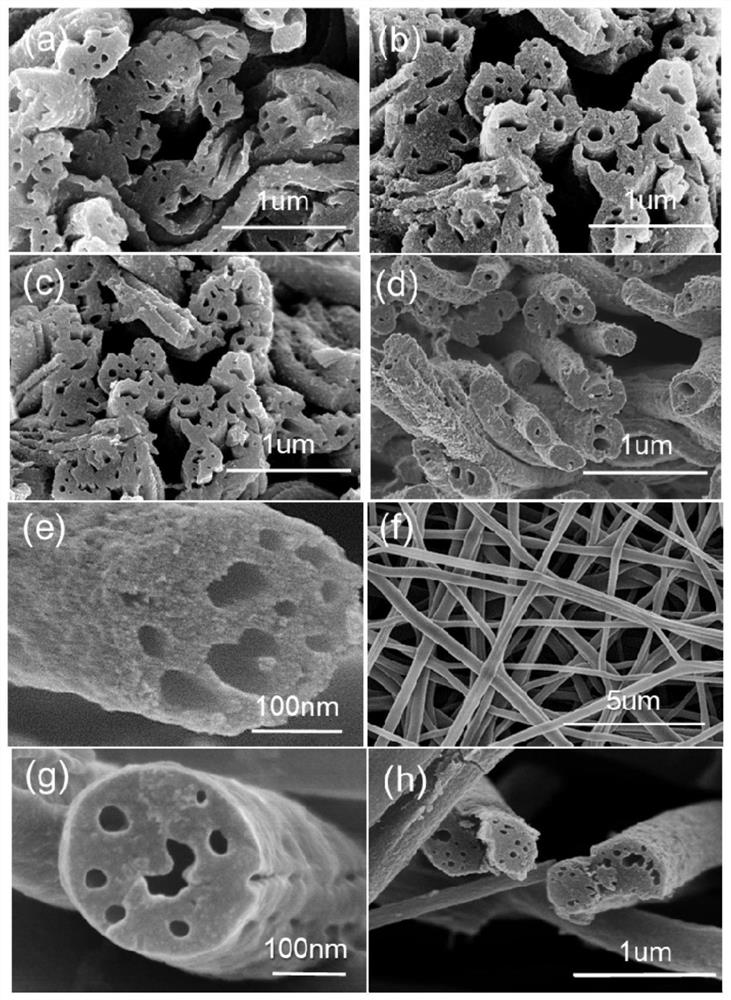

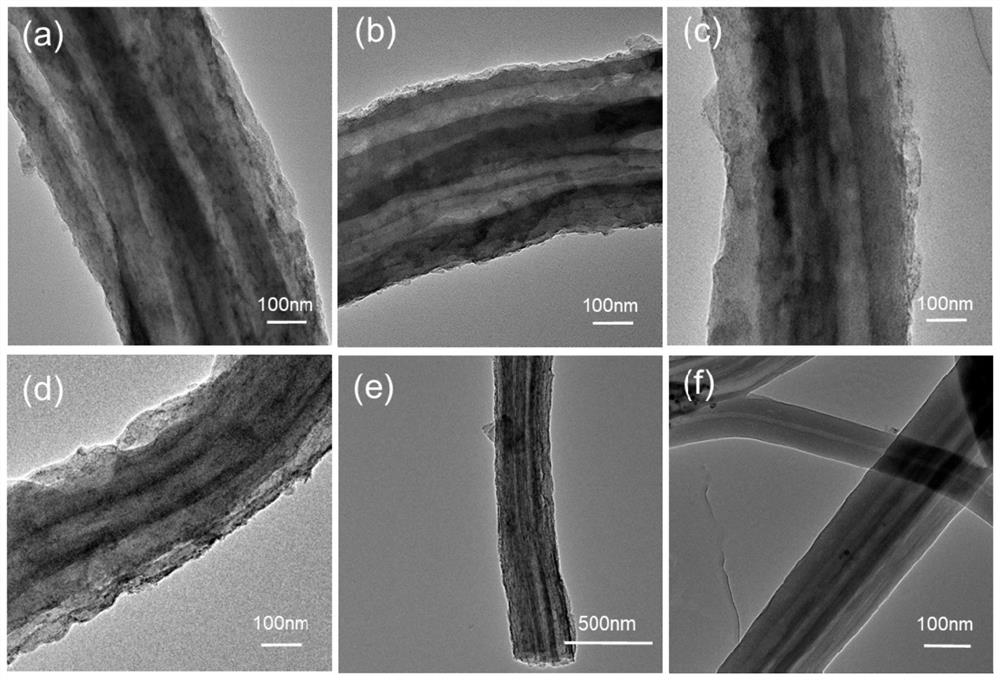

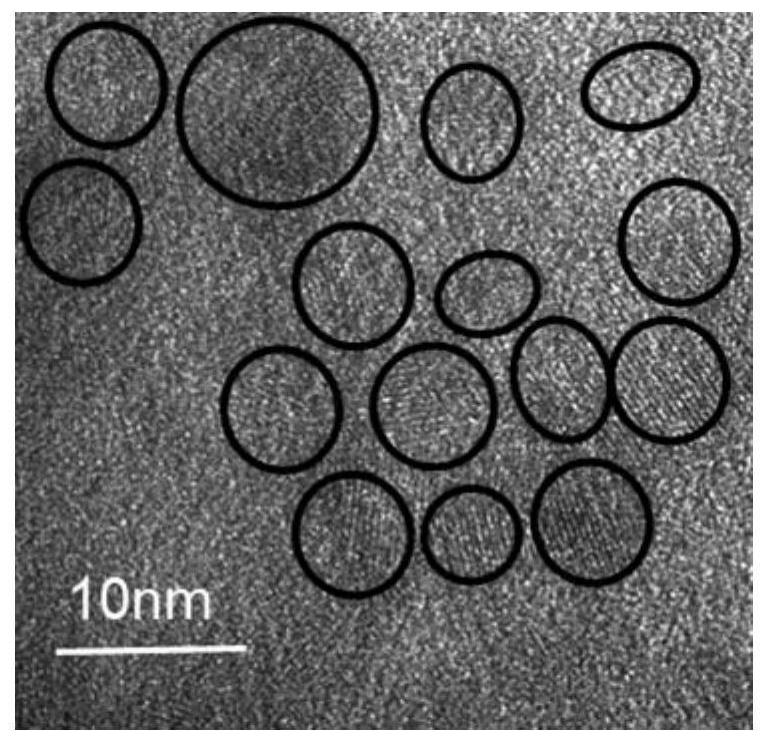

Porous multi-hollow flexible composite nanofiber membrane material and preparation method thereof

A technology of composite nanofibers and nanofibers, applied in hollow filament manufacturing, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of uneven dispersion of nanoparticles, reduced long-term performance, and poor fiber adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Method for preparing a porous multi-hollow flexible composite nanofiber film material, the specific steps are as follows:

[0050] (1) An outer solution of coaxial electrospinning and an inner layer solution of coaxial electrospinning;

[0051] Preparation of an outer solution of coaxial electrostatic spinning: Methyl methacrylate and polypropylene nitrile dissolved in N, N-dimethylformamide under 42 ° C, stirred for 6 h, mix well; wherein polypropylene Nitrile, polymethyl methacrylate and N, N-dimethylformamide mass ratio is 8: 2: 100;

[0052] Preparation of the inner layer of coaxial electrostatic spinning: Under 36 ° C, polymethyl methacrylate is dissolved in N, N-dimethylformamide, stirred for 5 h, then add titanate, stir 0.5 H, mixed uniform; molar ratio of tetrabutyrate and polymethyl methacrylate is 48: 1; polymethyl methacrylate and N, N-dimethylformamide mass ratio of 20: 100;

[0053] (2) In the disposable syringe of the outer solution of coaxial electrospinning ...

Embodiment 2

[0058] Method for preparing a porous multi-hollow flexible composite nanofiber film material, the specific steps are as follows:

[0059] (1) An outer solution of coaxial electrospinning and an inner layer solution of coaxial electrospinning;

[0060] Preparation of outer solution of coaxial electrostatic spinning: Methyl methacrylate and polypropylene nitrile in C, N-dimethylformamide under 25 ° C, stirred for 12 h, mix well; common polypropylene Nitrile, polymethyl methacrylate and N, N-dimethylformamide mass ratio of 11: 5: 100;

[0061] Preparation of the inner layer of coaxial electrostatic spinning: Under 25 ° C, polymethyl methacrylate is dissolved in N, N-dimethylformamide, stirred for 12 h, then titanate tetrabutyl, stirred for 2h , Mixed well; molar ratio of tetrabutyrate and polymethyl methacrylate is 95: 1; polymethyl methacrylate and N, N-dimethylformamide mass ratio of 28: 100;

[0062] (2) In the disposable syringe of the outer solution of coaxial electrospinning an...

Embodiment 3

[0067] Method for preparing a porous multi-hollow flexible composite nanofiber film material, the specific steps are as follows:

[0068] (1) An outer solution of coaxial electrospinning and an inner layer solution of coaxial electrospinning;

[0069] Preparation of outer solution of coaxial electrostatic spinning: Methyl methacrylate and polypropylene nitrile in N, N-dimethylformamide under 15 ° C, stirred for 12 h, mixed uniform; polypropylene Nitrile, polymethyl methacrylate and N, N-dimethylformamide mass of 9: 3: 100;

[0070] Preparation of the inner layer of coaxial electrostatic spun: Under 52 ° C, polymethyl methacrylate is dissolved in N, N-dimethylformamide, stirred for 3 h, then titanate tetrabutyl, stirred for 1 h , Mixed well; molar ratio of tetibutyl titanate and polymethyl methacrylate is 191: 1; polymethyl methacrylate and N, N-dimethylformamide mass ratio of 22: 100;

[0071] (2) In the disposable syringe of the outer solution of coaxial electrospinning and coaxial...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com