Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

76 results about "Neutral media" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A media neutral approach is all the more important in today’s digital world when the platform and the message can change quickly and the emphasis is on conversation and dialogue rather than targeted outreach – and where direct communication is increasingly taking the place of media relations in the tactical toolkit.

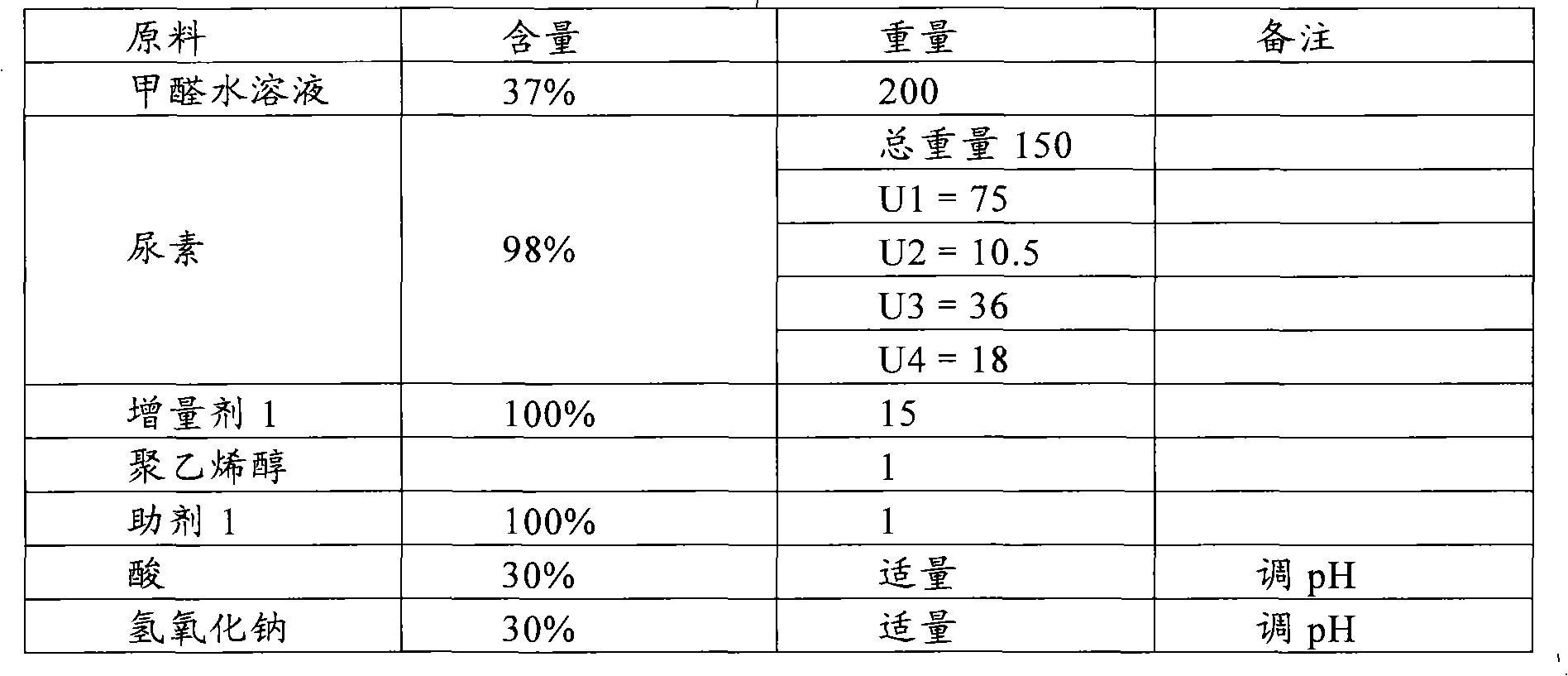

Urea-formaldehyde resin for non-dewatering particleboard and preparation method thereof

ActiveCN102086295AShorten the production cycleLower unit production costAldehyde/ketone condensation polymer adhesivesPolyvinyl alcoholWastewater

The invention relates to urea-formaldehyde resin and a preparation method thereof. The urea-formaldehyde resin comprises the following components in parts by weight: 200 parts of formaldehyde solution, 120-170 parts of urea, 0-2 parts of polyvinyl alcohol, 1-10 parts of additive and 3-20 parts of extender, wherein the concentration of formaldehyde solution is 37%; in the preparation process, ureais added three or four times and the reaction is performed in weakly alkaline medium, weakly acidic medium and neutral medium in turn; and additive and extender are added in the synthesis of urea-formaldehyde resin. The urea-formaldehyde resin can be used in the production of the particleboard without being dewatered, thus the problems of wastewater discharge and environmental pollution can be solved and the production cost of the particleboard can be greatly reduced; and the urea-formaldehyde resin is suitable for various large, medium and small particieboard enterprises.

Owner:江苏露水河人造板有限公司

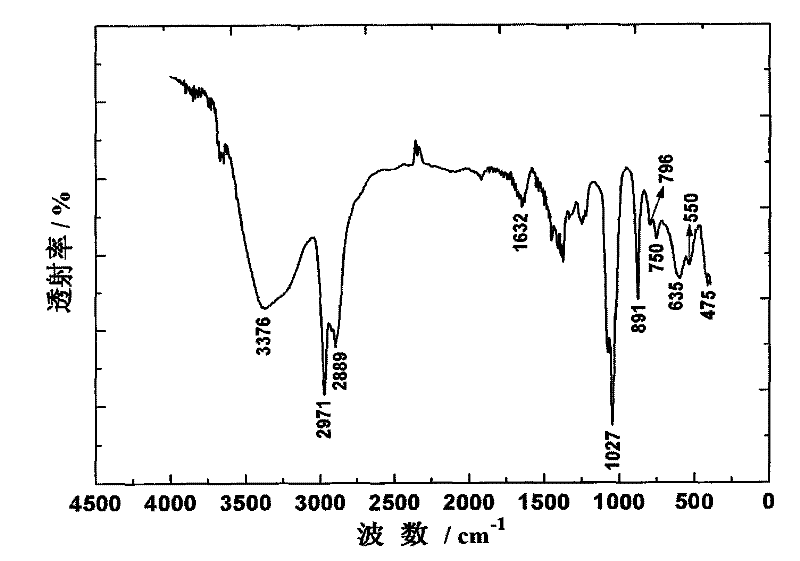

Preparation method of supported FeOOH catalyst, and electro-Fenton waste water treatment system

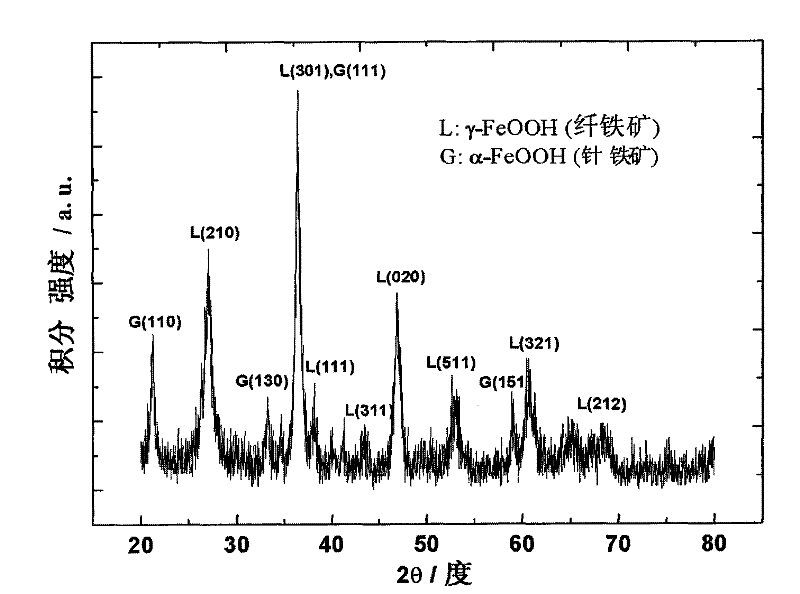

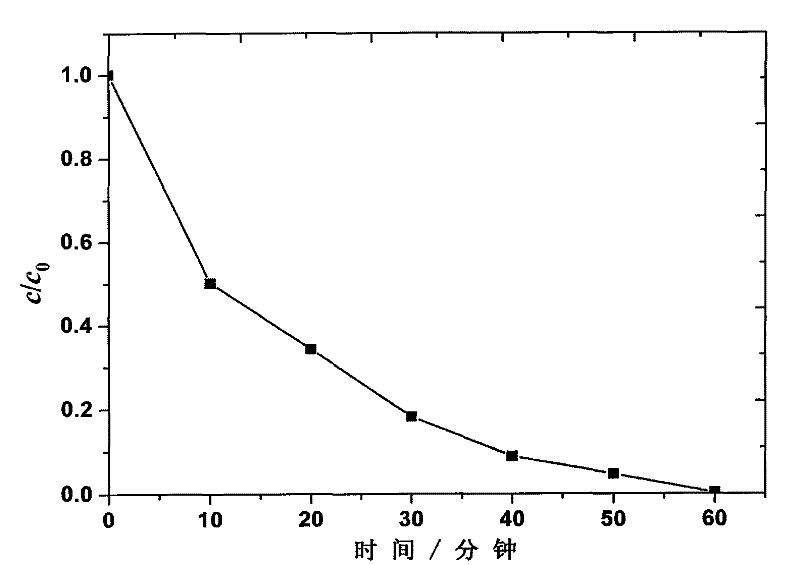

ActiveCN102218319AEasy to separateNothing producedMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationSludgeWater processing

The invention discloses a preparation method of a supported FeOOH catalyst, and an electro-Fenton waste water treatment system. The invention belongs to the technical field of waste water processing. The invention is characterized in that active carbon is utilized as a carrier and ferrous sulphate is utilized as a precursor; through dipping, ethylene diamine tetraacetic acid and ammoniacal undergo an oxidation reduction reaction with active carbon and ferrous sulphate in the presence of oxygen to produce active carbon supported objects and then the active carbon supported objects are washed by deionized water and then are placed in a vacuum oven to be dried at a temperature of 40 to 50 DEG C for 10 to 12 hours to form a supported FeOOH catalyst; active components of the supported FeOOH catalyst comprise alpha-FeOOH and gamma-FeOOH; and under an applied electric field, an out-phase electro-Fenton oxidation system is composed of the supported FeOOH catalyst and hydrogen peroxide and canremove efficiently organic pollutants in waste water. The invention has effects and advantages that an out-phase catalyst can be separated from waste water easily and recycled, and an out-phase electro-Fenton oxidation system can operate in a neutral medium without need of PH adjustment and generation of chemical sludge.

Owner:DALIAN UNIV OF TECH

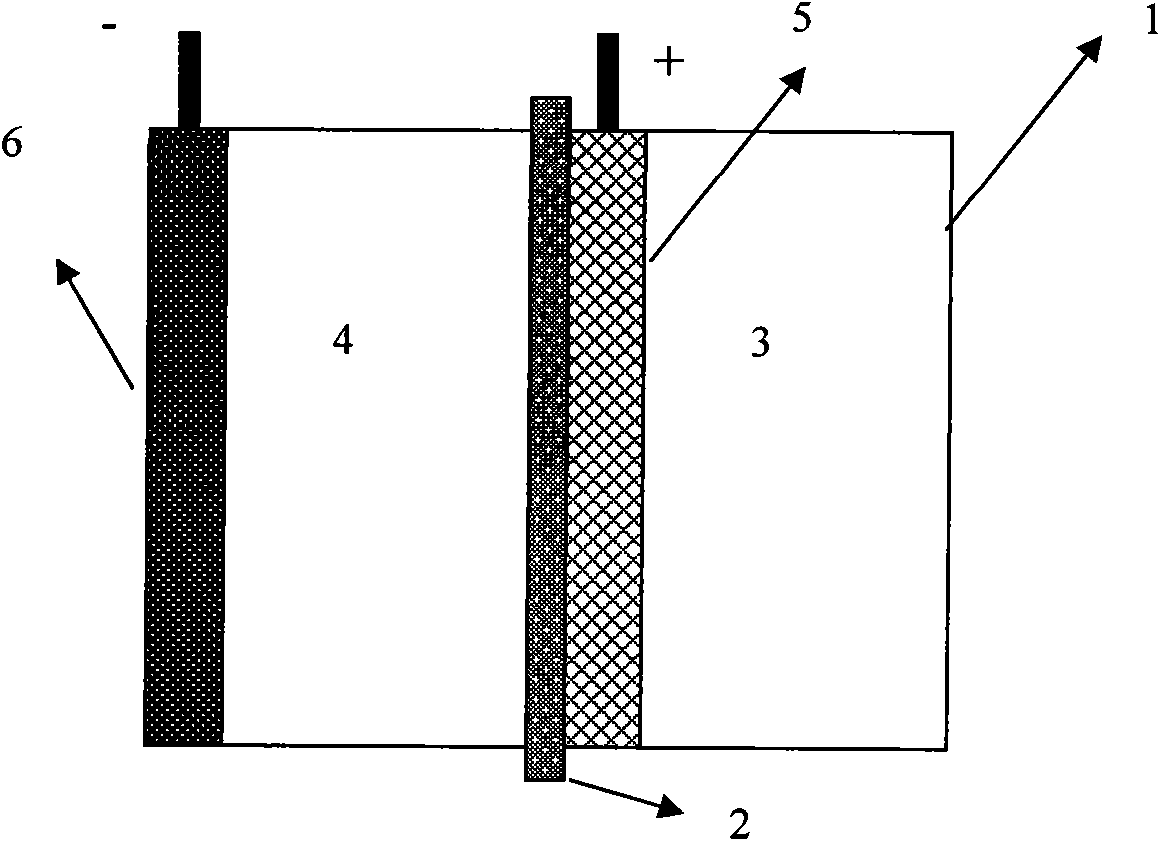

Electrochemical method and electrochemical device for synergistically generating ozone and hydrogen peroxide in neutral medium

The invention provides an electrochemical method and an electrochemical device for synergistically generating ozone and hydrogen peroxide in a neutral medium. The method comprises the following steps: oxygen is subject to reduction on an air-diffusion cathode to generate hydrogen peroxide and water is subject to oxidation decomposition on an anode to generate ozone in the same electrolytic cell. The device comprises a membrane electrode formed by hot-pressing a proton exchange membrane and the anode. The water solution of an inert salt, such as sodium sulfate or potassium sulfate, and sodium phosphate or potassium phosphate, or the mixed solution of the inert salts constitutes the electrolyte in a cathode chamber, while pure water without electrolytes or the same solution as that of the cathode chamber constitutes the electrolyte in an anode chamber. The cathode chamber and the anode chamber are separated by the proton exchange membrane, so as to prevent the generated ozone and hydrogen peroxide from being further subjected to electrochemical reduction or oxidation. Accordingly, the hydrogen peroxide with higher concentration can be obtained in the cathode chamber, and meanwhile, the ozone can be effectively generated in the anode chamber. The method and the device of the invention are also applicable to synergistic wastewater treatment using ozone and hydrogen peroxide.

Owner:XI AN JIAOTONG UNIV

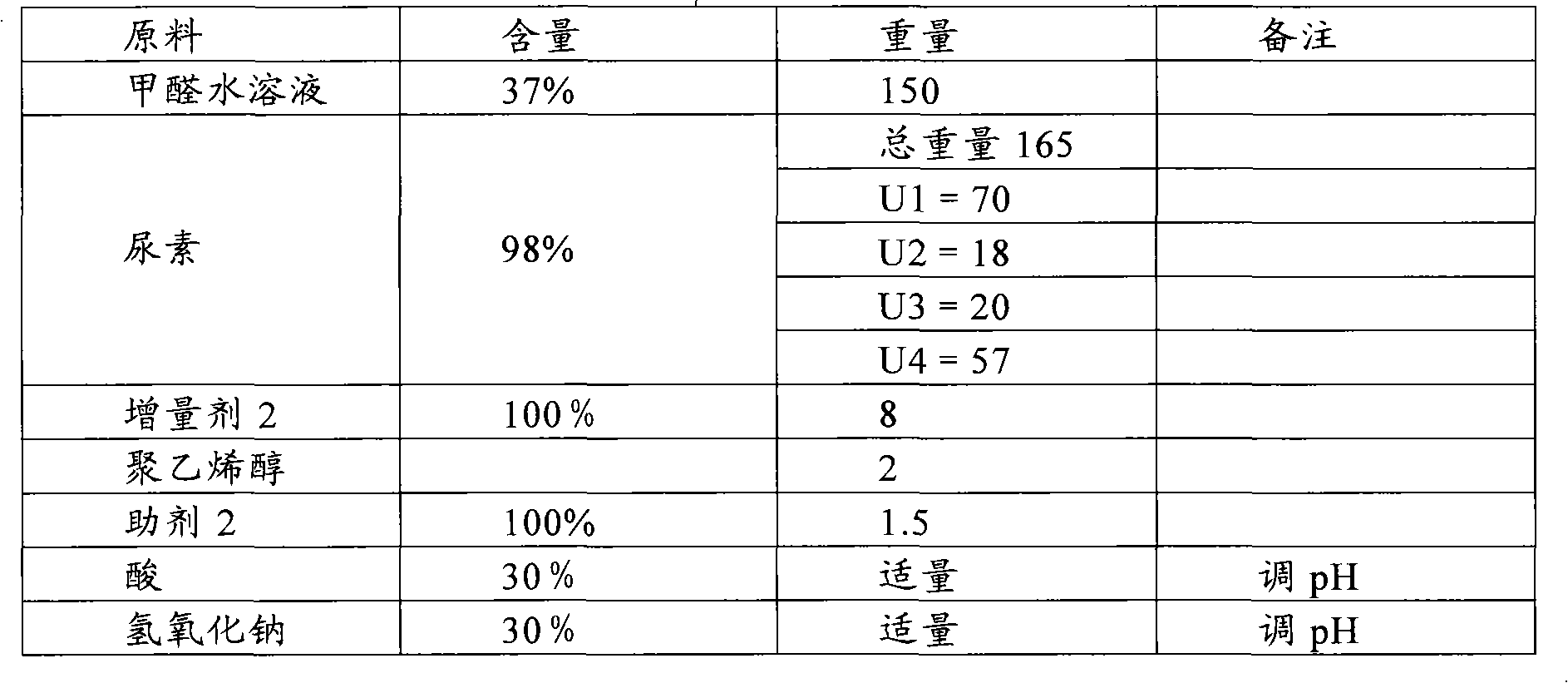

Adhesive for artificial board, and preparation method and application thereof

ActiveCN103173170AHigh strengthImprove the defect of low strengthNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesCross-linkPolyvinyl alcohol

The invention relates to an adhesive for producing an artificial board having a strong strength and a low formaldehyde release amount, and a preparation method and an application of the adhesive in the artificial board production field. The adhesive comprises the following components, by weight, 200 parts of formaldehyde, 150-170 parts of urea, 1-3 parts of polyvinyl alcohol, 12-15 parts of melamine, 5-8 parts of a formaldehyde catching agent, and 0.5-2 parts of a cross-linking agent, wherein the formaldehyde is an aqueous formaldehyde solution having a mass concentration of 35-40%. The preparation method of the adhesive comprises the following steps: adding urea three times, adding the formaldehyde catching agent and the cross-linking agent in the resin synthesis, and sequentially carrying out reactions in a weak alkaline medium, an acidic medium and a neutral medium. The artificial adhesive-bonded board produced through using the adhesive has a low formaldehyde release amount and a bonding strength reaching requirements of Chinese standard adhesive-bonded boards II.

Owner:北京海天科林技术有限公司

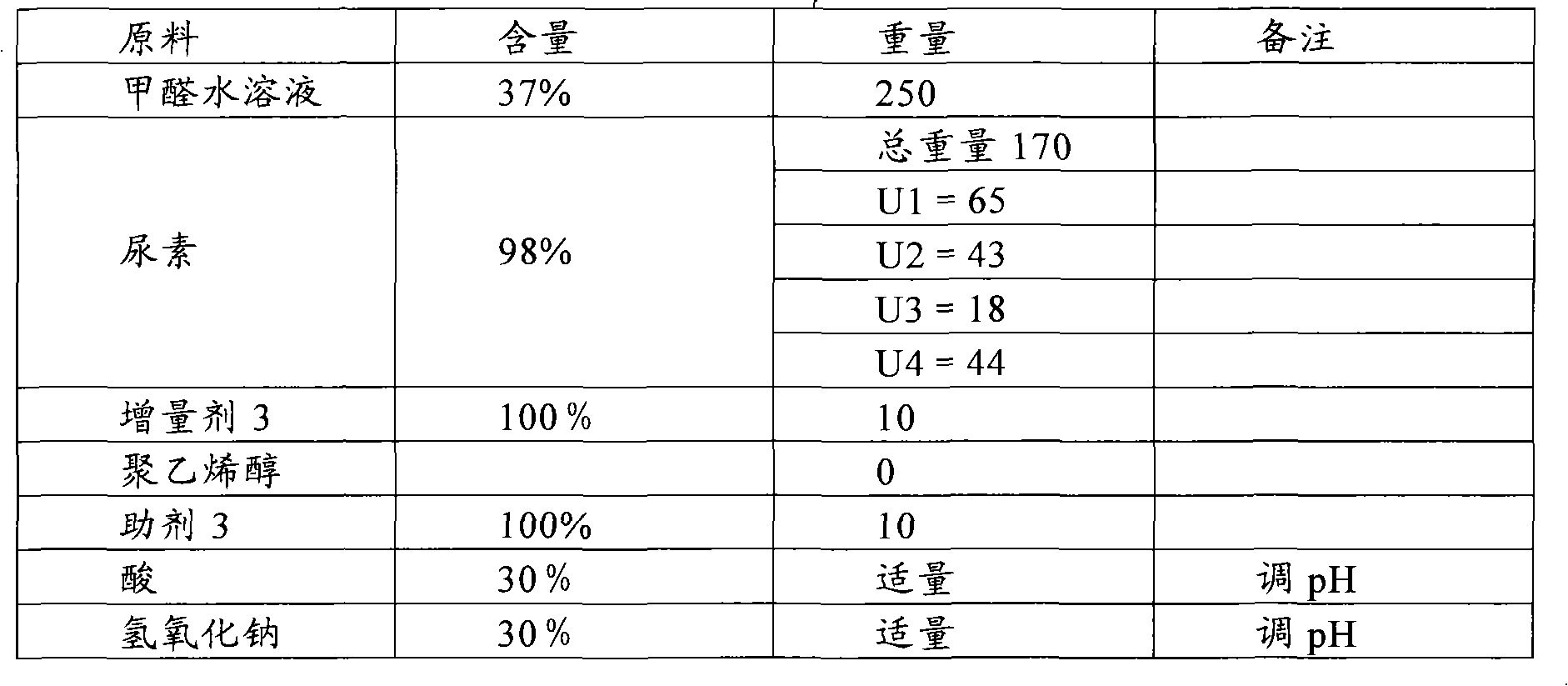

Urea formaldehyde resin, and preparation method

This invention discloses a method for preparing urea-formaldehyde resin, which is prepared from: formaldehyde 200 parts, urea 100-250 parts, poly (vinyl alcohol) 0.5-6 parts, accelerator 0.05-0.5 part, and additive 0.5-5 parts. The concentration of formaldehyde is higher than 42%. During the reaction process, urea is added in batches, so the raw materials react in strongly acidic, neutral to week alkaline, weak acidic and neutral media in sequence. The prepared urea-formaldehyde resin has a free formaldehyde content of only 0.05-0.20%. The production of artificial board, such as flake board and low / high density fiberboard, from the urea-formaldehyde resin has such advantages as no need for vacuum dehydration treatment, no wastewater discharge, short production period, and low fuel and energy consumption. The artificial board, when compared with that produced from low-concentration formaldehyde (37%), has such advantages as obviously improved physical and mechanical properties, and low free formaldehyde content.

Owner:EVERFIRST WISEFUND TECH BEIJING

Double-reverse flotation method applicable to silico-calcium phosphorite

The invention discloses a double-reverse flotation method applicable to silico-calcium phosphorite. According to the method, silico-calcium phosphorite is floated in a neutral medium; silicon-removed tailings are subjected to silicon removal twice and then floated; silicon-removed middlings are not returned; the silicon-removed middlings, silicon-removed coarse and refined ores are combined for floatation again for magnesium removal, so as to obtain a foamed product, namely, magnesium-removed tailings; products in a trough are phosphorus concentrates. The method avoids the influence of a fatty acid collecting agent on reverse flotation silicon removal through silicon removal and magnesium removal in sequence, so that the silicon removal sorting feature can be enhanced; the magnesium content of the silicon-removed middlings is higher; the silicon-removed middlings are combined with the silicon-removed coarse and refined ores for floatation for magnesium removal, and cannot be returned for floatation, so that the influence of slurry accumulation of the silicon-removed middlings on reverse flotation silicon removal is avoided; the silicon removal floatation process is stable and easy to operate; a floatation medium is neutral and weak in acidity; finally, the floated concentrates are easier to dehydrate in acidic slurry, and subsequent operation is facilitated.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Surface cleaning method after sapphire substrate material polishing

InactiveCN101912855AReduce surface tensionImprove uniformityCleaning using liquidsSurface cleaningMachining process

The invention relates to a surface cleaning technology after chemically mechanical polishing (CMP) in the surface high-precision machining process of sapphire substrate materials, and provides a water polishing solution prepared from neutral media. The water polishing solution comprises activator, chelator and corrosion inhibitor. By carrying out water polishing with the water polishing solution at a high output immediately after alkaline polishing is finished, the residual CMP polishing solution can be flushed away, easily-cleaned materials can be adsorbed, the surface tension can be quickly reduced, the reaction can be prevented from continuing (physical adsorption state) to form a unimolecule passive film, and metal ions are enabled to form a soluble chelate, thereby obtaining a clean and perfect polished surface. The water polishing solution has the advantages of low cost, no environmental pollution and no corrosion to equipment.

Owner:HEBEI UNIV OF TECH

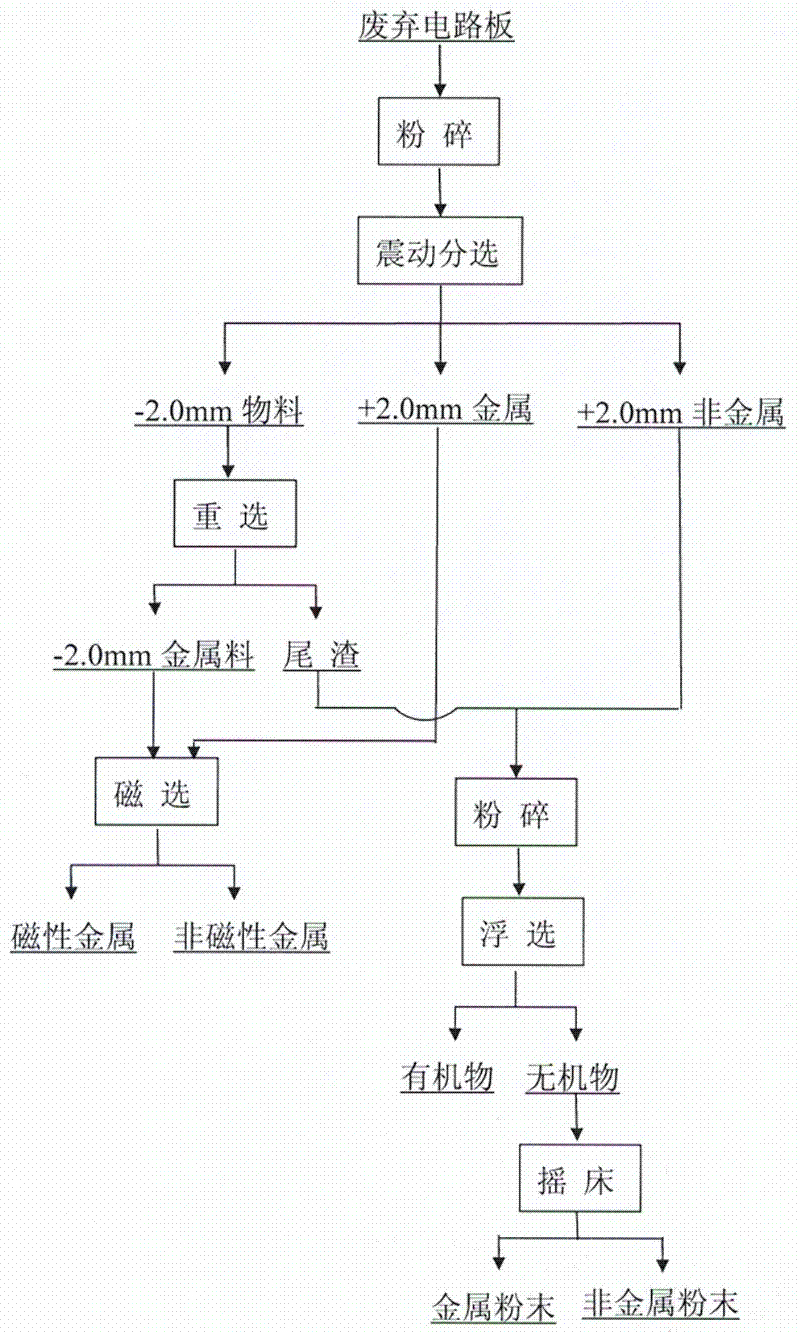

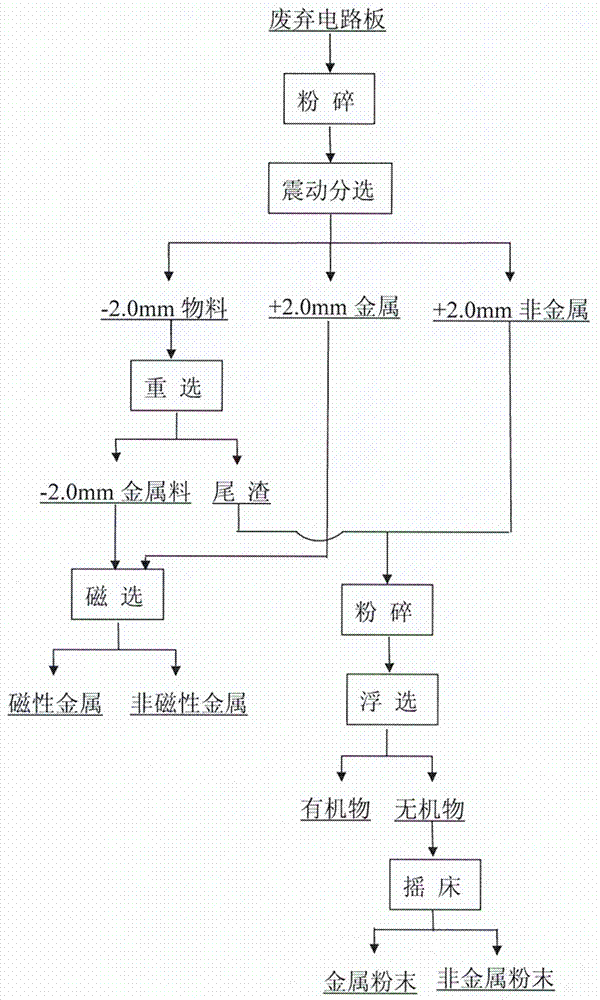

Discarded circuit board full-value recycling method

InactiveCN102172597AReach the purpose of recyclingAchieving Full Value Clean RecyclingSolid waste disposalElectronic waste recyclingRecovery methodOrganic matter

The invention relates to a discarded circuit board full-value recycling method. The method is characterized by comprising the following steps of: smashing a discarded circuit board, vibrating and sorting to obtain a material of minus 2.0mm, metal of plus 2.0mm and nonmetal of plus 2.0mm; sorting the material of minus 2.0mm by virtue of a table concentrator so as to obtain a metal material of minus 2.0mm and tailings; mixing the metal of plus 2.0mm and the metal material, and separating magnetic metal from nonmagnetic metal by wet magnetic separation; smashing the mixed nonmetal of plus 2.0mm and tailings until the particle size is less than 0.1mm, and under the condition of a neutral medium, carrying out flotation to separate organic matters and inorganic matters by adopting an octadecylamine collector; and sorting the inorganic matters by virtue of the table concentrator to obtain metal powder and nonmetal powder. The method provided by the invention is a high-efficiency, economic and clean discarded circuit board full-value recycling method and is applicable to recycling of electronic circuit boards of various electronic parts and components.

Owner:广东省资源综合利用研究所

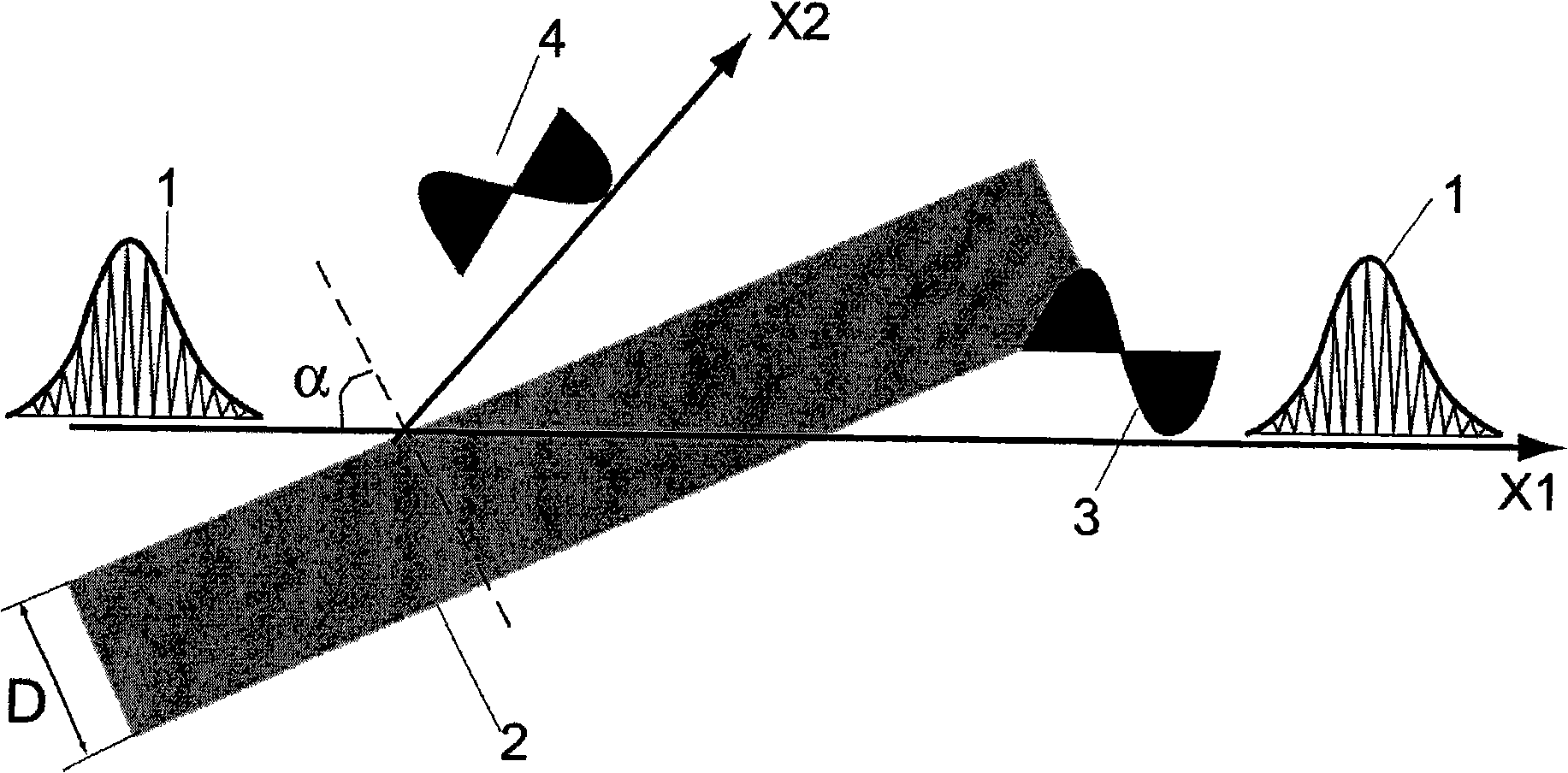

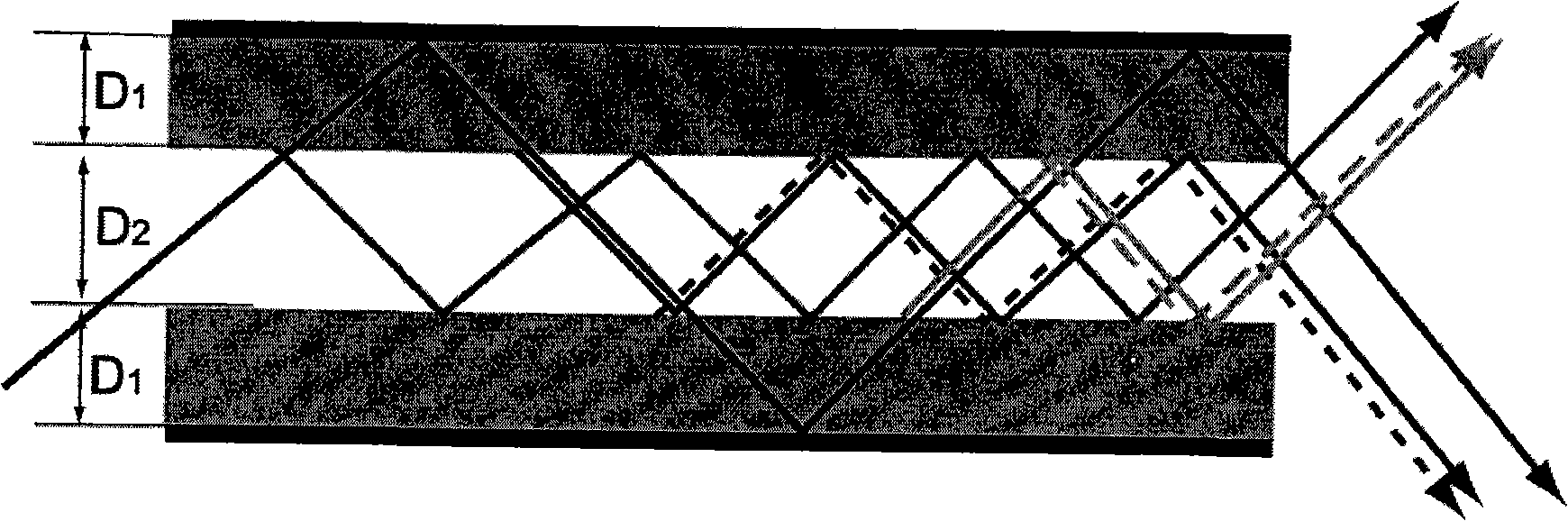

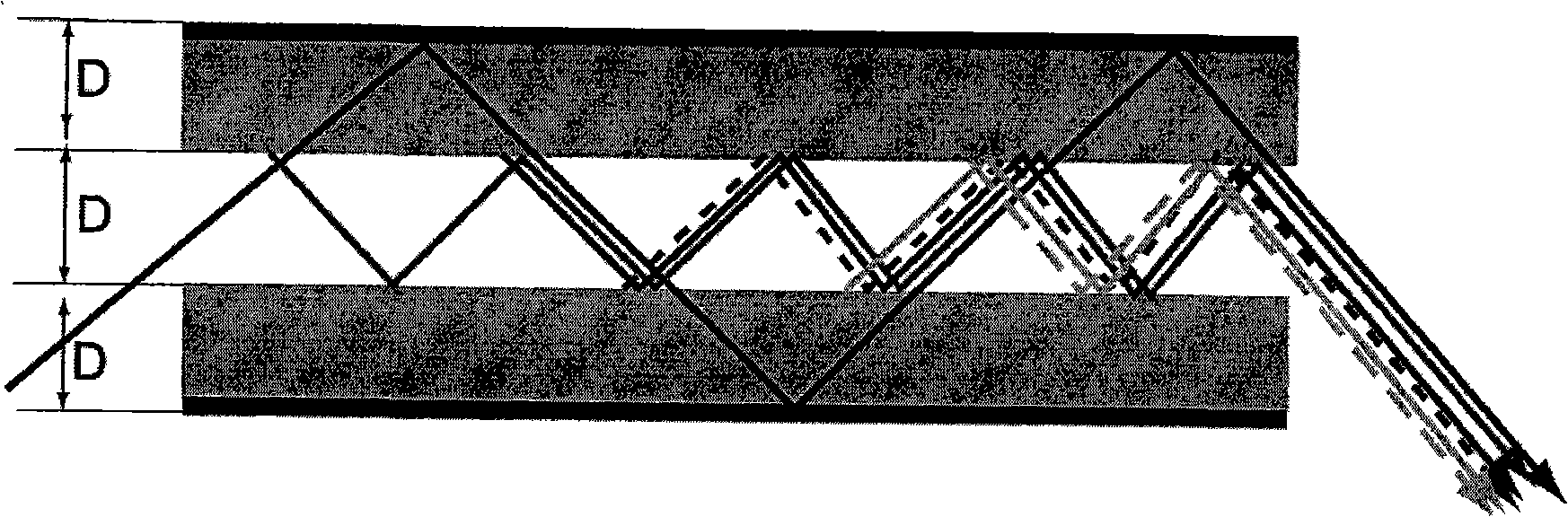

Apparatus and method generating powerful terahertz emission

The invention relates to a device which can generate high power Terahertz radiation and a method thereof. The device comprises a gas filling pipe, an ionizing laser which is used for outputting ionized laser pulse to form a vacuum layer and an ionized gas layer in the gas filling pipe and a pump laser which is used for outputting pump laser pulse to activate a plurality of coherent Terahertz radiations to overlay the radiations into a super high Terahertz radiation. The device and method of the invention have the technical effects that: plasma adopted in the invention is the fully ionized quasi neutral medium without threshold value in which the medium can be damaged by incident laser, and can generate THz radiation of 100MW. Through the control of the proper delay between two incident radiation pulses, the density of the gas inside the cavity of the pipe can be controlled to overlay by coherence and amplify the monocyclic Terahertz pulses generated in the cavity of the pipe and generate quasi monocyclic Terahertz pulses, and thereby the conversion efficiency is greatly improved and super high Terahertz radiation can be generated in a table site.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

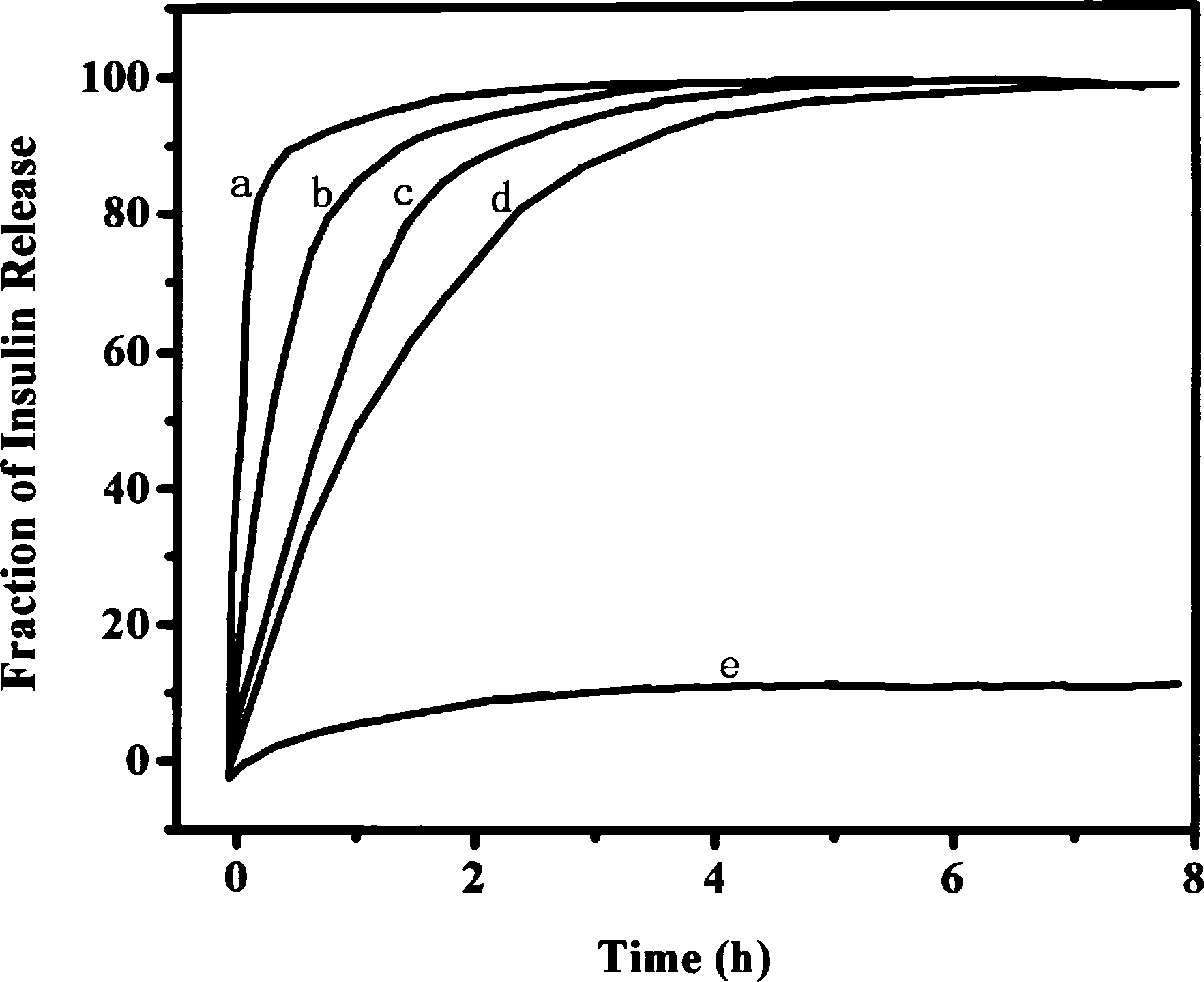

Method for preparing oral administered sustained-release peptide micro capsule

InactiveCN1879610ASimple processMild reaction conditionsPeptide/protein ingredientsMetabolism disorderMedicineMicrometer

The invention relates to a method for using template nanometer self-assemble technique to prepare polypeptide oral microcapsule, which comprises: using polypeptide grain as template grain; using two biological compatible macromolecules with reversed charges as wall material; based on mutual attraction between different charges, combining the macromolecule materials from layer to layer, to form thin protective film on the surface of polypeptide grain, to obtain the polypeptide microcapsule. The invention is stable in acid medium, but releases polypeptide medicine in neutral medium, to keep the function of polypeptide grain in oral. And the polypeptide microcapsule can be dispersed into water or other liquid to form variable micro nanometer polypeptide oral liquid; or mixing the micrometer or sub-micron polypeptide microcapsule to form sheets, ejections, etc.

Owner:HARBIN INST OF TECH

Release delayed solid oral prophylactic or pregnancy stopping pill and its use

InactiveCN1500478APrevents inaccuracies in actual doses takenPowder deliverySexual disorderPregnancy terminationPregnancy

The present invention relates to the preparation form of contraceptive, and is especially one delayed dissolving orally taken solid preparation form of contraceptive or pregnancy terminating medicine. The present invention also relates to the application of the preparation form. The preparation form has one or several layers of coating or is delayed dissolving capsule, and will dissolve for absorption in neutral medium inside intestinal tract, rather than acid medium. The present invention aims at preventing inaccurate medicine dosage caused by vomiting after taking the contraceptive or pregnancy terminating medicine.

Owner:REGENEX PHARMA LTD

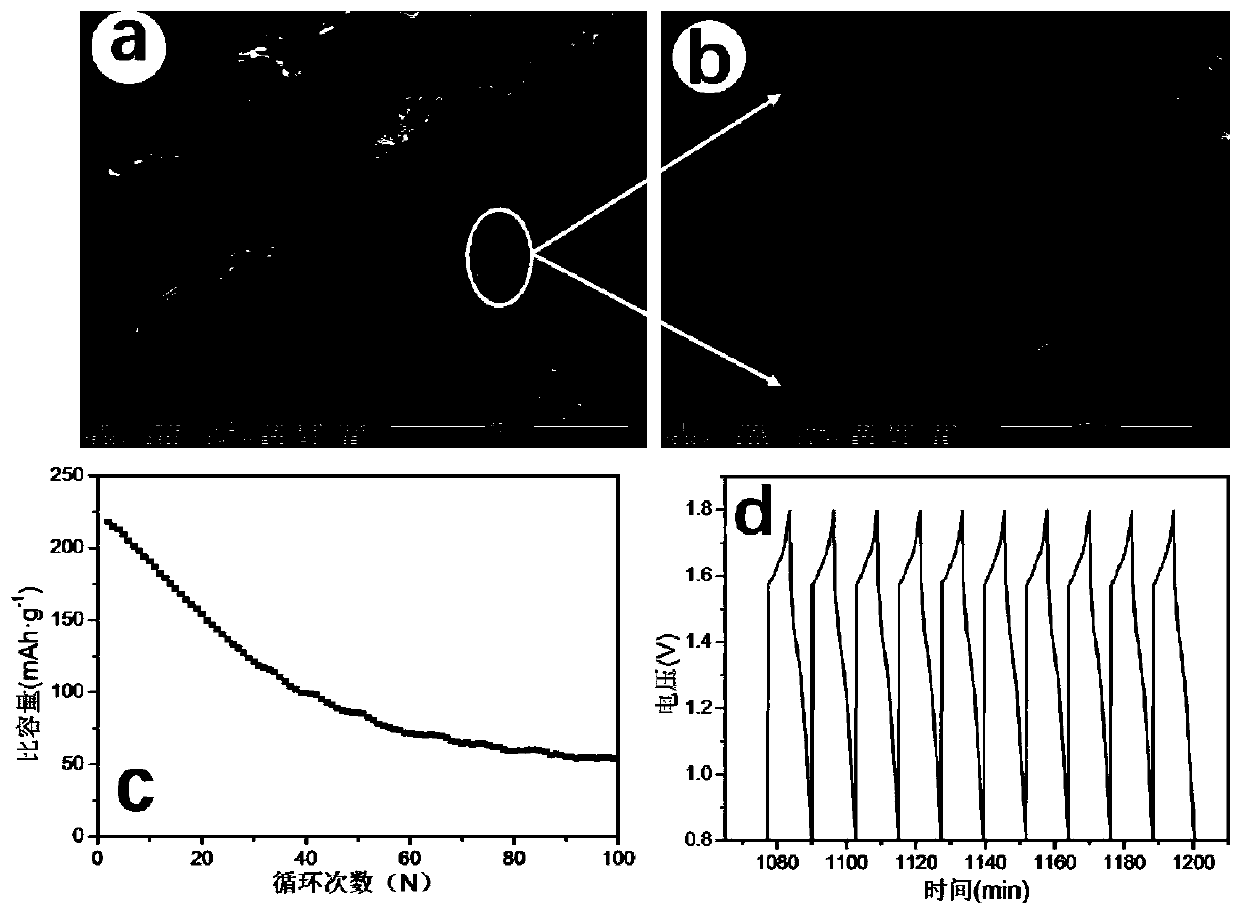

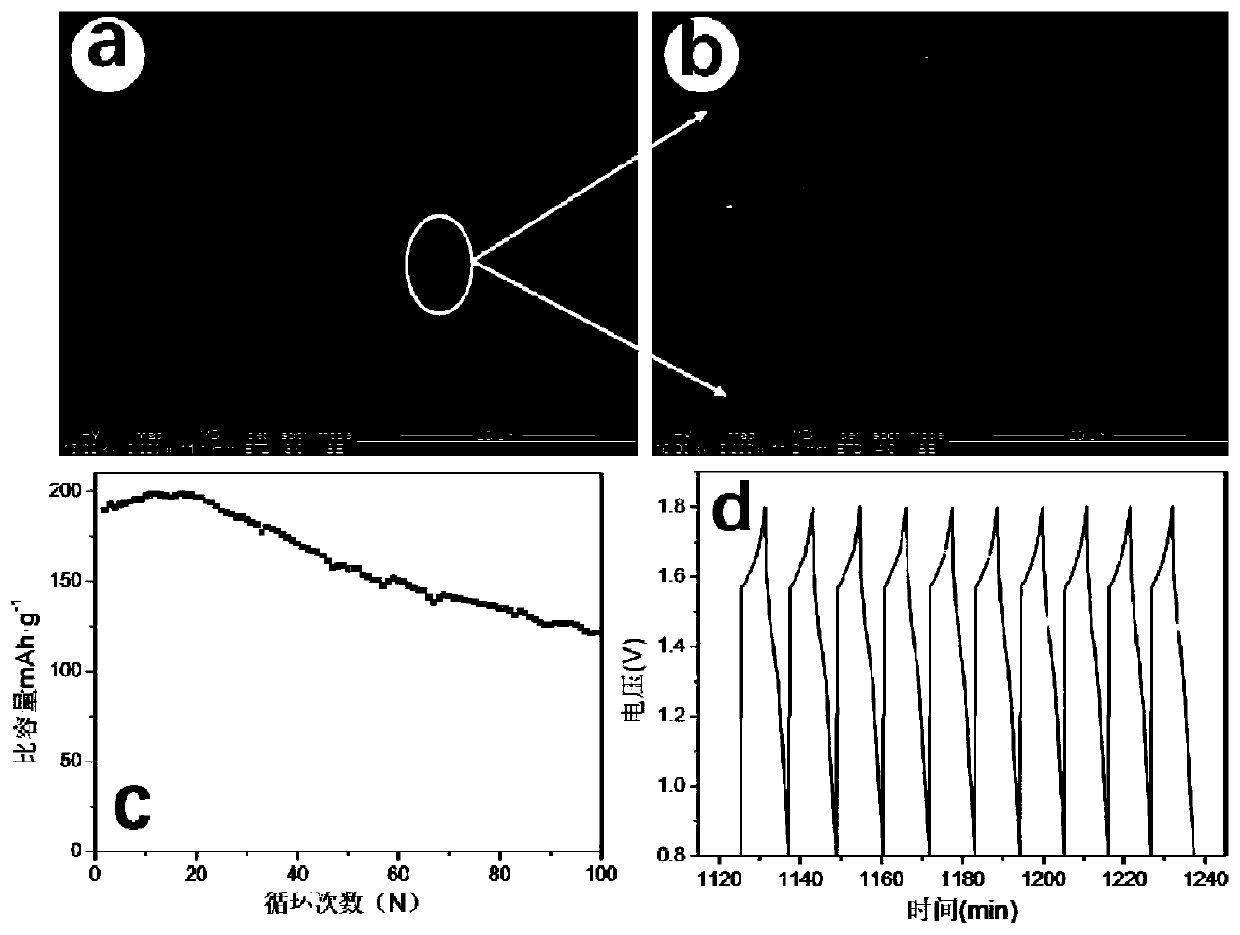

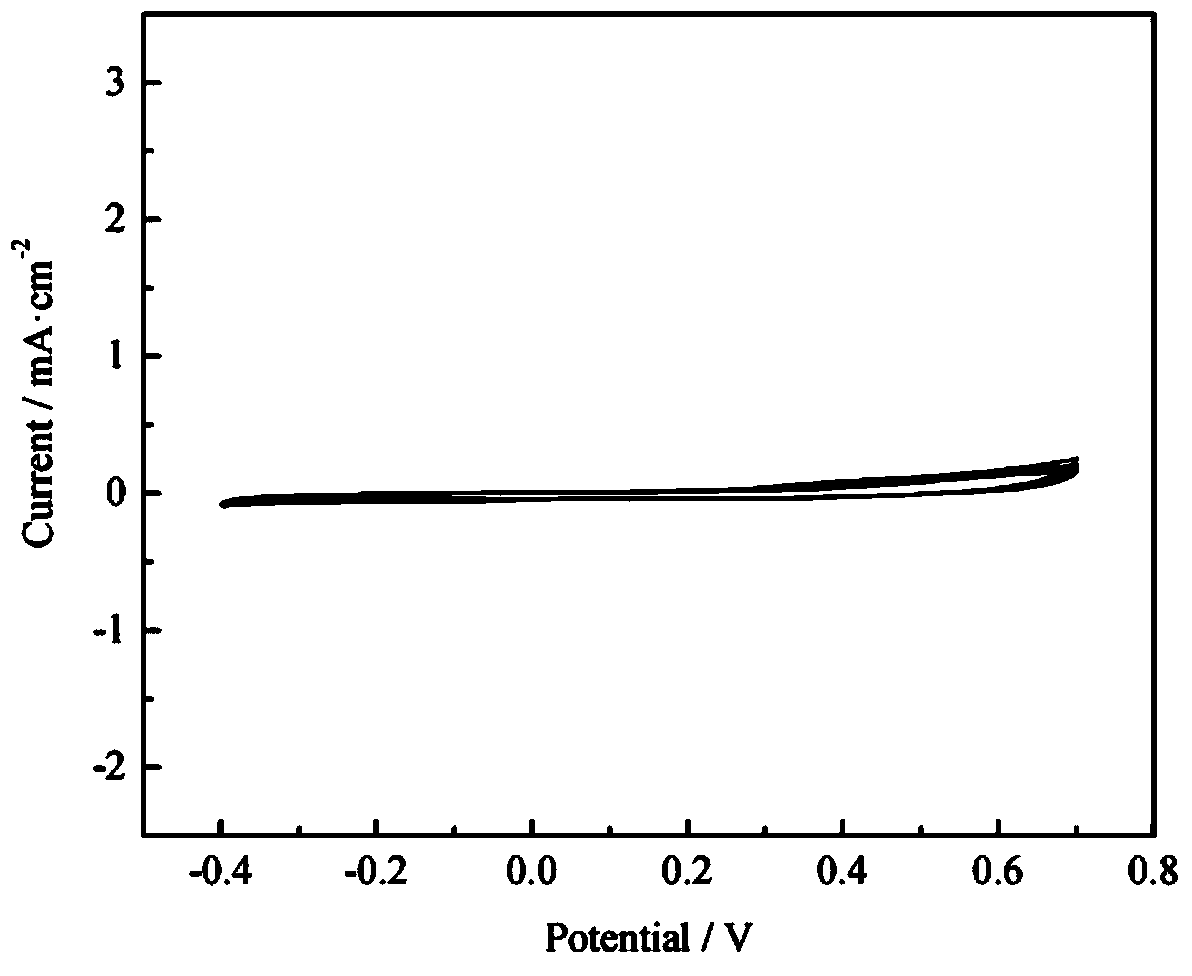

Aqueous zinc ion battery electrolyte membrane and preparation and application method thereof

ActiveCN110085925AHigh strengthExcellent electrochemical ion fluxSecondary cellsCross-linkComposite electrolyte

The invention discloses an aqueous zinc ion battery composite electrolyte membrane and a preparation and application method thereof. The prepared zinc alginate-based polymer composite gel electrolytemembrane has a homogeneous three-dimensional layered cross-linking network structure and high ion conductivity. According to the preparation method, the polysaccharide sodium alginate-based material and the zinc ion are utilized, and the zinc ion cross-linking electrolyte membrane is formed in a weak acid or neutral medium through stacking after the sodium-zinc ion exchange reaction. The electrolyte membrane prepared by the method has both excellent physical and electrochemical properties, the problems of negative electrode zinc dendrites and zinc corrosion can be effectively suppressed, and the method is simple and fast, low in cost, environmentally friendly and controllable in condition and is particularly suitable for low-cost large-scale energy storage zinc ion battery systems and alsosuitable for preparing flexible aqueous system zinc ion batteries in flexible devices.

Owner:CENT SOUTH UNIV

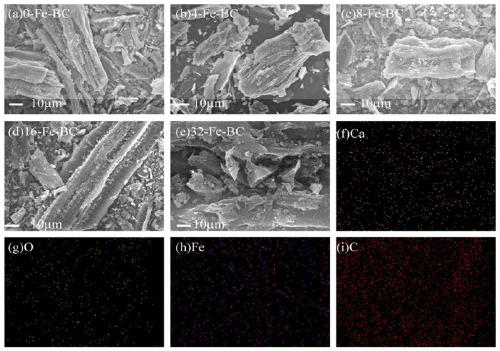

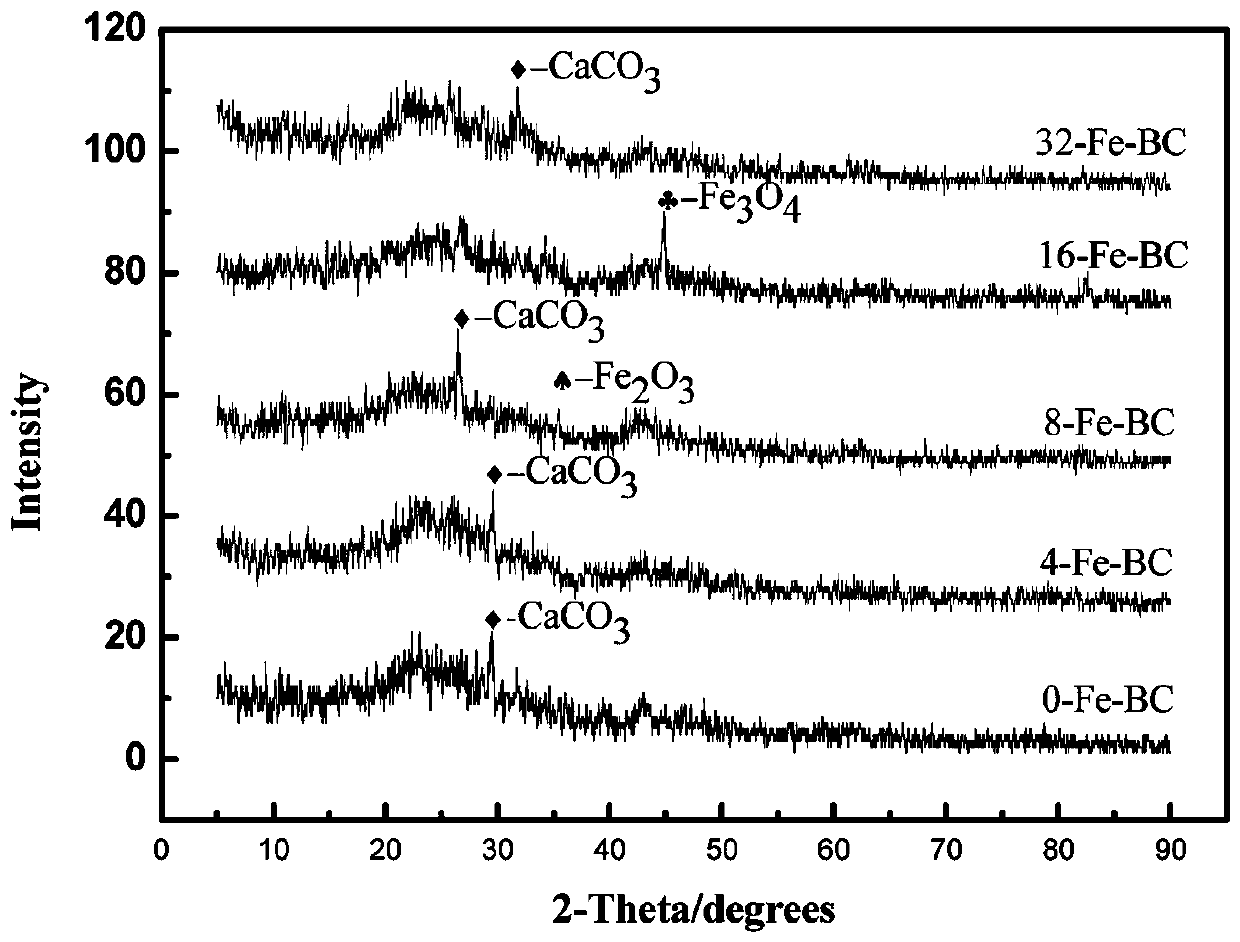

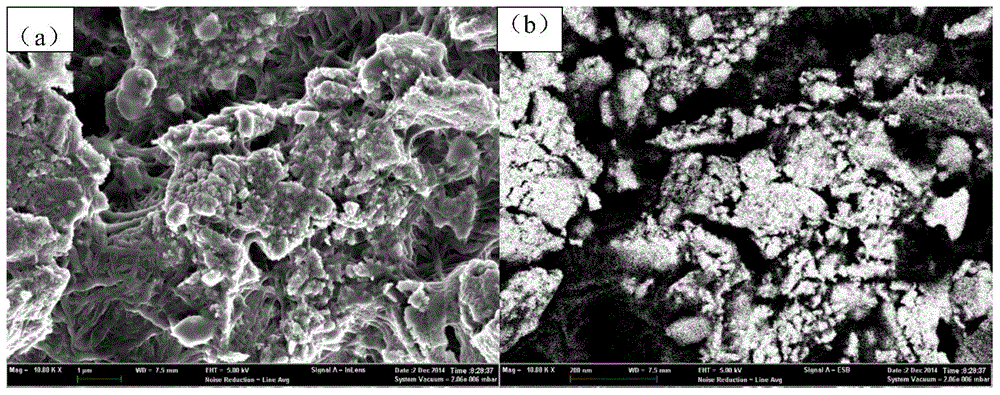

Preparation method of water hyacinth-Fe biochar and application of water hyacinth-Fe biochar

ActiveCN109675564AGood catalyticConducive to catalytic reductionMetal/metal-oxides/metal-hydroxide catalystsElectrodesNitrogen gasWater Hyacinths

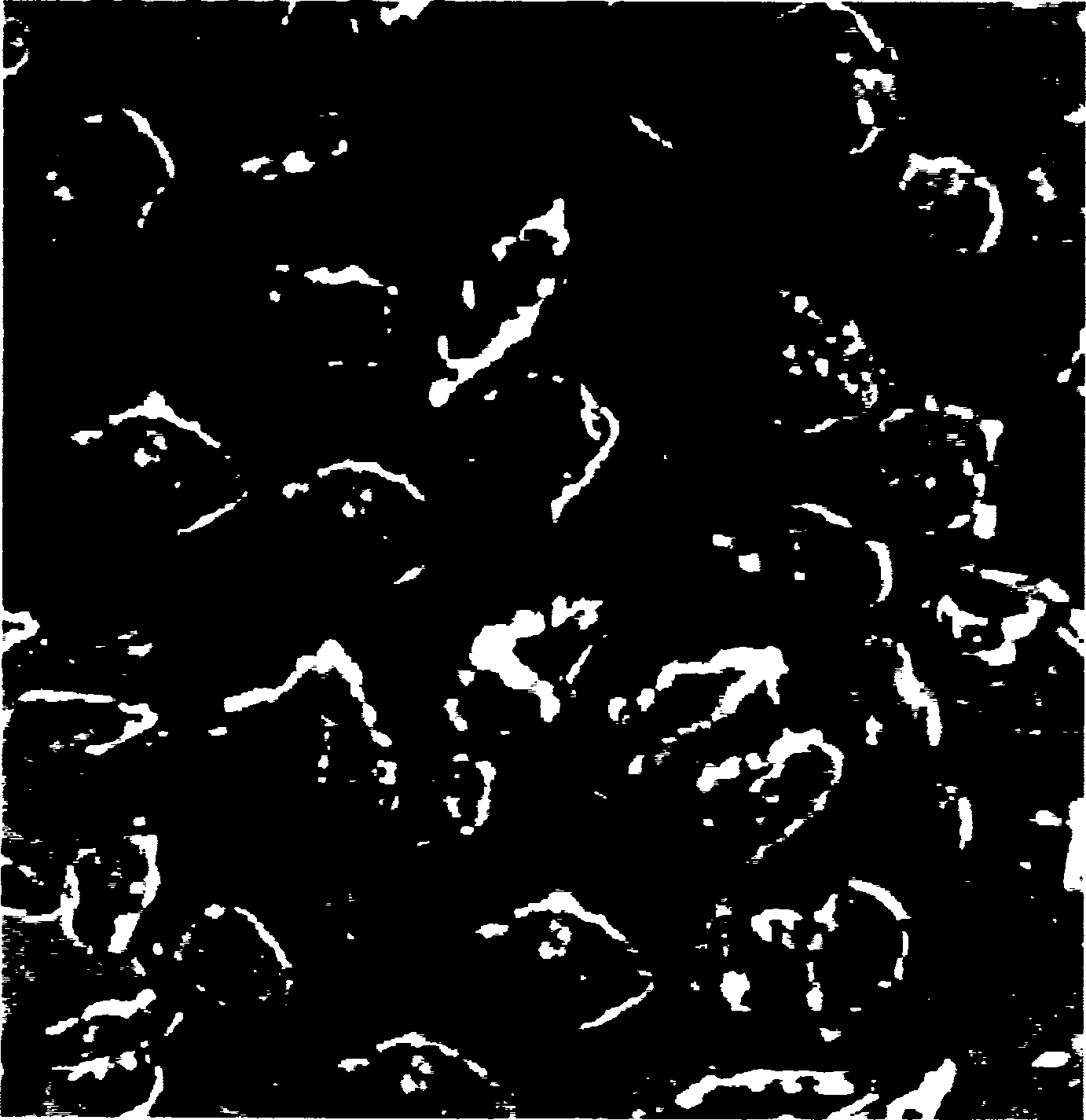

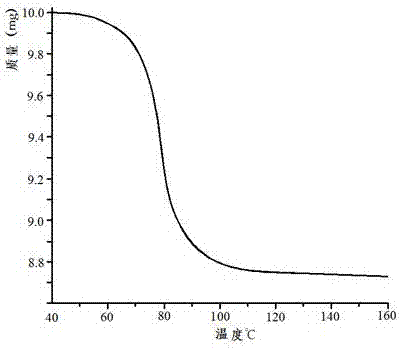

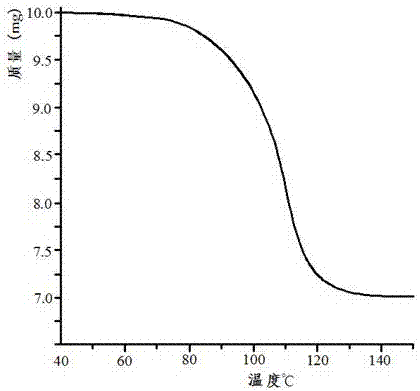

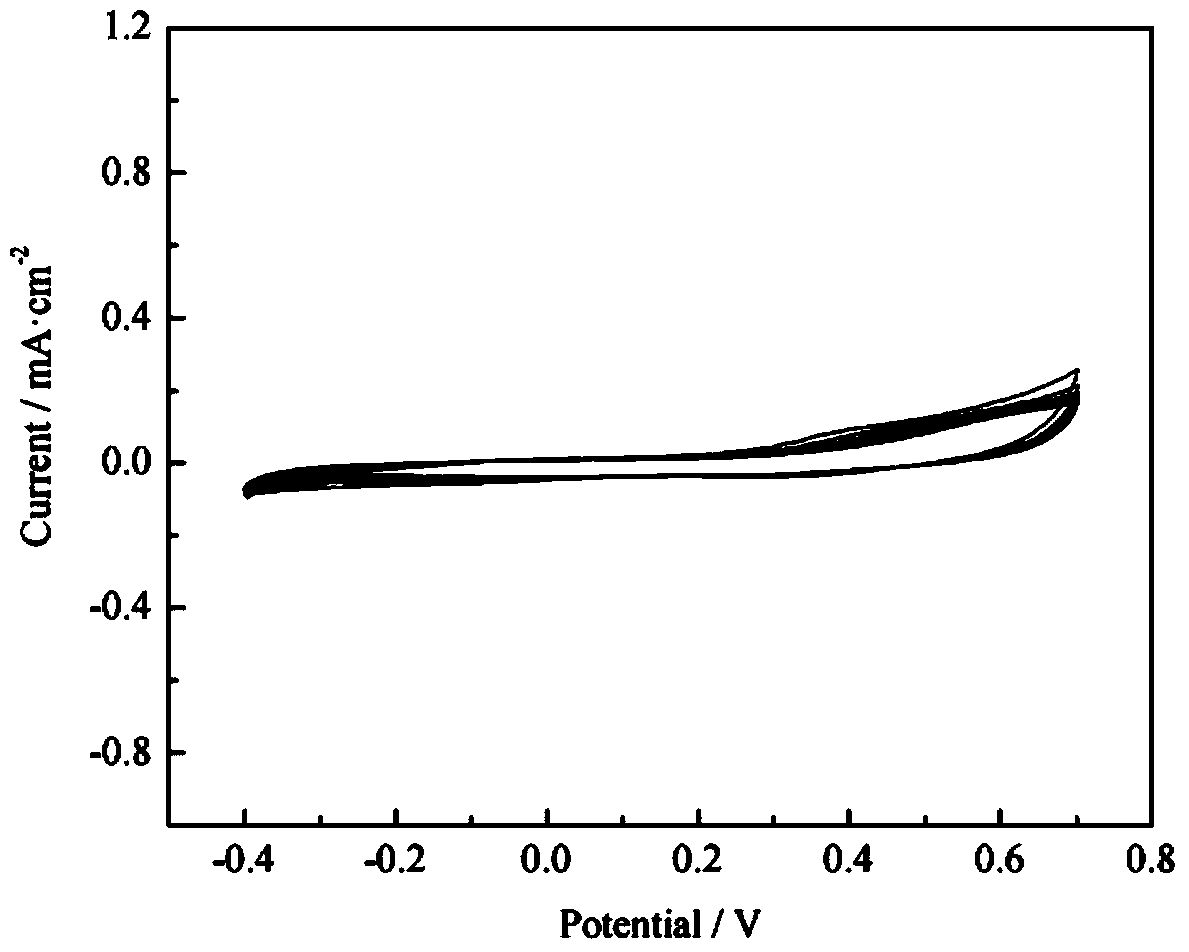

The invention provides a preparation method of water hyacinth-Fe biochar and application of the water hyacinth-Fe biochar. The preparation method comprises the following steps: taking water hyacinth as a raw material and cultivating the water hyacinth with plant solution for one month, so as to obtain water hyacinth enriching 4-64 mg.L<-1> of Fe; performing low pyrolysis on the Fe-enriched water hyacinth at the temperature of 500-900 DEG C in a nitrogen atmosphere, so as to prepare a series of Fe-loaded water hyacinth biochar with different concentrations. A result shows that the water hyacinth biochar is rough in surface and has a lumpy structure on the surface, and Fe in the biochar exists in forms of two oxides: Fe2O3 and Fe3O4. A glassy carbon rotating disk electrode modified by various biochar particles is utilized to explore the electrocatalytic reduction reaction of H2O2 in a neutral medium on different biochar catalysts according to a cyclic voltammetry scanning method, the exploration discovers that a water hyacinth biochar sample has the maximum reduction current value and is most excellent in electro-catalytic property on H2O2, and different scanning experiments also verifies that the water hyacinth biochar sample also has the potential property of energy storage.

Owner:CHINA THREE GORGES UNIV

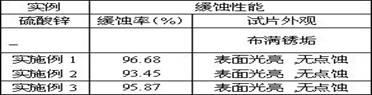

Aluminum alloy corrosion inhibitor for neutral medium

The invention belongs to the technical field of corrosion protection for aluminum alloy. The invention relates to an aluminum alloy corrosion inhibitor for a neutral medium. The aluminum alloy corrosion inhibitor for the neutral medium is characterized in that: 1 g of the aluminum alloy corrosion inhibitor comprises 0.1-0.2 mg of zinc sulfate, 0.1-0.2 mg of sodium oleate, 0.1-0.2 mg of sodium orthophosphate and 0.1-0.2 mg of tallow amine. According to the present invention, the corrosion inhibition effect is provided for the aluminum alloy through the synergistic reaction of the zinc sulfate and the sodium oleate; the aluminum alloy corrosion inhibitor formed according to the ratio of the zinc sulfate to the sodium oleate is the aluminum alloy corrosion inhibitor for the neutral medium, wherein the aluminum alloy corrosion inhibitor for the neutral medium is low-toxic, high-efficient and economic, and does not affect the existing technological process.

Owner:WUJIANG SHI FINE WORKMANSHIP & ALUMINUM WORD MANUFACTORY

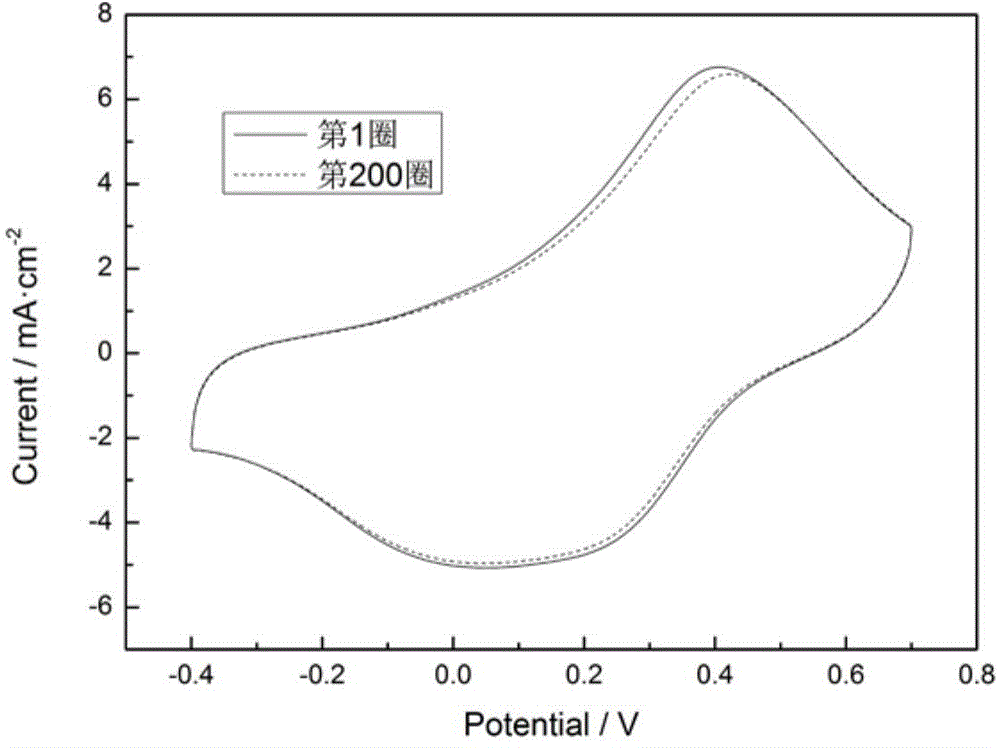

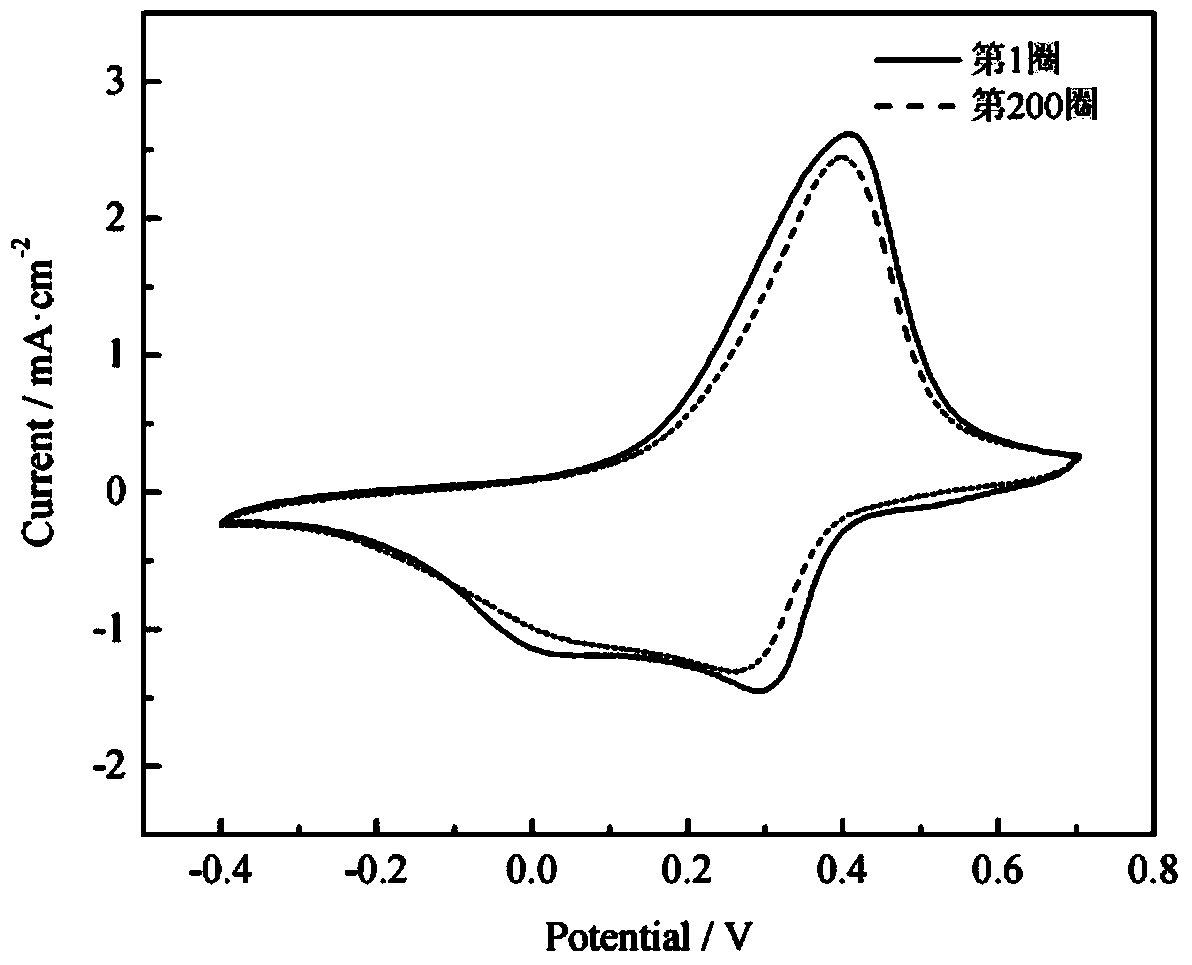

Method for enhancing electrochemical activity of polyaniline in neutral medium

InactiveCN105420792AImprove regularityLarge specific surface areaElectrolytic inorganic material coatingSurface reaction electrolytic coatingTio2 nanotubeAniline

The invention discloses a method for enhancing the electrochemical activity of polyaniline in a neutral medium. Firstly, titanium is oxidized under constant pressure by an anodic oxidation method and a titanium oxide nanotube array is obtained. Then an ammonium chloride solution serves as an electrolyte solution, and an annealed titanium oxide electrode is subjected to electrochemical reduction through a cyclic voltammetry method. Then the reduced titanium oxide electrode serves as a working electrode, a sodium tungstate solution serves as an electrolyte solution, electrochemical deposition of tungsten oxide is conducted through the constant pressure method at the room temperature, a titanium oxide / tungsten oxide compound film is prepared, and annealing treatment is conducted. Finally, the electrode of the titanium oxide / tungsten oxide compound film serves as a working electrode, a sulfuric acid aqueous solution containing aniline monomers serves as an electrolyte solution, electrochemical polymerization is conducted through the cyclic voltammetry method at the room temperature, and a polyaniline compound film is prepared. The method enables the polyaniline to have higher electrochemical activity in the neutral solution with the pH of 7.0, so that the polyaniline is better applied in the fields such as biosensors and metal corrosion resistance.

Owner:NANJING UNIV OF SCI & TECH

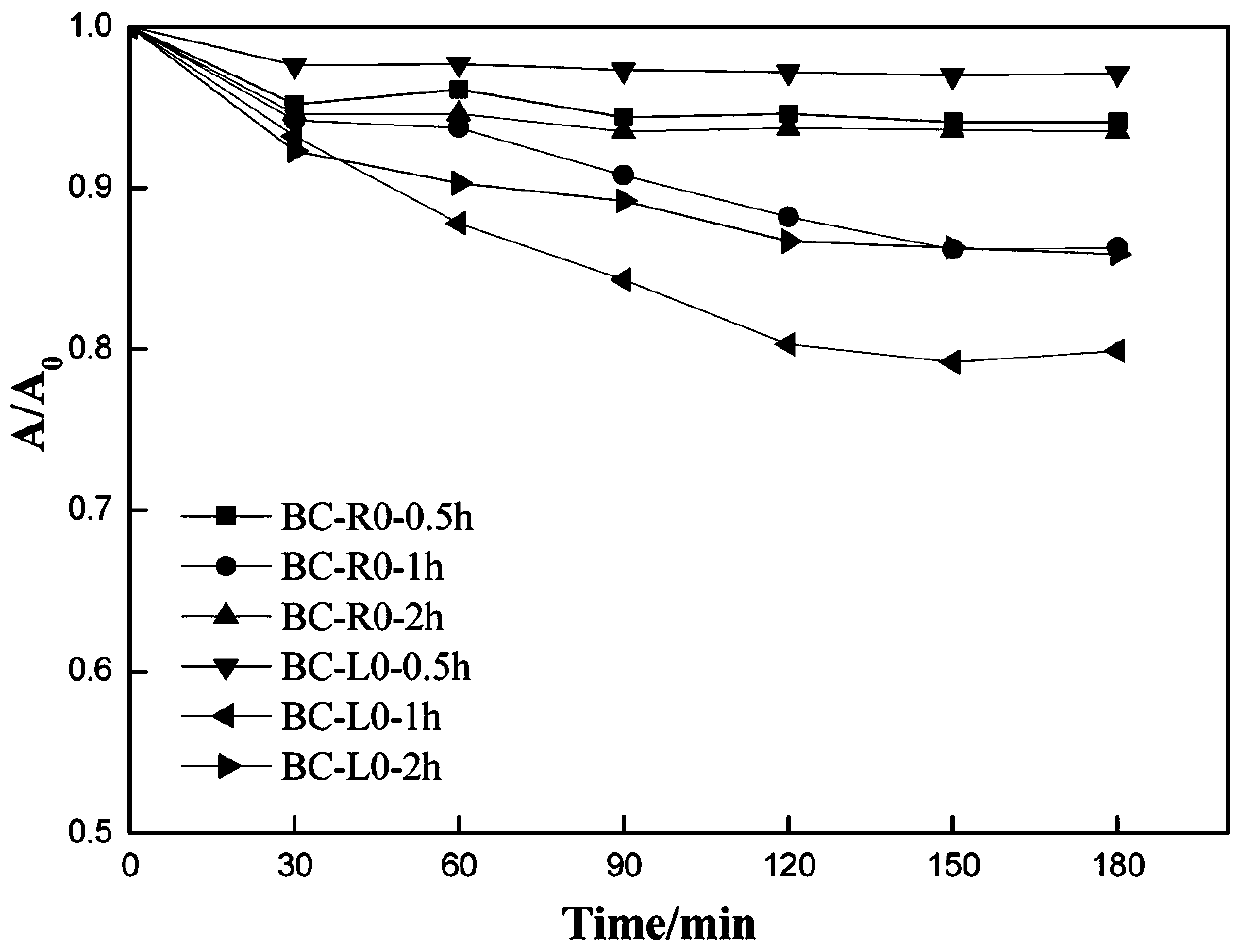

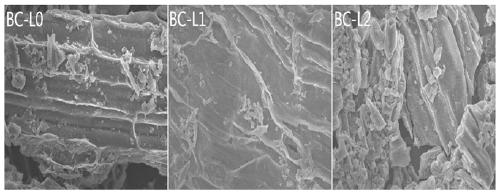

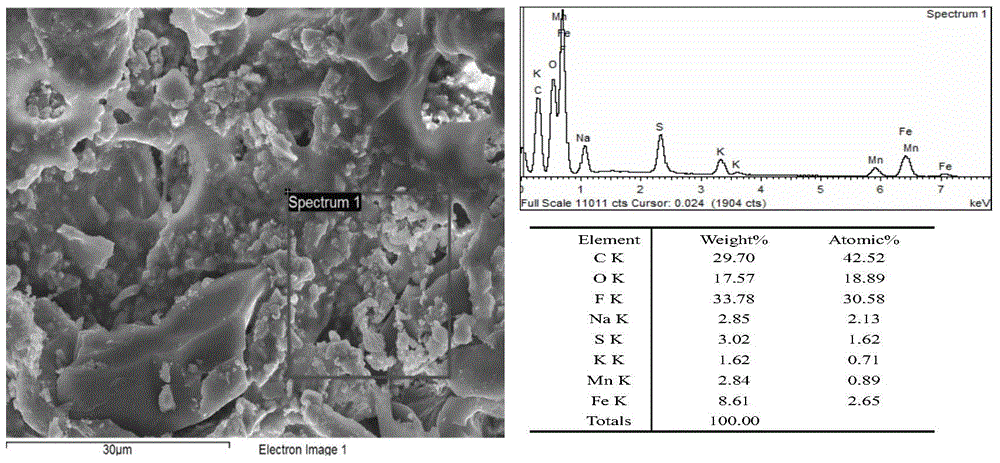

Preparation method for fleur-de-lis manganese-enriched biochars and application thereof

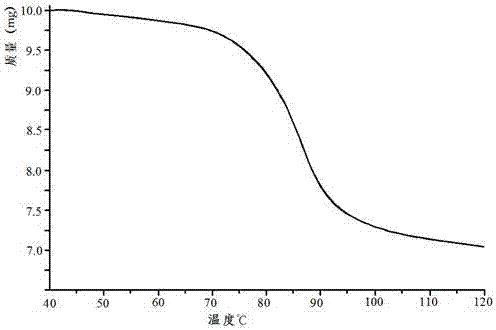

ActiveCN109529773AImprove catalytic performanceHigh catalytic activityWater/sewage treatment by irradiationOther chemical processesFleur-de-lisElectricity

The invention takes Mn stress-free fleur-de-lis as a blank group and utilizes a MnSO4 solution to respectively stress experimental groups of fleur-de-lis for 1 month and 2 months. In situ manganese-enriched biochars are acquired through pyrolysis under N2 atmosphere after harvesting treatment; the biochars are respectively named as BC-L0, BC-L1, BC-L2, BC-R0, BC-R1 and BC-R2 on the basis of collection parts; Rhodamine B is taken as a probe molecule for researching influences of conditions of pyrolysis temperature (500 DEG C, 700 DEG C and 900 DEG C) and pyrolysis time (0.5 h, 1 h and 2 h) andthe like on adsorption capacity of biochars, and screening the preparation conditions when the adsorption capacity of biochars is optimal; SEM, EDS, XRD, AAS and the like are adopted for physically representing biochars, and meanwhile establishing a Fenton-like system and researching the catalytic capacity of the manganese-enriched biochars; a biochar particle modified glassy carbon disc electrodeis utilized to research electrocatalytic reduction reaction of H2O2 in neutral medium on different biochar catalysts through a cyclic voltammetry scanning method, so as to represent electro-catalyticperformances of different biochars.

Owner:CHINA THREE GORGES UNIV

Functional chitosan derivative

InactiveUS7125968B2Overcome problemsIncrease moisture contentCosmetic preparationsBiocideSolubilityThrombogenicity

A functional chitosan derivative which comprises a chitin / chitosan, which is a natural polysaccharide, and incorporated therein at least one of a carbohydrate, a photo-reactive functional group, an amphipathic group, e.g. a polyoxyethylene alkyl ether, and a glycosaminoglycan and which, due to the incorporation, has solubility in a neutral medium, self-crosslinking ability, the property of highly containing water or healing wounds, and antithrombotic properties. Namely, the derivative has various properties required of health care materials such as medical products and cosmetics.

Owner:NETECH

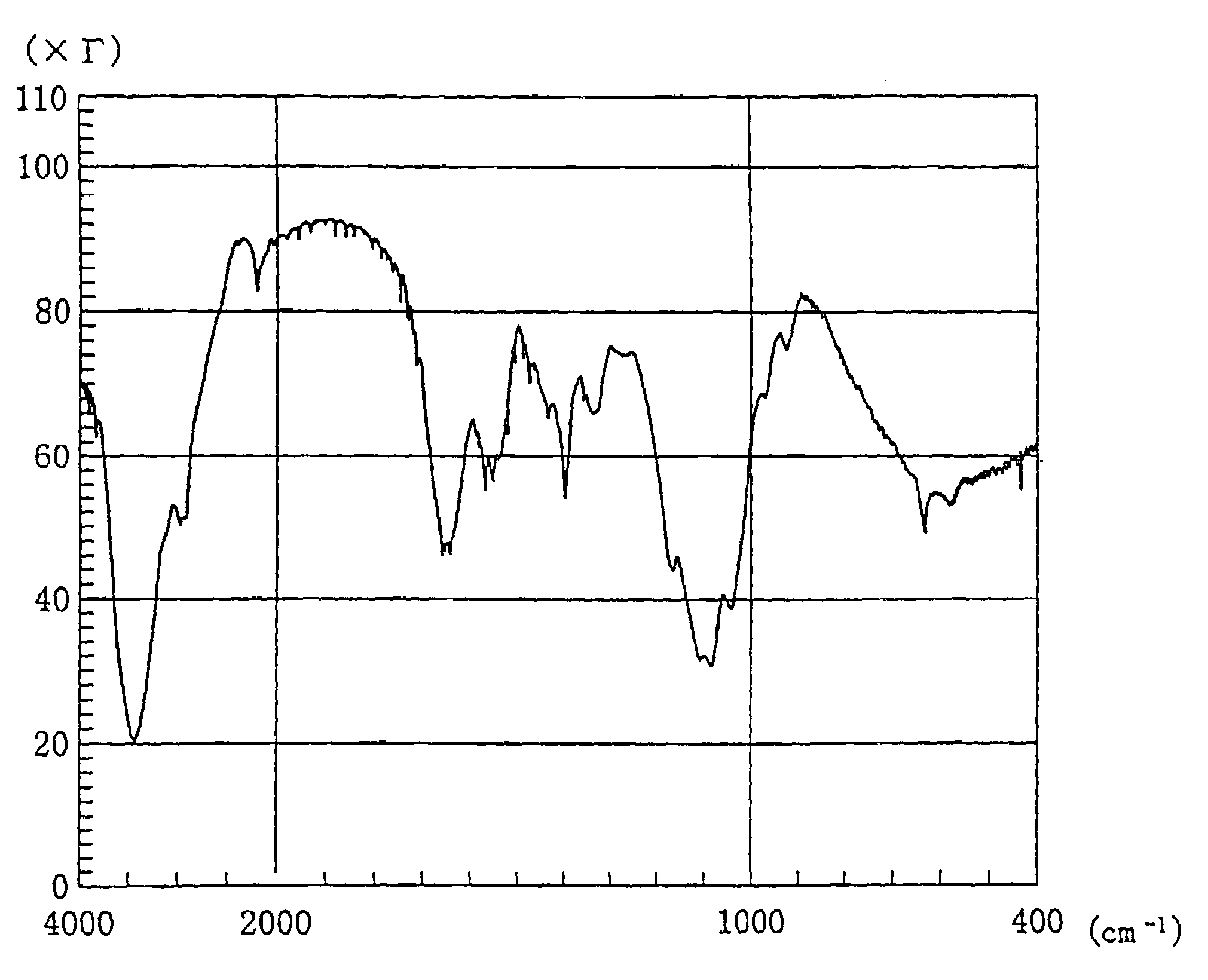

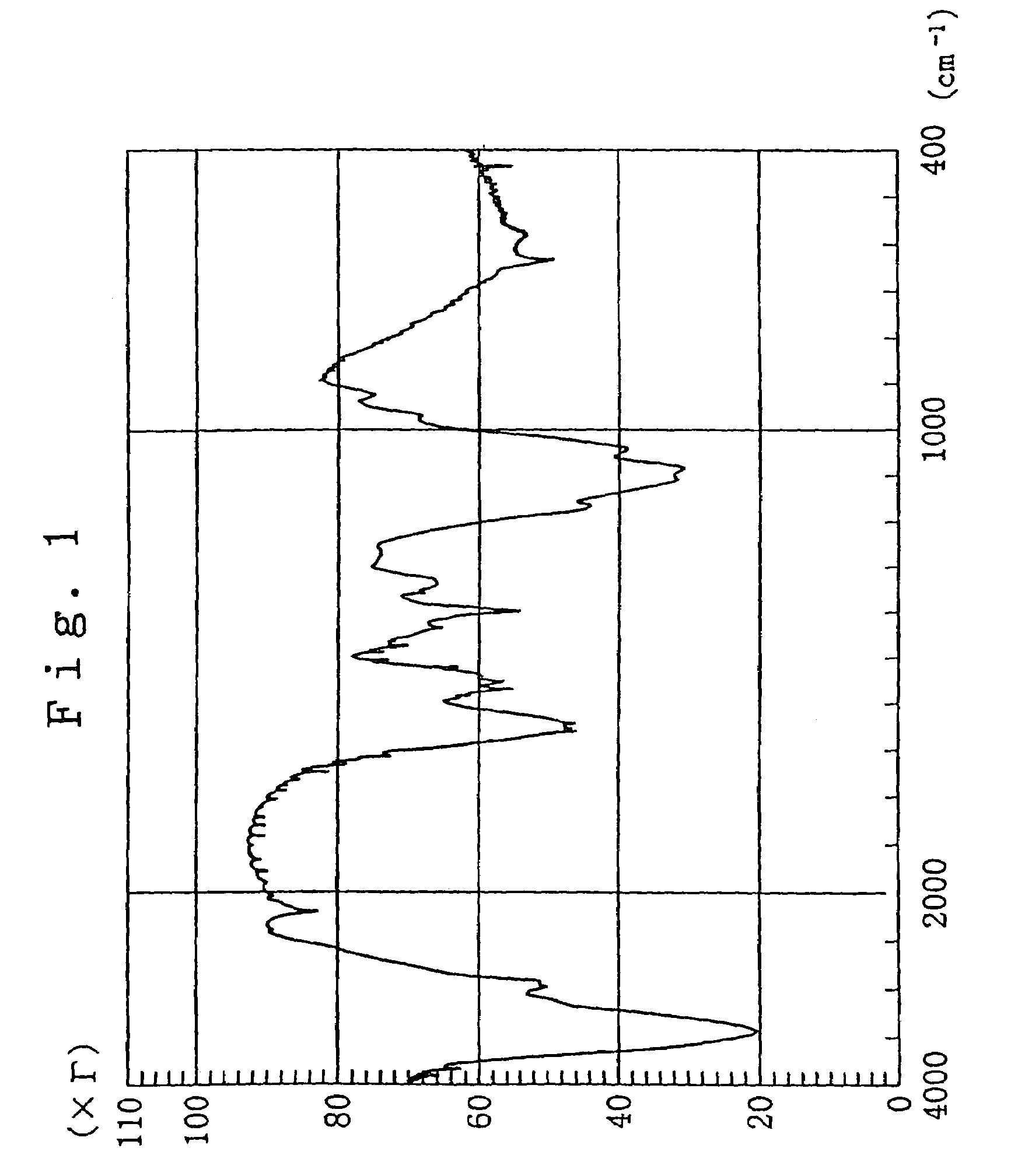

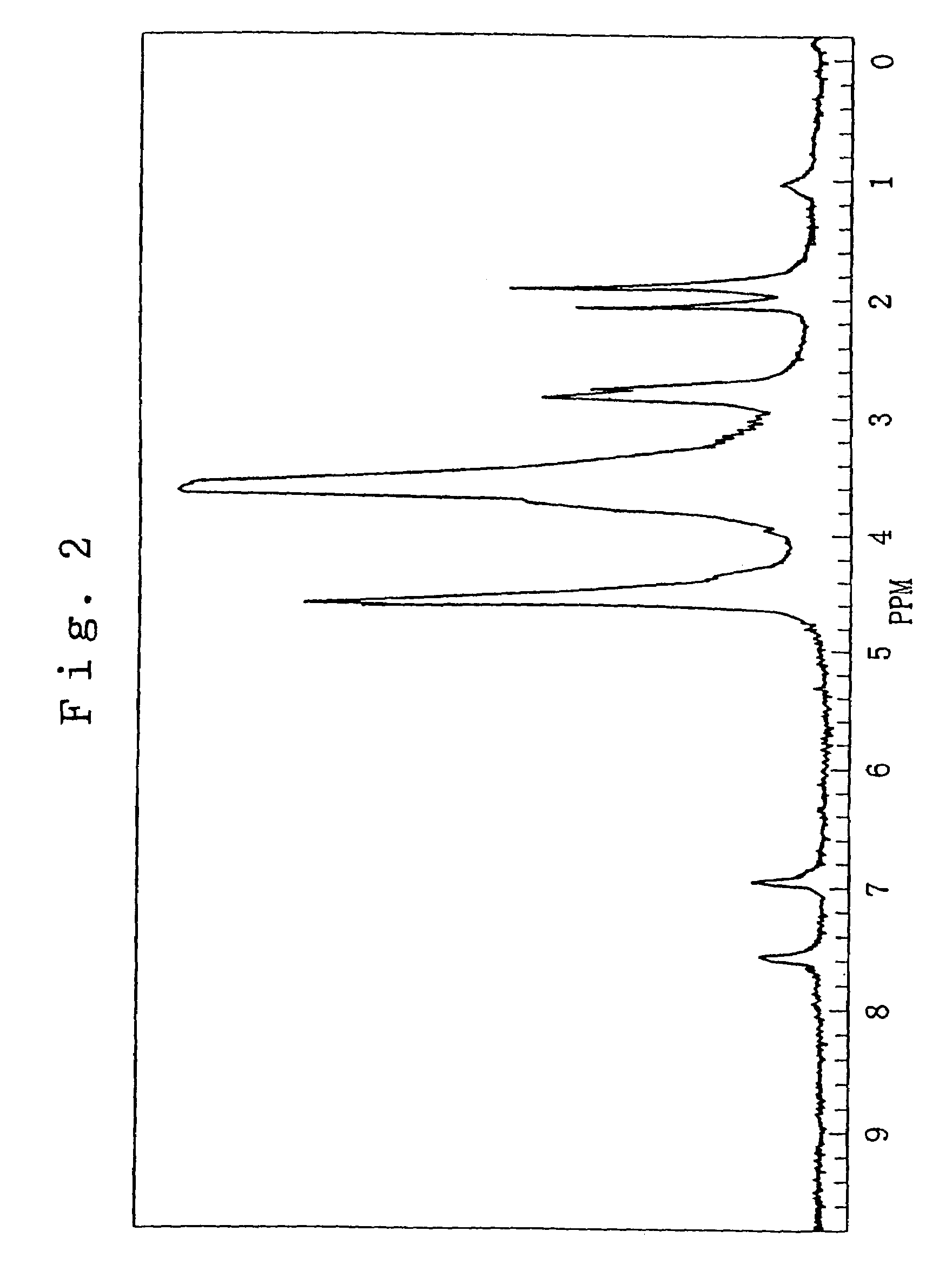

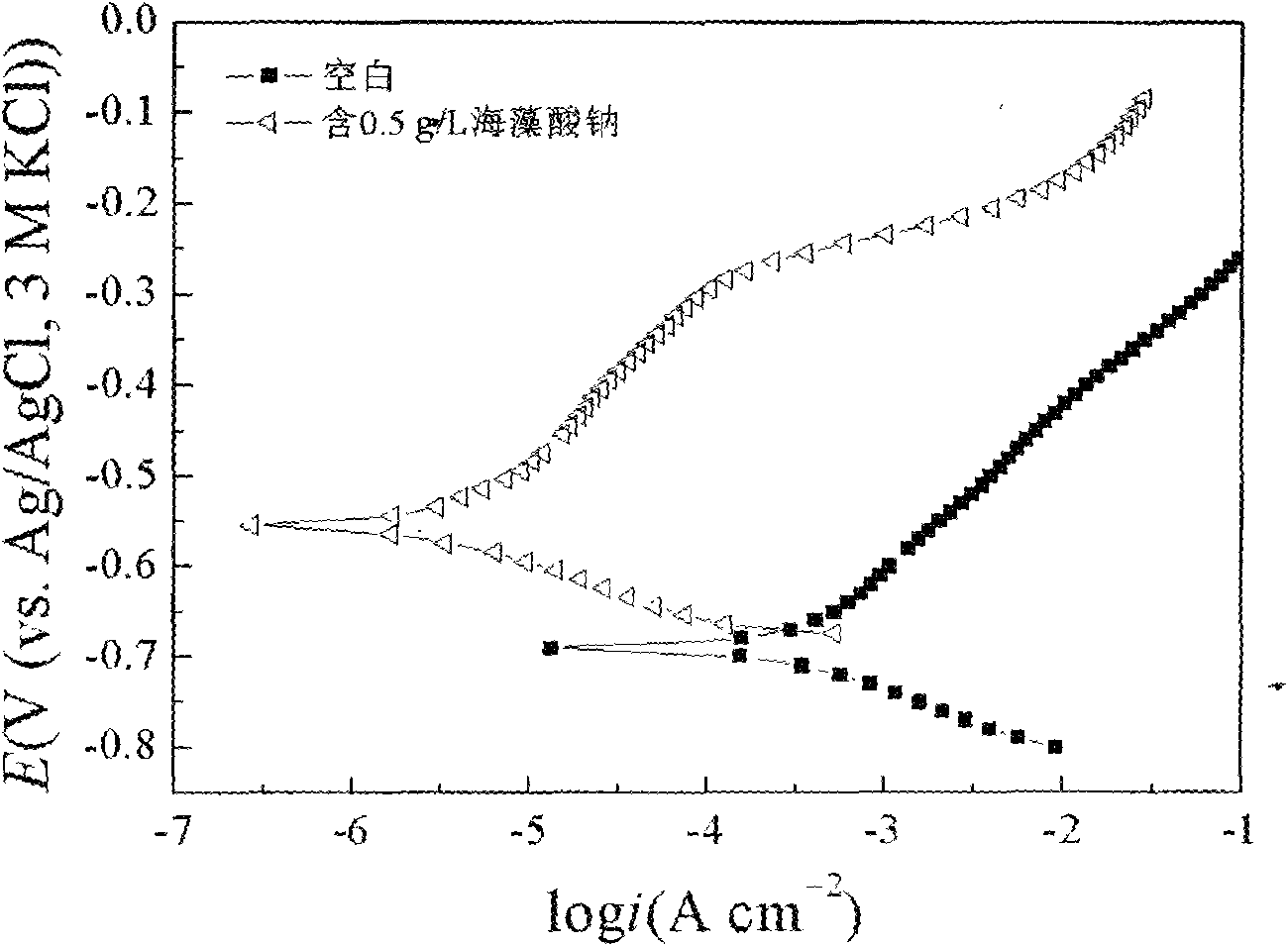

Green sodium alginate corrosion inhibitor for carbon steel neutral medium and application thereof

The invention relates to a corrosion inhibitor for a steel neutral medium, particularly relating to a green sodium alginate corrosion inhibitor for a carbon steel neutral medium as well as an application thereof. The corrosion inhibitor is sodium alginate of which the chemical general formula is (C6H7NaO6)n and the average molecular weight (Mw) is 20000-100000. The sodium alginate corrosion inhibitor disclosed by the invention is a natural product extracted from brown algae, and is widely applied to food industry. The corrosion inhibitor is a copolymer formed by connecting alpha-L-mannuronic acid (M units) with beta-D-guluronic acid through 1,4-glucosidic bonds and composed of different GGGMMM fragments. The alpha-L-mannuronic acid unit contains a large amount of carboxyl and can be coordinated with metals. Compared with the current commonly-used organic corrosion inhibitor, the corrosion inhibitor disclosed by the invention is non-toxic and harmless, thereby having no environmental problem after use. In addition, the corrosion inhibitor is non-toxic and harmless to environment and living beings, thus conforming to development of green corrosion inhibitors.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Novel amphiphilic ionic polypeptide and application thereof in cell culture aspect

The invention relates to novel amphiphilic ionic polypeptide. A polypeptide compound has the sequence of D F E F K D F E F K Y R G D (F represents phenylalanine, D F represents D configured phenylalanine, E represents glutamic acid, K represents lysine, Y represents tyrosine, R represents arginine, G represents glycine and D represents aspartic acid). Experiments show that the amphiphilic polypeptide can quickly form small molecular hydrogel in neutral medium. Experiments verify that a three-dimensional nanometer structure formed by the hydrogel is closer to the real cell growth environment and is very suitable for the cell three-dimensional culture.

Owner:NANKAI UNIV

Method for realizing stable electrochemical activity of polyaniline in neutral medium

InactiveCN103741193ATightly boundIncrease surface areaSurface reaction electrolytic coatingElectrophoretic coatingsAnilineMonomer

The invention discloses a method for realizing stable electrochemical activity of polyaniline in a neutral medium. By adopting the method, stable electrochemical activity is realized for polyaniline in a neutral solution of which the pH is equal to 7.0. The method comprises the following steps: oxidizing a tungsten foil under a constant pressure by taking a 0.1 mol.L<-1> perchloric acid aqueous solution as electrolyte and adopting an anode oxidation method to obtain tungsten oxide, and annealing; performing electrochemical polymerization at room temperature by taking an aniline monomer-containing sulfuric acid aqueous solution as polymerization electrolyte and adopting cyclic voltammetry in a three-electrode system in which an annealed tungsten oxide electrode is taken as a working electrode, a graphite rod is taken as a counter electrode, and a saturated calomel electrode is taken as a reference electrode to prepare a polyaniline film; reacting polyaniline with the tungsten oxide to achieve stable electrochemical activity on the polyaniline film in the neutral medium. The polyaniline film can be applied to wider fields compared with ordinary polyaniline, such as biosensors, metal corrosion prevention and the like.

Owner:NANJING UNIV OF SCI & TECH

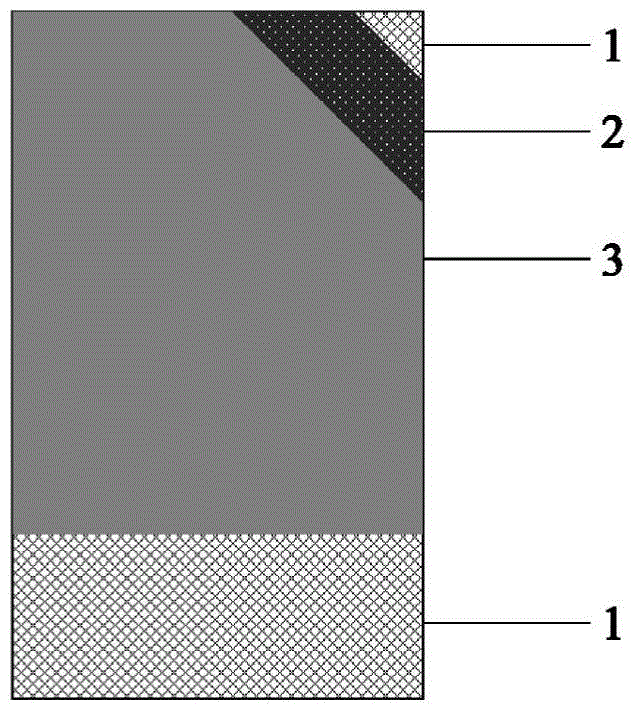

Nanometer iron-manganese composite oxide loaded gas diffusion electrode and preparation and application thereof

The invention discloses a nanometer iron-manganese composite oxide loaded gas diffusion electrode. A catalytic layer is added onto a gas diffusion layer of an electrode to form a catalytic gas diffusion electrode; the catalytic layer is composed of polytetrafluoroethylene and a nanometer-scale ferric oxide and manganese oxide loaded base material. The invention also provides a preparation method of the nanometer iron-manganese composite oxide loaded gas diffusion electrode. The nanometer iron-manganese composite oxide loaded gas diffusion electrode can be applied to poor-quality water treatment. The nanometer-scale iron-manganese composite oxide loaded on active carbon powder is prepared by a co-precipitation method, and finally, the nanometer iron-manganese composite oxide loaded catalytic gas diffusion electrode is prepared; by the loaded nanometer iron-manganese composite oxide, the catalytic efficiency of the electrode in a catalytic reaction is improved; the nanometer iron-manganese composite oxide loaded gas diffusion electrode can be applied at a neutral medium condition; the application range of the electrode is widened; the catalytic efficiency of the catalytic gas diffusion electrode is improved.

Owner:TSINGHUA UNIV

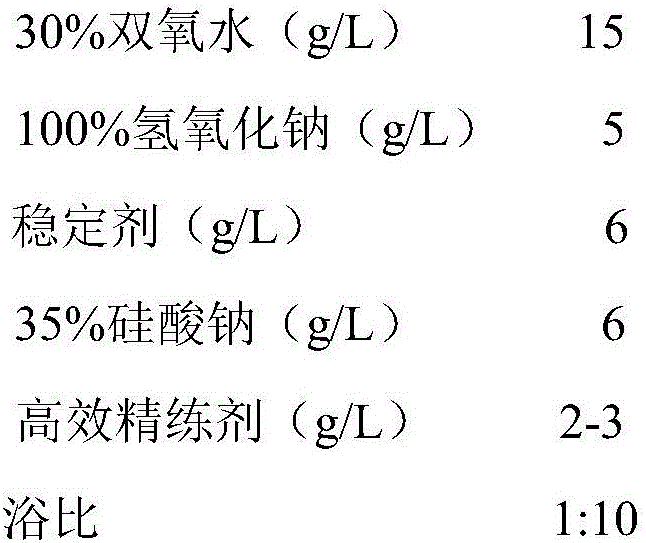

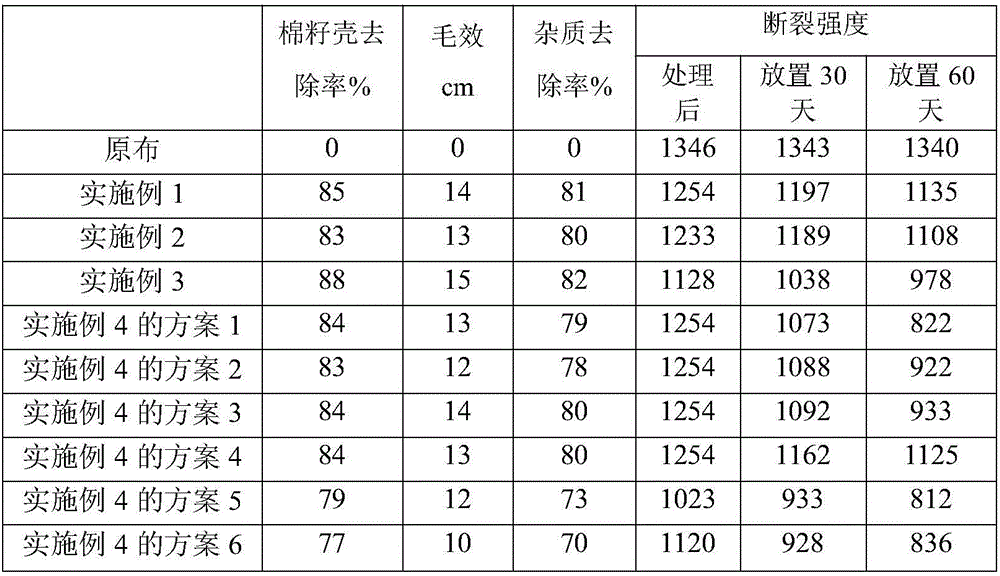

Method for scouring and bleaching cotton fabric in gaseous phase by utilizing ozone

InactiveCN106381680AHigh whitenessImprove vividnessDry-cleaning apparatus for textilesVegetal fibresTextile technologyGas phase

The invention discloses a method for scouring and bleaching a cotton fabric in a gaseous phase by utilizing ozone and belongs to the technical field of textiles. According to the invention, the cotton fabric is subjected to scouring-bleaching one-step treatment by utilizing high oxidizability of the ozone, so that natural pigments are removed, the whiteness and brightness of the fabric are improved, and the impurities are further removed. The method disclosed by the invention can be performed in a neutral medium at normal temperature, the water consumption is low, lots of energy can be saved in the bleaching process without high-temperature heating, any chemical agent is hardly used, a small amount of wastewater is produced, and the method is a simple and effective treatment method. After treated by ozone, the fabric can reach the whiteness of about 84%, the cottonseed hull removal rate of 88% and capillary effect of 15cm. The cotton fabric subjected to ozone treatment is further subjected to free-radical scavenger solution detergent washing treatment, so that residual hydroxyl radicals, active oxygen atoms and the like on the fabric are removed, and stable performance indexes, such as whiteness value, degree of polymerization and the like, of the fabric in the subsequent standing process are maintained.

Owner:JIANGNAN UNIV

Discarded circuit board full-value recycling method

InactiveCN102172597BReach the purpose of recyclingAchieving Full Value Clean RecyclingSolid waste disposalElectronic waste recyclingRecovery methodOrganic matter

The invention relates to a discarded circuit board full-value recycling method. The method is characterized by comprising the following steps of: smashing a discarded circuit board, vibrating and sorting to obtain a material of minus 2.0mm, metal of plus 2.0mm and nonmetal of plus 2.0mm; sorting the material of minus 2.0mm by virtue of a table concentrator so as to obtain a metal material of minus 2.0mm and tailings; mixing the metal of plus 2.0mm and the metal material, and separating magnetic metal from nonmagnetic metal by wet magnetic separation; smashing the mixed nonmetal of plus 2.0mm and tailings until the particle size is less than 0.1mm, and under the condition of a neutral medium, carrying out flotation to separate organic matters and inorganic matters by adopting an octadecylamine collector; and sorting the inorganic matters by virtue of the table concentrator to obtain metal powder and nonmetal powder. The method provided by the invention is a high-efficiency, economic and clean discarded circuit board full-value recycling method and is applicable to recycling of electronic circuit boards of various electronic parts and components.

Owner:广东省资源综合利用研究所

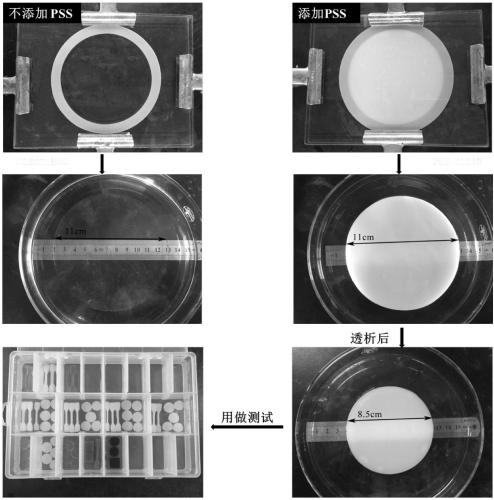

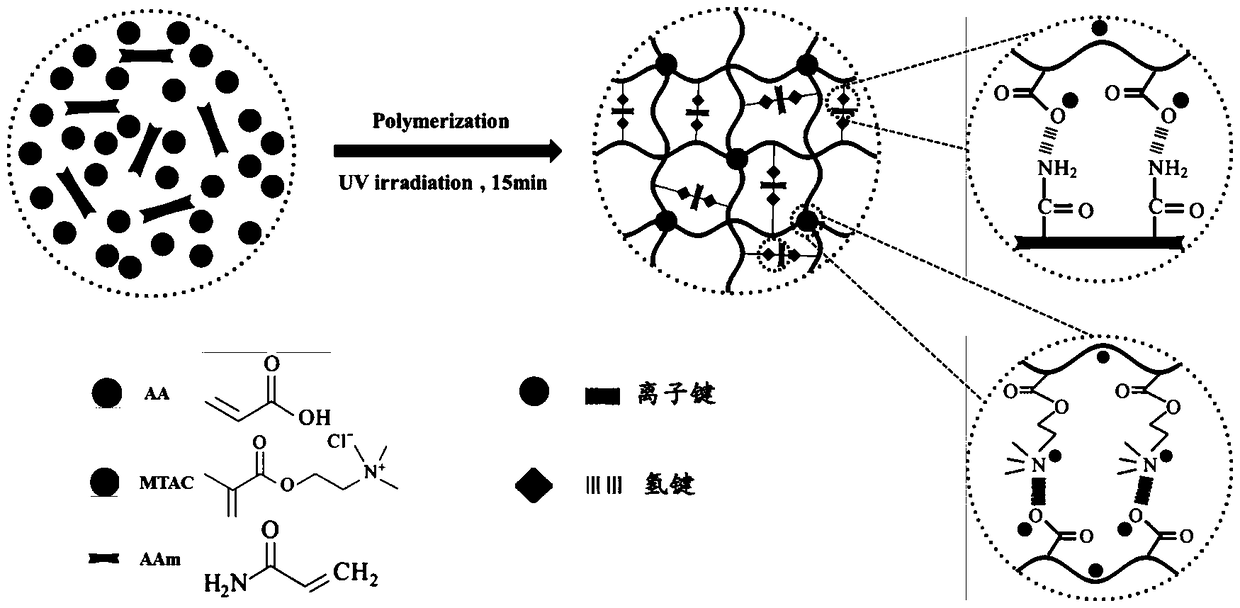

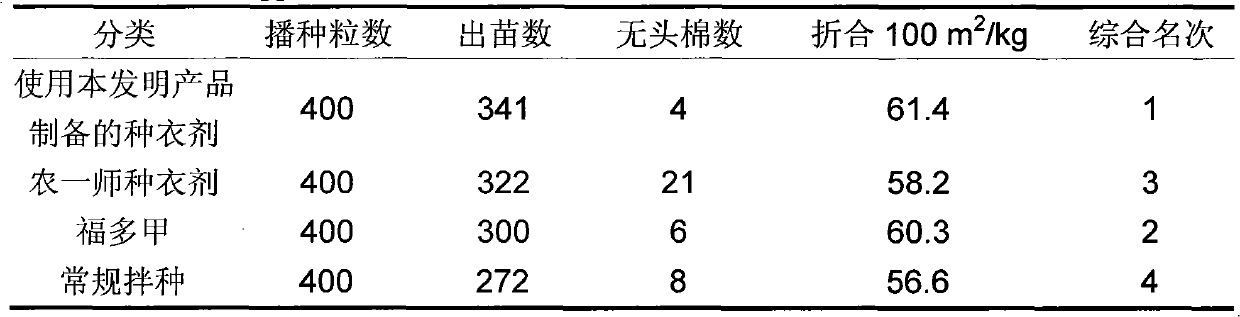

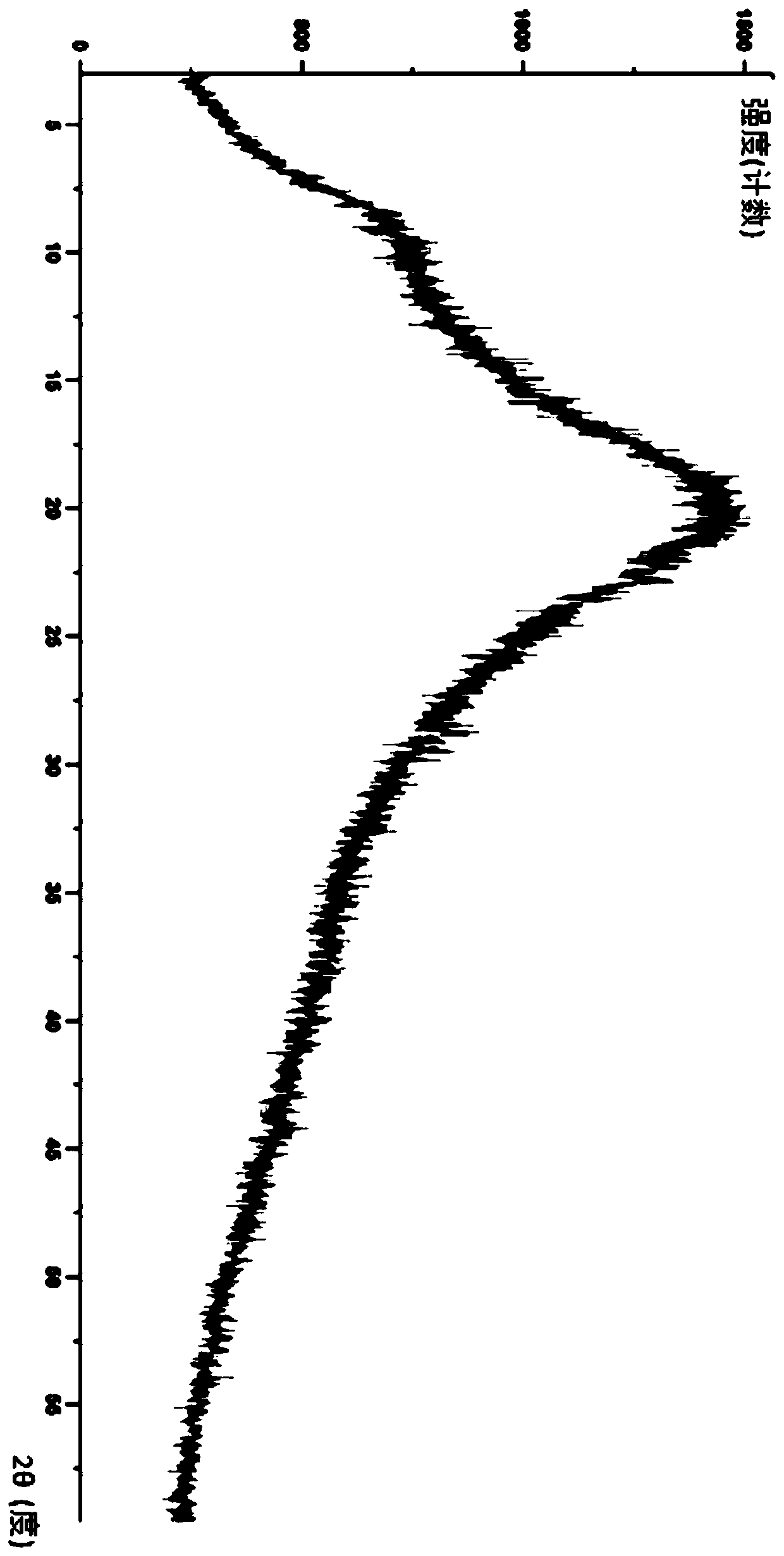

Bionic cartilago articularis polyion complex hydrogel and preparation method thereof

ActiveCN108976350AImprove mechanical propertiesHigh viscoelasticityTissue regenerationProsthesisOxygenMechanical property

The invention discloses a bionic cartilago articularis polyion complex hydrogel and a preparation method thereof. The hydrogel is prepared from the free radical polymerization reaction of a mixed solution of the following four materials: acrylic acid served as an anionic monomer, poly(sodium p-styrenesulfonate) served as an anionic polyelectrolyte, methyl acrylyl ethyl trimethyl ammonium chlorideserved as a cationic monomer and acrylic amide served as a neutral medium for supplying an oxygen-containing functional group. The invention utilizes a free radical polymerization method to prepare apolyion complex hydrogel within a short period of time; even if the prepared sample is radiated for 5min, the sample still shows excellent viscoelasticity; the hydrogel samples acquired within the scope of concentration all show excellent mechanical properties and biological friction performances; the adopted chemicals need not be specially treated; one-step preparation process is simple; the reaction condition is mild; the bionic cartilago articularis polyion complex hydrogel is suitable for large-scale production.

Owner:NANJING UNIV OF SCI & TECH

Production method of chitooligosaccharide

The invention provides a production method of chitooligosaccharide, belongs to the technical field of fine chemical industry. The method is characterized in that hydrogen peroxide is utilized as an oxidizer for oxidizing chitosan to produce the chitooligosaccharide, wherein, mass fraction of the chitosan is 5%-35%; when a reaction end point is reached, the ratio of n (the hydrogen peroxide) to n (the chitooligosaccharide) is 1.3-5.5, and reaction temperature is 50-90 DEG C; the obtained reaction liquid is cooled to 0-10 DEG C, and materials are separated out with ethanol with volume fraction of 95% at minus 30-0 DEG C, wherein, the ratio of w (the ethanol) to w (the reaction liquid) is 1-4; and the obtained filter cake is washed with ethanol with volume fraction of 99% at minus 30-10 DEG C for 1-5 times, and then the filter cake is dried at the temperature of 40-60 DEG C for 2-8 hours. The production method has the beneficial effects that molecular weight of the chitooligosaccharide is low, and the solubility thereof can reach up to 80g per 100g of water; degradation is performed in a neutral medium, thus the obtained product contains no inorganic salts; the reducing substance is added to the reaction liquid so as to completely eliminate the remaining peroxide; and three wastes are avoided during the production process. The obtained chitooligosaccharide product has the advantages of high yield and bioactivity and improved color, and a toxicology test proves that the product belongs to a non-toxic substance.

Owner:DALIAN XINDIEHONGXIANG CHITINS

Environmentally-friendly silkete penetrating agent and production method thereof

InactiveCN108221385AGood alkali resistanceImprove permeabilityVegetal fibresSolubilityAlkylphosphate

The invention discloses an environmentally-friendly silkete penetrating agent and a production method thereof. The environmentally-friendly silkete penetrating agent is prepared by compounding three surfactants and water. The environmentally-friendly silkete penetrating agent comprises 5-15% of alkyl alcohol sodium sulfate salt, 40-60% of alkyl phosphate polyoxyethylene ether, 5-15% of fatty alcohol-polyoxyethylene ether, and 20-40% of water. The three surfactants, namely, alkyl alcohol sodium sulfate salt, alkyl phosphate polyoxyethylene ether and fatty alcohol-polyoxyethylene ether are compounded and synergistically interact to realize the permeating and dispersing effects; the three substances are resistant to strong base. The environmentally-friendly silkete penetrating agent which isprepared by compounding the abovementioned three surfactants and water is good in base permeating resisting effect, and high in water solubility, and can be quickly wetted and permeated in 15-20% of base medium, so that the wetting and permeating performance is high; the environmentally-friendly silkete penetrating agent remains the wetting performance and the permeating performance in a neutral medium and does not contain materials damaging the environment.

Owner:SHANGHAI TIANTAN AUX

Lurasidone solid dispersion and preparation method thereof

It relates to a lurasidone solid dispersion and a preparation method, wherein the method comprises melting treatment of a mixture containing lurasidone, a medicinal hot melt carrier, optionally an acidic regulator and plasticizer in order to obtain the solid dispersion described herein, and wherein the lurasidone is provided in a form of free base. The lurasidone solid dispersion obtained by the preparation method according to the example of the invention has the characteristics of high dissolution rate (dissolution rate can reach 30%-70%) in a partial neutral medium (e.g. pH 6.0). The bioavailability of lurasidone solid dispersion increased significantly and the food effect of lurasidone solid dispersion prepared from the example decreased remarkably. It overcomes the limitation of too many medication in the prior art and avoids the reduction of curative effect of the improper medication for the patient or even invalid, ensures the normal efficacy, thereby increases the patient's medication flexibility and compliance.

Owner:SUNSHINE LAKE PHARM CO LTD

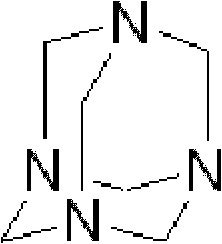

Manufacturing method for tobacco essence perfume temperature control sustained-release microcapsule

InactiveCN107485047AKeep inclusiveRetention of adsorptionTobacco preparationEssential-oils/perfumesTemperature controlFlavor

The invention discloses a manufacturing method for tobacco essence perfume temperature control sustained-release microcapsules. Amino of chitosan molecule easily reacts with carbonyl in a neutral medium to generate Schiff base, and generated Schiff base is made into cyclodextrin modified chitosan by reduction. The cyclodextrin modified chitosan wraps tobacco essence perfume, to manufacture tobacco essence perfume temperature control sustained-release microcapsules. The tobacco essence perfume temperature control sustained-release microcapsules are applied in a binary composite filter rod. In a smoking process, tobacco essence perfume is released at temperature of 65 DEG C to 160 DEG C, to achieve high-quality smoking effect.

Owner:KUNMING UNIV OF SCI & TECH

Method for keeping stable electrochemical activity of polyaniline in neutral medium

InactiveCN103741182AInhibition of dissolutionStable electrochemical activityElectrolytic inorganic material coatingElectrophoretic coatingsAnilineMonomer

The invention discloses a method for keeping a stable electrochemical activity of polyaniline in a neutral medium. With the adoption of the method, the polyaniline has the stable electrochemical activity in a neutral solution with the pH (Potential of Hydrogen) of 7.0. In a two-electrode system which takes a graphite rod as an anode and tin oxide conductive glass (FTO) doped with fluorinions as a cathode, a 0.2mol.L sodium tungstate water solution is used as electrolyte to electrically deposit tungsten oxide on the surface of the cathode. In a three-electrode system which takes the FTO deposited with the tungsten oxide on the surface as a working electrode, the graphite rod as a pair electrode and a saturated mercurous chloride electrode as a reference electrode, the electrolyte is a sulfuric acid water solution containing an aniline monomer; electrochemical polymerization is carried out by using a constant-pressure method to prepare a polyaniline film. The prepared polyaniline film can keep the stable electrochemical activity in the neutral medium so that the application field of the polyaniline is greatly expanded.

Owner:NANJING UNIV OF SCI & TECH

Cinacalcet hydrochloride solid dispersion and preparation method thereof and cinacalcet hydrochloride oral solid dosage form

ActiveCN108186576AHigh dissolution rateWide variety of sourcesPowder deliveryOrganic active ingredientsCelluloseHot melt

The invention discloses a cinacalcet hydrochloride solid dispersion and a preparation method thereof and a cinacalcet hydrochloride oral solid dosage form. The cinacalcet hydrochloride solid dispersion is prepared from cinacalcet hydrochloride and hydroxy propyl cellulose according to a hot-melt extrusion technology, wherein the weight ratio of cinacalcet hydrochloride to hydroxy propyl celluloseranges from 1:0.5 to 1:3. The preparation method comprises the following steps: uniformly mixing cinacalcet hydrochloride and hydroxy propyl cellulose based on the weight ratio; adding the mixture into a hot-melt extrusion machine for thermally melting and extruding; cooling and crushing the extruded materials to obtain the product. According to the preparation method, hydroxy propyl cellulose isused as a carrier; cinacalcet hydrochloride and hydroxy propyl cellulose are processed according to the hot-melt extrusion technology based on a certain weight ratio to prepare the solid dispersion; the solid dispersion is further processed into the solid form which is high in dissolution ratio in a neutral medium. The method is simple in process, convenient to operate, wide in raw material source, low in raw material price, and suitable for industrial mass production.

Owner:CHANGZHOU SUNLIGHT PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com