Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69results about How to "Short carbonization time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chitosan activated carbon and preparation method thereof

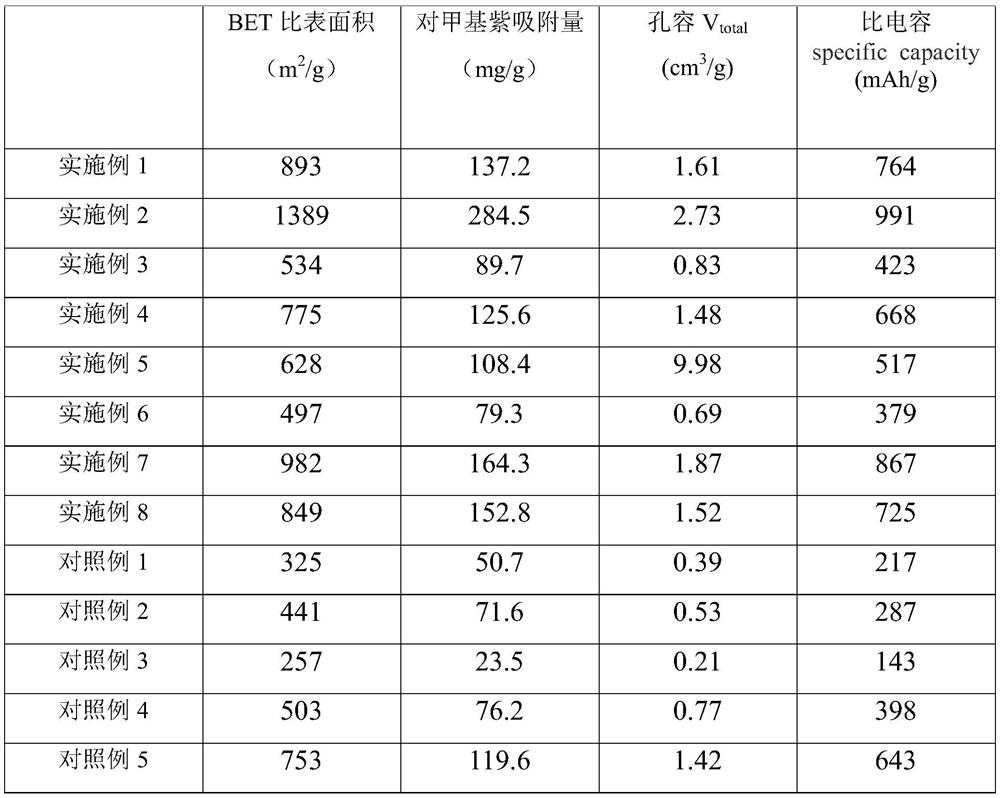

InactiveCN101780955AAddressing the inability to directly convert chitosan into activated carbonShort carbonization timeActivated carbonMicrowave

The invention provides chitosan activated carbon and a preparation method thereof, which belong to the field of biomass activated carbon. This invention enriches preparation methods of biomass activated carbon. The chitosan activated carbon is formed by taking chitosan as raw material, performing activation treatment through metal ion solution and then performing microwave carbonization. The method activates chitosan through metal ions and then utilizes microwave carbonization to quickly carbonize the activated chitosan so as to obtain the chitosan activated carbon. The preparation method solves the problem that the conventional thermal-decomposition carbonization method is long in time consumed for preparing chitosan carbon materials and incapable of directly subjecting chitosan to microwave carbonization, and synchronously completes the carbonization and activation of chitosan activated carbon materials. Meanwhile, the chitosan activated carbon prepared by the method has the advantages of short needed time, simple preparation method and readily available equipment.

Owner:HARBIN INST OF TECH

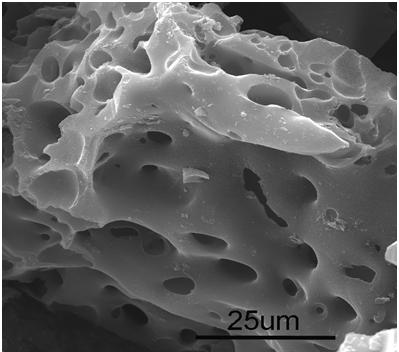

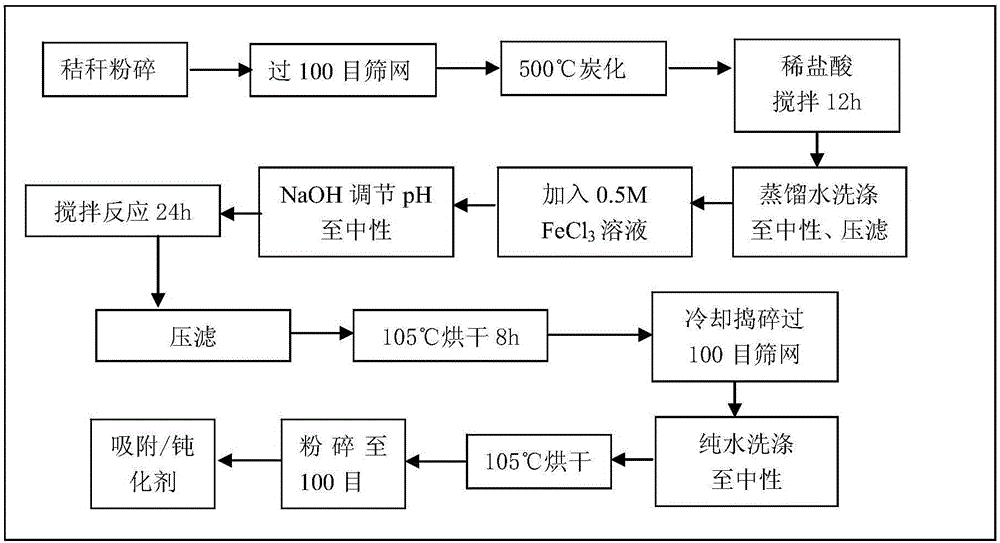

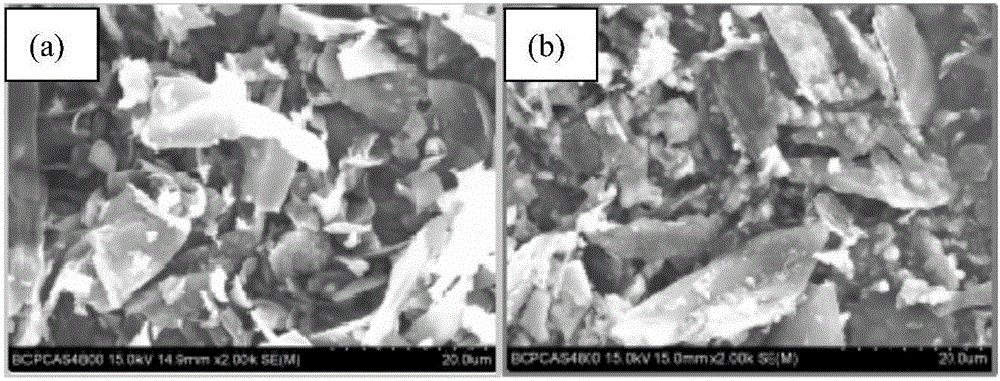

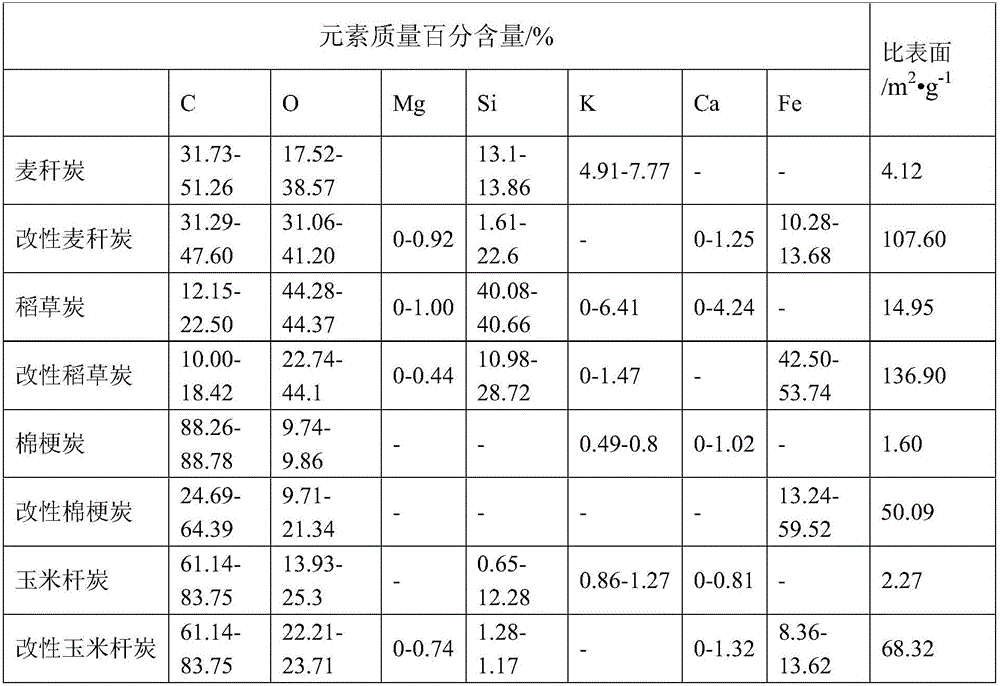

Modified biomass charcoal for treating arsenic pollution as well as preparation method and application of modified biomass charcoal

InactiveCN105944668AImprove stabilityLow carbonization temperatureOther chemical processesWater contaminantsArsenic pollutionFood safety

The invention provides modified biomass charcoal for treating arsenic pollution as well as a preparation method and an application of the modified biomass charcoal. The preparation method of the modified biomass charcoal comprises steps as follows: (1) biomass raw materials are charred, and the biomass charcoal is obtained; (2) the biomass charcoal is subjected to a reaction with a hydrochloric acid solution, solid-liquid separation is performed, a solid substance is obtained, is washed till the pH is neutral and then is dried, and the pretreated biomass charcoal is obtained; (3) the pretreated biomass charcoal and a FeCl3 solution are subjected to a reaction under the condition that the solution pH is neutral, solid-liquid separation is performed after the reaction, and mud cake is obtained; (4) the mud cake is dried and then washed till the pH is neutral, solid-liquid separation is performed, an obtained solid is dried for a second time, and the modified biomass charcoal is obtained. The modified biomass charcoal has large specific surface area and high iron content; the preparation method is simple and easy to operate; the modified biomass charcoal can be applied to treatment of arsenic waste and passivation of arsenic in farmland soil, and food safety is guaranteed.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

Process for preparing sodium dichromate

InactiveCN101693556AReduce Chloride ContentReduce Sulfate LevelsChromates/bichromatesCarbonizationSodium dichromate

The invention provides a process for preparing sodium dichromate, namely producing the sodium dichromate through a carbonization method comprising: converting sodium chromate into the sodium dichromate via carbon dioxide under pressurizing condition; delivering sodium chromate neutral liquor with impurities removed to a carbonization tower after a cascade reaction of more than three continuous towers; obtaining carbonizing liquor by controlling different gradient parameters (concentration and temperature of the carbonizing liquor, partial pressure of the carbon dioxide, carbonizing time and the like), continuously carbonizing and separating under pressure; obtaining sodium dichromate finished products through concentrating, filtering, evaporating, crystallizing and centrifugal dehydrating.

Owner:SICHUAN YINHE CHEM

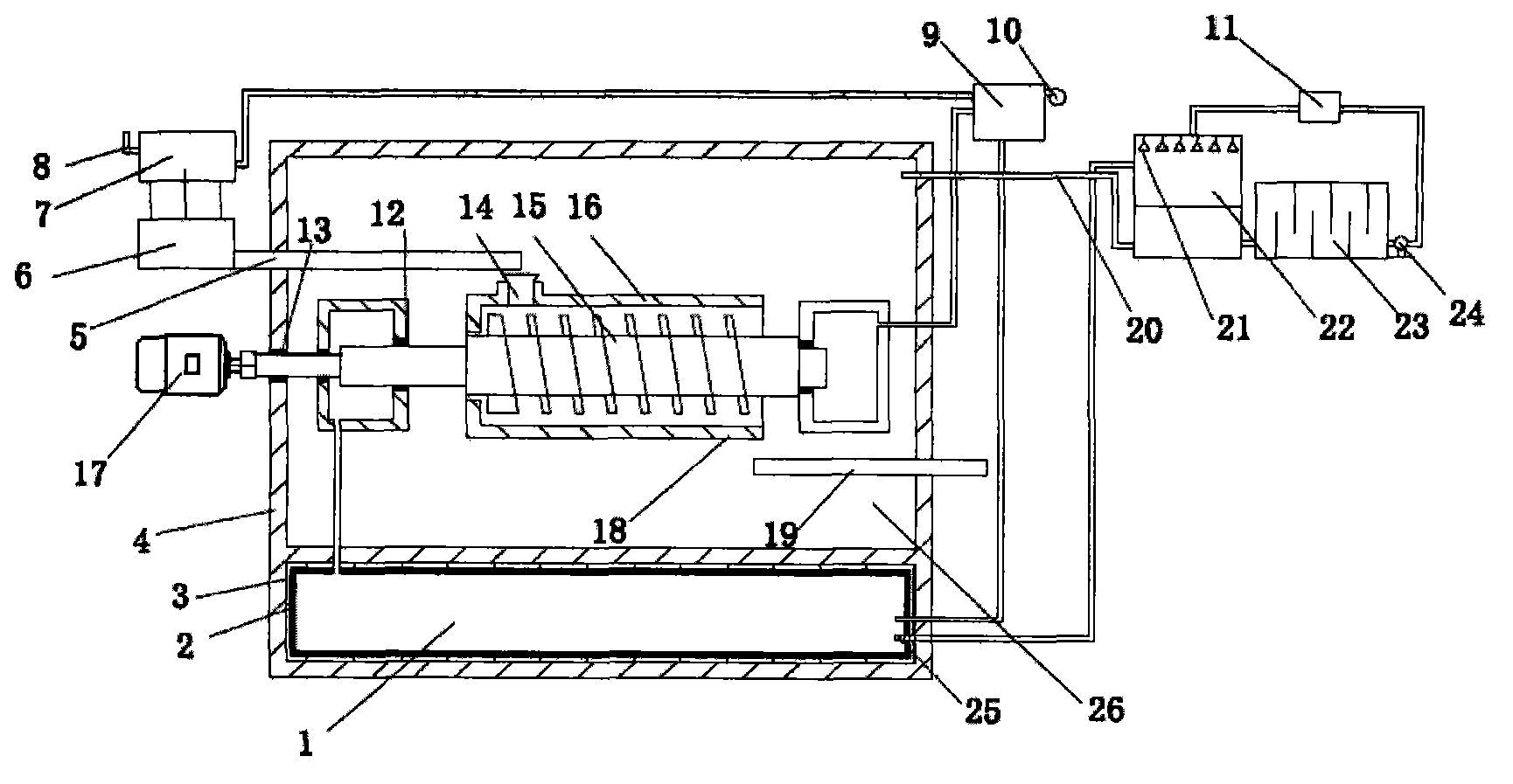

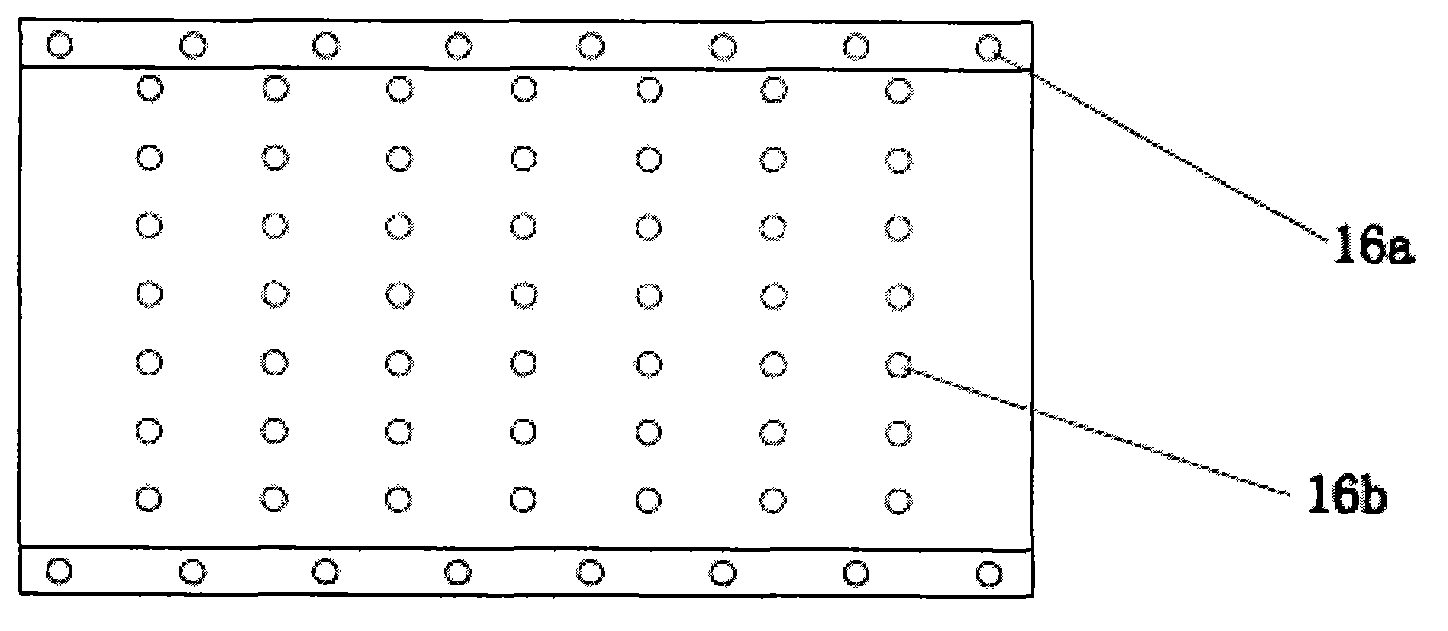

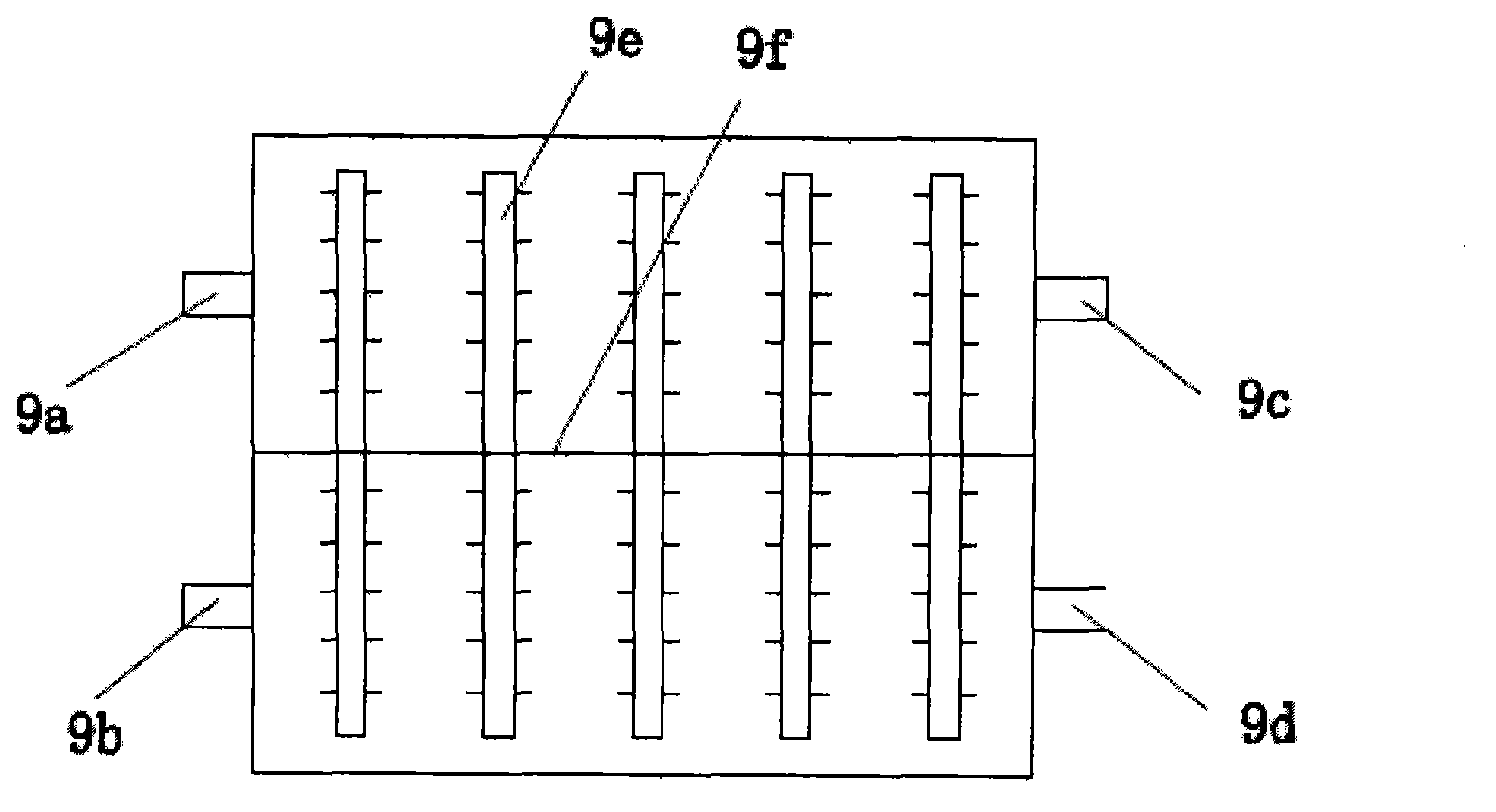

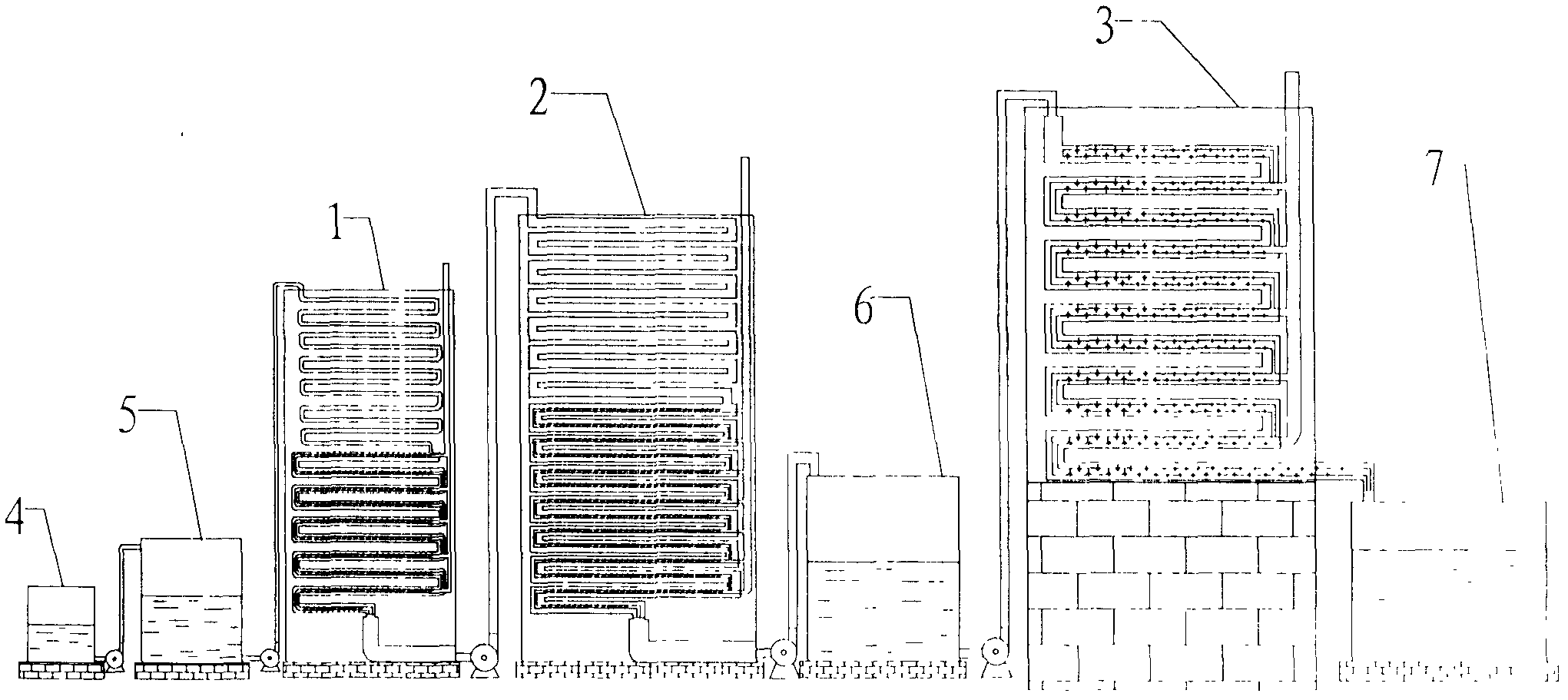

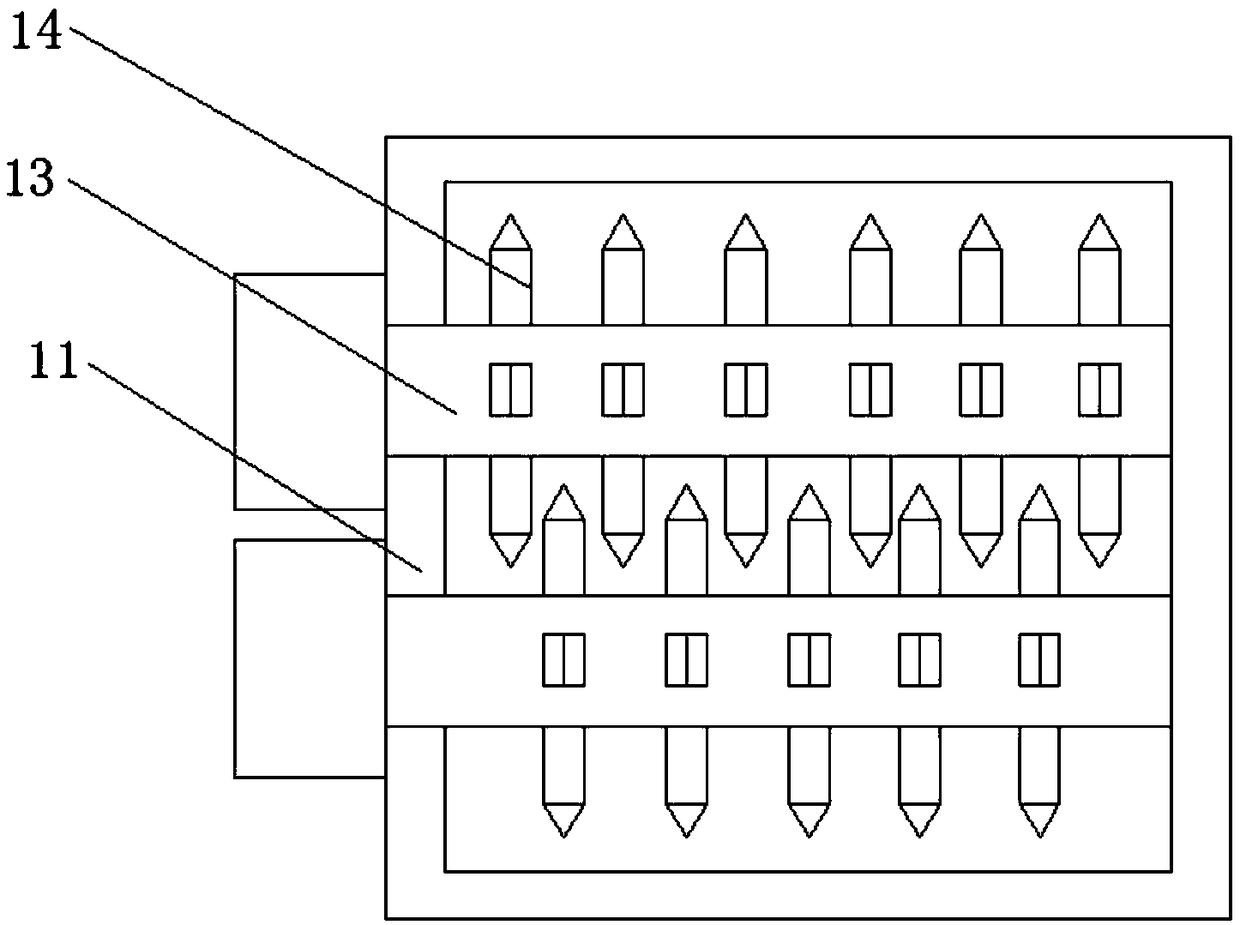

Biomass carbonization device

InactiveCN103254917AQuality improvementAvoid Hygroscopic ReactionBiofuelsEnergy inputAir preheaterAutomatic control

The invention relates to a biomass carbonization device, which mainly includes: a combustion chamber, a feed transmission belt, a biomass stock bin, a flash dryer, a flue gas outlet, a heat pipe air preheater, a hollow screw shaft with a heat accumulator, an upper sleeve, a lower sleeve, a biomass charcoal transmission belt, a pipeline, a spraying settling chamber, an oil separation pool, a carbonization chamber and auxiliary equipment. The device can realize comprehensive utilization of biomass carbonization products, and can realize co-production of biomass charcoal and bio-oil. At the same time, by adopting a circulating heat exchanger repeatedly, the emptied gas can have a low temperature, and the energy loss can be substantially reduced. The design of the hollow screw shaft with the heat accumulator realizes staged carbonization and combustion, thus improving the carbonization efficiency. The biomass carbonization device provided in the invention has the advantages of little pollution, high carbonization efficiency, good production environment, etc., and can achieve automated control. The biomass carbonization device is applicable to carbonization of straws, rice husks, sawdust, peanut shells and other biomass, and is suitable for rural families.

Owner:HEFEI UNIV OF TECH

Spherical calcium carbonate and preparation method thereof

InactiveCN109824077ANarrow particle size distributionSmall particle sizeCalcium/strontium/barium carbonatesCarbonizationSlurry

The invention discloses a spherical calcium carbonate and a preparation method thereof. The preparation method comprises following steps: mixing quicklime with water according to a ratio, carrying outdigestion and aging, then sieving the solution to remove impurities, adding ethanol into the slurry, carrying out refining and regulating to obtain calcium hydroxide slurry; transferring the preparedslurry to a super gravity reactor, adding a crystal form controller, controlling the carbonization temperature, CO2 gas flow, and super gravity level to carry out countercurrent contact between the calcium hydroxide slurry and CO2 gas to trigger carbonization reactions; after carbonization, carrying out centrifugation, drying obtained precipitates, and grinding to obtain spherical calcium carbonate. Calcium hydroxide is taken as the raw material, alcohol and water are taken as the solvents, the cost is low, the spherical calcium carbonate is prepared in a super gravity field by a carbonization method, the microscopic mixing and mass transfer process are greatly enhanced, the carbonization time is short, the production efficiency is high, the particle size distribution range is narrow, theparticle size is small, the morphology is uniform, the dispersing property is good, and the spherical calcium carbonate is suitable for industrial application.

Owner:GUANGXI UNIV +1

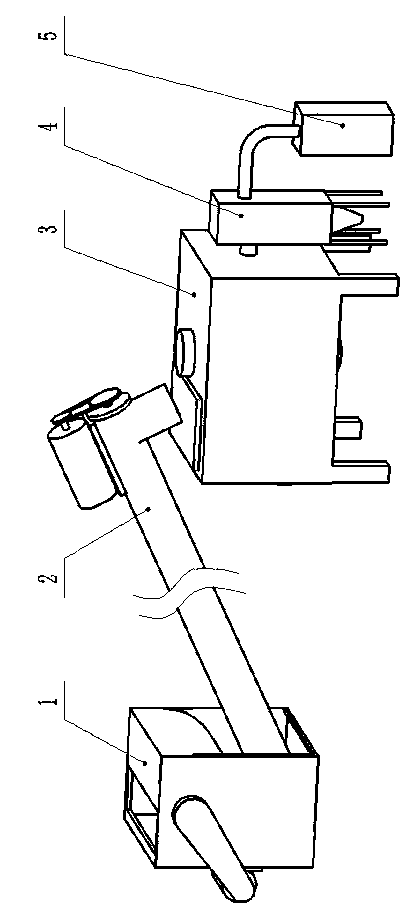

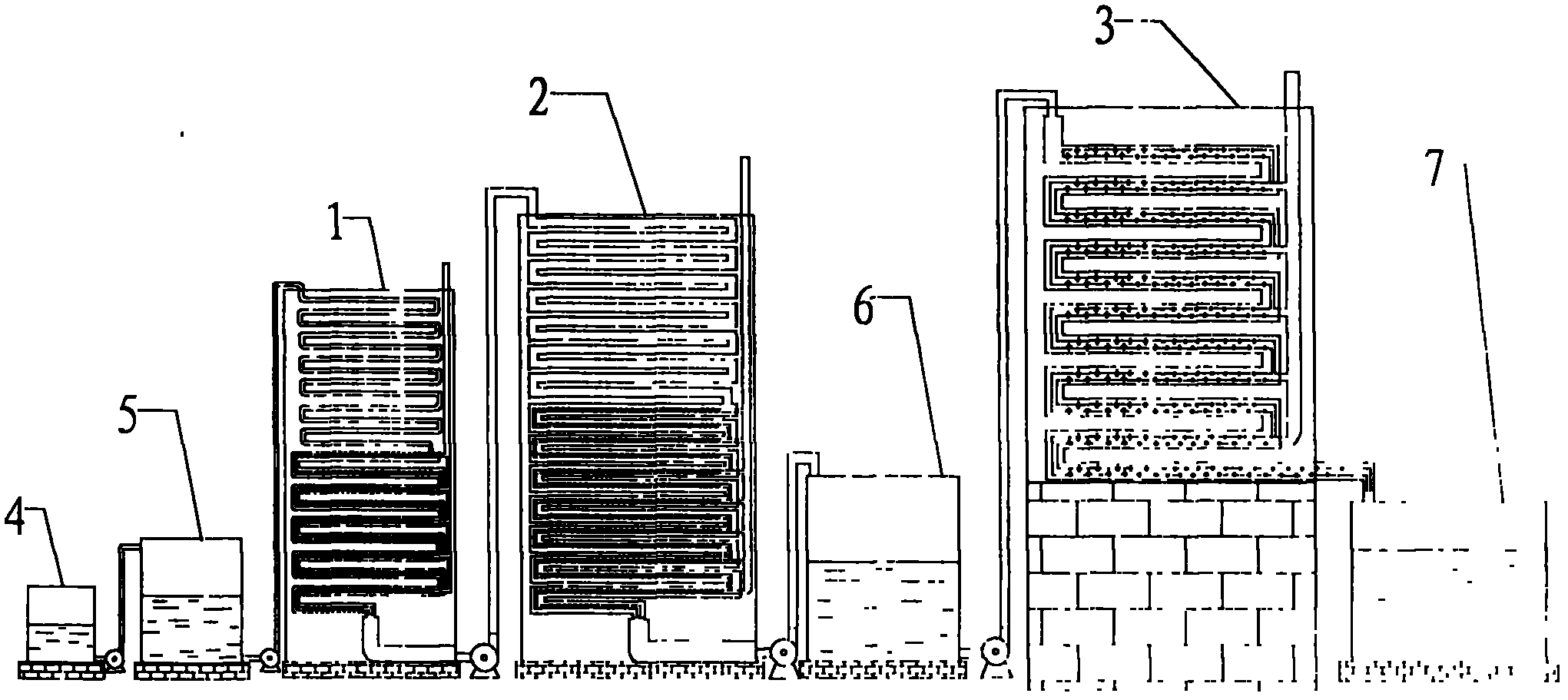

High-efficiency straw carbonization device

InactiveCN103275739AShort carbonization timeImprove efficiencyBiofuelsSpecial form destructive distillationCarbonizationCoke

The invention relates to a high-efficiency straw carbonization device. The high-efficiency straw carbonization device is characterized by comprising a crushing machine (1), an auger drying and conveying mechanism (2), a carbonization furnace (3), coke and dust removal equipment (4) and a gas collecting device (5), wherein straws are firstly crushed by the crushing machine (1) and then fed into the auger drying and conveying mechanism (2); during the conveying process, the crushed straws are quickly dried and then fed into the carbonization furnace (3) for carbonization so as to improve the carbonization efficiency; and dust and gas generated during the carbonization process are respectively collected and processed by the coke and dust removal equipment (4) and the gas collecting device (5) so as to realize zero-pollution emission. The high-efficiency straw carbonization device overcomes the disadvantages that the dehydration and carbonization of raw materials in a traditional carbonization furnace are long in time period and low in efficiency, has the advantages that the structure is reasonable, energy is saved, the environment is protected, the labor force can be reduced and the production efficiency of straw carbonization is improved, and is multipurpose, thus being easy for popularization and use.

Owner:JIANGSU ANXIN BOILER

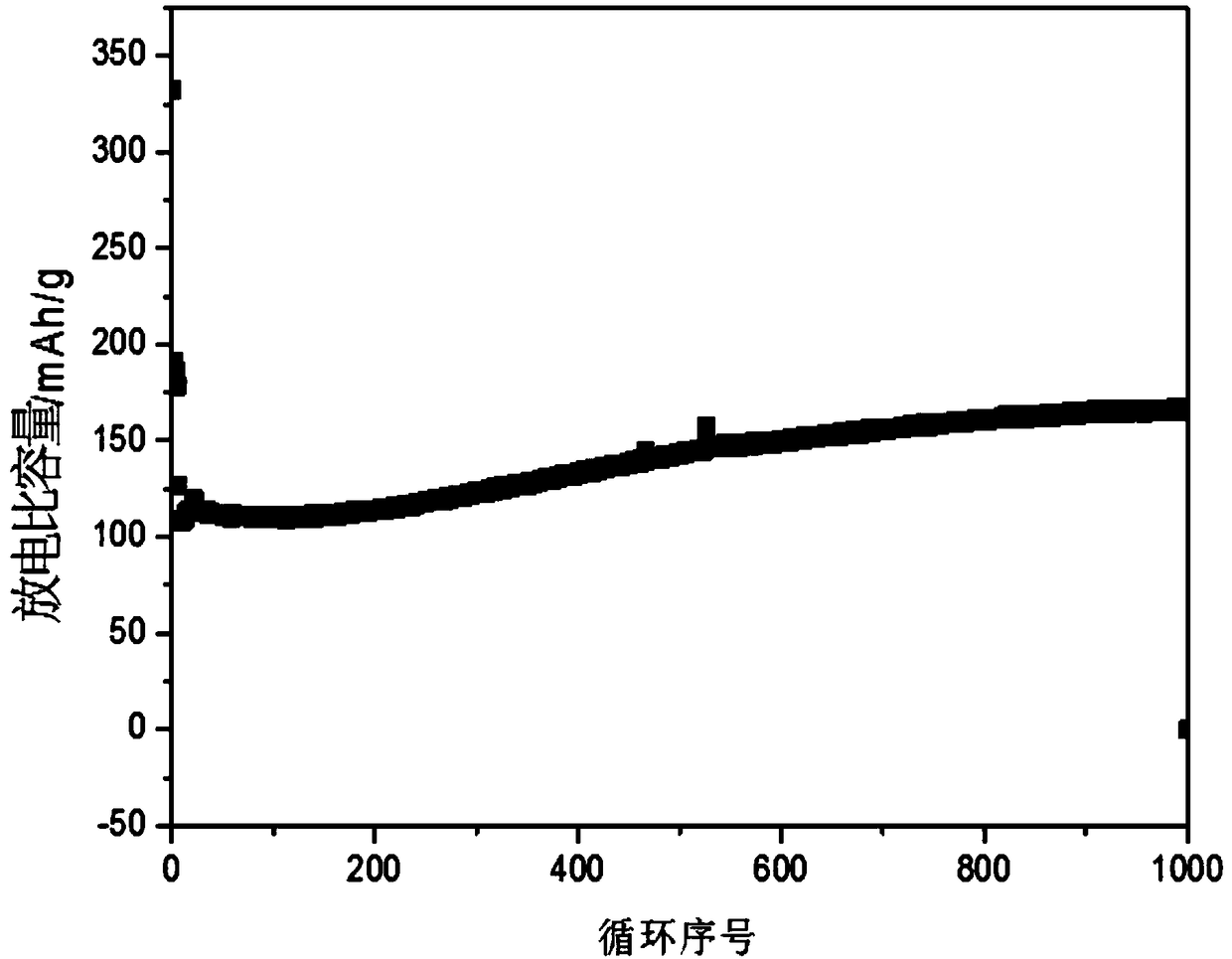

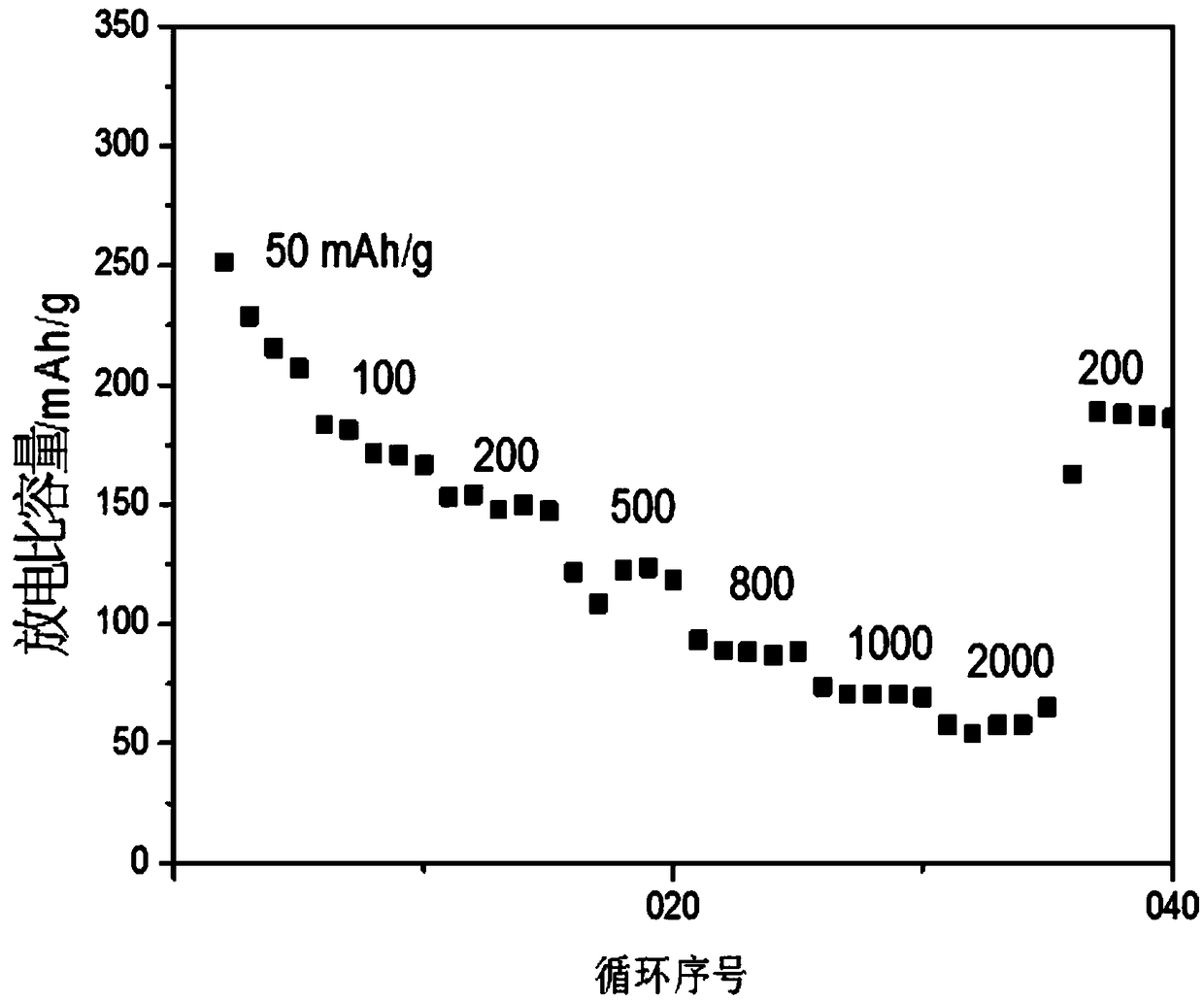

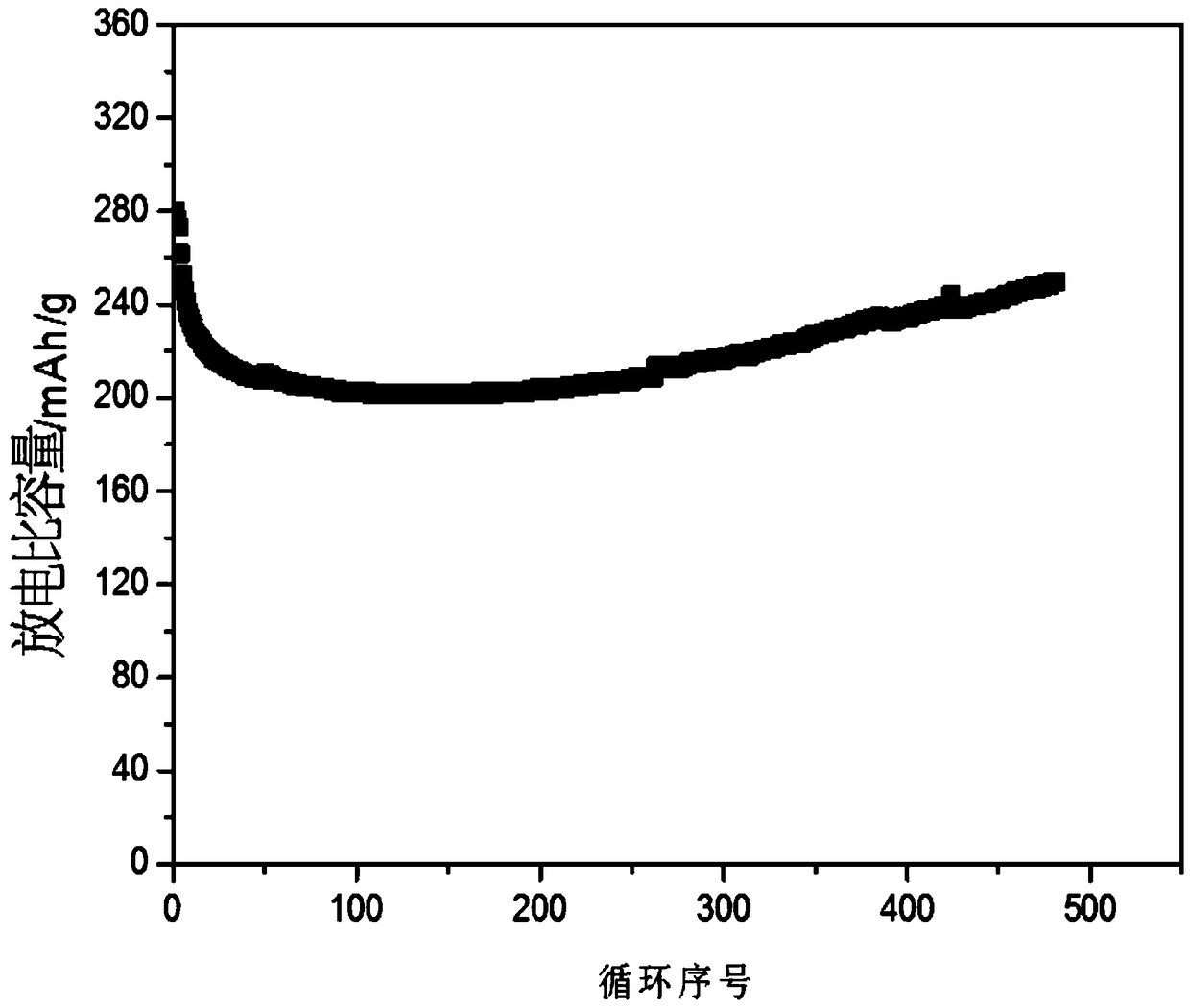

Selenium-doped ferrous disulfide carbon-coated composite material and preparation and application methods thereof

ActiveCN109437123AHigh activityImprove electrochemical activityCell electrodesSecondary cellsSodium-ion batteryCarbon coated

The invention discloses a selenium-doped ferrous disulfide carbon-coated composite material. The composition of the selenium-doped ferrous disulfide carbon-coated composite material is FeSe*S2-*@C, wherein x is 0.1-1.9. When applied to sodium ion batteries, the selenium-doped ferrous disulfide carbon-coated composite material can effectively inhibit volume expansion effects and increase actual specific capacity, rate capability and cycling performance. The invention also discloses preparation and application methods of the selenium-doped ferrous disulfide carbon-coated composite material.

Owner:中山高容新能源科技有限公司

Method for preparing active carbon with high specific surface area from coal and waste and old plastics by microwave

The invention relates to a novel method for preparing active carbon with high specific surface area from coal and waste and old plastics by microwave, which belongs to the technical field of preparation of active carbon. The method comprises the following steps of: separating different components in coal; carrying out pulverization and oxidization preprocessing on the obtained fusain and vitrinite component; mixing with different waste and old plastics in a certain proportion; adding certain amount of activating agent and uniformly mixing and then placing the mixture into a crucible; embedding the crucible into a ceramic container provided with a heat insulating material and placing the ceramic container into a microwave oven; preheating the ceramic container under the radiation of small microwave power and carrying out carbonized activation by needed power in certain time; cooling and washing by a proper amount of hydrochloric acid; drying and pulverizing to obtain the active carbon with high specific surface area. The preparation process is based on a microwave heating technology and is simple and quick; the active carbon prepared by the synergistic effect of the coal and the plastics has high adsorptive values of methylene blue and iodine and can be used for the treatment of wastewater; meanwhile, the white pollution is eliminated, and the application prospect is wide.

Owner:XIAN UNIV OF SCI & TECH

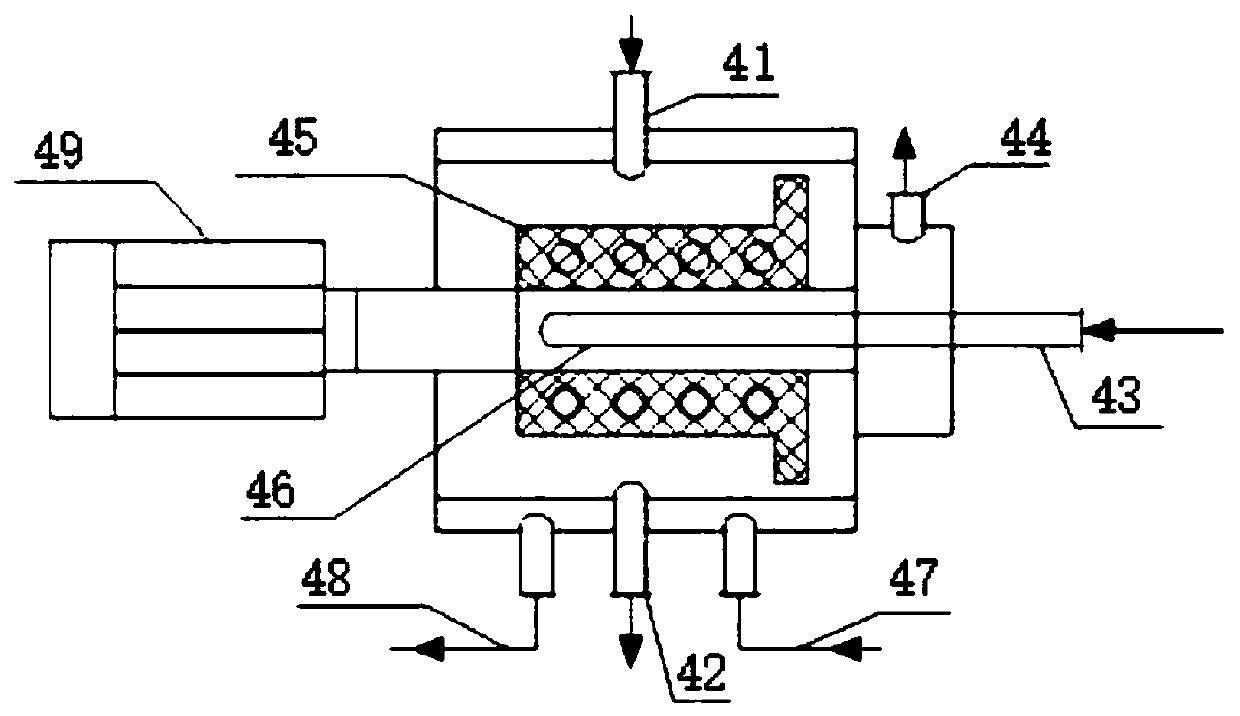

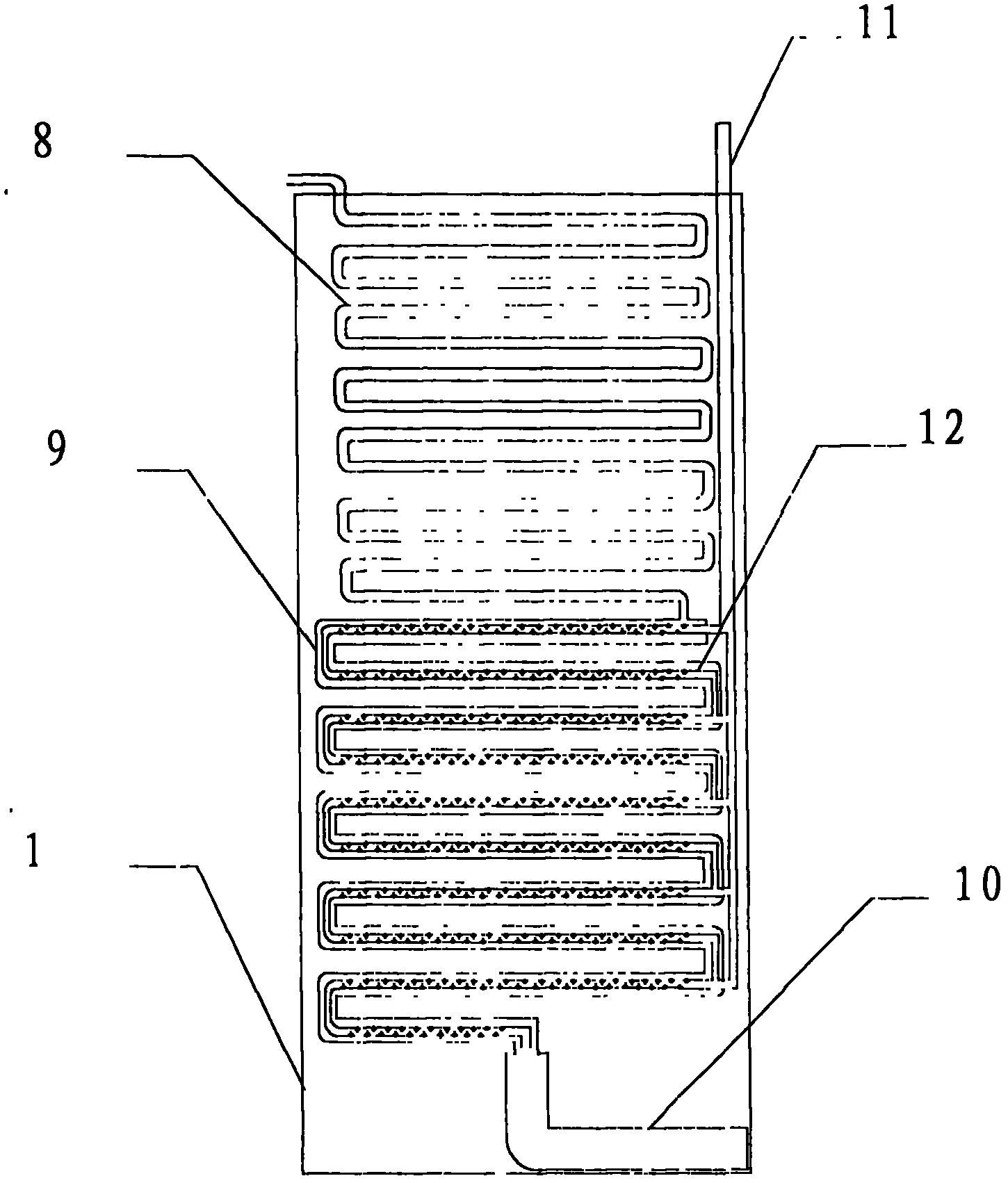

Carbonizer and method for producing nano calcium carbonate

ActiveCN102531017AImprove product qualityUniform particle size distributionCalcium/strontium/barium carbonatesNanotechnologyCalcium hydroxideCarbonization

The invention discloses a carbonizer for producing nano calcium carbonate. The carbonizer comprises a calcium hydroxide blending tank, a calcium hydroxide slurry storage tank, a primary carbonization nucleation reactor, a primary carbonization growth reactor, a primary carbonization ageing tank, a secondary carbonization tubular reactor and a calcium hydroxide activating tank; and a slurry carbonization reaction tube and a carbon dioxide porous reaction tube which have two-end uninterrupted repeated arch structures are arranged in the primary carbonization nucleation reactor, the primary carbonization growth reactor and the secondary carbonization tubular reactor respectively. By the method for producing the nano calcium carbonate through the carbonizer, the calcium carbonate can be produced by the nucleation stage and the growth stage, and is controlled stepwise, the reaction degree of the whole carbonization process can be monitored, the nano calcium carbonate with uniform particle size distribution, regular crystal structures and stable quality can be produced, and the invention has the advantages of small equipment investment, short carbonization time, low energy consumption and the like.

Owner:连州市凯恩斯纳米材料有限公司

Method for preparing charcoal through microwaves

InactiveCN105771897AIncrease the gapReduce voidsOther chemical processesWater/sewage treatment by sorptionMicrowave ovenSludge

The invention discloses a method for preparing charcoal through microwaves. The method comprises the following steps: I) mixing half-dried sludge, biological straw powder and charcoal powder, and pelletizing and molding so as to obtain molded granules; II) putting the molded granules in a microwave oven for carbonization so as to obtain carbonized granules; III) dividing the carbonized granules into two unequal parts, crushing a small part of the carbonized granules so as to obtain the charcoal powder serving as a raw material of the step I), and feeding back to the step I); soaking a large part of the carbonized granules into a 3-5mol / L KOH or NaOH solution for 12-18 hours, soaking in 5-6mol / L diluted hydrochloric acid for 0.5-2 hours, bleaching the material after acid pickling by using distilled water till the pH value is 6.5-7, and drying at 120 DEG C, so as to obtain charcoal of a porous structure. By adopting the method, the reaction velocity is accelerated, the reaction time is shortened, the energy consumption is reduced, and defects of a conventional pyrolysis method and a microwave wet method can be overcome.

Owner:TIANJIN CHENGJIAN UNIV +1

Gasification, dry distillation and carbonization integrated system carbonization

The invention relates to a coking method which adopts two-step methods to produce formed coke to fat coal, gas coal, non-caking coal, long flame coal, brown coal and peat. The two-step method comprises adding raw material coal into a coking furnace to coke after thermally process to be semi coke in middle temperature, namely gasification, dry distillation, carbonization integrated system coking method, and achieving the purpose of coking fat coal, gas coal, non-caking coal, long flame coal, brown coal and peat through utilizing the two-step coking method, breaking raw material coal to be grain size which is under 1.5mm, adding right amount of mineral binder bond and coke tar to mix, molding through cold pressure, and modeling coke products through high temperature carbonization. Since the above mill coal can coke, which solves the problem of coking coal shortage, generates bigger social benefit, and can local and ground proximity coal coking, therefore the production cost is lowed, and considerable economic benefit can be produced. The appearance of GCC two-step coking method colors the integral coking technique, and extends the development of the field.

Owner:朱海涛

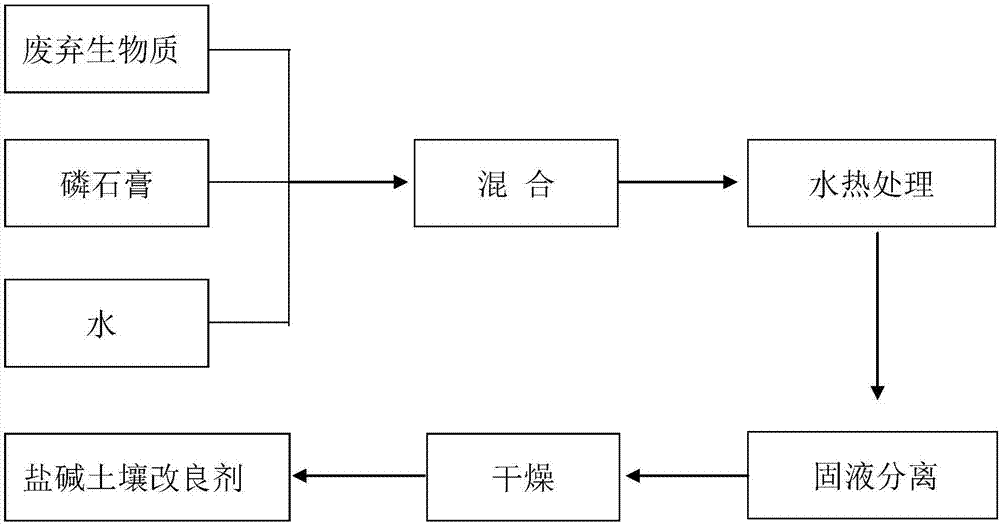

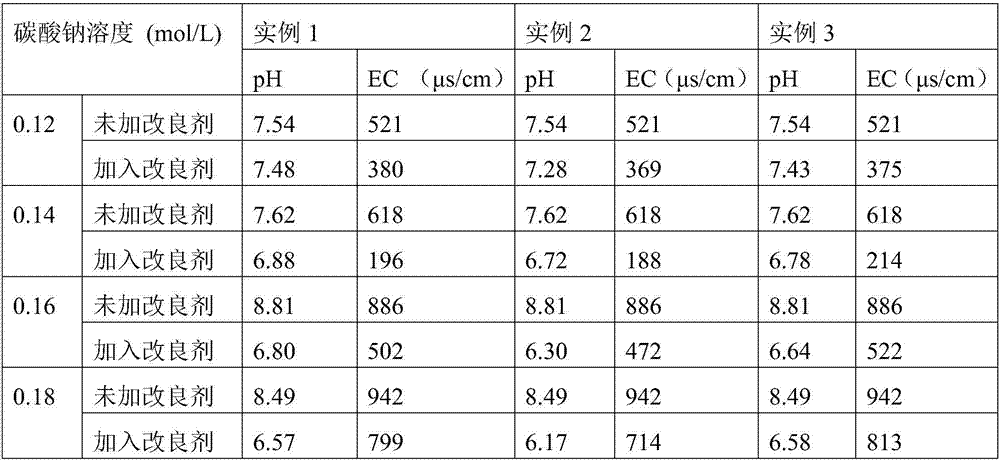

Novel process of preparing saline-alkali soil modifier using solid waste

ActiveCN106929034AImprove interface performanceImprove fertilityAgriculture tools and machinesOther chemical processesAlkali soilResource utilization

The invention discloses an environment-friendly novel process of a saline-alkali soil modifier suitable for waste biomass and ardealite preparation. The advantage of rich waste biomass and ardealite resources in China and the current situation of severe soil alkalization in China are taken into consideration. According to the novel process of preparing the saline-alkali soil modifier using the solid waste, the hydro-thermal treatment is conducted on the mixture after the waste biomass and a certain amount of ardealite are mixed on specific conditions, and the saline-alkali soil modifier is obtained by centrifugation and solid-liquid separation. The saline-alkali soil modifier is simple in preparation process, capable of regenerating, low in cost and capable of reducing the soil alkalization of the soil and improving soil fertility. The modifier is prepared from the waste biomass and the ardealite, the saline-alkali soil is effectively improved, and the clean resource utilization on the waste biomass and the ardealite is achieved at the same time.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

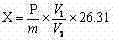

Method for measuring phospholipid in lipid

InactiveCN102175672APrevent splashAvoid burnsMaterial analysis by observing effect on chemical indicatorLipid formationMolybdenum blue

The invention discloses a method for measuring phospholipid in lipid, and the method comprises the following steps: carbonizing, ashing and dissolving of lipid; and molybdenum blue colorimetry measurement of phosphorus, wherein the lipid is carbonized by adding concentrated sulphuric acid, and a hydroxide, a carbonate or a bicarbonate of an alkali metal. In the invention, the concentrated sulphuric acid is used for pre-carbonizing, and alkali is added for reacting, so that the carbonization of different amounts of various lipids can be completed within 15 minutes, splashing and combustion generated in a direct electric furnace heating carbonization procedure are prevented, and the carbonization time is shortened; the hydroxide, carbonate or bicarbonate of the alkali metal is used for displacing ZnO, so that the soluble phosphate with higher thermal decomposition temperature is generated, and the ashing time is shortened; and the ashed product can be dissolved and filtered directly, sothat the following operations are simpler and safer.

Owner:NORTHWEST UNIV(CN)

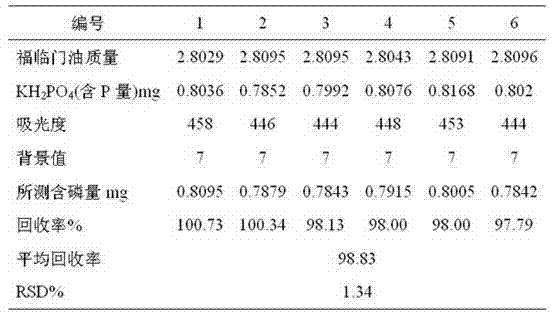

Production method of formed coke

ActiveCN102079982AIncrease the drying processHigh calorific valueCoke quenchingEnergy inputEngineeringWater jacket

The invention discloses a production method of formed coke. In the method, the working procedure of drying formed coke is added, thus the carbonization time can be shortened, the calorific value of dry distillation gas can be increased, and the large-scale production of formed coke can be ensured; an external combustion type carbonization furnace is used in the carbonization process, the carbonization equipment has long flue stroke, the residence time of flue gas is long and the thermal efficiency is high; the quantity of heat can be adjusted to ensure the carbonization quality of the formed coke; the integration of carbonization and dry quenching can be realized, energy-saving analysis is performed on the energy requirement and supply of the carbonization process and a specific energy-saving scheme is provided; a specific temperature control scheme of the carbonization process is provided particularly for the carbonization of formed coke prepared from calcium carbide; and a novel water jacket is used for dry quenching, thus the water content of the formed coke product can be reduced, the water pollution can be prevented, the energy can be saved and the strength of formed coke canbe increased. The formed coke produced by the method meets the quality requirements, the operating cost is low, the floor space is small, the investment is less, the technology and equipment are mature and the industrial and large-scale production can be realized.

Owner:YIBIN TIANYUAN GRP CO LTD

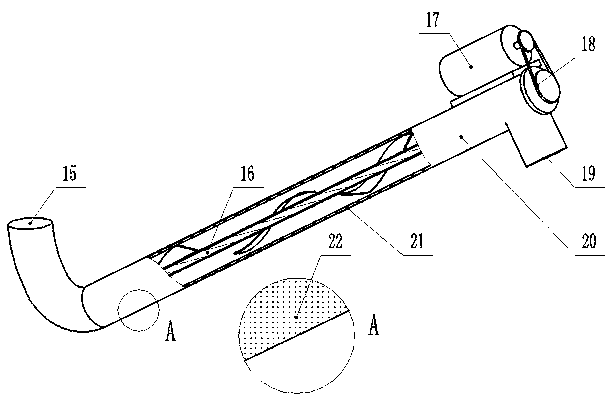

Porous multi-hollow flexible composite nanofiber membrane material and preparation method thereof

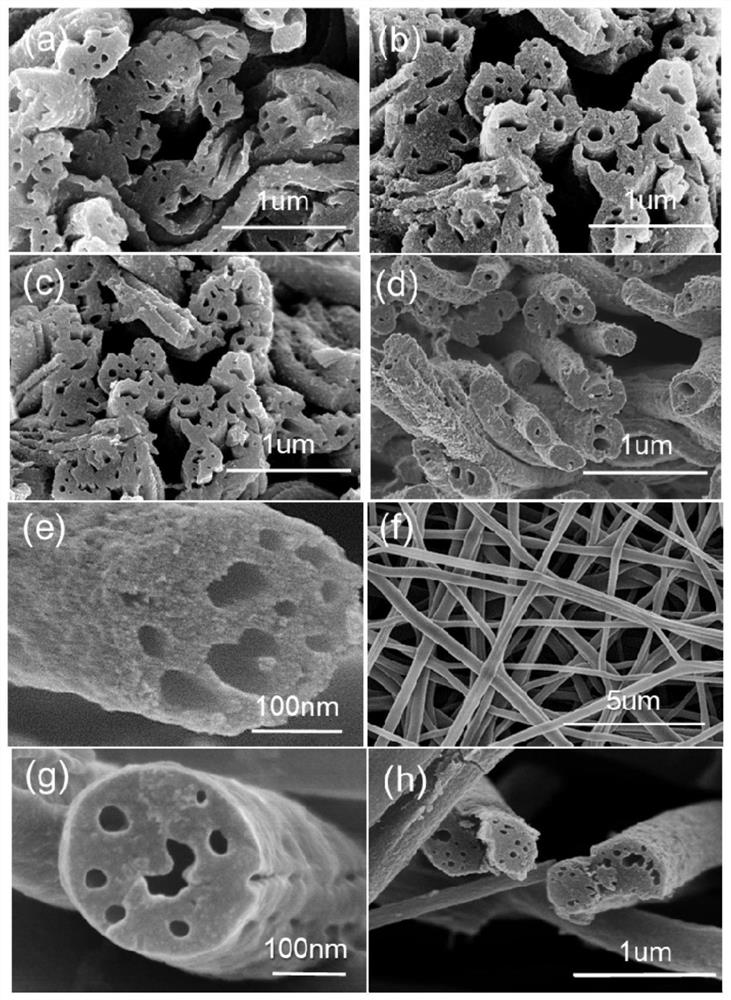

ActiveCN113073426AImprove flexibilityHigh mechanical strengthHollow filament manufactureNon-woven fabricsHollow fibreFiber

The invention relates to a porous multi-hollow flexible composite nanofiber membrane material and a preparation method thereof. According to the method, a porous multi-hollow flexible composite nanofiber membrane is prepared through coaxial electrostatic spinning, wherein an outer layer solution for coaxial electrostatic spinning consists of a sacrificial high-molecular polymer, a retained high-molecular polymer and a solvent A, and an inner layer solution for coaxial electrostatic spinning is composed of a sacrificial high-molecular polymer, a material capable of generating a substance with semiconductor characteristics and low surface energy in the spinning process, and a solvent B; and then the sacrificial high-molecular polymer in the porous multi-hollow flexible composite nanofiber membrane is removed to obtain the membrane material formed by stacking porous multi-hollow nanofibers, wherein the porous multi-hollow nanofibers are provided with a plurality of hollow pipelines and three-dimensional penetrating through hole micro-nano structures with the hollow surfaces. The membrane material disclosed by the invention has relatively high flexibility and mechanical strength, and the problems of fragility, low mechanical strength and the like of a porous composite fiber material and a single hollow fiber material are solved.

Owner:DONGHUA UNIV

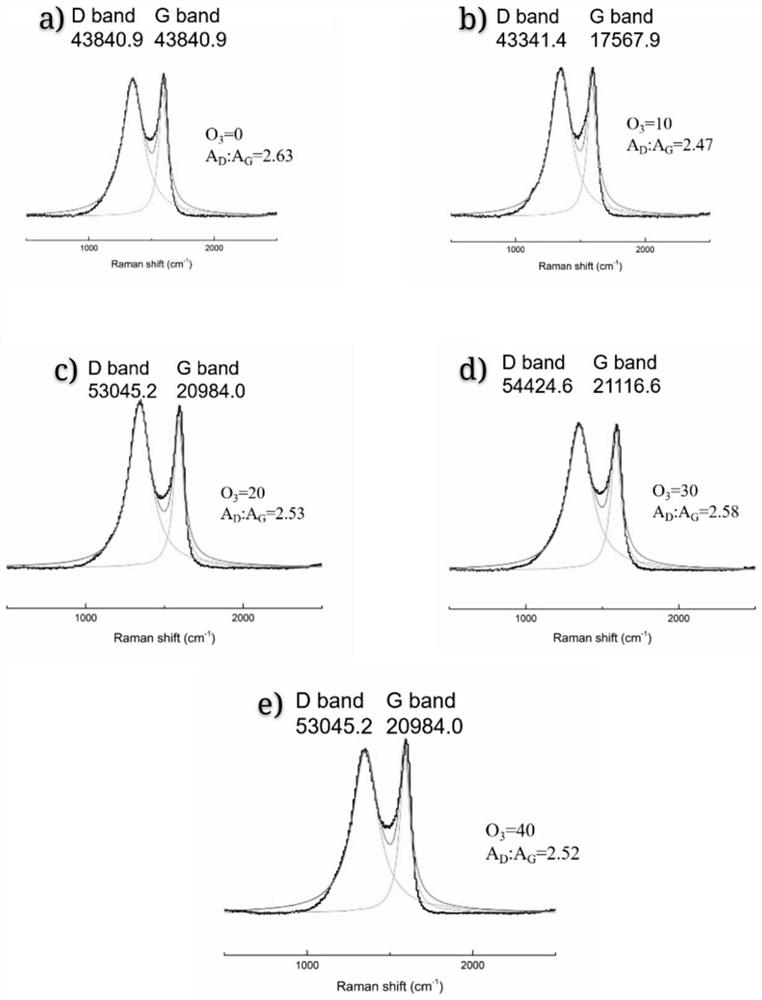

Preparation method of lignin-based porous carbon material

ActiveCN112110445AAvoid pollutionAvoid complicated activation processCarbon compoundsPorous carbonPhosphate

The invention belongs to the field of carbon material preparation, and particularly relates to a preparation method of a lignin-based porous carbon material. Under the oxidation action of low-concentration hydrogen peroxide, ozone blowing during low-temperature carbonization and a low-temperature carbonization charking process are combined, so that the orderliness and regularity of lignin molecules are improved, the oxidation of unsaturated bonds of lignin is promoted, and the activation of an activating agent melamine pyrophosphate is carried out, so that small molecules can be quickly removed during high-temperature cracking, the charking time is shortened, the yield of the carbon material is increased, and the obtained carbon material is more excellent in performance.

Owner:CHANGZHOU UNIV

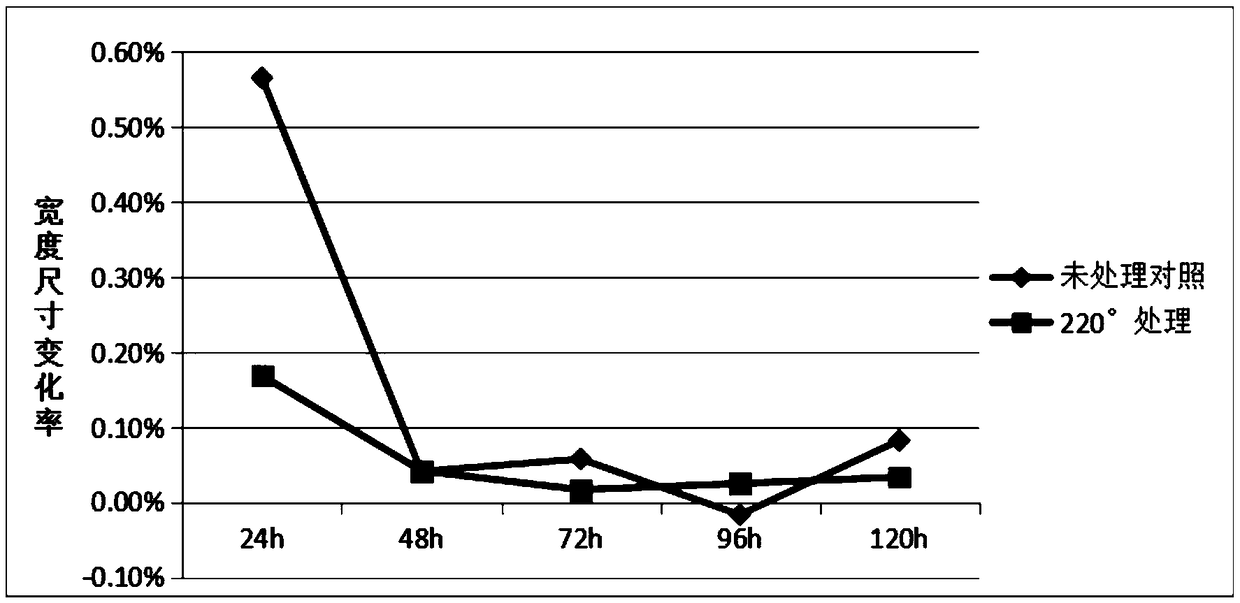

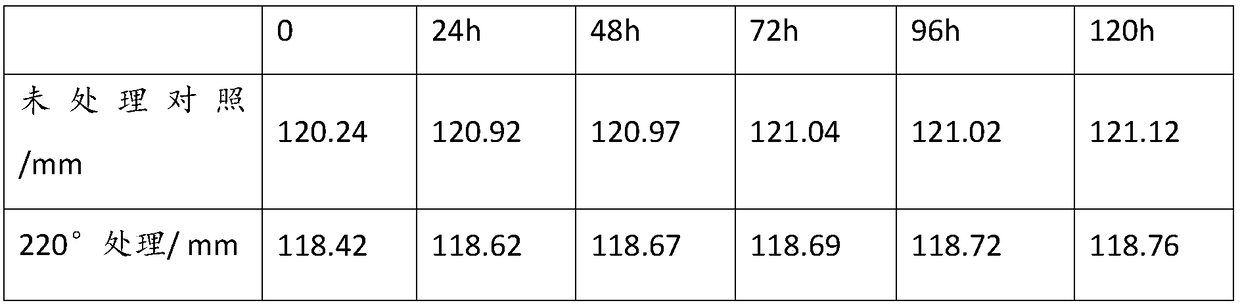

Processing method of surface-carbonized poplar solid wood floor

InactiveCN109176811AHigh surface hardnessImprove waterproof performanceWood treatment detailsWood charring/burningSolid woodCarbonization

The invention discloses a processing method of a surface-carbonized poplar solid wood floor, and belongs to the technical field of floor processing. The method comprises the following steps of S1, placing a poplar board into a drying kiln for drying until the moisture content of the poplar board is 8-12%, carrying out steam-injection softening treatment on the surface of the poplar board for 3-5 minutes, and keeping the poplar board for 10-20 minutes under the condition that the hot-pressing pressure is 1.0-1.2 MPa and the temperature is 160-190 DEG C; S2, machining the poplar board into a floor blank; S3, putting the floor blank into a high-temperature carbonization tank, carrying out carbonization treatment by using steam or nitrogen as protective gas, wherein the carbonization temperature is 220-300 DEG C, and the carbonization time is 5-20 minutes; and S4, brushing and painting the carbonized floor blank to obtain a finished floor. The processing method is used for modifying the fast-growing poplar, the surface strength and the dimensional stability of the poplar are improved, the moisture-proof effect is good, and the service life is long.

Owner:河南省林业科学研究院

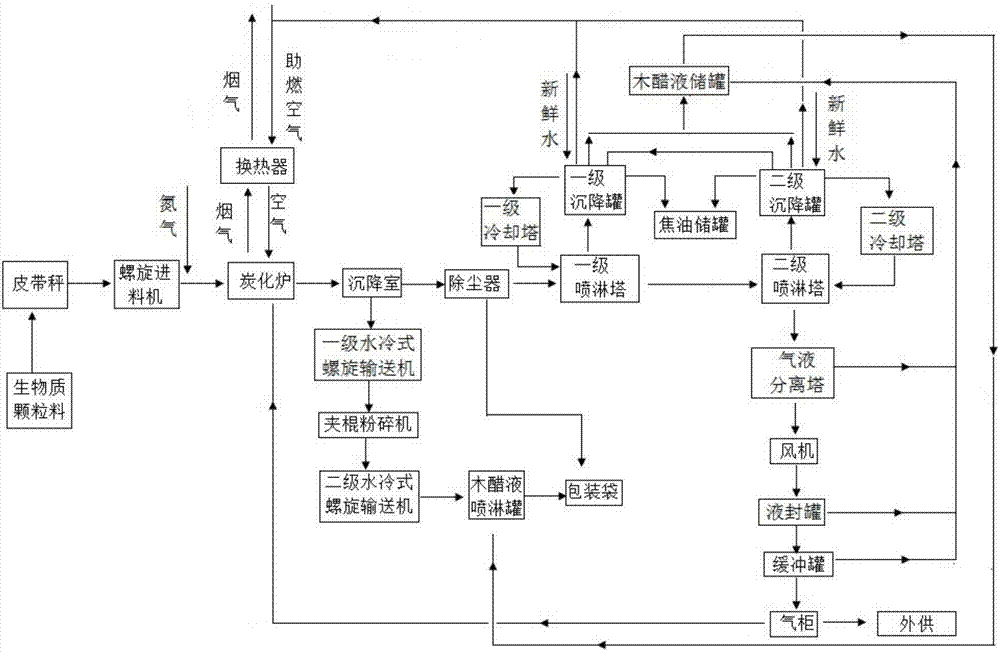

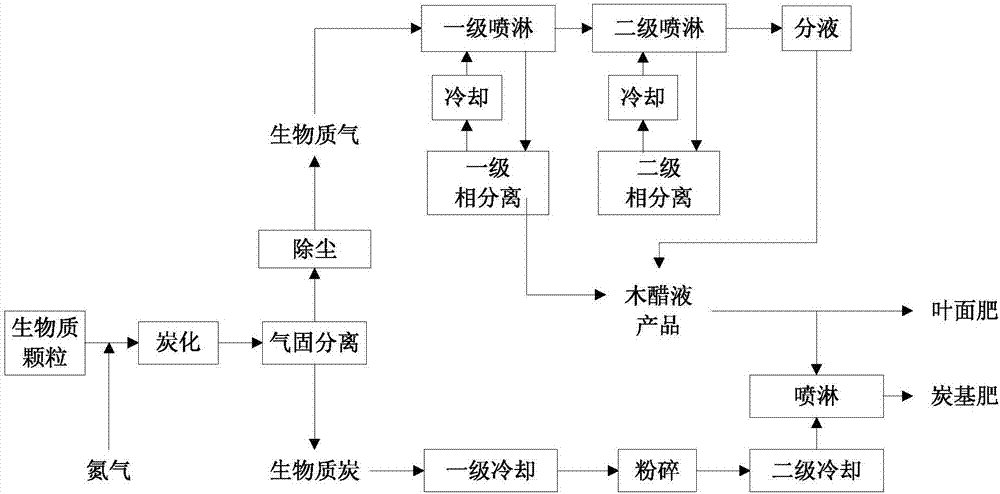

Continuous carbonizing treatment process for biomass

The invention discloses a continuous carbonizing treatment process for biomass. Biochar is obtained by carbonizing a biomass raw material; biomass gas which is produced in a carbonizing process is subjected to gas-solid separation at first in a settling chamber and a dust collector, is sprayed in a spraying tower and is separated and purified in a gas-liquid separating tower, so that wood vinegarand tar are separated; part of the purified and separated biomass gas serves as rotary furnace fuel, and surplus biomass gas is supplied to production of soil conditioner carbon fertilizer or domesticfuel. The continuous carbonizing treatment process improves comprehensive utilization of crops and the like, and achieves an important effect on protecting the environment of a producing place, stabilizing agricultural ecological balance, alleviating resource constraints, and promoting income of farmers.

Owner:BEIJING SANJU GREEN ENERGY TECH CO LTD

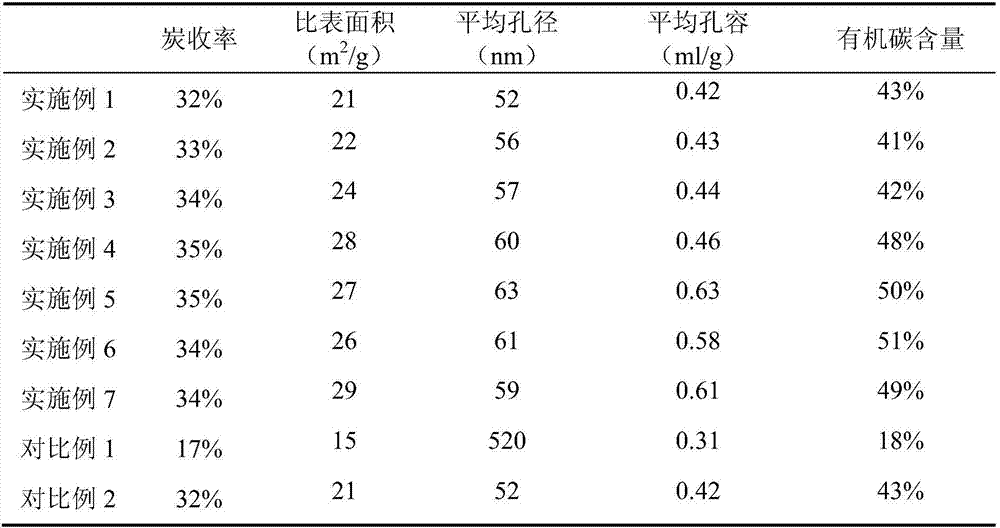

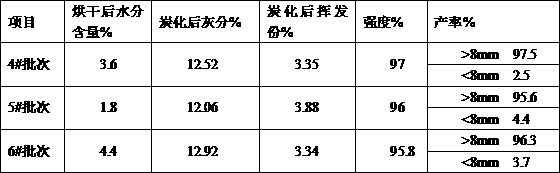

Process of preparing high-quality biomass charcoal for carbon-based fertilizer and co-producing wood vinegar

ActiveCN107541227AKeep active ingredientsActive ingredient accumulationProductsReagentsFlue gasPollution

The invention relates to the technical field of biomass utilization, and particularly provides a process of preparing high-quality biomass charcoal for carbon-based fertilizer and co-producing wood vinegar. Multi-pore high-quality biomass charcoal and wood vinegar are obtained by adopting a low and medium-temperature cracking mode. Under an anoxic condition, a biomass raw material is carbonized, so that organic carbon in biomass is retained to the maximum extent; the wood vinegar is operated through phase separation of spraying liquid, so that energy waste and flue gas pollution which are caused by combustion are avoided; the low-concentration wood vinegar is further cyclically used as a spraying agent at the same level for recycling, so that effective components in the wood vinegar can beaccumulated. As the obtained wood vinegar is sprayed to the biomass charcoal, the sterilization and parasite expelling effects of the biomass charcoal can be enhanced, and the biomass charcoal is also entitled with nutritional components.

Owner:BEIJING SANJU GREEN ENERGY TECH CO LTD

Method for producing activated coke without coal tar by utilizing vertical carbonization furnace

InactiveCN109319780ANo pollution in the processAvoid uneven mixingCarbon compoundsCoke ovensCarbonizationAnthracite

The invention provides a method for producing activated coke without coal tar by utilizing a vertical carbonization furnace. The method comprises the following steps: preparing materials, grinding thematerials into powder, stirring, granulating, drying and carbonizing, wherein the materials comprise powder composed of coke powder, anthracite coal, coke coal, bituminous coal and asphalt, and a binding agent; the step of stirring comprises the steps of carrying out primary powder mixing, carrying out secondary powder mixing, and carrying out wet mixing; the wet mixing step comprises the following steps: adding a liquid solvent which accounts for 20 percent of the mixed powder into a mixing and kneading machine, and stirring to form a paste mixture; the step of drying comprises the steps ofstacking the granular blank into a material layer with the thickness which is not greater than 5 cm on a continuous conveyor belt. According to the method provided by the invention, the adding and mixing of a binding agent are divided into two steps including the secondary powder mixing and the wet mixing, and the dry powder is very easy to uniformly mix in advance, so that the uniform degree after mixing is relatively good; a solvent is added in the step of wet mixing and the problem that the binding agent is not uniformly mixed because the dry powder is blocked and agglomerated after water is added is avoided.

Owner:PINGLUO XIANGTAI COAL CHEM

Cultivation farm solid waste continuous pyrolysis carbonization treatment method and device

ActiveCN104910931ASimple structureEasy to controlIndirect heating destructive distillationSpecial form destructive distillationHigh energyCombustion chamber

The invention relates to a cultivation farm solid waste continuous pyrolysis carbonization treatment method and device. The device comprises a solid waste crushing treatment part, a heat supply part, a prepositive treatment part, a carbonization treatment part, a gas treatment part and a gas utilization part, wherein the solid waste crushing treatment part is used for carrying out crushing treatment on solid waste; the heat supply part is provided with a combustor, and used for introducing a flaming port of the combustor into a combustion chamber to obtain high-temperature flue gas; the prepositive treatment part is used for putting the crushed solid waste into a prepositive treatment chamber, and introducing the high-temperature flue gas of the heat supply part to perform heating; the carbonization treatment part is used for sending the solid waste subjected to prepositive treatment into the carbonization treatment chamber, and introducing the high-temperature flue gas of the heat supply part to perform heating; the gas treatment part is used for respectively collecting gas-phase products generated in the prepositive treatment and carbonization treatment, and performing condensation to obtain a condensed liquid and an incondensable gas; and the gas utilization part is used for introducing the incondensable gas into the combustion chamber of the heat supply part to perform combustion. The invention also relates to a device for implementing the method. The method and device have the advantages of simplified technique, simple equipment structure, high operation stability and reliability, short carbonization time, high energy utilization efficiency and the like.

Owner:ZHE JIANG ECO ENVIRONMENTAL TECH CO LTD

Carbonization treatment device for waste of animal husbandry

InactiveCN108998059AAvoid cloggingImprove stabilitySpecial form destructive distillationCombustorCarbonization

The invention discloses a carbonization treatment device for the waste of animal husbandry. The carbonization treatment device comprises a base, wherein the top part of the base is connected with a carbonization box through bolts; rollers horizontally arranged at the same side are rotatably connected with two inner ends of the carbonization box through mechanical sealing elements; one ends of therollers are connected with a blanking valve through flanges; the inner wall of the bottom part of the carbonization box are connected with equidistantly-distributed burners through bolts; a drying boxis connected with the top part of the carbonization box through bolts; and a conveying rotating shaft is rotatably connected with the inner wall of one side of the drying box through a mechanical sealing element. According to the invention, crushing treatment of caked organic waste can be performed through crushing teeth, so carbonization treatment of the organic wastes is convenient, and the time of carbonization is shortened; meanwhile, through crushing of the organic waste, the problem of blockage of the carbonization treatment device can be effectively avoided, the operation stability ofthe carbonization treatment device is improved, the problem of environmental pollution can be effectively avoided, and the cost of carbonization treatment of the waste of the animal husbandry is reduced.

Owner:佛山市北科科技创新服务中心

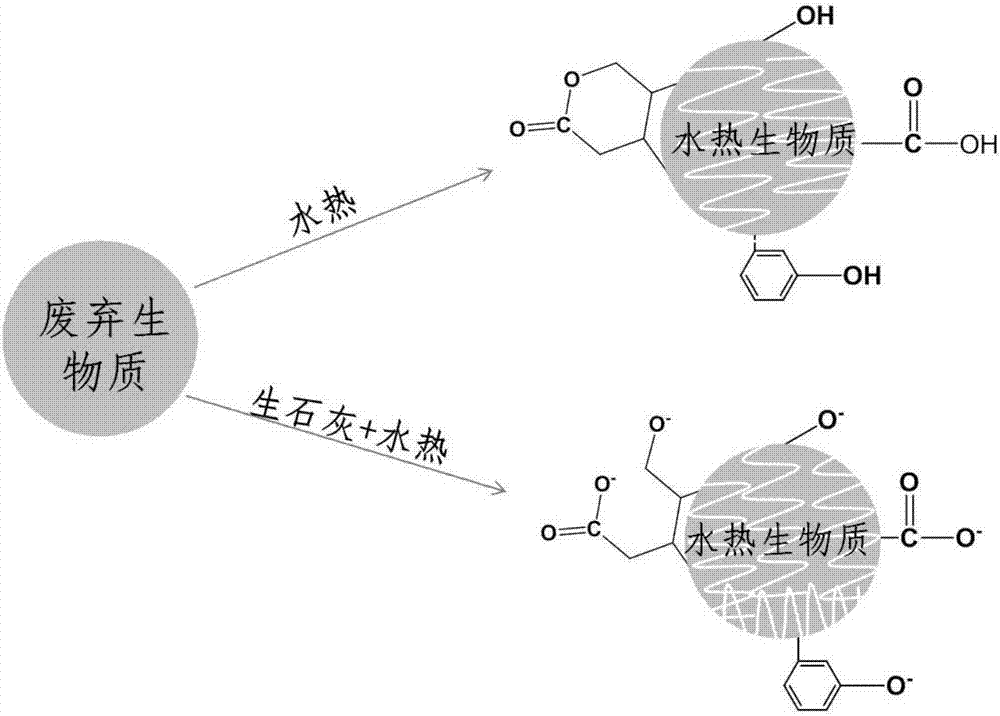

Method for preparing compound contaminated-soil in-situ repairing agent with abandoned biomass

InactiveCN106964643ALow costEnvironmentally friendlyContaminated soil reclamationContaminated soilsPollutant

The invention discloses a novel process for preparing an environment-friendly compound contaminated-soil in-situ repairing agent with abandoned biomass by combining the advantage of rich abandoned biomass resources in our country and the current situation that the soil combined pollution is serious in our country. According to the process, the abandoned biomass and a certain amount of quick lime are mixed and then subjected to hydro-thermal treatment under a certain condition, centrifugal solid-liquid separation is performed, and the compound contaminated-soil in-situ repairing agent is obtained. The soil repairing agent is simple in preparation process, regenerable and low in cost, the occurrence mode of heavy metal in soil can be changed, the heavy metal in the contaminated soil is efficiently passivated, and the total amount of bioavailable organic pollutants PAHs in the soil can also be remarkably lowered, in other words, efficient in-situ repairing of the organic-inorganic compound contaminated soil is achieved. The repairing agent is prepared through the abandoned biomass, and efficient in-situ repairing of the compound contaminated soil is achieved while clean recycling utilization of the abandoned biomass is achieved.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

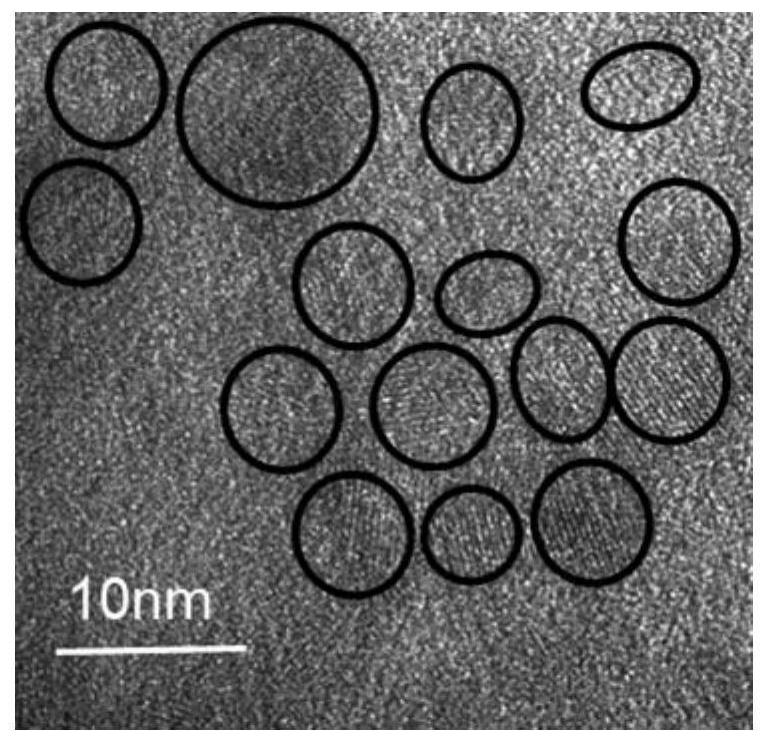

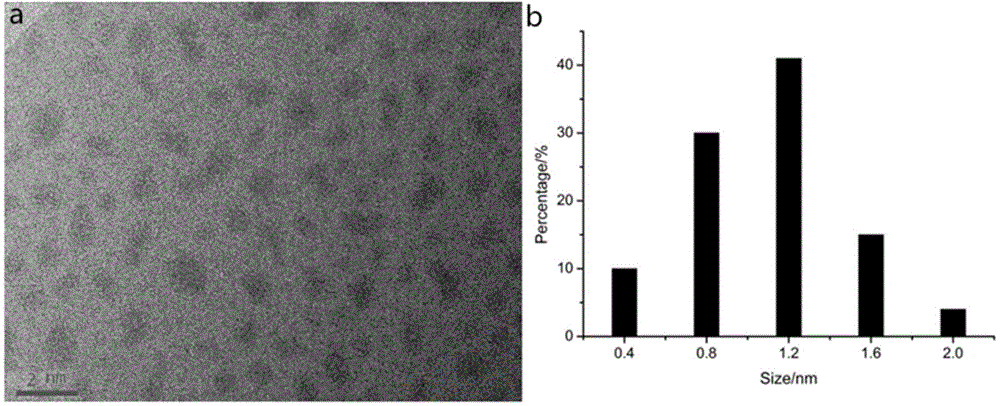

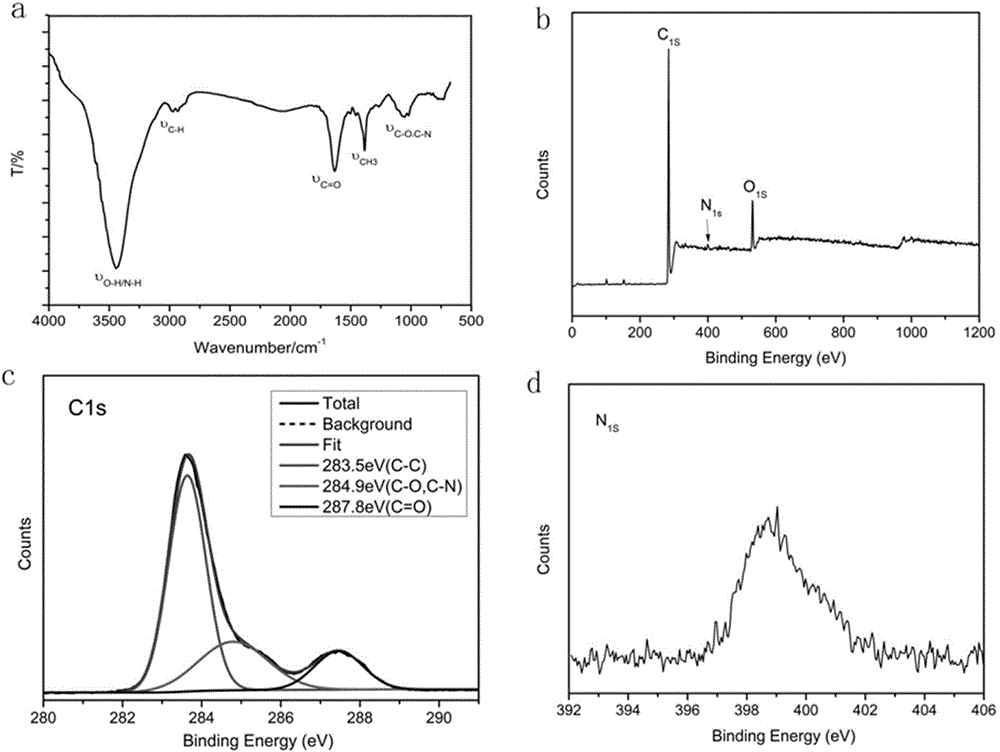

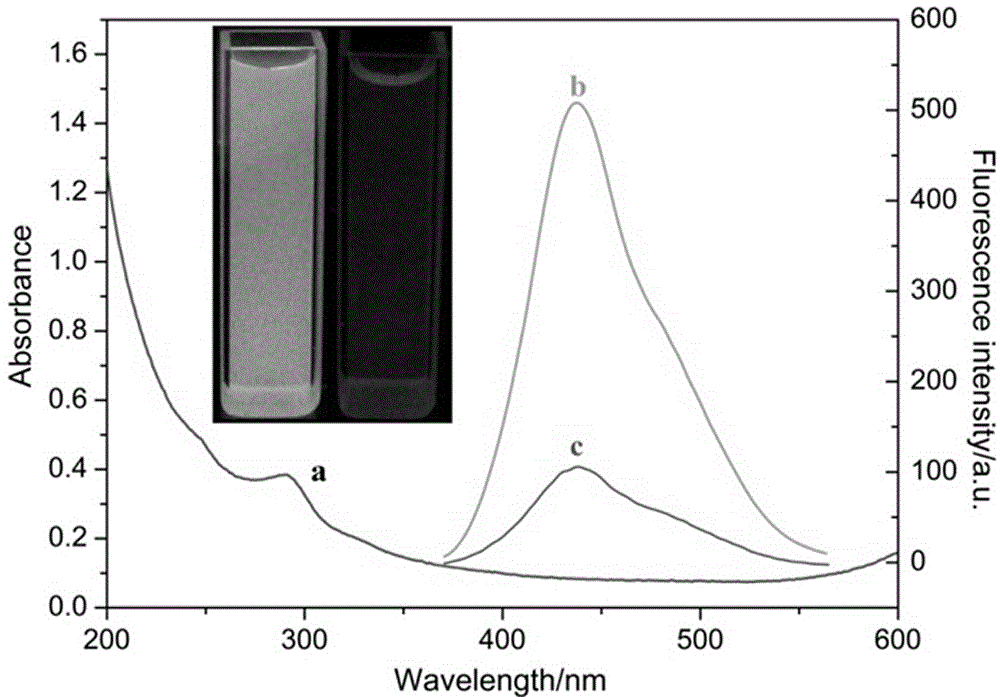

Preparation and application of fluorescent carbon dot nanoprobe for detecting methylene blue and living cell imaging

The invention relates to preparation and application of a fluorescent carbon dot nanoprobe for detecting methylene blue and living cell imaging. Under the excitation wavelength of 320nm, the maximum emission wavelength of carbon dots (CDs) appears at 440nm and strong blue fluorescence is emitted. Methylene blue can be used for quenching the fluorescence of the carbon dots, and in a cell culture dish, a living cell incubates for 24 hours with the methylene blue, and the cell is observed by using a laser confocal microscopy system and continuously emits blue fluorescence. According to the preparation and the application, the carbon dots carbonized by semen litchi can be used for detecting the methylene blue by quenching a fluorescent signal. As an effective means for detecting the methylene blue, the method shows a remarkable advantage. The detection limit is as low as 0.05micro mol / L and the linear response range is 0.8-10micro mol / L [R<2>=0.9930]. As being a fluorescent probe, a sensing system has the optical characteristics of simplicity, low cost, greenness, high selectivity, rapidness and sensitivity and is successfully applied to methylene blue detecting and living cell imaging analysis. The sensing method has a broad application prospect in the field of environmental analysis and the cell imaging analysis.

Owner:GUANGXI NORMAL UNIV

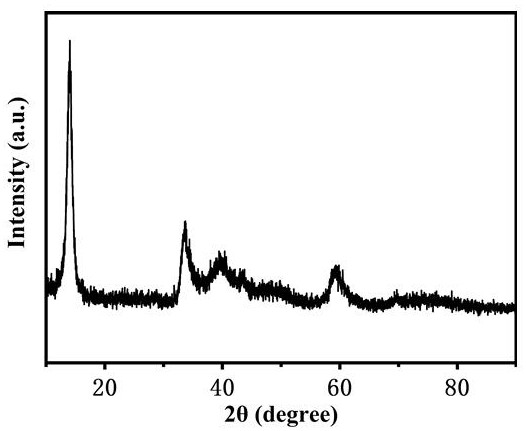

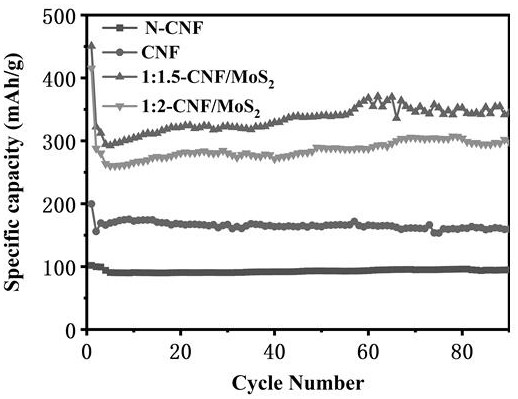

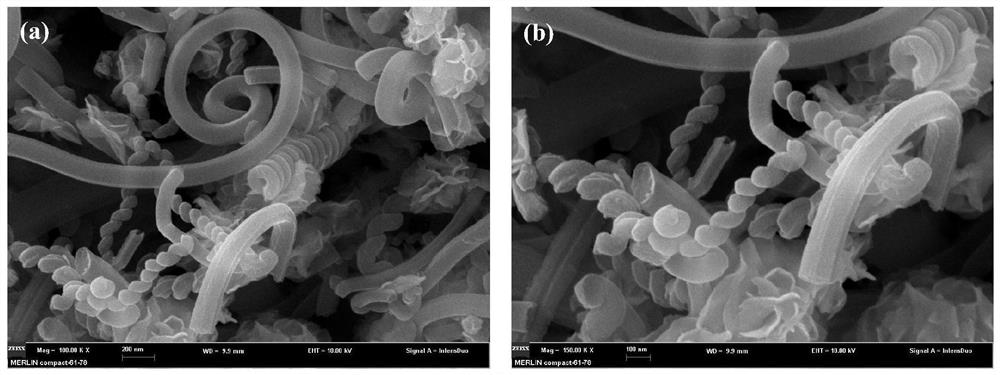

Sodium ion battery negative electrode material and preparation method thereof

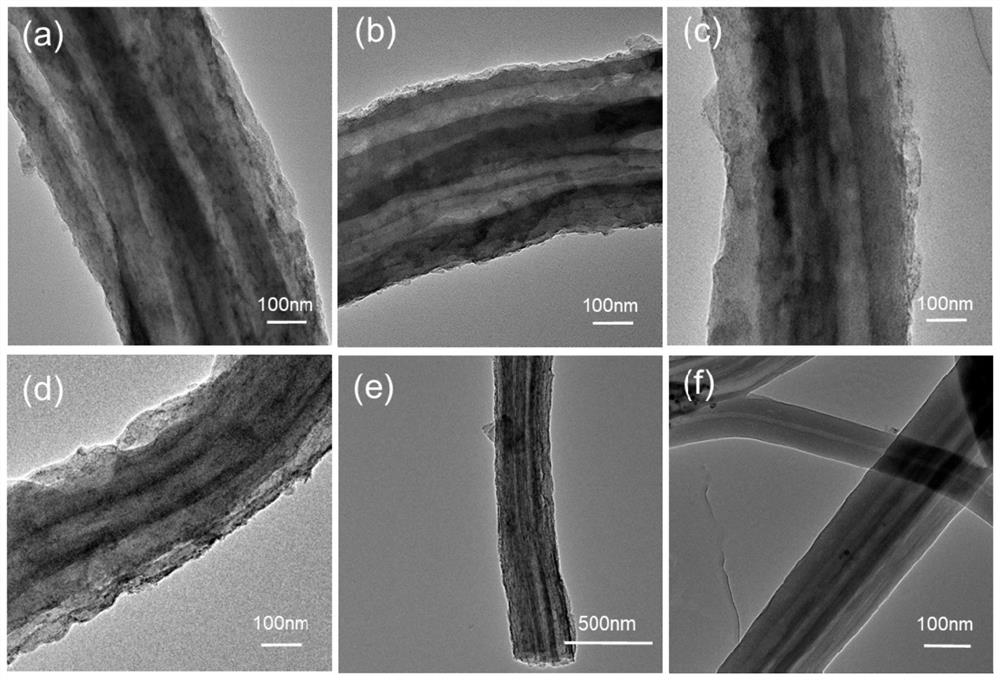

ActiveCN113622055AReduce energy consumptionLow costMaterial nanotechnologyCarbon fibresFiberCarbon fibers

The invention discloses a sodium ion battery negative electrode material and a preparation method thereof. The preparation method comprises the steps that spiral nanometer carbon fibers are prepared at low temperature through a chemical vapor deposition method, then the spiral nanometer carbon fibers are carbonized and acidified in sequence, finally, a molybdenum source, a sulfur source and the acidified spiral nanometer carbon fibers are mixed, and then the mixture is put into a reaction kettle for hydrothermal reaction, and then is subjected to centrifuging, freeze-drying and annealing to obtain the sodium ion battery negative electrode material. The sodium ion battery negative electrode material prepared by the method has good conductivity and cycling stability.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Carbonizer for continuously synthesizing calcium carbonate and production method of calcium carbonate

InactiveCN102295306BContinuous productionIncrease supersaturationCalcium/strontium/barium carbonatesNanotechnologyCalcium hydroxidePrecipitated calcium carbonate

The invention relates to a carbonizer for continuously synthesizing calcium carbonate and a production method of calcium carbonate, an input port of calcium hydroxide, an input port of carbon dioxide are provided on the body of the carbonizer, a discharge port is provided at the bottom of the carbonizer, the input port of calcium hydroxide and the input port of carbon dioxide are positioned at the top of the carbonizer body, the transverse trays with displacement from each other are uniformly arranged from the lower part to the bottom of two input ports in the body of the carbonizer, a layout of a S shape backflow baffle plate or a snaky shape backflow baffle plate is used between the adjacent trays. The calcium hydroxide slurry is a fluid suspension, and enables an equidirectional flow with carbon dioxide on the transverse trays between the trays, the calcium hydroxide slurry enters to the next tray from an outlet, three phases of gas, liquid and solid phase are reacted to generate precipitated calcium carbonate, the reacted material-carbonized boiled slurry is flowed out from the outlet of lower part of the reactor. The product has the advantages of adjustable particle size, narrow grain size distribution and stable quality, dispersibility, stability and alkali efflorescence are improved; the invention has the advantages of less equipment investment, short reaction time, less energy consumption, low cost, and the product enables continuous production.

Owner:连州市凯恩斯纳米材料有限公司

Production processing method of homogeneous carbonized wood of paulownia wood

InactiveCN104400866AImprove the homogenization effectPromote precipitationWood charring/burningPaulownia coreanaPaulownia

The invention relates to a production processing method of homogeneous carbonized wood of paulownia wood. The production processing method comprises the following steps of cutting and sawing, degreasing, drying, re-damping, stacking, feeding into a kiln, temperature rising, carbonizing, temperature lowering, and delivery out of the kiln. The production processing method has the beneficial effects that firstly the paulownia wood is degreased, so good foundation is laid for the homogeneous carbonizing; when the wood is fed into the kiln, the wood is coated by kaolin, air is completely isolated, and the uniform carbonizing effect is realized; after the kiln is sealed, the carbonizing temperature is integrally lowered, the carbonizing time is extended, the uniform carbonizing of the paulownia wood from exterior to exterior is guaranteed, and all parts of the paulownia wood have the good moisture absorbing property, size stability, mechanical property, anti-corrosive property, hardness and compressive strength, adhesion property, and surface coating property, especially same color property; by improving the degreasing method, the carbonizing auxiliary material, the carbonizing temperature and the carbonizing time, the carbonized wood can reach better homogenous effect; the adhesion effect is improved, and the application value and economic benefits of a product are increased.

Owner:CHONGQING HOUHUANG JIASHU WOOD IND

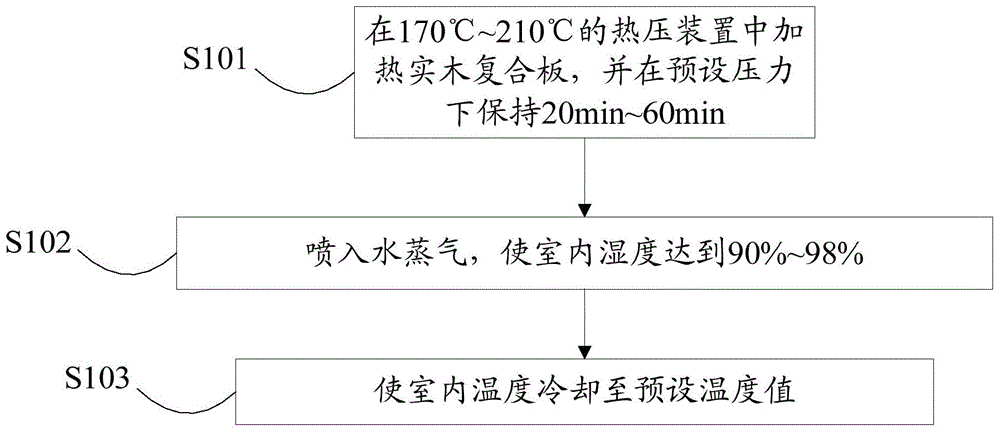

Charring solid-wood composite board and production method thereof

InactiveCN104875266AExpand application spaceFast temperature conductionWood veneer joiningWood charring/burningSolid woodWater vapor

The invention discloses a charring solid-wood composite board and a production method thereof. The charring solid-wood composite board production method includes the steps that step S101, a solid-wood composite board body is heated in a hot-press plant ranging from 170 DEG C to 210 DEG C in temperature and kept for 20 min to 60 min under the preset pressure; step S102, water vapor is sprayed into the hot-press plant, and the indoor humidity is made to reach 90% to 98%; step S103, the indoor temperature is made to be cooled to be at the preset temperature value. According to the charring solid-wood composite board and the production method, the solid-wood composite board body is put into the hot-press plant to be heated to be 170 DEG C to 210 DEG C and kept for 20 min to 60 min under the preset pressure, and charring and then cooling are conducted on the solid-wood composite board body, and charring is finished. The solid-wood composite board is smaller in thickness, and certain pressure is applied in the heating process, so that the heat conduction speed is high in the charring process, the charring time is shorter, accordingly the charring cost is reduced to a certain degree, the charring cycle is shortened, production efficiency is improved, and the application space of the solid-wood composite board is expanded.

Owner:桦甸市惠邦木业有限责任公司

Carbonizer and method for producing nano calcium carbonate

ActiveCN102531017BImprove product qualityUniform particle size distributionCalcium/strontium/barium carbonatesNanotechnologyCarbonizationSlurry

The invention discloses a carbonizer for producing nano calcium carbonate. The carbonizer comprises a calcium hydroxide blending tank, a calcium hydroxide slurry storage tank, a primary carbonization nucleation reactor, a primary carbonization growth reactor, a primary carbonization ageing tank, a secondary carbonization tubular reactor and a calcium hydroxide activating tank; and a slurry carbonization reaction tube and a carbon dioxide porous reaction tube which have two-end uninterrupted repeated arch structures are arranged in the primary carbonization nucleation reactor, the primary carbonization growth reactor and the secondary carbonization tubular reactor respectively. By the method for producing the nano calcium carbonate through the carbonizer, the calcium carbonate can be produced by the nucleation stage and the growth stage, and is controlled stepwise, the reaction degree of the whole carbonization process can be monitored, the nano calcium carbonate with uniform particle size distribution, regular crystal structures and stable quality can be produced, and the invention has the advantages of small equipment investment, short carbonization time, low energy consumption and the like.

Owner:连州市凯恩斯纳米材料有限公司

Biogas residue machine-made charcoal and preparation method thereof

InactiveCN107880913AImprove performanceStable combustionBiofuelsSolid fuelsCarbonizationVolumetric Mass Density

The invention provides biogas residue machine-made charcoal and a preparation method thereof. The preparation method comprises the following steps: (1) carrying out dry-wet separation on biogas residue and biogas slurry; (2) flatly paving for natural air drying; (3) crushing wood processing residues, so as to obtain crushed wood flour; (4) uniformly stirring the air-dried biogas residue with the wood flour, so as to obtain a mixed material; (5) drying the mixed material; (6) carrying out extrusion forming on the dried mixed material, so as to obtain a formed bar-shaped porous material; and (7)carbonizing the bar-shaped porous material, and naturally cooling under an anoxic condition, so as to obtain the machine-made charcoal. By effectively utilizing biogas residue, the formation pressurerequired for realizing a relax density standard of the machine-made charcoal is reduced, the formation energy consumption is reduced, the equipment loss is reduced, meanwhile, the carbonization temperature is low, the carbonization time is long, the production cost is low, the produced machine-made charcoal is good in property, and the combustion is stable.

Owner:DALIAN DEETOP ENVIRONMENTAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com