Method for measuring phospholipid in lipid

A method of determination, oil technology, which is applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions, which can solve problems such as cumbersome operation, long time-consuming carbonization, and difficult control of the carbonization process. Achieve the effect of simple and safe operation, shortening carbonization time and shortening ashing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 precision test

[0034] Take 5 crucibles, add 3.0g of Zanthoxylum bungeanum seed oil to each, then add 1.0mL of concentrated sulfuric acid and 3.0g of solid potassium hydroxide, place on a 600W electric furnace and heat for 15min to carbonize until the oil sample is solid, and then put it into a programmed heating Ashing in a furnace at 700°C for 1.5h, cooling to room temperature, dissolving and filtering with 50mL hot water, after cooling, adjust the pH value to about 3 with 1:1 hydrochloric acid, and set the volume to 100mL;

[0035] Pipette 10 mL of the above test solution into a 50 mL colorimetric tube, add 8 mL of hydrazine sulfate solution and 2 mL of sodium molybdate solution, stopper, shake well, remove the plug, place the colorimetric tube in a boiling water bath for 10 min, take it out, Cool to room temperature, dilute to the mark with water, shake well, let it stand for 10 min, and measure its absorbance with a spectrophotometer at 650 nm. Subst...

Embodiment 2

[0038] Embodiment 2 Recovery test

[0039] Prepare phosphorus standard solutions of low, medium and high concentrations respectively, add them to Fulinmen first-grade refined soybean oil, and measure the phosphorus content therein after mixing. The operating conditions are the same as those in Example 1. See Tables 2, 3, and 4 for specific experimental data;

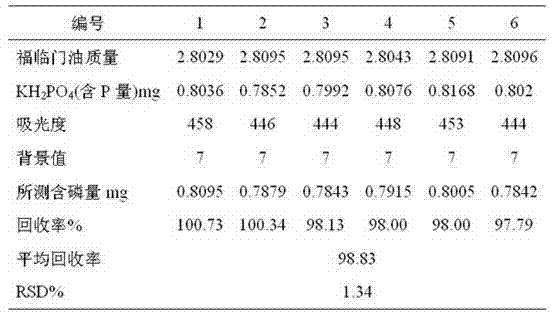

[0040] Table 2 Experimental results of recovery at high concentration (with P content about 0.8 mg)

[0041]

[0042] Table 3 Experimental results of recovery at medium concentration (containing about 0.4 mg of P)

[0043]

[0044] Table 4 Experimental results of recovery at low concentration (with P content about 0.1 mg)

[0045]

[0046] As can be seen from Tables 2, 3, and 4, the recovery rate is between 97.57% and 101.88%, and the accuracy of the present invention meets the detection requirements.

[0047] Comparative experiment Comparative experiment with GB5537-2008

[0048] Repeat the above measuremen...

Embodiment 3

[0058] Example 3 Detection of Phospholipid Content in Tung Oil Crude Oil

[0059] ( ) Preparation of phosphate standard stock solution: Weigh 0.4387 g of potassium dihydrogen phosphate dried for 24 hours, dissolve with water and dilute to 1000mL;

[0060] ( ) Preparation of hydrazine sulfate solution: dissolve 0.15 g hydrazine sulfate in 1L water to obtain 0.015% hydrazine sulfate solution;

[0061] ( ) Preparation of sodium molybdate dilute sulfuric acid solution: Measure 140mL of concentrated sulfuric acid and pour it into 300mL of water, cool to room temperature, add 12.5 g of sodium molybdate, dissolve and dilute to 500mL with water, shake well, and let it stand for 24 hours for later use;

[0062] (4) Preparation of hydrochloric acid solution: dissolve 37% concentrated hydrochloric acid in equal volume of water;

[0063] (5) Draw the standard curve: Add 0, 1, 2, 4, 6, 8 mL of phosphate standard solution to 6 colorimetric tubes, add water to make up to 10 mL; then a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com