Spherical calcium carbonate and preparation method thereof

A calcium carbonate, spherical technology, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of low content of spherical calcium carbonate, unfavorable industrial production, high cost, etc., and achieve uniform shape, short carbonization time and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

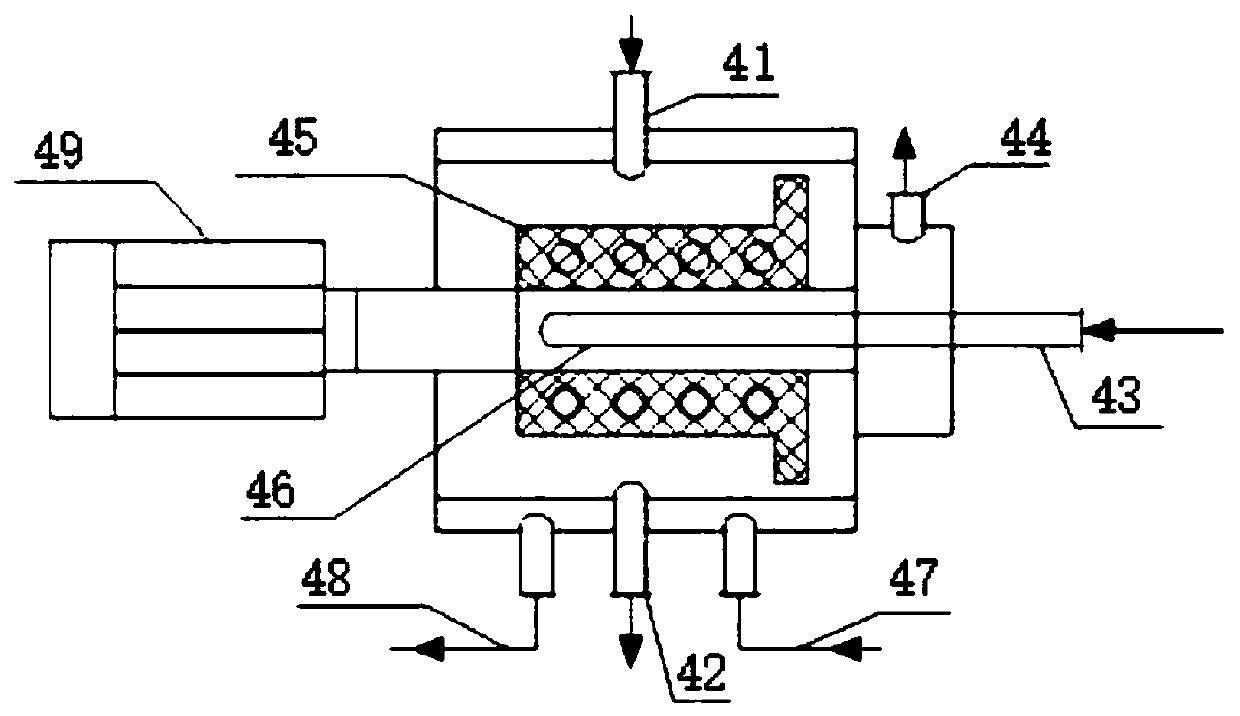

Image

Examples

Embodiment 1

[0031] A preparation method for spherical calcium carbonate, comprising the following steps:

[0032] S1. Digest quicklime and hot water at a mass ratio of 1:10, pass through a 200-mesh sieve to remove impurities, add ethanol solution with a volume fraction of 30% as a solvent, adjust and refine to obtain calcium hydroxide with a concentration of 70g / L slurry;

[0033] S2. drop the calcium hydroxide slurry configured in step S1 into the circulating feed liquid tank of the process device of the high gravity carbonization reaction process, add the 5wt% glutamic acid of the calcium hydroxide slurry configured in step S1 as crystal type control agent, set the carbonization temperature to 10°C, and the carbon dioxide gas flow to 0.6m 3 / h, the rotor speed of the supergravity reactor is set to 1000rpm, and the calcium hydroxide slurry and carbon dioxide gas are contacted in countercurrent to carry out the carbonization reaction; the digital display pH meter is used to track the who...

Embodiment 2

[0036]A preparation method for spherical calcium carbonate, comprising the following steps:

[0037] S1. Digest quicklime and hot water at a mass ratio of 1:5, pass through a 200-mesh sieve to remove impurities, add ethanol solution with a volume fraction of 80% as a solvent, adjust and refine to obtain calcium hydroxide with a concentration of 115g / L slurry;

[0038] S2. drop the calcium hydroxide slurry configured by step S1 into the circulating feed liquid kettle of the processing device of the high gravity carbonization reaction process, add the aspartic acid of 1wt% of the calcium hydroxide slurry configured by step S1 as Crystal form control agent, set the carbonization temperature to 40°C and the flow rate of carbon dioxide to 0.2m 3 / h, the rotor speed of the supergravity reactor is set to 1800rpm, let the calcium hydroxide slurry contact with the carbon dioxide gas countercurrently, and carry out the carbonization reaction; use the digital display pH meter to track t...

Embodiment 3

[0041] A preparation method for spherical calcium carbonate, comprising the following steps:

[0042] S1. Digest quicklime and hot water at a mass ratio of 1:8, pass through a 200-mesh sieve to remove impurities, add ethanol solution with a volume fraction of 60% as a solvent, adjust and refine to obtain calcium hydroxide with a concentration of 105g / L slurry;

[0043] S2. drop the calcium hydroxide slurry configured in step S1 into the circulating feed liquid tank of the process device of the high gravity carbonization reaction process, add the 3wt% glutamic acid of the calcium hydroxide slurry configured in step S1 as crystal type control agent, set the carbonization temperature to 30°C, and the carbon dioxide gas flow to 0.5m 3 / h, the rotor speed of the supergravity reactor is set to 1600rpm, and the calcium hydroxide slurry and carbon dioxide gas are contacted in countercurrent to carry out the carbonization reaction; the digital display pH meter is used to track the who...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com