Biodegradable polyester and preparation method thereof

A biodegradable polyester and esterification technology, applied in the preparation of carboxylate, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of increasing production costs, complex catalyst preparation processes, and small molecule residues.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] The invention provides a kind of preparation method of biodegradable polyester, it comprises the steps:

[0058] First carry out esterification-precondensation, then carry out copolycondensation and final polycondensation.

[0059] Specifically, esterification-precondensation includes: using methanesulfonic acid as an esterification catalyst, catalyzing the esterification reaction of terephthalic acid (PTA) and 1,4-butanediol (BDO), removing methyl After sulfonic acid, add a titanium-based catalyst for pre-condensation to obtain oligoesterification (BHBT) of terephthalic acid and 1,4-butanediol;

[0060] Use methanesulfonic acid as the catalyst for esterification reaction to catalyze the esterification reaction of 1,6-adipic acid (AA) and 1,4-butanediol. After removing methanesulfonic acid, add titanium catalyst for precondensation , to obtain the oligoesterification of 1,6-adipic acid and 1,4-butanediol (BHBA);

[0061] Co-polycondensation includes: co-condensation o...

Embodiment 1

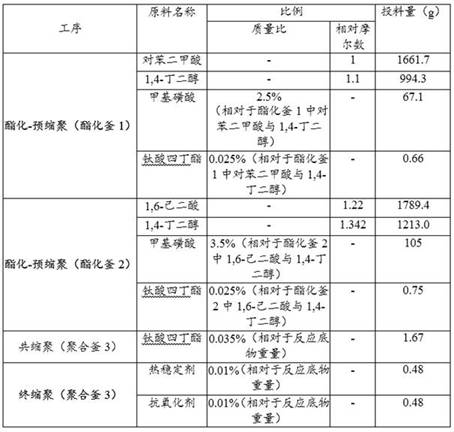

[0110] Table 1 The feed list of Example 1.

[0111]

[0112] The present embodiment provides a kind of preparation method of biodegradable polyester, comprises following steps carried out in sequence:

[0113] (1) Esterification-precondensation:

[0114] Weighed 1661.7g of terephthalic acid (wt%≥99.90%), 994.3g of 1,4-butanediol (wt%≥99.70%) and 67.1g of methanesulfonic acid (wt%≥99.00%) ) into 10L esterification kettle 1, turn on the heating, stir evenly, raise the temperature to 180°C, carry out the esterification and dehydration reaction, and react for 2 hours. , Reaction 0.5h, removal of methanesulfonic acid.

[0115] Then adjust the temperature, add 0.54g tetrabutyl titanate, the reaction temperature is 200°C, the reaction pressure is 100KPa, pre-condensation is carried out, the reaction is 0.6h, and the molecular weight is measured by sampling.

[0116] Weighed 1789.4g of 1,6-hexanedioic acid (wt%≥99.80%), 1213.0g of 1,4-butanediol (wt%≥99.70%) and 105g of methanes...

Embodiment 2

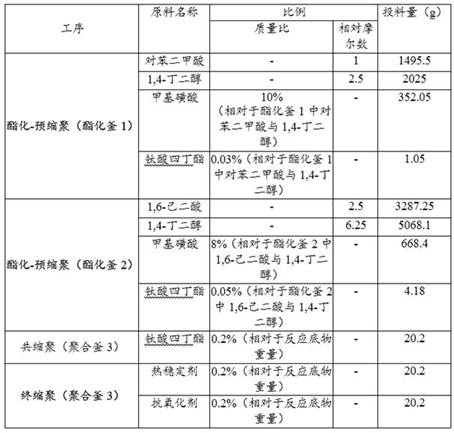

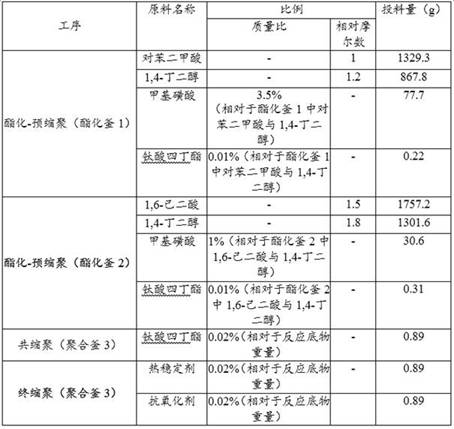

[0121] Table 2 Feeding table of Example 2.

[0122]

[0123] The present embodiment provides a kind of preparation method of biodegradable polyester, comprises following steps carried out in sequence:

[0124] (1) Esterification-precondensation:

[0125] Weighed 1661.7g of terephthalic acid (wt%≥99.90%), 994.3g of 1,4-butanediol (wt%≥99.70%) and 67.1g of methanesulfonic acid (wt%≥99.00%) ) into 10L esterification kettle 1, turn on the heating, stir evenly, raise the temperature to 180°C, carry out the esterification and dehydration reaction, and react for 2 hours. , Reaction 0.5h, removal of methanesulfonic acid.

[0126] Then adjust the temperature, add 0.66g of tetrabutyl titanate, the reaction temperature is 200°C, the reaction pressure is 100KPa, carry out pre-polycondensation, react for 0.5h, and take samples for molecular weight detection.

[0127] Weighed 1789.4g of 1,6-hexanedioic acid (wt%≥99.80%), 1213.0g of 1,4-butanediol (wt%≥99.70%) and 105g of methanesulfon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com