Aqueous zinc ion battery electrolyte membrane and preparation and application method thereof

A zinc-ion battery, electrolyte membrane technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of battery short circuit, weak physical strength, fire, etc., and achieve the effect of reducing interface impedance, rich sources, and conducive to uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

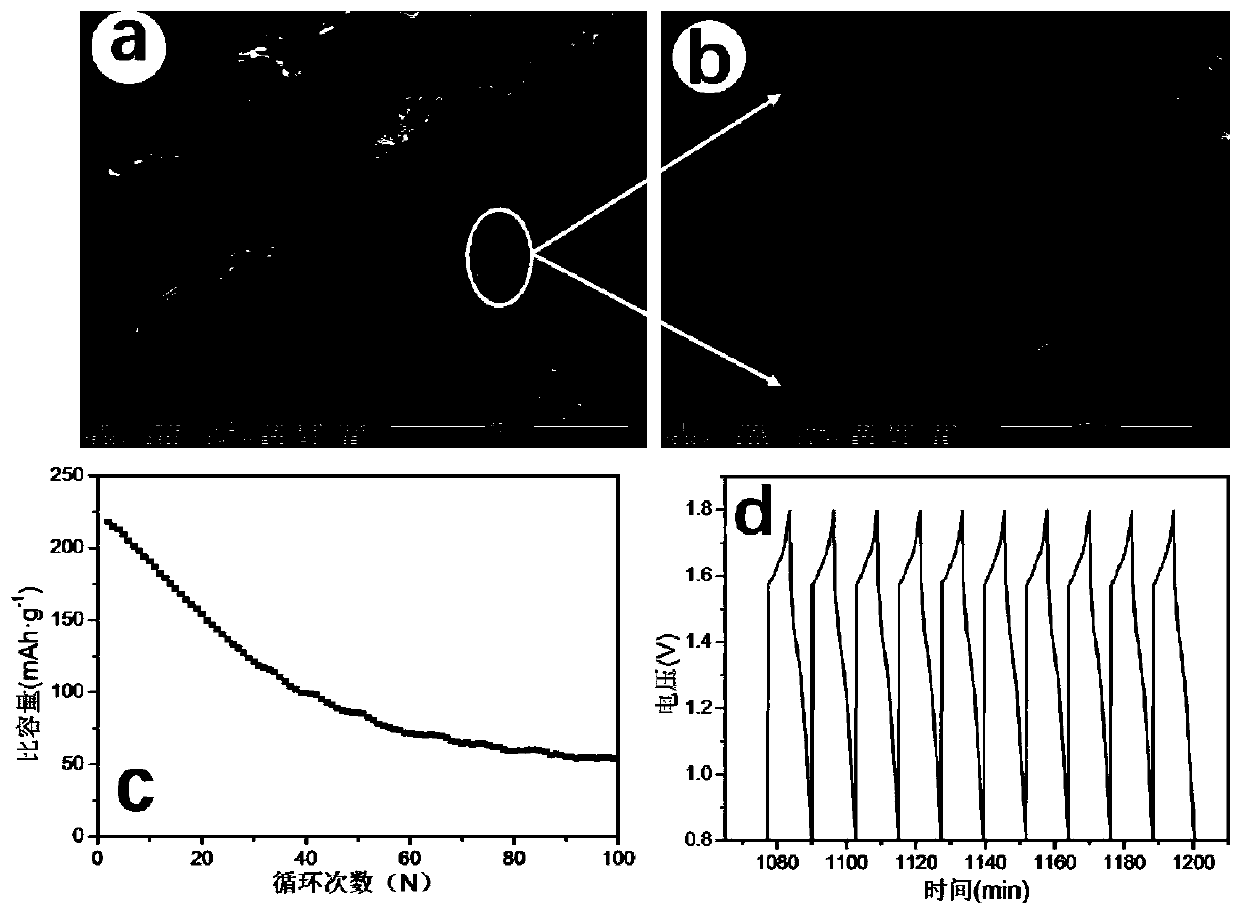

Embodiment 1

[0042] Prepare a sodium alginate aqueous solution with a mass concentration of 3%, and apply the solution evenly on the surface of the zinc negative electrode with a thickness of 100 μm. The preparation method is similar to that of Comparative Example 1, and the ZnSO 4 The aqueous solution was adjusted to 2mol / L, and dilute sulfuric acid was added dropwise to adjust the pH to 4.3 for zinc-sodium ion exchange reaction. The aging time was 3 hours. After crosslinking, a gel electrolyte membrane with a thickness of 90 μm was obtained, and the material was characterized. Then adopt the gel electrolyte membrane prepared in this embodiment, and conventional zinc ion positive electrode MnO 2 Matching Fabrication of Gel Zinc-ion Batteries, MnO 2 The pole pieces were immersed in 0.1mol / L MnSO in advance 4 In order to inhibit the dissolution of the positive electrode material in the battery cycle process, assemble the CR2016 button battery according to the conventional method, without u...

Embodiment 2

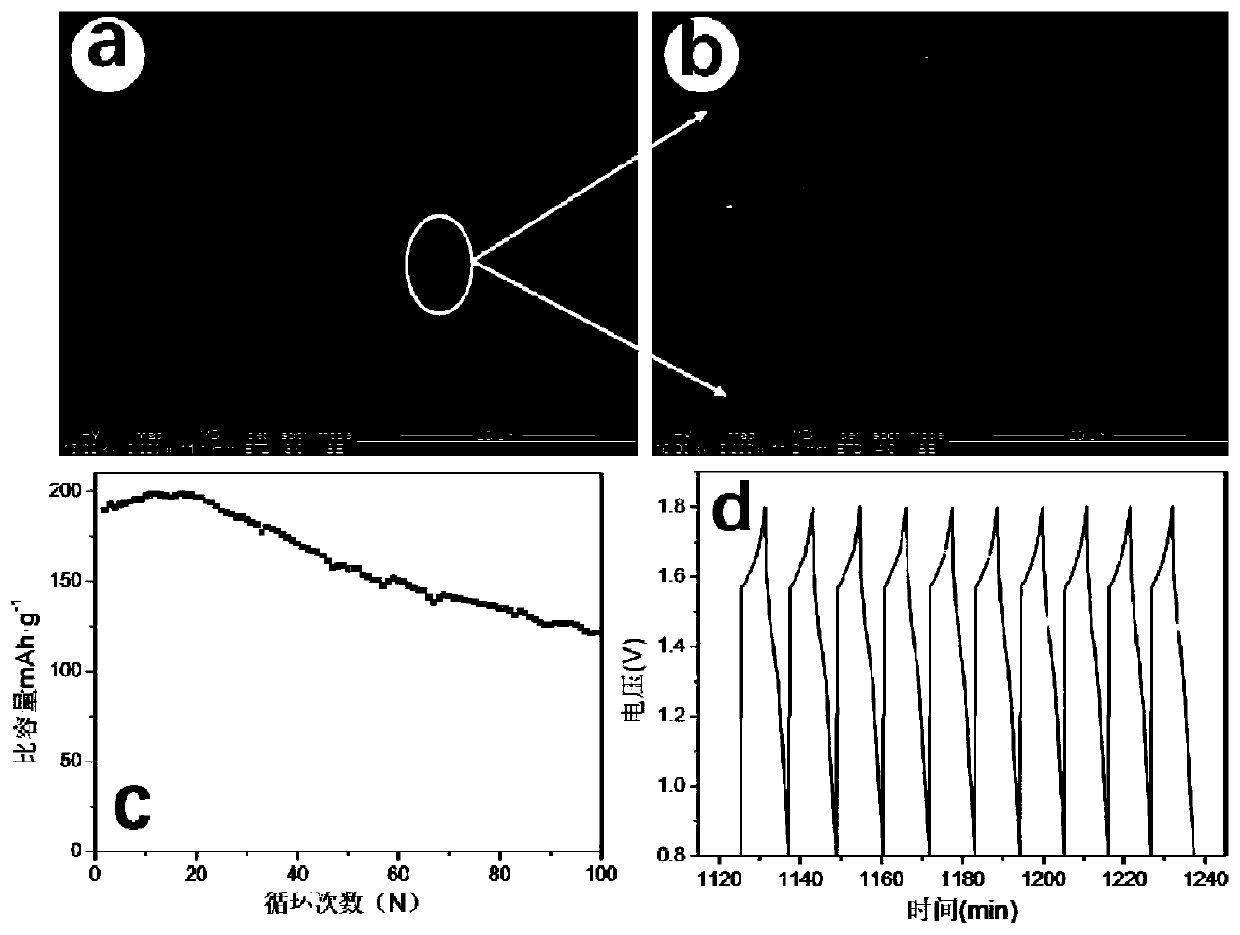

[0045] To prepare a sericin-zinc alginate composite electrolyte membrane, the sericin accounting for 10% of the mass fraction of sodium alginate was mixed uniformly with sodium alginate powder in advance, and then an aqueous solution with a mass fraction of the mixed material of 3% was prepared according to the preparation of Example 1 method, the solution is coated on the zinc negative electrode, using 2mol / L ZnSO 4 Add dilute sulfuric acid dropwise to the aqueous solution to adjust the pH to 4.3 for zinc-sodium ion exchange reaction. The aging time is 3 hours. After cross-linking, a gel electrolyte membrane with a thickness of 90 μm is obtained, and the material is characterized. Then adopt the gel electrolyte membrane prepared in this embodiment, and conventional zinc ion positive electrode MnO 2 Matching Fabrication of Gel Zinc-ion Batteries, MnO 2 The pole pieces were immersed in 0.1mol / L MnSO in advance 4 In order to inhibit the dissolution of the positive electrode ma...

Embodiment 3

[0048] To prepare a pectin-zinc alginate composite electrolyte membrane, pre-mix pectin accounting for 5% of the mass fraction of sodium alginate with sodium alginate powder, and then configure an aqueous solution with a mass fraction of the mixed material of 4%, according to the preparation of Example 1 method, the solution is coated on the zinc negative electrode, using 2mol / L ZnSO 4 The aqueous solution was added dropwise with dilute sulfuric acid to adjust the pH to 4.3 for zinc-sodium ion exchange reaction. The aging time was 3 hours. After cross-linking, a gel electrolyte membrane with a thickness of 90 μm was obtained, and the material was characterized. Then adopt the gel electrolyte membrane prepared in this embodiment, and conventional zinc ion positive electrode MnO 2 Matching Fabrication of Gel Zinc-ion Batteries, MnO 2 The pole piece is immersed in 0.1mol / L MnSO in advance 4 In order to inhibit the dissolution of the positive electrode material in the battery cy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com