Manufacturing method for tobacco essence perfume temperature control sustained-release microcapsule

A technology of essence and fragrance for tobacco, which is applied in the direction of essential oil/fragrance, preparation of tobacco, tobacco, etc. It can solve the problems of single flavor and fragrance, complex ingredients, and limited effect, and achieve high utilization rate, low cost, and slow temperature control. clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

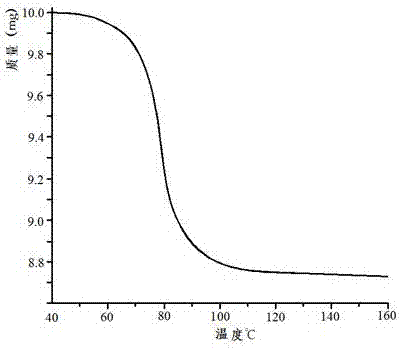

[0023] Example 1: Preparation of temperature-controlled slow-release microcapsules of No. 101 tobacco flavor and fragrance

[0024] (1) Dissolve 200mg chitosan in 100mL acetic acid-sodium acetate buffer solution with pH 4.4, and record it as solution A; dissolve 2g hydroxypropyl-β-cyclodextrin in 50mL water, and record it as solution B; Mix solution A and solution B, stir at room temperature for 1 hour, add 300 mg of sodium borohydride, stir the mixture at room temperature at 800 r / min for 12 hours, adjust the pH to neutral with ammonia water with a volume concentration of 5%, centrifuge at 3000 rpm for 30 minutes, and dry in vacuum at 50°C for 12 hours to prepare Obtain cyclodextrin modified chitosan;

[0025] (2) Dissolve the cyclodextrin-modified chitosan prepared in step (1) in an acetic acid solution with a volume concentration of 1% to prepare a cyclodextrin-modified chitosan solution with a concentration of 30 mg / mL;

[0026] (3) At 30°C, add No. 101 tobacco flavor and...

Embodiment 2

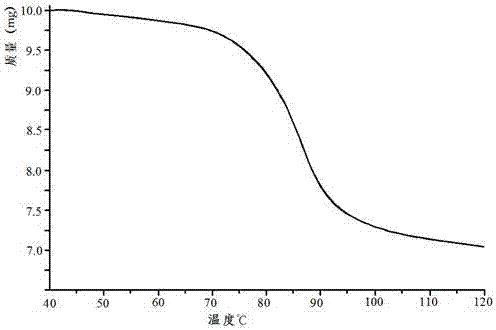

[0030] Example 2: Preparation of temperature-controlled slow-release microcapsules of No. 113 tobacco flavor and fragrance

[0031] (1) Dissolve 150mg of chitosan in 100mL of acetic acid-sodium acetate buffer solution with pH 5, and record it as solution A; dissolve 1g of hydroxypropyl-β-cyclodextrin in 50mL of water, and record it as solution B; Mix the solution with solution B, stir at room temperature for 2 hours, add 250 mg of sodium borohydride, stir the mixture at room temperature at 1000 r / min for 15 hours, adjust the pH to neutral with ammonia water with a volume concentration of 5%, centrifuge at 4000 rpm for 25 minutes, and dry in vacuum at 60°C for 12 hours to obtain Cyclodextrin modified chitosan;

[0032] (2) Dissolving the cyclodextrin-modified chitosan prepared in step (1) in an acetic acid solution with a volume concentration of 2% to prepare a cyclodextrin-modified chitosan solution with a concentration of 25 mg / mL;

[0033] (3) At 40°C, add No. 113 tobacco f...

Embodiment 3

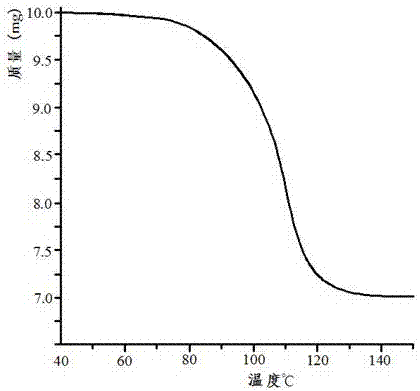

[0037] Example 3: Preparation of temperature-controlled slow-release microcapsules of No. 107 tobacco flavor and fragrance

[0038] (1) Dissolve 180mg of chitosan in 100mL of acetic acid-sodium acetate buffer solution with pH 4.5, which is recorded as solution A; dissolve 1.5g of hydroxypropyl-β-cyclodextrin in 50mL of water, and record as solution B; Mix solution A and solution B, stir at room temperature for 1.5 h, add 260 mg of sodium borohydride, stir the mixture at room temperature at 1200 r / min for 13 h, adjust the pH to neutral with 5% ammonia water, centrifuge at 5000 rpm for 20 min, and vacuum-dry at 55°C for 12 h. Prepare cyclodextrin modified chitosan;

[0039] (2) Dissolve the cyclodextrin-modified chitosan prepared in step (1) in an acetic acid solution with a volume concentration of 1.5%, to make a cyclodextrin-modified chitosan solution with a concentration of 28mg / mL;

[0040] (3) At 40°C, add No. 107 tobacco flavor and fragrance solution dropwise to step (2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com