Chitosan activated carbon and preparation method thereof

A chitosan and activated carbon technology, applied in the field of chitosan activated carbon, can solve the problems of animal biomass carbon conversion, which have not been reported, and achieve the effects of easy implementation, short carbonization time, and complex equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

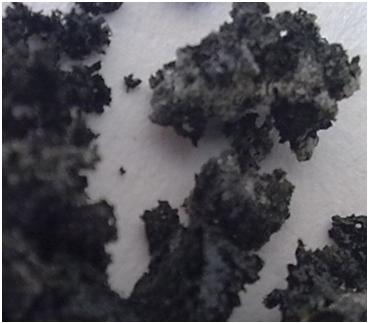

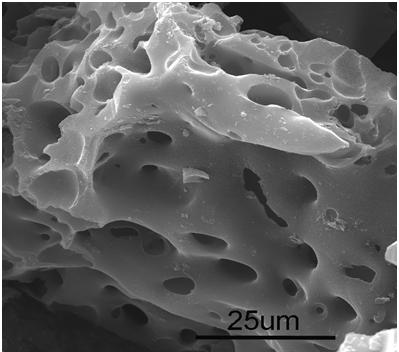

[0014] Specific embodiment 1: In this embodiment, chitosan-based activated carbon is prepared from chitosan as a raw material, activated by a metal ion solution, and then subjected to microwave carbonization, pickling, water washing, centrifugation and drying. The appearance is Black, porous structure, amorphous pores, pore diameter 2nm~5μm, pore volume 0.20~45.00cm 3 / g, the specific surface area is 500~996m 2 / g.

[0015] The chitosan activated carbon composition described in the present embodiment is made up of C, H, N and O, and the C element mass percentage content is 78%~94% in the described chitosan activated carbon mass percentage content, and the H element mass percentage content is 0.14%~1.52%, the mass percentage content of N element is 0.98%~8.22%, and the balance is O.

specific Embodiment approach 2

[0016] Specific embodiment two: the preparation method of chitosan activated carbon in the present embodiment is carried out according to the following steps: one, chitosan powder is dissolved in the acetic acid solution that concentration is 0.01~0.05g / mL, prepare chitosan Sugar concentration is 0.02 ~ 0.06g / mL chitosan acid solution; 2, the chitosan acid solution prepared in step 1 is poured into a concentration of 0.03 ~ 0.10g / mL NaOH solution to precipitate chitosan hydrogel, and then use Wash the chitosan hydrogel with ionic water until the pH is 7, then soak the chitosan hydrogel in a metal ion solution with a concentration of 0.02-0.30 g / mL, and activate it at room temperature for 0.5-48 hours, wherein the metal ion solution The metal ions in it can chelate with chitosan; 3. Then carbonize for 6-15min at a microwave power of 500-800W, and then pickle, wash, centrifuge and dry to obtain chitosan Activated carbon.

specific Embodiment approach 3

[0018] Specific embodiment three: the difference between this embodiment and specific embodiment two is: the metal ion in the metal ion solution described in step two is Cu 2+ , Zn 2+ 、Ni 2+ , Fe 2+ , Fe 3+ or Co 2+. Other steps and parameters are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com