Preparation method of lignin-based porous carbon material

A lignin-based, porous carbon material technology, applied in the field of preparation of lignin-based porous carbon materials, can solve the problems of high consumption, heavy metal pollution, equipment, environmental damage, etc., to reduce the cost of carbon production, increase yield, and produce The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

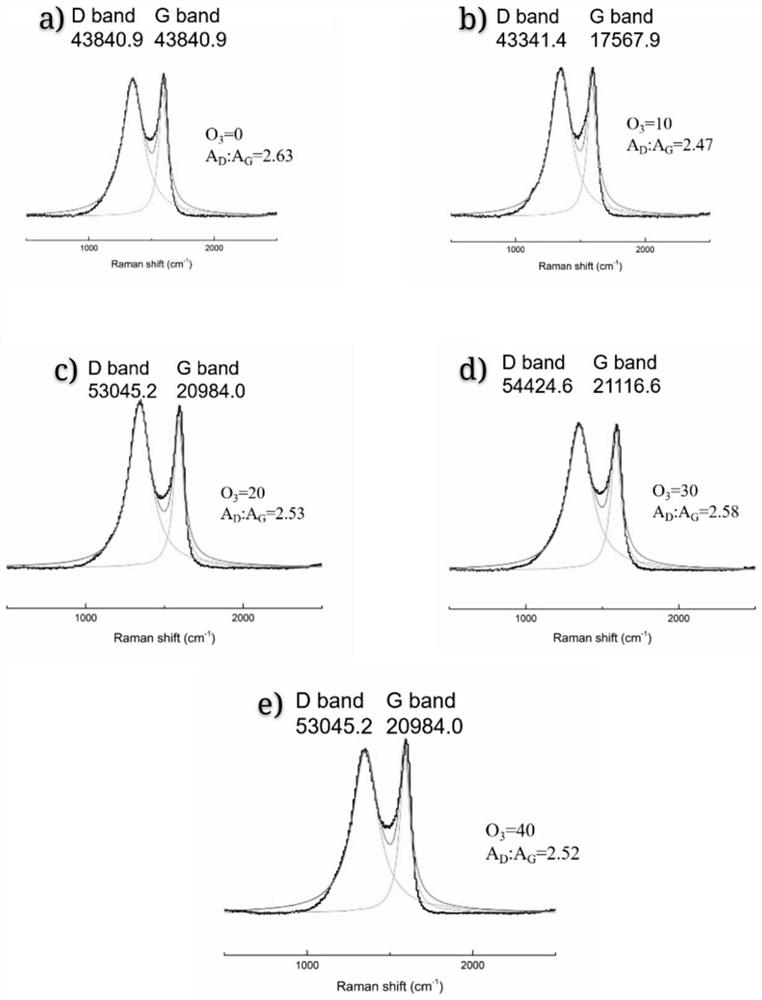

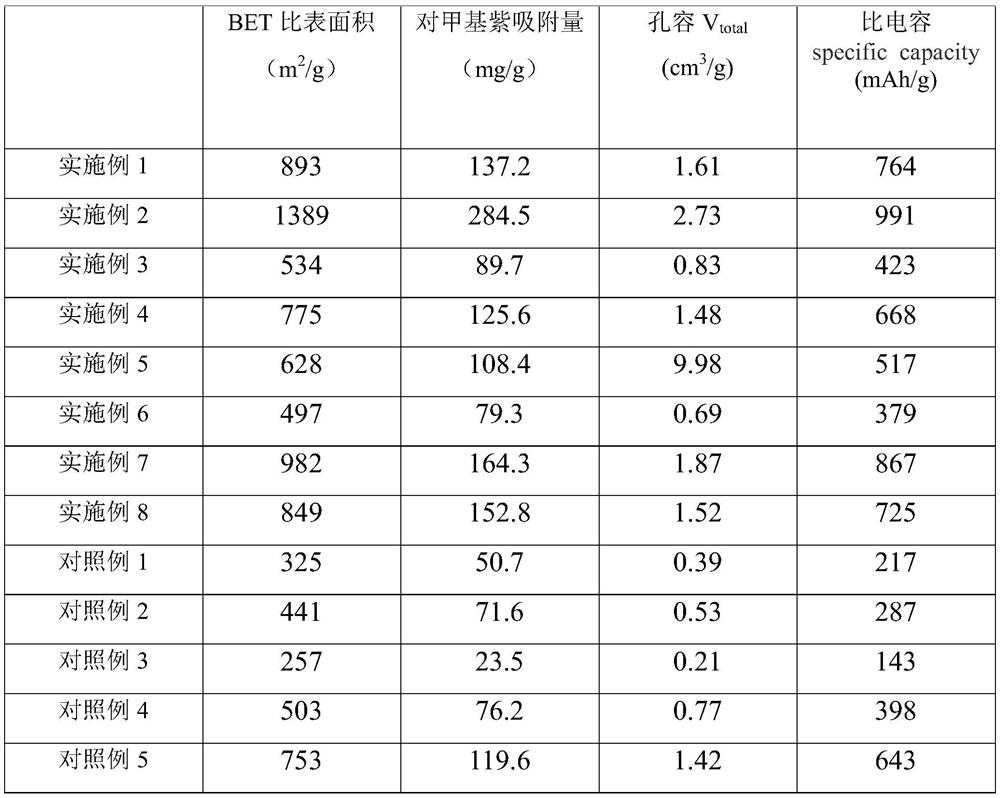

Embodiment 1

[0026]Take 3g of sodium hydroxide, 3g of lignin, 1g of hydrogen peroxide (concentration of 30%, AR) to make 100mL alkaline solution with water, then add 2g of melamine pyrophosphate, put it in a three-necked flask, magnetically stir for 6h, and ultrasonically disperse for 1h , And then spray drying (outlet temperature 100 ℃), the obtained powder is put into a tube furnace, using an odor generator to blow air into the tube furnace for 40 minutes (ozone content about 3.33g), 190 ℃ low temperature carbonization for 2 hours, heating at It is calcined at a high temperature in a nitrogen atmosphere at a temperature of 850°C. The obtained carbon block is pickled, washed with water, pulverized with an ultrafine wet pulverizer, and finally vacuum dried for 12 hours to obtain the final product carbon material. The yield of the carbon material obtained in this example was 17%, and the high-temperature carbonization time was 55 minutes.

Embodiment 2

[0028]Take 3g of sodium hydroxide, 3g of lignin, 1g of hydrogen peroxide (concentration of 30%, AR) and add water to make a 100mL alkaline solution, then add 6g of melamine pyrophosphate, put it into a three-necked flask, magnetically stir for 6h, and ultrasonically disperse for 1h , And then spray drying (outlet temperature 100 ℃), the obtained powder is put into a tube furnace, using an odor generator to blow air into the tube furnace for 40 minutes (ozone content about 3.33g), 190 ℃ low temperature carbonization for 2 hours, heating at It is calcined at a high temperature in a nitrogen atmosphere at a temperature of 850°C. The obtained carbon block is pickled, washed with water, pulverized with an ultrafine wet pulverizer, and finally vacuum dried for 12 hours to obtain the final product carbon material. The yield of the carbon material obtained in this embodiment was 26.8%, and the high-temperature carbonization time was 20 minutes.

Embodiment 3

[0030]Take 3g of sodium hydroxide, 3g of lignin, 1g of hydrogen peroxide (concentration of 30%, AR) to make 100mL alkaline solution with water, then add 2g of melamine pyrophosphate, put it in a three-necked flask, magnetically stir for 6h, and ultrasonically disperse for 1h , And then spray drying (outlet temperature 100 ℃), the obtained powder is put into a tube furnace, using an odor generator to blow into the tube furnace for 20 minutes (ozone content about 3.33g), 190 ℃ low temperature carbonization for 2 hours, heating at It is calcined at a high temperature in a nitrogen atmosphere at a temperature of 850°C. The obtained carbon block is pickled, washed with water, pulverized with an ultrafine wet pulverizer, and finally vacuum dried for 12 hours to obtain the final product carbon material. The yield of the carbon material obtained in this embodiment is 10%, and the high-temperature carbonization time is 60 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com