Method for scouring and bleaching cotton fabric in gaseous phase by utilizing ozone

A technology of cotton fabric and ozone, which is applied to plant fiber, textiles, papermaking, and dry-cleaning fiber products. It can solve the problems of many chemical additives, large fiber damage, and large energy consumption, and achieve stable performance indicators, not easy to yellow, Energy Saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

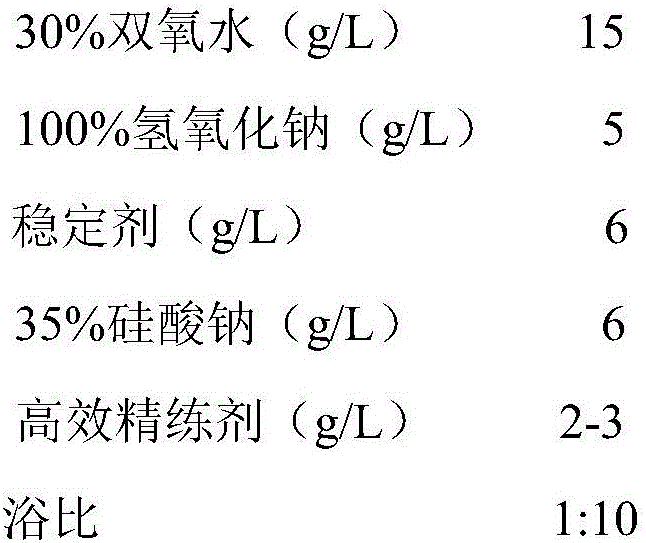

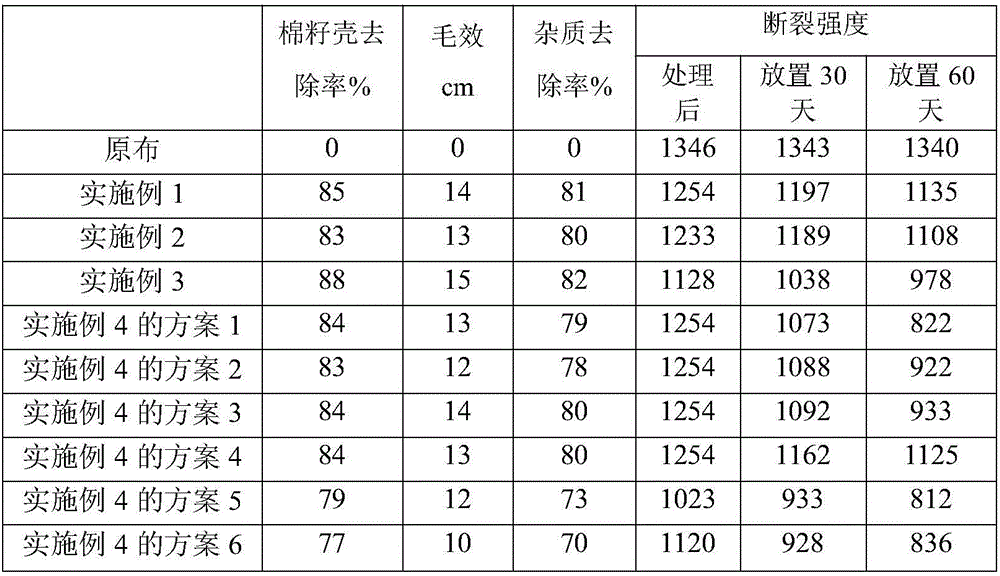

[0046] Example 1: One-bath scouring-bleaching of cotton fabric

[0047] Cotton woven fabrics after desizing are subjected to one-bath scouring-bleaching of cotton fabrics by the following method:

[0048] (1) Immerse the desized cotton fabric into a non-ionic penetrant solution containing a concentration of 1g / L, repeat padding three times to make the liquid-carrying rate 80%, and then enter the ozone reaction chamber (volume 2L);

[0049] (2) Open the oxygen valve in advance to control the flow rate at 1.5L / min, then turn on the ozone generator switch, and after the ozone is stabilized, it will pass into the bottom of the reaction chamber, and the volume concentration of ozone that is passed into the reaction chamber will be controlled to be 0.06L / (min· L); the bottom of the reaction chamber contains a certain amount of water, and the water can dissolve a certain amount of ozone to delay the rapid decomposition and overflow of ozone, and the treatment time of the fabric in th...

Embodiment 2

[0051] Embodiment 2: one bath scouring-bleaching of cotton fabric

[0052] One-bath scouring-bleaching of cotton fabrics using the following method:

[0053] (1) Immerse the desized cotton fabric into a non-ionic penetrant solution containing a concentration of 2g / L, repeat the padding three times to make the liquid-carrying rate 50%, and then enter the ozone reaction chamber (volume 2L);

[0054] (2) Open the oxygen valve in advance to control the flow rate at 1.5L / min, then turn on the ozone generator switch, and after the ozone is stabilized, it will pass into the bottom of the reaction chamber, and the volume concentration of ozone that is passed into the reaction chamber will be controlled to be 0.06L / (min· L); the bottom of the reaction chamber contains a certain amount of water, and the water can dissolve a certain amount of ozone to delay the rapid decomposition and overflow of ozone, and the treatment time of the fabric in the aqueous solution above the reaction chamb...

Embodiment 3

[0056] Example 3: One-bath scouring-bleaching of cotton fabric

[0057] One-bath scouring-bleaching of cotton fabrics using the following method:

[0058] (1) Immerse the desized cotton fabric into a non-ionic penetrant solution containing a concentration of 1.5g / L, repeat the padding three times to make the liquid-carrying rate 100%, and then enter the ozone reaction chamber (volume 2L);

[0059] (2) Open the oxygen valve in advance to control the flow rate at 1.5L / min, then turn on the ozone generator switch, and after the ozone is stabilized, it will pass into the bottom of the reaction chamber, and the volume concentration of ozone that is passed into the reaction chamber will be controlled to be 0.06L / (min· L); the bottom of the reaction chamber contains a certain amount of water, and the water can dissolve a certain amount of ozone to delay the rapid decomposition and overflow of ozone, and the treatment time of the fabric above the aqueous solution in the reaction chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com