Composite curing agent and preparation method thereof

A technology of composite curing agent and formaldehyde copolymerized resin, which is applied in adhesive types, protein adhesives, starch adhesives, etc., can solve the problems of short resin pot life and inability to meet the needs of bonding, and achieve excellent physical and mechanical properties The effect of performance and weatherability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

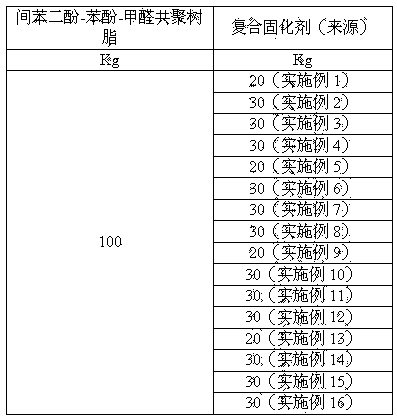

Examples

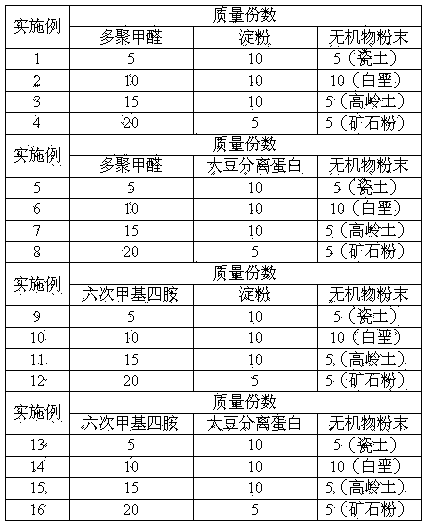

Embodiment 1

[0017] Knead 5 parts of paraformaldehyde powder, 10 parts of starch and 5 parts of China clay evenly, add 5 parts of water during the kneading process, so that the water content of the mixture is 20%; put the mixture with a water content of 20% and knead evenly in an extruder for puffing, puffing The temperature of the machine is 120°C, the puffing pressure is 5.0MPa, and the gelatinization rate of starch is 70%; after the puffed product is dried at low temperature, it is re-grinded into a powder of more than 200 mesh; the preparation of the composite curing agent is completed.

Embodiment 2

[0019] Knead 10 parts of paraformaldehyde powder, 10 parts of starch and 10 parts of chalk evenly, add 7.5 parts of water during the kneading process, so that the moisture content of the mixture is 20%; put the uniformly kneaded mixture with a moisture content of 20% in an extruder for puffing, puffing The temperature of the machine is 130°C, the puffing pressure is 5.5MPa, and the gelatinization rate of the starch is 72%. After the puffed product is dried at low temperature, it is re-grinded into a powder of more than 200 meshes; the preparation of the composite curing agent is completed.

Embodiment 3

[0021] Knead 15 parts of paraformaldehyde powder, 10 parts of starch and 5 parts of kaolin evenly, add 7.5 parts of water during the kneading process, so that the moisture content of the mixture is 20%; the kneaded mixture with a moisture content of 20% is placed in an extruder for puffing, puffing The temperature of the machine is 140°C, the puffing pressure is 6.0MPa, and the gelatinization rate of the starch is 75%. After the puffed product is dried at low temperature, it is re-pulverized into a powder of more than 200 meshes; the preparation of the composite curing agent is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com