Ultrahigh-acid-value polyester resin for powder coating and preparation method of polyester resin

A powder coating and polyester resin technology, applied in powder coatings, polyester coatings, coatings, etc., can solve problems such as poor storage stability and high glass transition temperature, and achieve good extinction effect and high glass transition temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

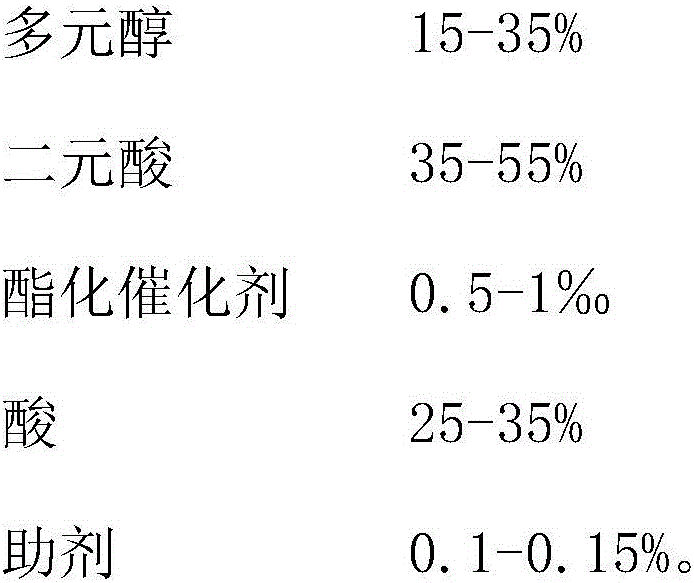

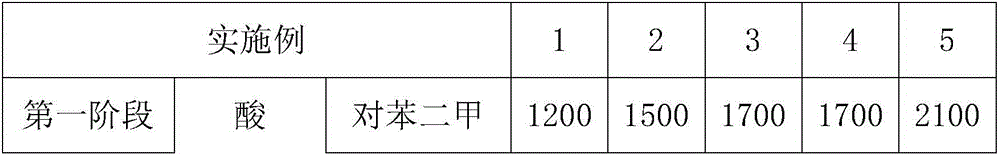

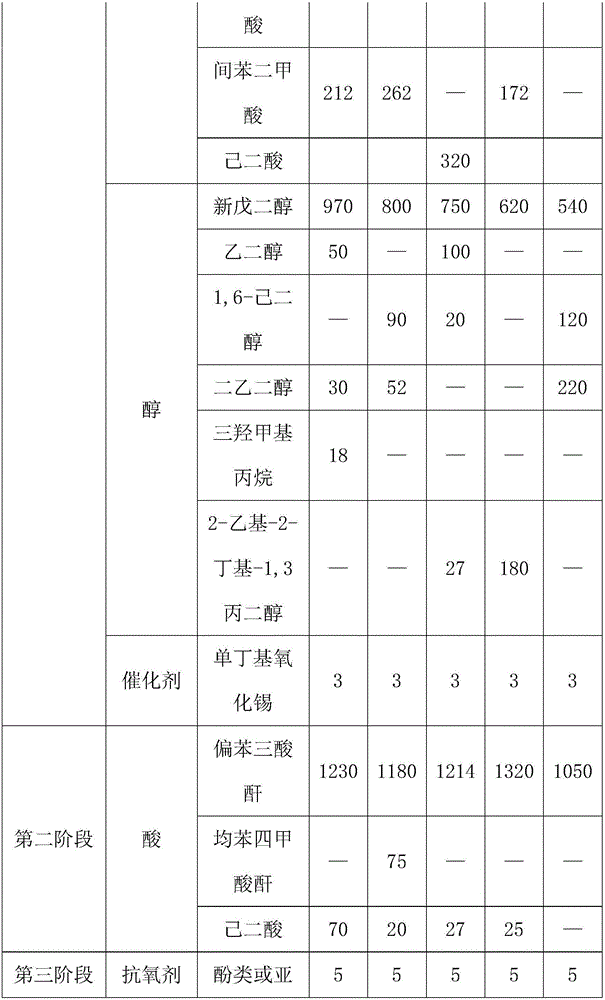

[0024] A kind of ultra-high acid value powder coating polyester resin, its each component weight percent is as shown in table 1 below;

[0025] A preparation method of super high acid value powder coating polyester resin, comprising the following steps:

[0026] 1) The first stage: Put 970g of neopentyl glycol, 50g of ethylene glycol, 30g of diethylene glycol and 18g of trimethylolpropane into a 5L reactor, heat to 115°C and melt at a speed of 130-150r / min Stir, then add 1200g of terephthalic acid and 212g of isophthalic acid and 3g of monobutyltin oxide as an esterification catalyst, raise the temperature to 170-180°C, then raise the temperature to 245°C at a heating rate of 5°C / 30min, until the reactant Clear, the acid value of the sampling test sample is 17.2mgKOH / g;

[0027] 2) The second stage: control the temperature at 180°C, add 1230g of trimellitic anhydride and 70g of adipic acid, raise the temperature to 200°C and maintain until the reactants are clear, and the aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com