Processing method of surface-carbonized poplar solid wood floor

A processing method and carbonization technology, applied in the direction of wood processing utensils, wood treatment, manufacturing tools, etc., can solve the problems of aggravating the shortage of high-quality wood supply, unable to use solid wood floors, easy to deform, etc., to achieve the degree of carbonization and uniformity, easy to control, Maintain natural performance, save time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of processing method of surface carbonized poplar solid wood floor provided by the invention comprises the following steps:

[0022] S1. Surface densification treatment: Saw poplar wood into poplar boards with a thickness of 20mm, put them in a drying kiln and dry them to a moisture content of 10%, and then put them into a hot press for compression and densification treatment. The surface of the poplar board is sprayed and softened for 5 minutes, and kept for 15 minutes under hot pressing pressure of 1.1MPa and temperature of 180°C;

[0023] S2, cutting the poplar plank into floor blanks, the size of which is 920×127×16mm;

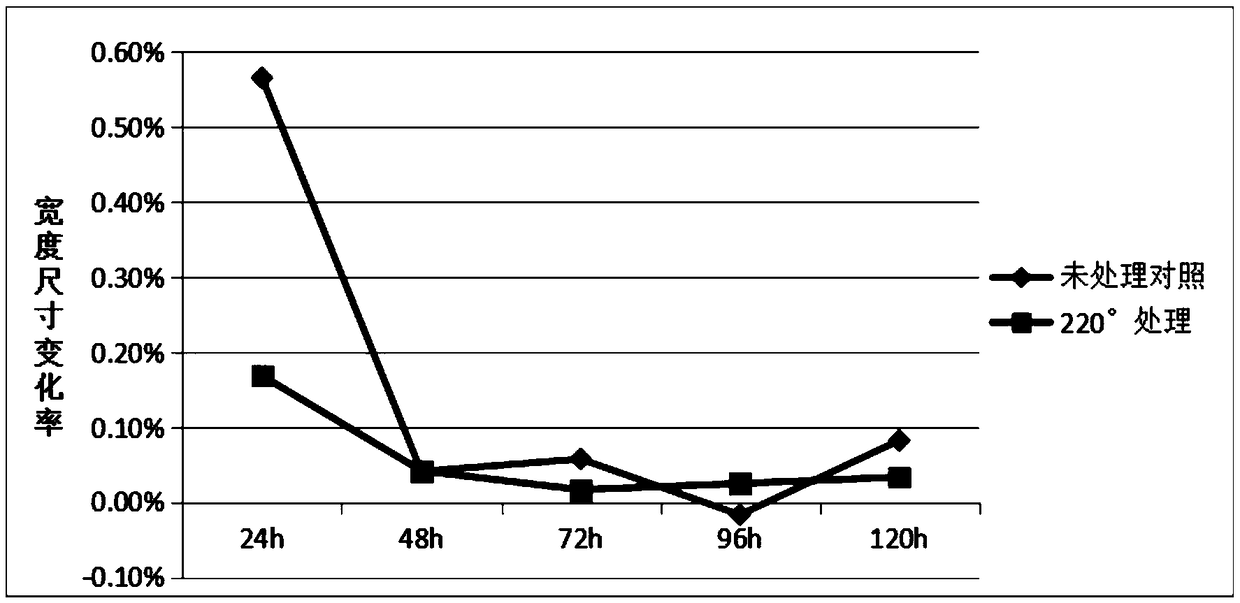

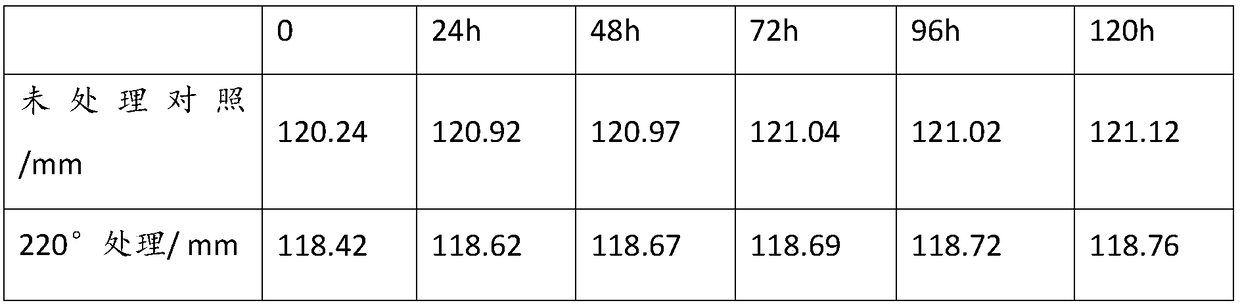

[0024] S3. Carbonization treatment of floor blank material: put the floor blank into a high-temperature carbonization tank, use steam or nitrogen as a protective gas, and carry out carbonization treatment. The carbonization temperature is 220°C and the time is 15 minutes; the carbonization treatment in step S3 is carried out in four stages. ...

Embodiment 2

[0027] S1. Surface densification treatment: Saw poplar wood into poplar boards with a thickness of 25mm, put them in a drying kiln and dry them to a moisture content of 12%, and then put them into a hot press for compression and densification treatment. The surface of the poplar board is sprayed and softened for 3 minutes, and kept for 20 minutes under hot pressing pressure of 1MPa and temperature of 160°C;

[0028] S2, cutting the poplar board into floor blanks, the size of which is 920×127×18mm;

[0029] S3. Carbonization treatment of floor blank material: put the floor blank into a high-temperature carbonization tank, use steam or nitrogen as a protective gas, and carry out carbonization treatment. The carbonization temperature is 280 ° C, and the time is 20 minutes; the carbonization treatment in step S3 is carried out in four stages. In the preheating stage, the carbonization furnace is first heated to 150°C for preheating. The second stage is the rapid heating stage: qui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com