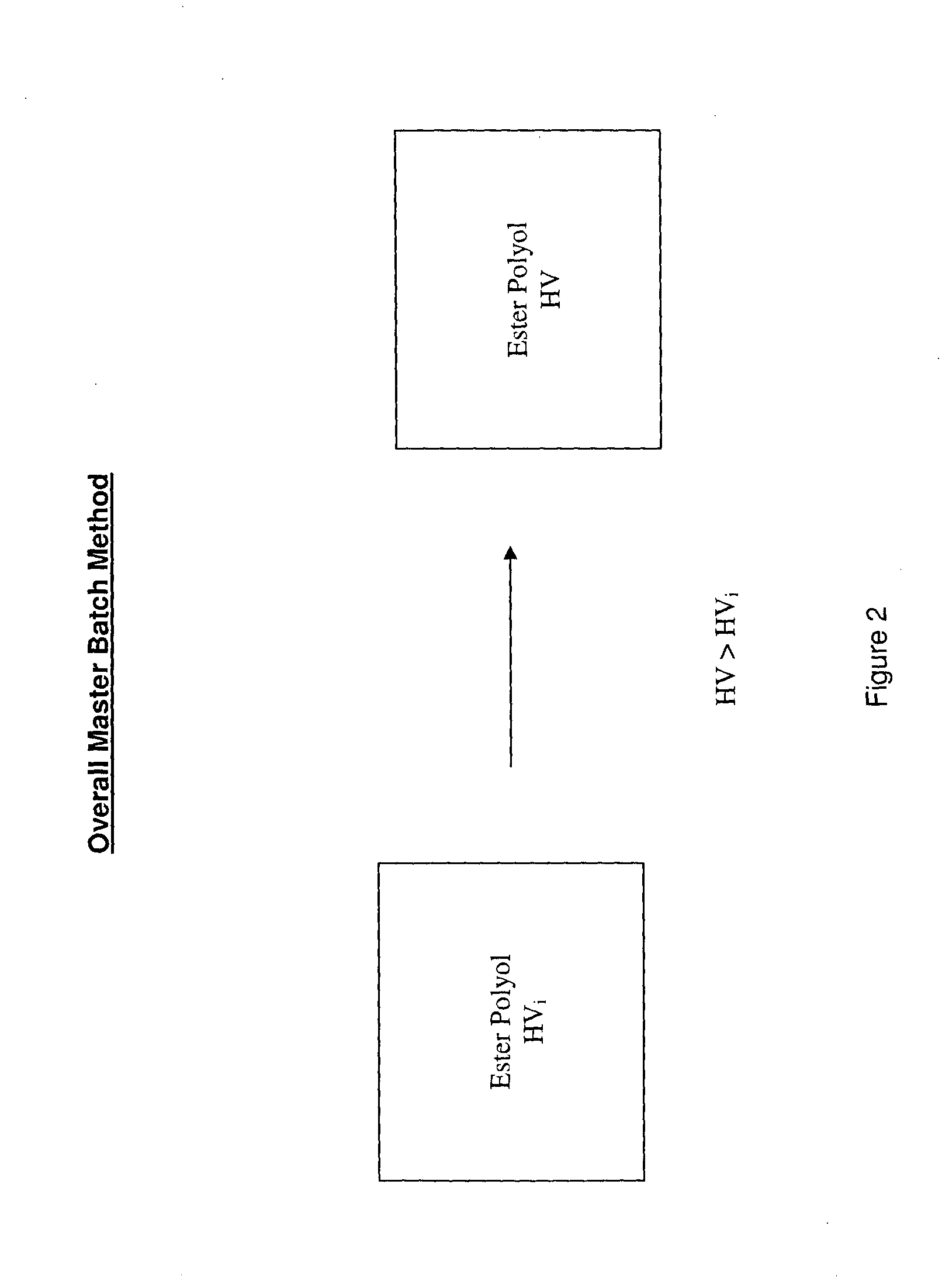

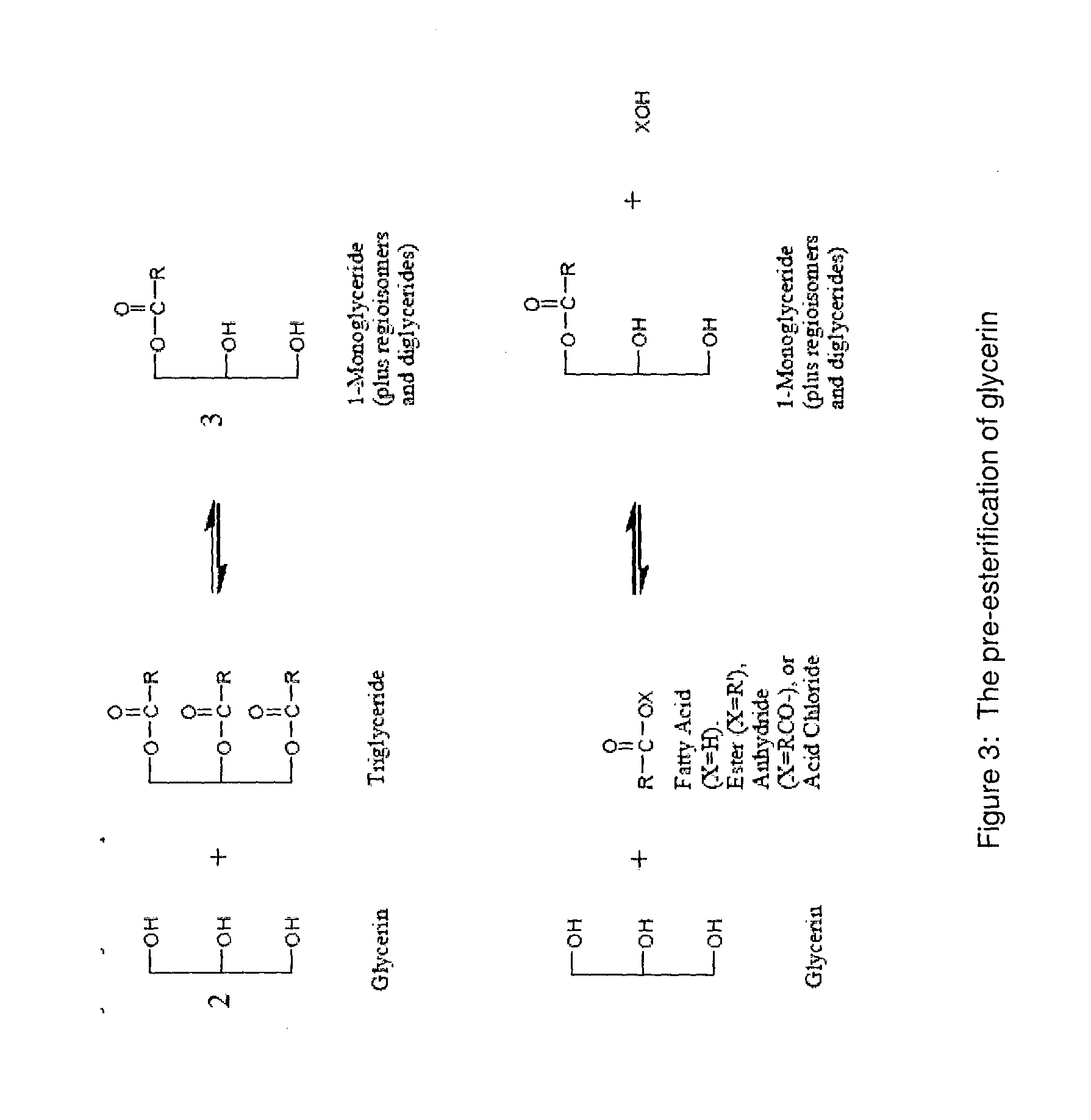

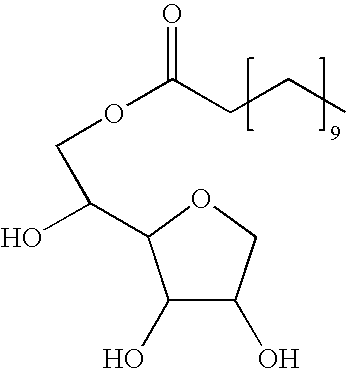

Bio-polyols for bio-lubricant and bio-polymer and methods for the preparation thereof

ActiveUS20150087850A1Increase valueSynthetic is simpleFatty acid esterificationOrganic compound preparationBiopolymerHydroxyl value

A method for producing an ester polyol, comprising transesterifying a first ester polyol with a primary polyol to produce a second ester polyol, wherein the second ester polyol has a higher hydroxyl value than the first ester polyol.

Owner:GASOLINEIAM NASIONAL BERHAD

Preparation method and using method for paraffin catalyst

InactiveCN102921447AIncrease the areaLarge apertureMolecular sieve catalystsPetroleum chemical modificationNitrateDistillation

The invention discloses a preparation method and a using method for a paraffin catalyst, and relates to a preparation method and an application method for a catalyst. The method for preparing the paraffin catalyst comprises the following steps of: adding SBA-15 into water solution of cobalt nitrate; soaking the SBA-15 for 3h at the room temperature; removing the water in a distillation mode; drying the obtained solid for 5h at 120 DEG C; and roasting the solid for 5h at 500 DEG C in the air to prepare an oxidation-state catalyst Co / SBA-15. The prepared paraffin catalyst can be used for catalyzing the oxidized paraffin. The prepared paraffin catalyst has a large specific surface area and aperture; and therefore, the paraffin catalyst is a novel and excellent catalyst of the oxidized paraffin; and moreover, the catalyst is used for catalyzing and preparing the paraffin to obtain the oxidized paraffin with light lustre, light smell and high acid value.

Owner:SHAANXI QIYUAN TECH DEV

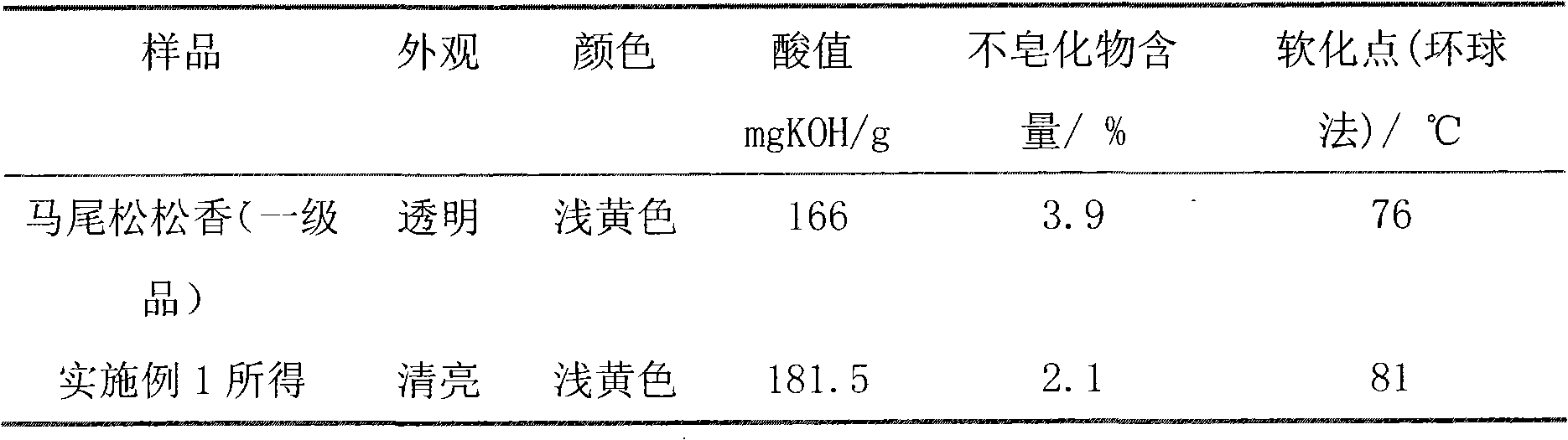

Method of refining and processing rosin

InactiveCN101665660AReduce consumptionThe method steps are simpleNatural resin purificationResin acidRoom temperature

The invention provides a method of refining and processing rosin, comprising the following steps: (1) dissolving rosin in dichloromethane, and filtering the solution of the rosin and the dichloromethane to remove the insoluble impurities; (2) adding acetonitrile to the solution of the rosin and the dichloromethane to precipitate resin acid, filtering the solution of the rosin and the dichloromethane, and collecting the precipitated resin acid; heating to distill filtrate, collecting the distillate formed blow 70 DEG C, recycling the dichloromethane, filtering and collecting part of resin acidwhich is precipitated after the residual filtrate is cooled to the room temperature; combining the filtrate, and then heating to distill the filtrate and recycle the dichloromethane; and (3) heating to melt the precipitated resin acid at normal pressure under the protection of N2 or CO2, and cooling the melted precipitated resin acid to obtain the refined rosin of light color, high acid value andlow unsaponifiable matter. The method of refining and processing rosin uses no special pressure resisting equipment, is easy to operate, has low production cost and is particularly suitable for industrial production.

Owner:GUANGXI UNIV FOR NATITIES

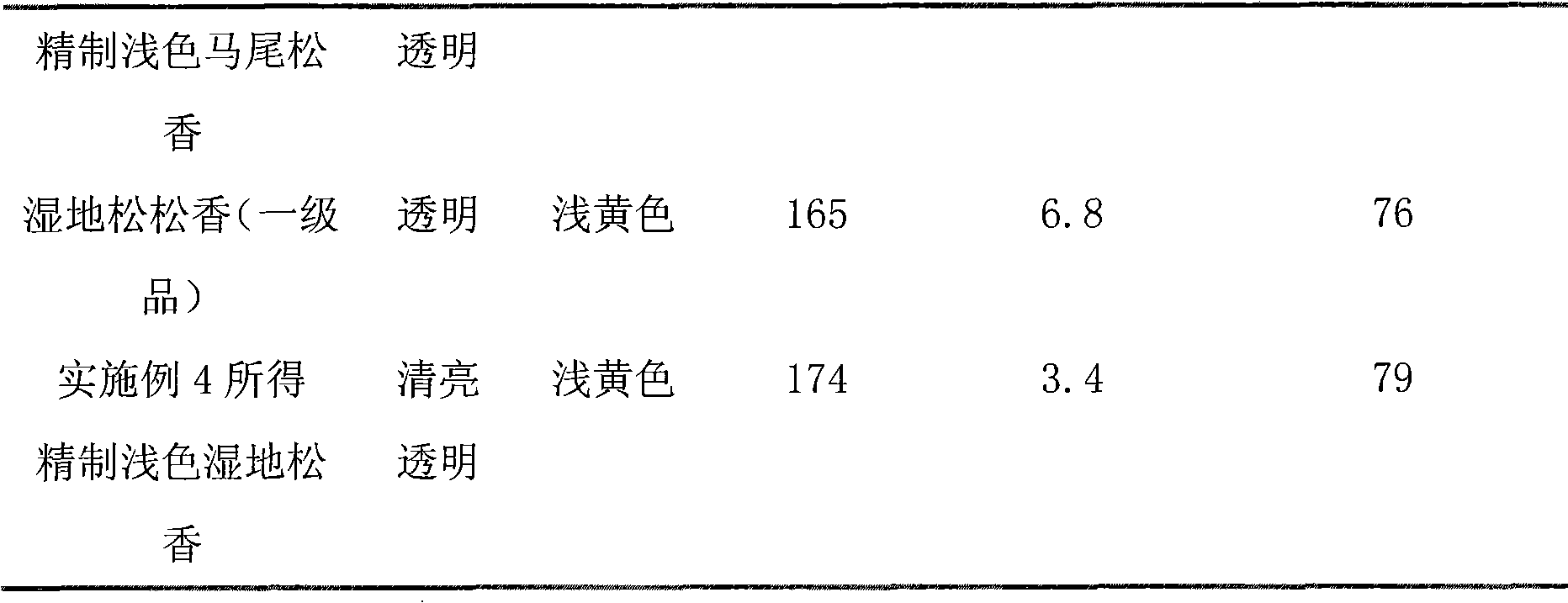

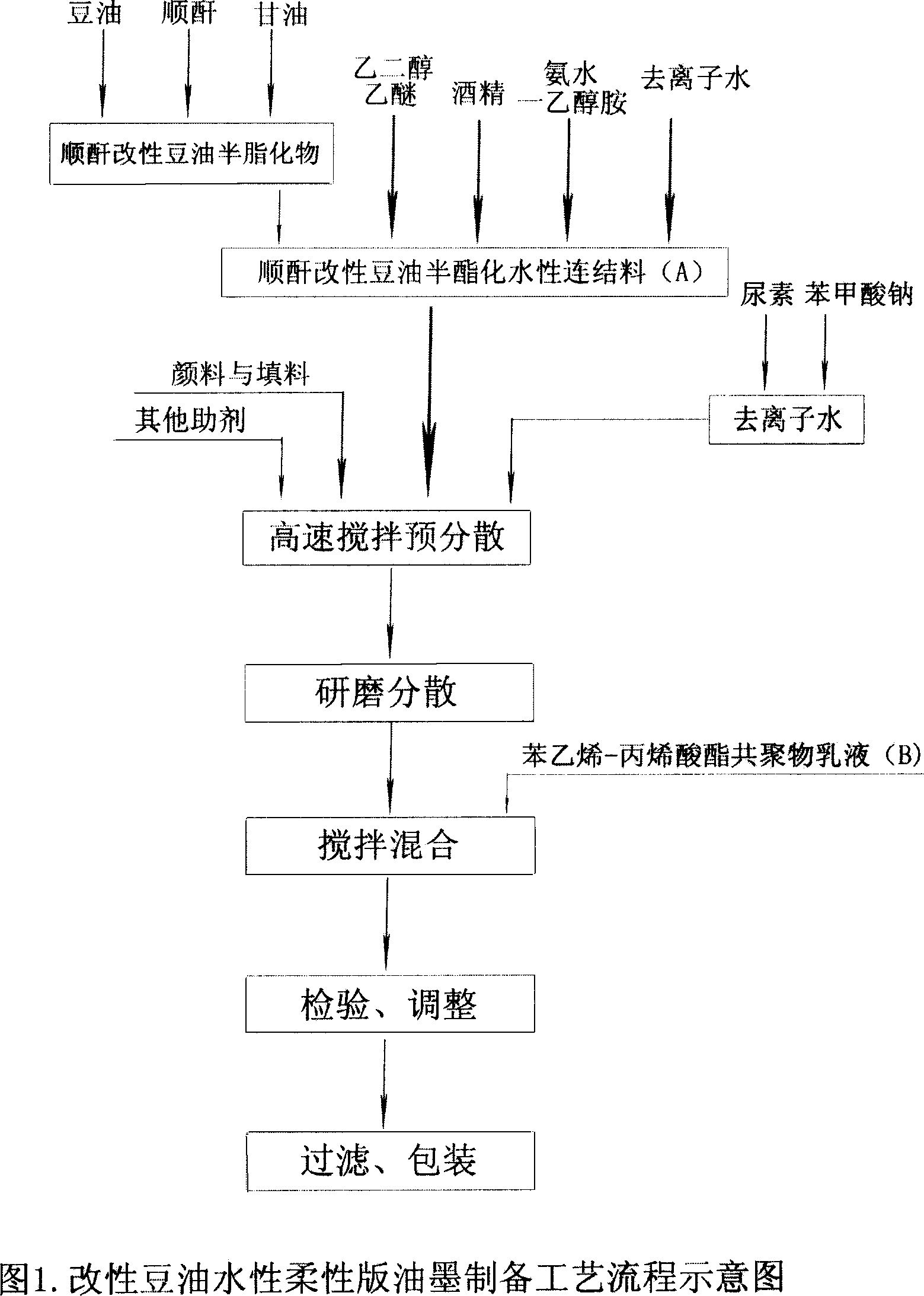

Modified soyabean oil aqueous flexographic printing ink

InactiveCN1966589AGood safety and environmental protectionLow costInksOther printing apparatusMaleic anhydrideChemistry

The invention relates to a kind of reshaped bean oil aqueous flexible printing ink, the ingredient of which includes syn-anhydride reshaped bean oil half esterized aqueous connecting material(A), benzene vinyl-acrylate copolymer latex(B), pigment and filling, deionized water and accessory ingredient. The soft printing ink is safe, environment-friendly; it also has the advantages of high drying rate, wet friction proof, good adaptability for printing, light sheen and low cost. The key to reshape the insoluble bean oil to the aqueous oil is to reshape the material with polyacid of maleic anhydride sort and half-esterize the polyalcohol, after amination, the producer can get the aqueous connecting material. The product in the invention can be used as container of soft printing paper, carton, cardboard box, paper napkin, paper label and paper for ads, newspapers and magazines.

Owner:北京康丽普科技有限公司

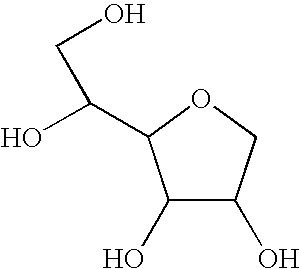

Carbon-based solid acid as well as preparation method and application thereof

InactiveCN102059140AImprove thermal stabilityHigh acid value of solid acidOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsChemical synthesisCarbonization

The invention discloses carbon-based solid acid as well as a preparation method and application thereof, belonging to the technical field of chemical synthesis. The preparation method is characterized in that a polyhydroxy compound is used as a raw material, isethionic acid is used as active molecules, the molar ratio of the raw material to the isethionic acid is (2:1)-(10:1), and the carbon-based solid acid is prepared through the steps of: carrying out carbonization and condensation reaction on the polyhydroxy compound and the isethionic acid at 120-400 DEG C for 2-32h, adding hot water above 80 DEG C for washing after the reaction, filtering to remove dissociative acidic substances, and drying the obtained product in a drying oven at 120 DEG C. The carbon-based solid acid has the advantages of high heat stability, high acid value, good catalytic effect, reusability and the like.

Owner:SHAOXING UNIVERSITY

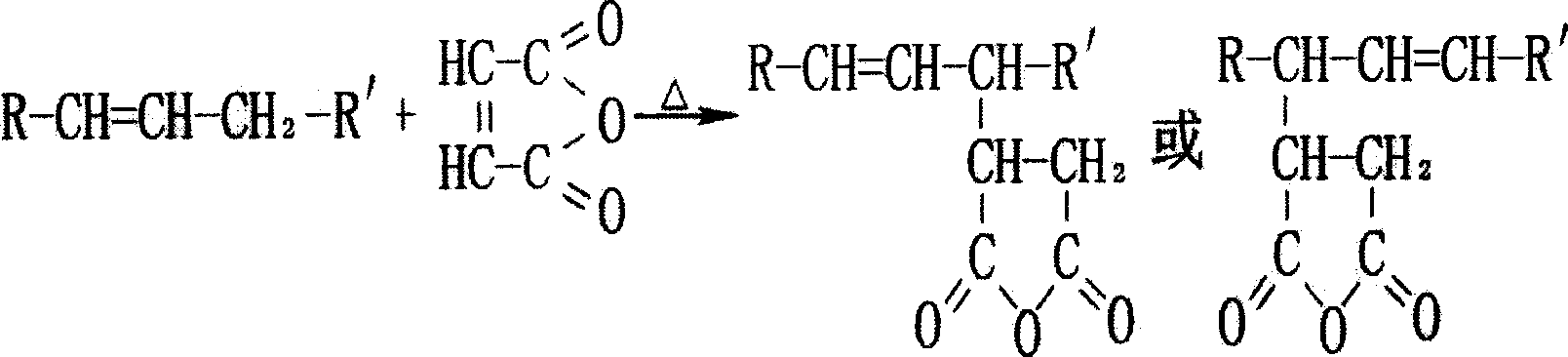

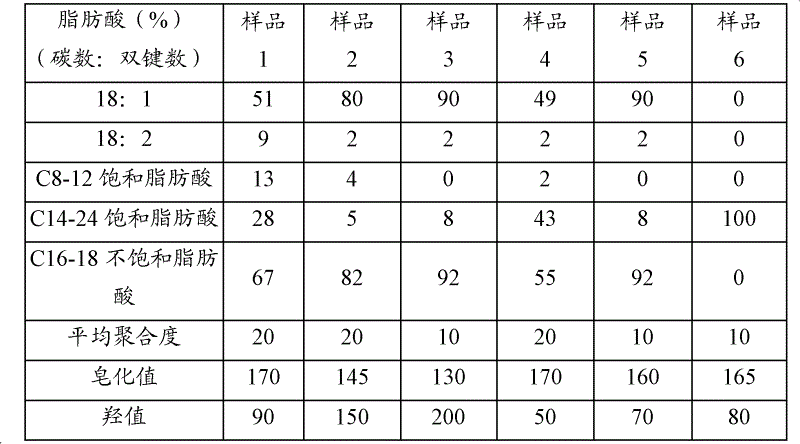

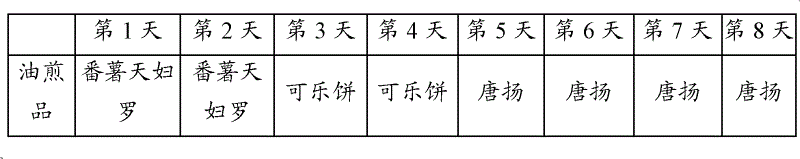

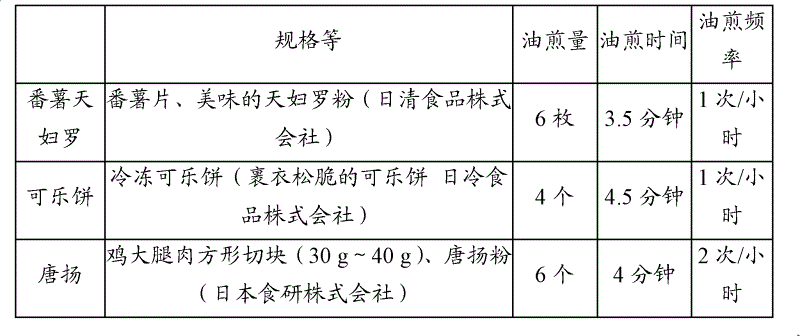

Oil-fat composition for heat cooking, manufacturing method thereof, and acid-value increase inhibitor for oil-fat composition for heat cooking

ActiveCN102613313AHigh acid valueReduces the deterioration of fats and oils such as cooked odorEdible oils/fatsAcid valueHydroxyl value

The invention provides an oil-fat composition for heat cooking capable of substantially reducing an increase in acid value thereof in heat cooking over a long period of time, a manufacturing method thereof, and an acid-value increase inhibitor for the oil-fat composition for heat cooking. The oil-fat composition is characterized in that the oil-fat composition contains, by mass, 0.01-2% of polyglycerol fatty acid ester, the average degree of polymerization of the polyglycerol that constitutes the polyglycerol fatty acid ester is 12-40, and the hydroxyl value is below 180.

Owner:THE NISSHIN OILLIO GRP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for producing 4-propyl-[1,3,2]dioxathiolane-2,2-dioxide Method for producing 4-propyl-[1,3,2]dioxathiolane-2,2-dioxide](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/93bc29aa-fe83-41af-a96c-e8d9f68ba748/HDA0000728080960000011.PNG)