Discarded circuit board full-value recycling method

A technology of discarded circuit boards and recycling methods, which is applied in the direction of electronic waste recycling, recycling technology, chemical instruments and methods, etc., can solve the problems of environmental pollution and low recycling efficiency, and achieve high labor intensity, thorough recycling, and cleanliness The effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

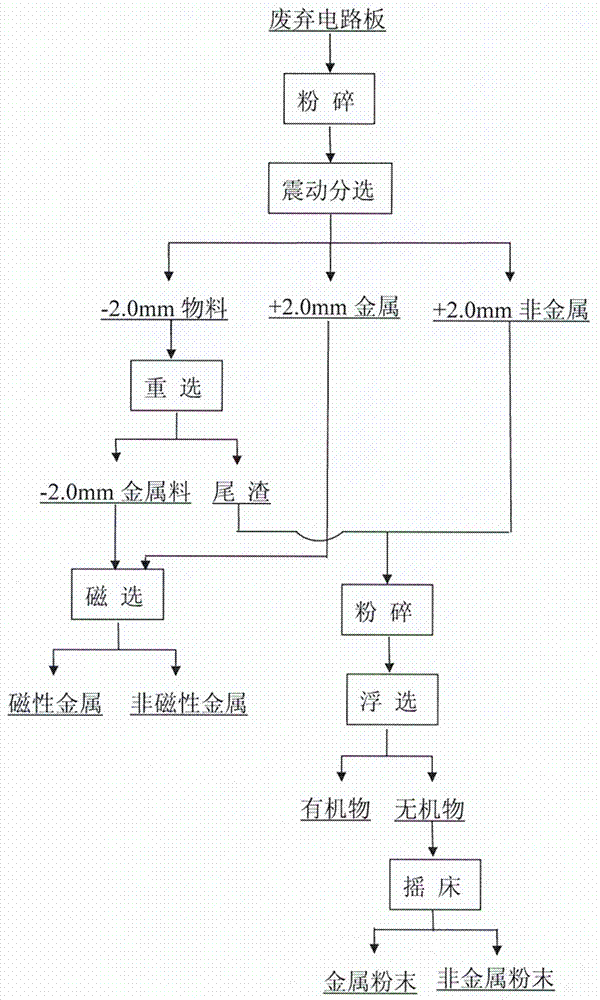

Image

Examples

Embodiment 1

[0012] Example 1: Computer main board 19.85kg, crushed as a whole by an intelligent crusher to a particle size of <20×20mm, and then secondary crushed to a particle size of <5.0mm by a high-speed hammer mill, and passed through a sieve size of 2.0mm oblique vibrating screening machine After sorting, 1.22kg of +2.0mm metal, 7.12kg of +2.0mm non-metal and 11.51kg of -2.0mm material were obtained. The -2.0mm material was gravity sorted on a conical shaker to obtain 4.19kg of -2.0mm metal material and 7.32kg of tailings. The -2.0mm metal material and +2.0mm metal 5.41kg were separated by wet magnetic separation with a field strength of 500Oe to obtain 1.61kg of magnetic metal and 3.8kg of non-magnetic metal. The main element content of non-magnetic metal was Cu: 45.78%, Ni: 0.45%, Sn: 8.11%, Au: 178.1g / t, Ag: 1656g / t, Pd: 93.0g / t. 14.44kg of tailings and +2.0mm non-metallic substances were deeply crushed to a particle size of <0.1mm by a vortex jet mill, and 2.85kg of inorganic s...

Embodiment 2

[0013] Example 2: 12.26 kg of microcomputer boards are crushed as a whole by an intelligent crusher to a particle size of <20×20mm, and then secondary crushed to a particle size of <5.0mm by a high-speed hammer mill, and vibrated obliquely through a sieve size of 2.0mm After sorting by the sieving machine, 0.67kg of +2.0mm metal, 4.93kg of +2.0mm non-metal and 6.66kg of -2.0mm material were obtained. The -2.0mm material was gravity-sorted on a tapered shaker to obtain 2.51kg of -2.0mm metal material and 4.15kg of tailings. The -2.0mm metal material and +2.0mm metal 3.18kg were separated by wet magnetic separation with a field strength of 800Oe to obtain 1.23kg of magnetic metal and 1.95kg of non-magnetic metal. The main element content of non-magnetic metal was Cu: 48.25%, Ni: 0.52%, Sn: 9.56%, Au: 194.2g / t, Ag: 1587g / t, Pd: 86.5g / t. 10.08kg of tailings and +2.0mm non-metals were deeply crushed to a particle size of <0.1mm by a vortex jet mill, and 7.25kg of organic matter an...

Embodiment 3

[0014] Example 3: 20.38 kg of electrical control circuit boards are crushed as a whole by an intelligent crusher to a particle size of <20×20mm, and then secondary crushed to a particle size of <5.0mm by a high-speed hammer mill. After sorting by the sieving machine, 2.15kg of +2.0mm metal, 7.65kg of +2.0mm non-metal and 10.58kg of -2.0mm material were obtained. The -2.0mm material was gravity-sorted on a tapered shaker to obtain 4.34kg of -2.0mm metal material and 6.24kg of tailings. The -2.0mm metal material and +2.0mm metal 6.49kg were separated by wet magnetic separation with a field strength of 1000Oe to obtain 2.32kg of magnetic metal and 4.17kg of non-magnetic metal. The main element content of non-magnetic metal was Cu: 48.23%, Ni: 0.51%, Sn: 7.42%, Au: 163.2g / t, Ag: 1754g / t, Pd: 84.2g / t. 13.89kg of tailings and +2.0mm non-metallic materials were deeply pulverized by a vortex jet mill to a particle size of <0.1mm. Under neutral medium conditions, 10.91kg of organic ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com