Bionic cartilago articularis polyion complex hydrogel and preparation method thereof

A bionic joint and polyion technology, which is applied in tissue regeneration, prosthesis, medical science, etc., can solve problems hindering industrial scale production, achieve good mechanical properties and bio-friction properties, mild reaction conditions, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

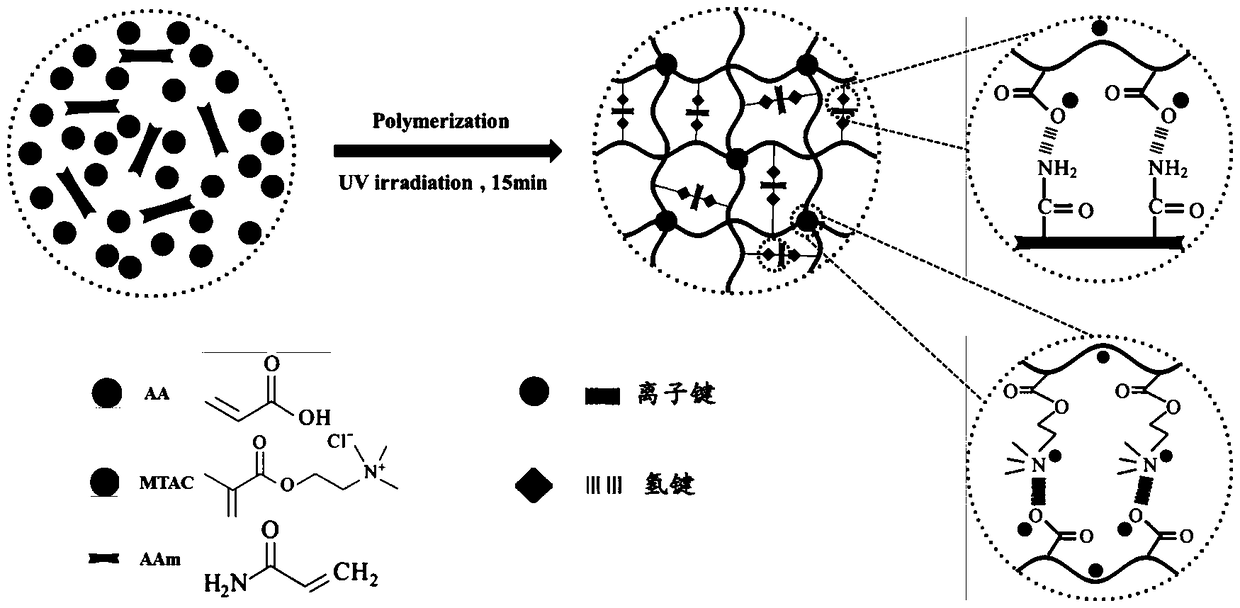

[0034] (1) Prepare an AA solution with a volume fraction of 20% (v / v), which contains 1mol / L AAm.

[0035] (2) 30% (v / v), 0.1% (v / v) and 0.4% (v / v) of MTAC, photoinitiator and crosslinker were added to the solution obtained in step 1, respectively, in the volume ratio of AA , and then placed on a magnetic stirrer, and stirred until it was colorless and transparent.

[0036] (3) The solution obtained in (2) was poured into a mold consisting of two parallel glass plates and a silicone ring (the outer side of the silicone ring was coated with vaseline to prevent the solution from seeping out), and the four sides were clamped with clips, and placed in a self-made UV lamp (Wavelength range 200~2500nm, including ultraviolet part) irradiation for different time: 5min, 10min, 15min, 20min.

[0037] (4) The hydrogel sample obtained in (3) was dialyzed in a large amount of deionized water to remove residual monomers and cross-linking agents and other impurities.

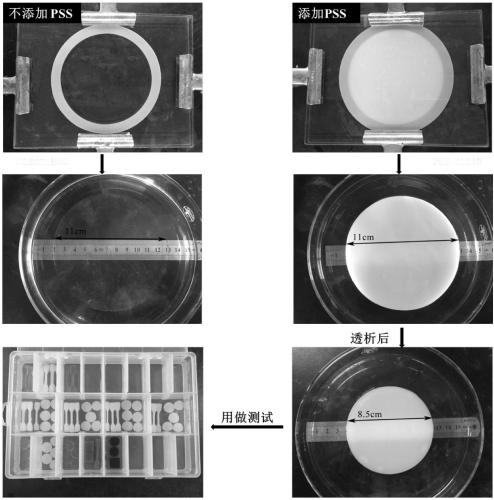

[0038] figure 1 The...

Embodiment 2

[0042] (1) Prepare an AA solution with a volume fraction of 20% (v / v), which contains 1mol / L AAm.

[0043] (2) MTAC and PSS with a volume ratio of 30% (v / v) of AA, photoinitiators and crosslinkers with a volume ratio of 0.1% (v / v) and 0.4% (v / v) of AA, respectively Add it to the solution obtained in step 1, then place it on a magnetic stirrer, and stir until it is colorless and transparent.

[0044] (3) The solution obtained in (2) was poured into a mold consisting of two parallel glass plates and a silicone ring (the outer side of the silicone ring was coated with vaseline to prevent the solution from seeping out), and the four sides were clamped with clips, and placed in a self-made UV lamp (Wavelength range 200~2500nm, including ultraviolet part) irradiation for different time: 5min, 10min, 15min, 20min.

[0045] (4) The hydrogel sample obtained in (3) was dialyzed in a large amount of deionized water to remove residual monomers and cross-linking agents and other impuritie...

Embodiment 3

[0053] (1) Prepare an AA solution with a volume fraction of 20% (v / v), which contains 1mol / L AAm.

[0054] (2) MTAC and PSS that account for 20%, 30%, and 40% (v / v) of AA by volume (PSS content is consistent with MTAC), and 0.1% by volume of AA (v / v) , 0.4% (v / v) photoinitiator and cross-linking agent were added to the solution obtained in step 1, then placed on a magnetic stirrer, and stirred in shading until a colorless and transparent state appeared.

[0055] (3) The solution obtained in (2) was poured into a mold consisting of two parallel glass plates and a silicone ring (the outer side of the silicone ring was coated with vaseline to prevent the solution from seeping out), and the four sides were clamped with clips, and placed in a self-made ultraviolet lamp (wavelength range 200~2500nm, including ultraviolet part) irradiation for 15min.

[0056] (4) The hydrogel sample obtained in (3) was dialyzed in a large amount of deionized water to remove residual monomers and cro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com