Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Reduce solid waste generation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

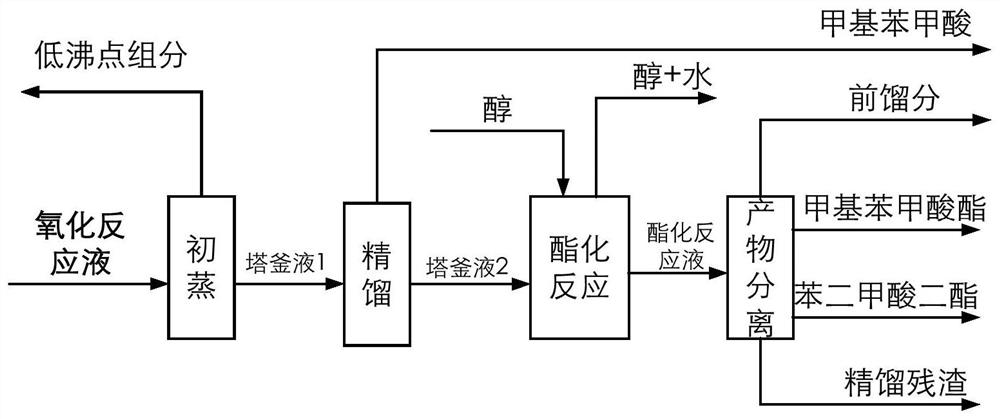

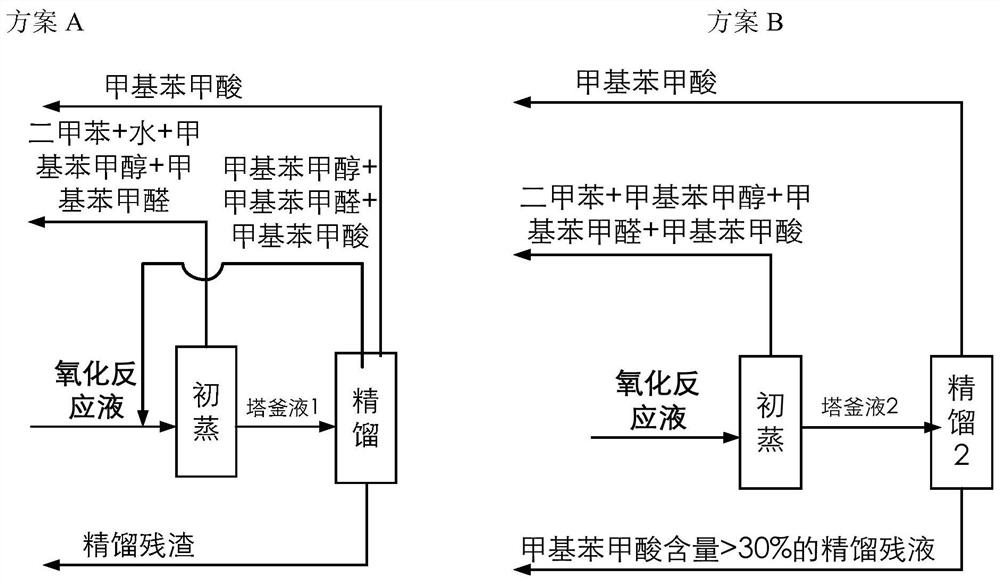

Coproduction method of methylbenzoic acid, methyl benzoate and benzenedicarboxylic acid diester

ActiveCN108047034ARaw materials are easy to getStructural diversificationOrganic compound preparationCarboxylic acid esters preparationAlcoholDistillation

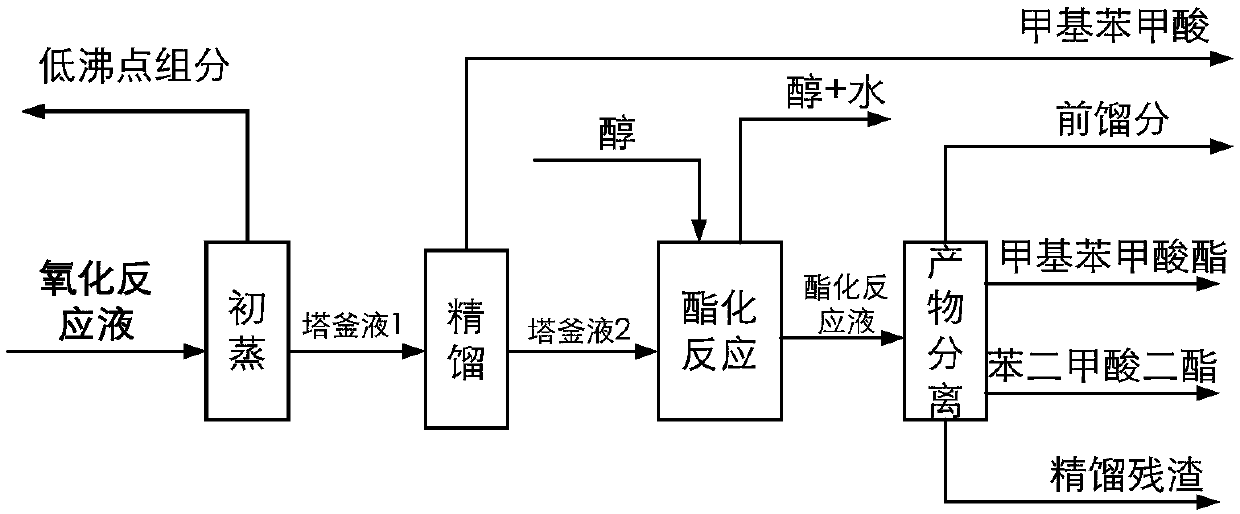

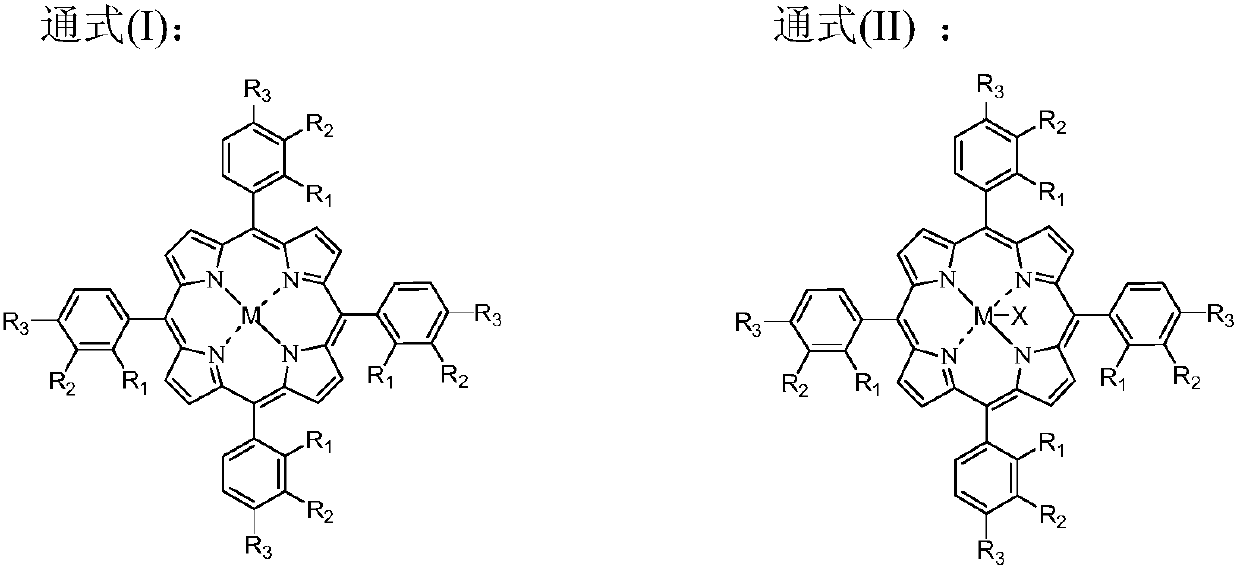

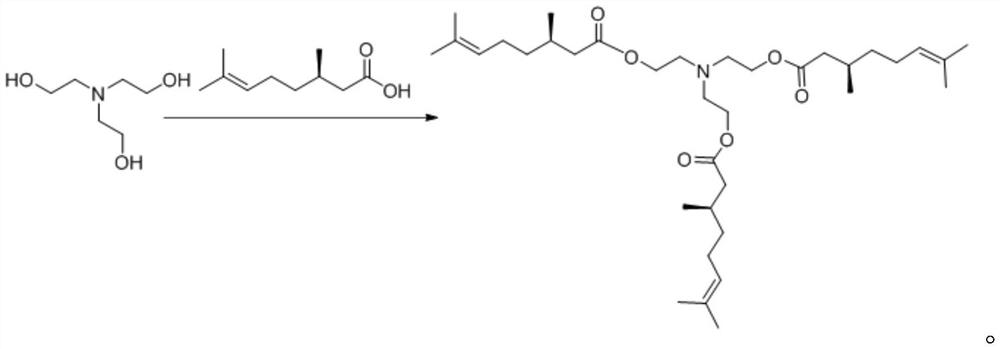

The invention discloses a coproduction method of methylbenzoic acid, methyl benzoate and benzenedicarboxylic acid diester. The method comprises the following steps: (1) continuously introducing xylene, a catalyst and oxygen-containing gas into an oxidation reactor for a reaction, and controlling oxygenic concentration in the tail gas to not exceed 5% by controlling introduction amount of the oxygen-containing gas to obtain an oxidation reaction liquid; (2) feeding the obtained oxidation reaction liquid into a predistillation tower for distillation separation to obtain a low-boiling-point component and a predistillation tower bottom liquid; (3) feeding the predistillation tower bottom liquid into a distillation tower for distillation to obtain a methylbenzoic acid product and a distillationtower bottom liquid; (4) mixing the distillation tower bottom liquid and alcohol for an esterification reaction, and controlling the reaction endpoint to be lower than 0.5wt% of the content of methylbenzoic acid to obtain an esterification reaction liquid; (5) performing distillation separation on the obtained esterification reaction liquid to obtain methyl benzoate and benzenedicarboxylic acid diester products. The method has the advantages that the process is simple, equipment investment is low, and the method is environmentally friendly and has good comprehensive economic benefits.

Owner:JIANGXI KEYUAN BIOPHARM

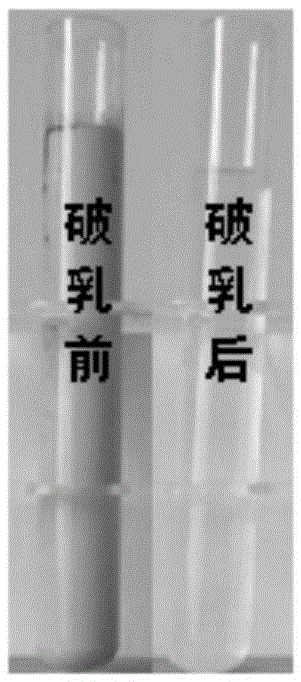

Waste emulsion demulsification processing method

InactiveCN106630246AGood demulsification effectStrong adaptability to water qualityWater/sewage treatment by centrifugal separationTreatment involving filtrationChemical oxygen demandIndustrial waste water

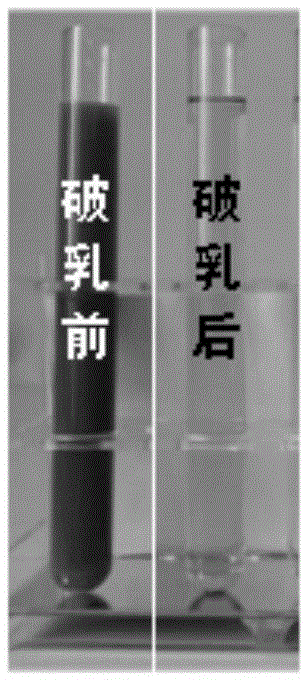

The invention belongs to the field of industrial waste water treatment, and relates to a waste emulsion demulsification processing method. The method employs at least one of bentonite, diatomite and activated clay as an adsorbent, employs at least one of polymeric aluminium, polymerization ferric chloride, polyferric sulfate and polyacrylamide as a flocculating agent, and performs demulsification processing on waste emulsion, wherein grease adsorption is carried out by an adsorbent, flocculation settlement is carried out by a flocculating agent, and solid-liquid separation is carried out. The method has the advantages of simple process, low operation cost, low energy consumption and high processing efficiency. the used agent has the advantages of nontoxicity and innocuousness, low cost and easy acquisition, has obvious maneuverability, and can be widely used for processing the waste emulsion, waste cutting fluid and waste saponification liquor for metal product, machining and other industries. According to the invention, more than 90% of chemical oxygen demand (COD) in the waste emulsion can be removed by a one step, and favorable condition can be provided for subsequent deep treatment such as chemical oxidation and biodegradation.

Owner:ZHANGJIAGANG GREEN TECH ENVIRONMENTAL PROTECTION EQUIP

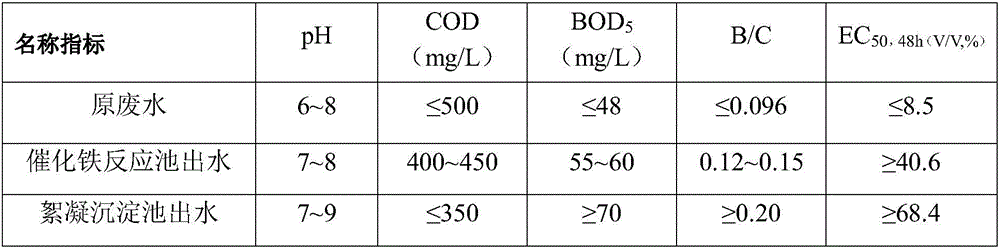

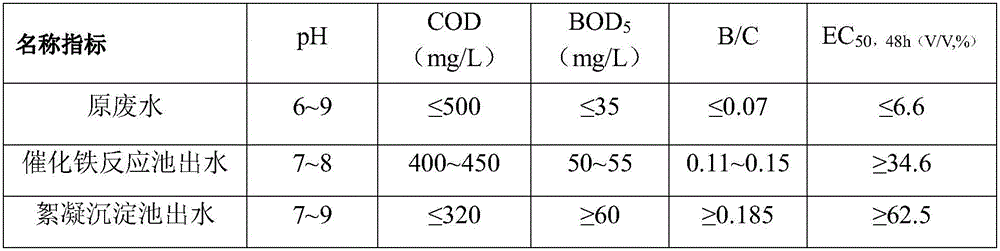

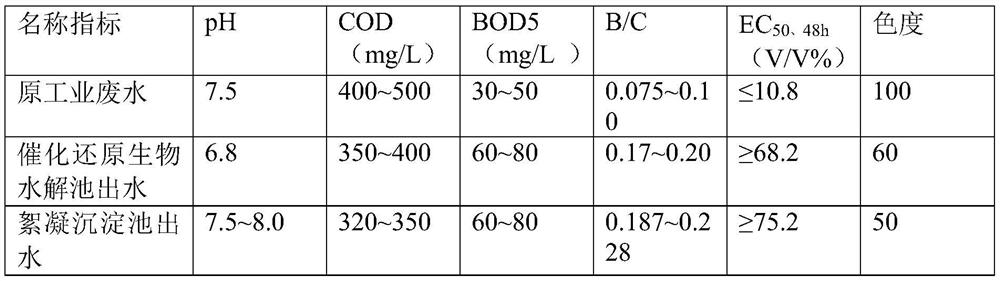

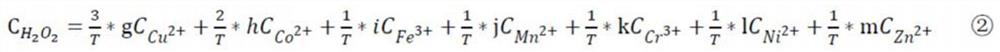

Method for pretreating wastewater in industrial zone based on coupling oxidation of catalyzed iron reduction and application thereof

InactiveCN106673274AImprove biodegradabilityLow biological toxicityMultistage water/sewage treatmentWater/sewage treatment by neutralisationWater qualityToxic material

The invention discloses a method for pretreating wastewater in an industrial zone based on coupling oxidation of catalyzed iron reduction and an application thereof, and belongs to the technical field of organic industrial wastewater treatment. The process is carried out as described in the description. According to the characteristics of wastewater quality of an industrial zone, a treatment technology based on coupling oxidation of catalyzed iron reduction is adopted, an industrial zone wastewater pretreatment technology of 'reductively promoting wastewater B / C and reducing biotoxicity and oxidatively subtracting biologically inhibited organic pollutant ingredients' is developed, the wastewater biodegradability can be remarkably improved, and toxic action of toxic substances in waste water on microorganisms can be effectively reduced. The method has the advantages of stable treatment effect and strong impact resistance, provides excellent pretreatment technical guarantee to up-to-standard emission of wastewater treatment in the industrial zone and upgrading and reconstruction, and has an excellent popularization and application prospect.

Owner:NANJING UNIV +1

Sodium chloride-containing pesticide production wastewater resource treatment system and method

InactiveCN108128968AMaintain microbial biomassIncrease concentrationGeneral water supply conservationWater contaminantsReverse osmosisWater quality

The invention discloses a sodium chloride-containing pesticide production wastewater resource treatment system and method, and belongs to the field of a sewage treatment method. The system comprises asalt-tolerant bacterium biochemical system, a nanofiltration membrane device, an electrodialysis device and an electrocatalytic oxidation device, wherein the salt-tolerant bacterium biochemical system comprises a first salt-tolerant bacterium aerobic device, a salt-tolerant bacterium anaerobic device and a second salt-tolerant bacterium aerobic device; the second salt-tolerant bacterium aerobic device comprises a salt-tolerant bacterium MBR device; the treatment system also comprises a reverse osmosis device. The invention also discloses a wastewater treatment method. The flow process of themethod of the salt-tolerant bacterium biochemical treatment, MBR treatment, nanofiltration membrane treatment, electrodialysis treatment and electrocatalytic treatment is used; after the pesticide production wastewater is subjected to treatment, the water quality of produced water is high; when the system and the method are applied to enterprise production, water resources in the waste water are recovered; the general organic carbon content in the obtained sodium chloride salt wastewater is low; the system and the method can be used for chlor-alkali production; sodium chloride salt in the wastewater is recovered.

Owner:JIANGSU LASON CHEM ENVIRONMENTAL PROTECTION

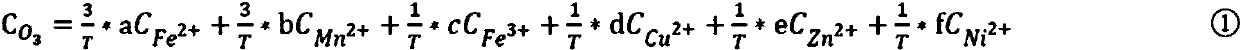

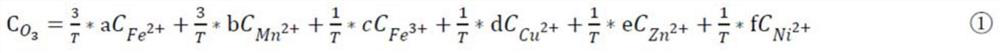

Wastewater processing control method for promoting advanced oxidation effect

ActiveCN110451681AReduce secondary pollutionGuaranteed response speedWater contaminantsMultistage water/sewage treatmentWater qualityOxidative treatment

The invention discloses a wastewater processing control method for promoting the advanced oxidation effect, and belongs to the field of wastewater processing. The method comprises following steps: (1)detecting the kinds and corresponding mole concentrations of heavy metal ions in wastewater; (2) adding an oxidizing agent into wastewater to carry out an advanced oxidation treatment, wherein the addition amount of the oxidizing agent is determined based on the content of heavy metal ions in the wastewater; (3) detecting the effluent of the step (2), and stopping the advanced oxidation treatment, if the COD concentration is not greater than 50 mg / L and the TOC concentration is not more than 20 mg / L; if not, carrying out a further advanced oxidation treatment. The method has the advantages that the actual water quality is taken into account, the oxidation reaction efficiency is maximized, the medicaments are effectively saved at the same time, and the operation cost is reduced therefore.

Owner:NANJING UNIV +1

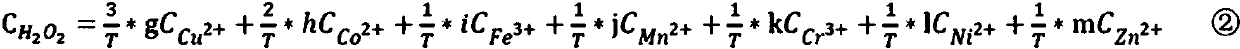

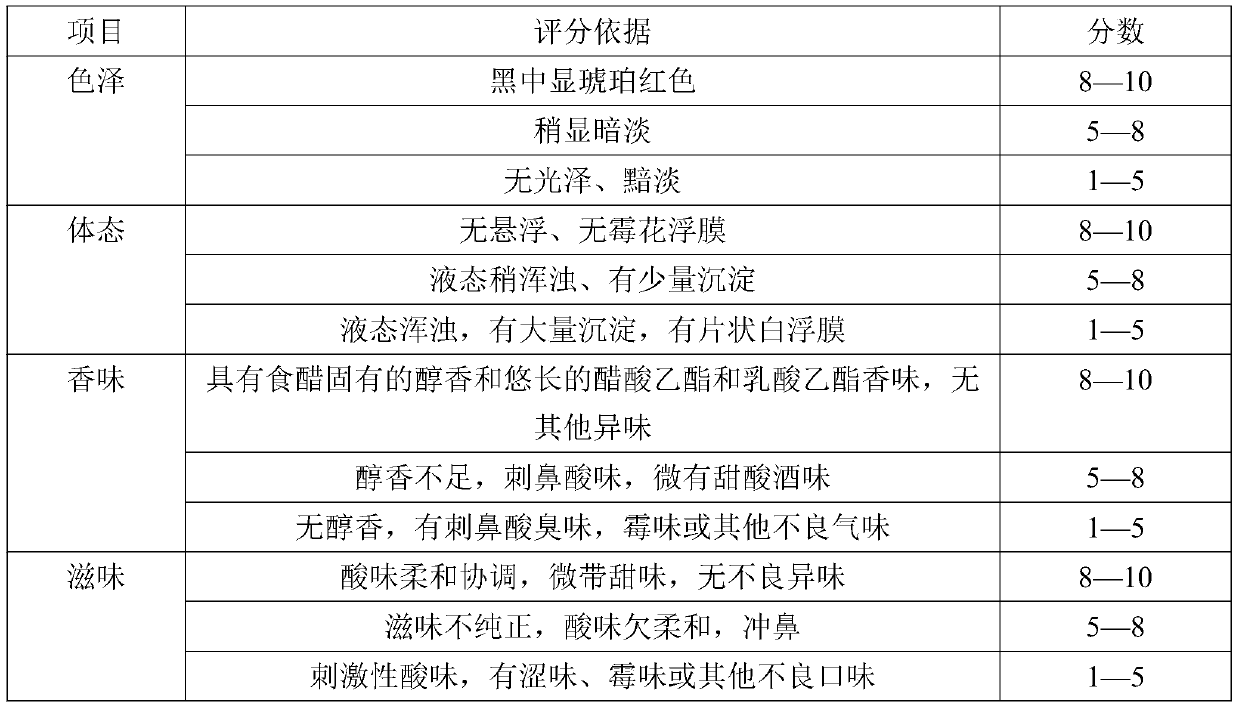

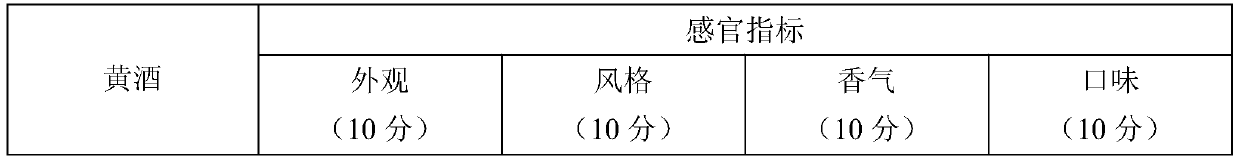

Method for co-producing yellow rice wine and table vinegar by utilizing dendrobium nobile

PendingCN110951574AReduce solid waste generationEnvironmentally friendlyAlcoholic beverage preparationVinegar preparationDendrobiumBran

The invention belongs to the field of food seasonings, and particularly relates to a method for co-producing yellow rice wine and table vinegar by utilizing dendrobium nobile. The dendrobium nobile, rice and the like are used as raw materials to brew dendrobium nobile yellow rice wine, then by-product yellow rice wine dregs are mixed with bran, rice husks and wine to brew dendrobium nobile vinegar, and dendrobium nobile is used for co-producing yellow rice wine and vinegar. The yellow rice wine dregs obtained after dendrobium yellow rice wine is brewed are further utilized, the generation of solid waste is reduced while two products are obtained, which is more environmentally friendly, and economic benefits of enterprises can be improved. The umami of table vinegar is improved. The bioactive components in the table vinegar are improved, and the health-care effect of the table vinegar is further improved.

Owner:WUXI RES INST OF APPLIED TECH TSINGHUA UNIV

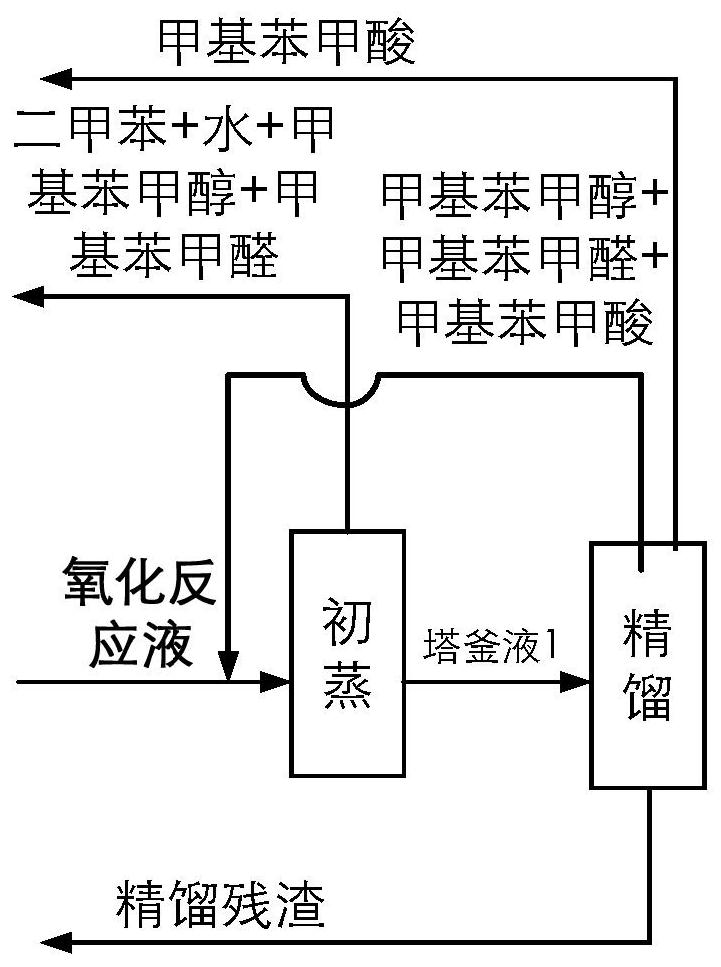

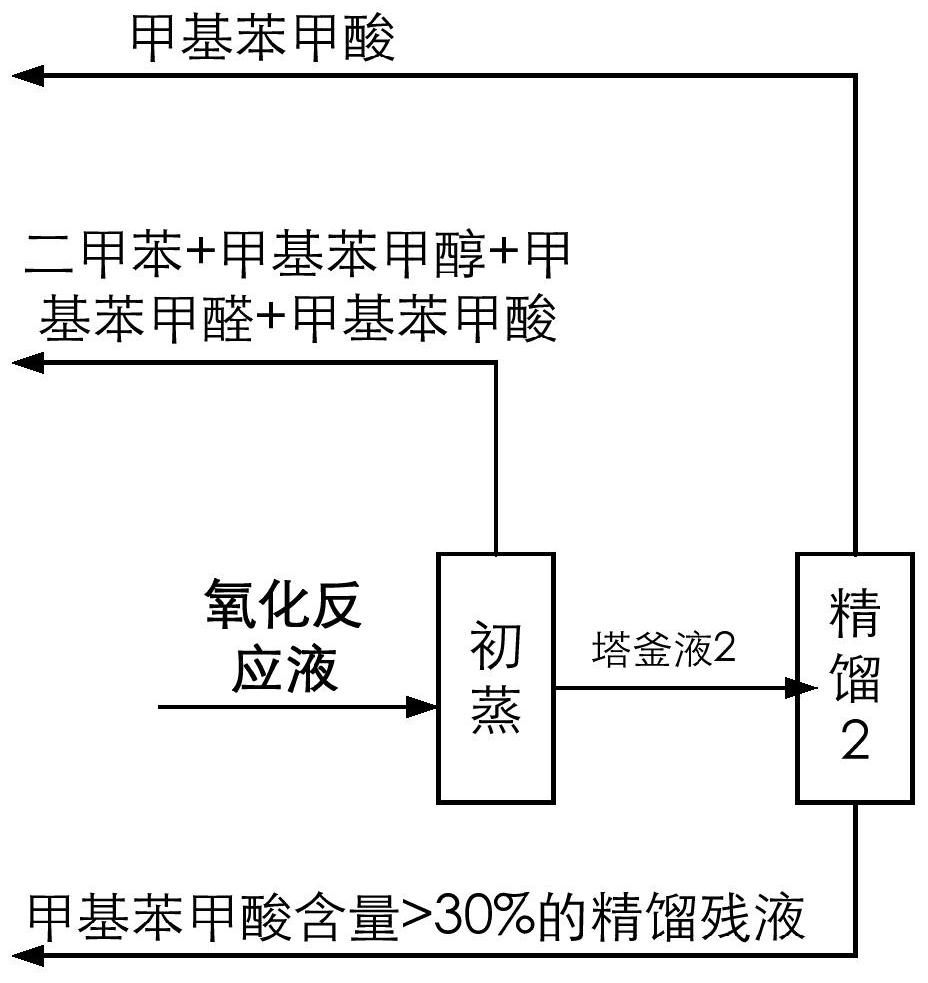

A method for co-producing methylbenzoic acid, methylbenzoic acid ester and phthalic acid diester

ActiveCN108047034BRaw materials are easy to getStructural diversificationOrganic compound preparationCarboxylic acid esters preparationBenzoic acidXylylene

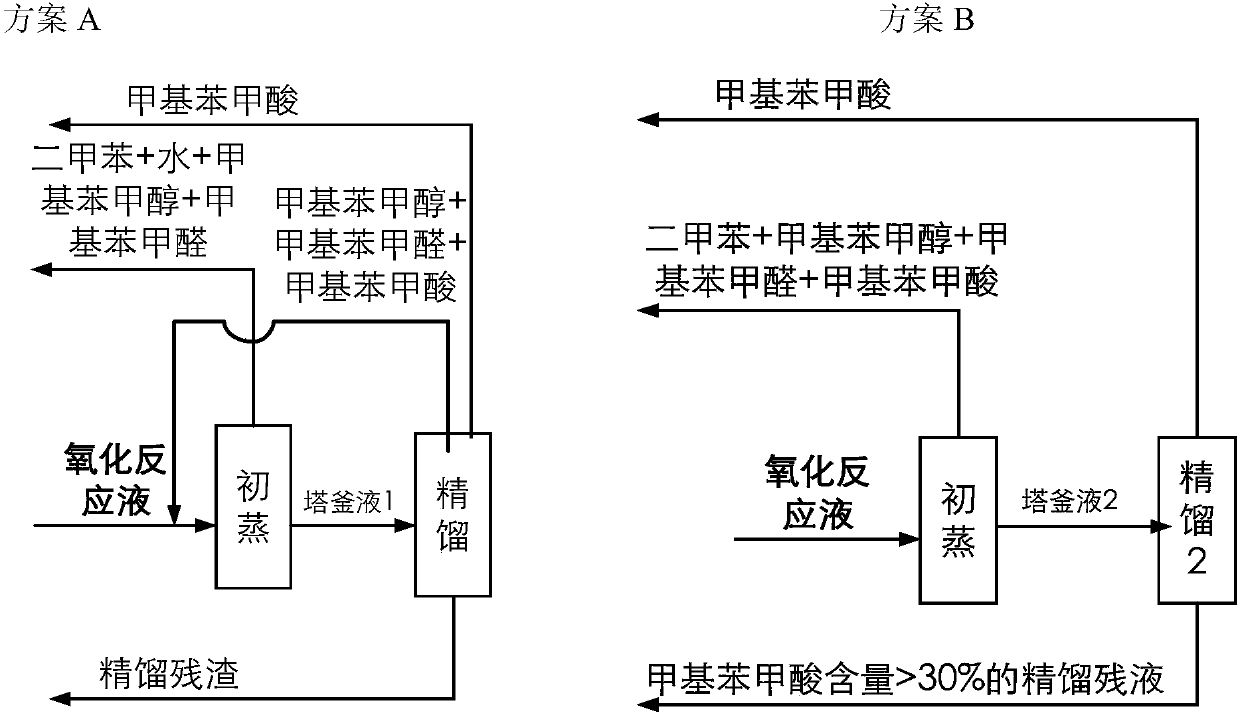

The invention discloses a method for co-producing methyl benzoic acid, methyl benzoate and phthalic acid diester, comprising: (1) continuously feeding xylene, a catalyst and an oxygen-containing gas into an oxidation reactor to carry out reaction, by controlling the amount of oxygen-containing gas to control the tail oxygen concentration to be no more than 5%, to obtain an oxidation reaction liquid; (2) enter the obtained oxidation reaction liquid into an initial distillation tower for rectification separation, to obtain low boiling point components and initial (3) enter the rectifying tower still liquid into the rectifying tower for rectification to obtain toluic acid product and rectifying tower still liquid; (4) mix the rectifying tower tower liquid with alcohol , carry out the esterification reaction, control the reaction end point to be that the content of toluic acid<0.5wt%, obtain the esterification reaction solution; (5) carry out rectification separation with the esterification reaction solution obtained, obtain methyl benzoic acid ester respectively and diester phthalate products. The invention has the advantages of simple process, less equipment investment, environmental protection and good comprehensive economic benefits.

Owner:JIANGXI KEYUAN BIOPHARM

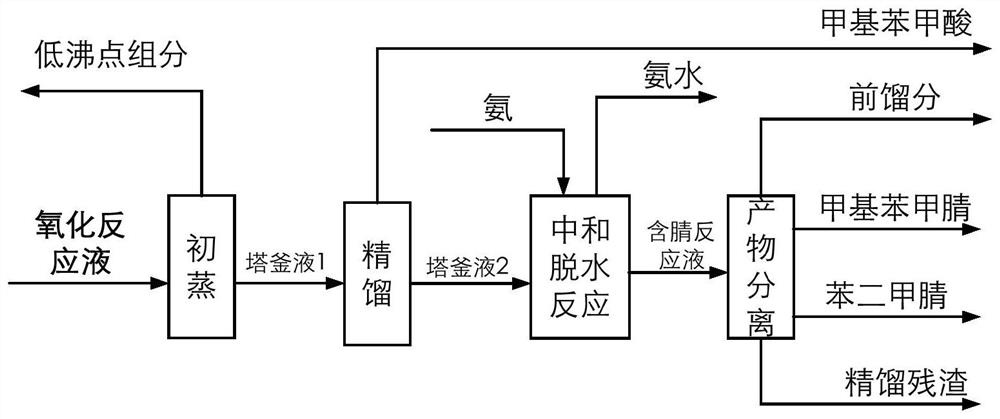

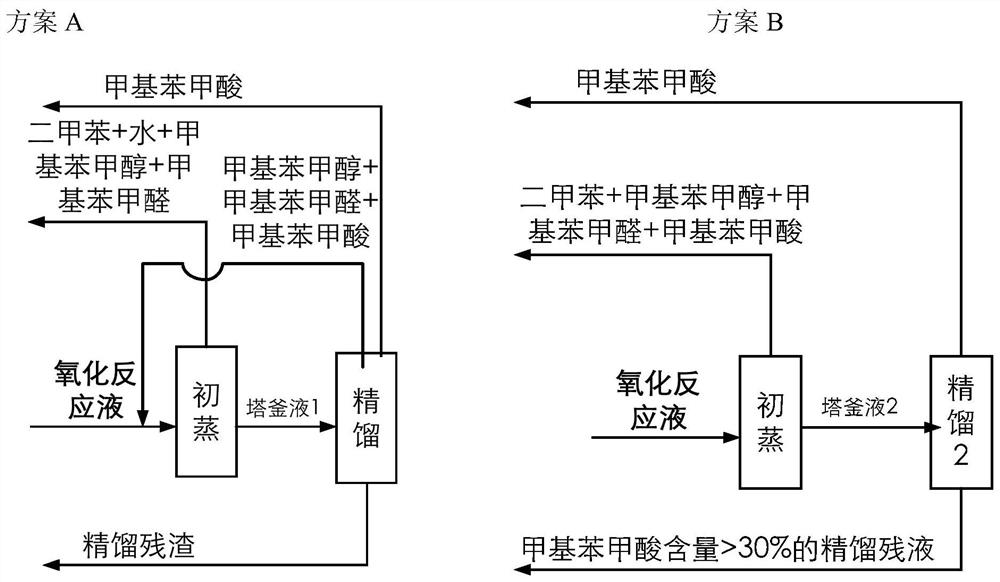

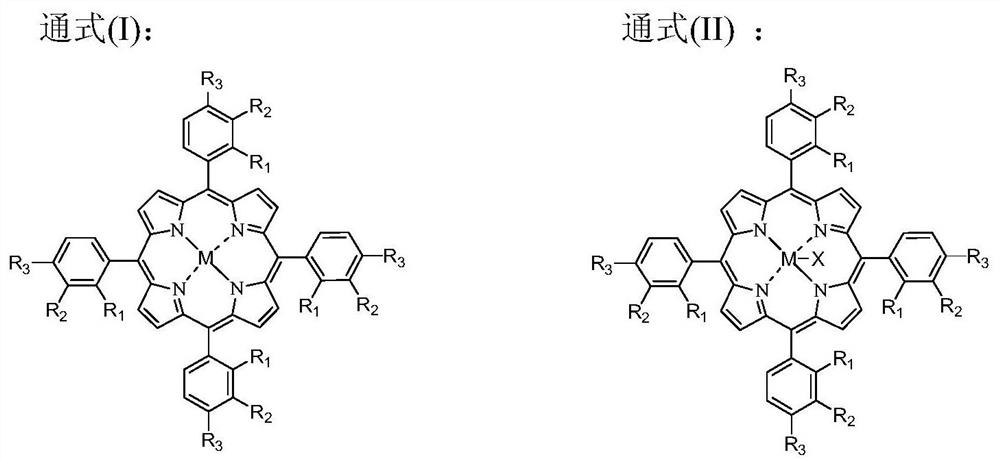

A kind of co-production methyl benzoic acid, methyl benzonitrile and phthalonitrile method

ActiveCN108863757BHigh concentration of production industryImprove concentrationOrganic compound preparationPreparation by ammonia-carboxylic acid reactionBenzoic acidPtru catalyst

The invention discloses a method for co-producing methylbenzoic acid, methylbenzonitrile and phthalonitrile, comprising: (1) continuously feeding xylene, a catalyst and an oxygen-containing gas into an oxidation reactor for reaction, Obtain the oxidation reaction liquid; (2) enter the oxidation reaction liquid into the initial distillation tower and carry out rectification separation, stop the rectification when the methyl benzyl alcohol content reaches 0.01~0.15wt% in the initial distillation tower bottom liquid, obtain low boiling point component and (3) enter the rectification tower with the initial distillation tower still liquid; (3) stop rectification when toluic acid content reaches 30~90wt% in the rectifying tower tower still liquid, obtain formosan (4) mixing the rectifying tower and tower liquid with ammonia to obtain a nitrile-containing reaction liquid; (5) carrying out rectification and separation of a nitrile-containing reaction liquid to obtain methylbenzene respectively Carbonitrile and phthalonitrile products. The invention has the advantages of simple process, less equipment investment, environmental protection and good comprehensive economic benefits.

Owner:JIANGXI KEYUAN BIOPHARM

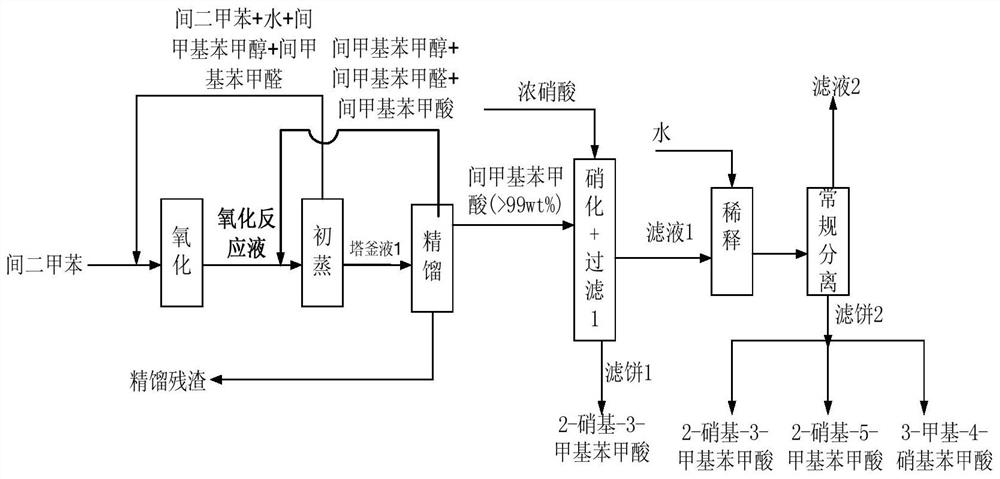

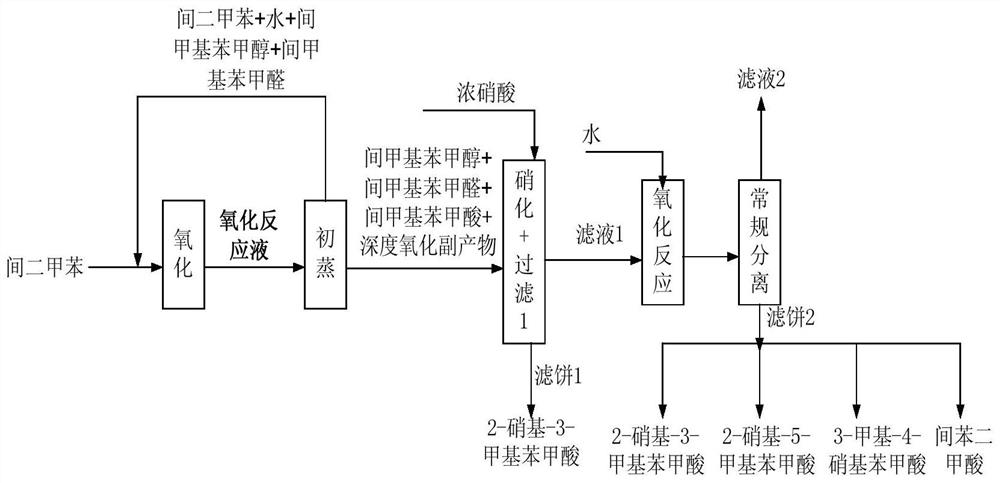

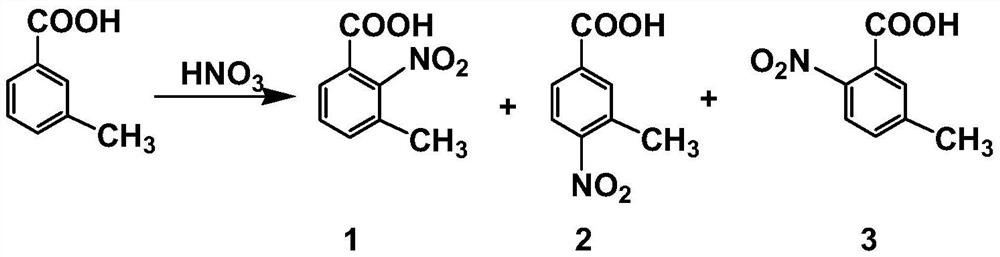

Method for co-producing m-toluic acid nitride and isophthalic acid

ActiveCN112441926ALow resolutionSolve benefitsOrganic compound preparationCarboxylic compound preparationBenzoic acidMethyl benzene

The invention discloses a method for co-producing m-toluic acid nitride and m-phthalic acid. The method takes a coarse distillation tower bottom liquid in an m-toluic acid production process as a rawmaterial and comprises the following steps: (1) adding the coarse distillation tower bottom liquid into nitric acid for reaction to obtain a nitration reaction solution; (2) filtering the nitration reaction solution obtained in the step (1) to obtain a first filtrate and a first filter cake, and washing and drying the first filter cake to obtain a product 2-nitro-3-methyl benzoic acid; (3) mixingthe first filtrate obtained in the step (2) with water to obtain a nitric acid aqueous solution, and carrying out an oxidation reaction to obtain a nitric acid oxidation reaction solution; and (4) crystallizing and filtering the nitric acid oxidation reaction solution obtained in the step (3) to obtain a second filtrate and a second filter cake, and refining the second filter cake to obtain the products 2-nitro-3-methyl benzoic acid, 2-nitro-5-methyl benzoic acid, 3-methyl-4-nitro benzoic acid and isophthalic acid. The method has the advantages of simple process, low equipment investment, environmental protection and good comprehensive benefits.

Owner:山东友道化学有限公司

Filtering device and filtering method for reducing nuclear power filtering solid waste quantity

InactiveCN113599882AReduce solid waste generationReduce processing costsStationary filtering element filtersNuclear powerFiltration

The invention discloses a filtering device and a filtering method for reducing nuclear power filtering solid waste quantity. The filtering device comprises a filter shell, a filter element assembly, a water inlet pipe, a water outlet pipe, a water inlet valve, a water outlet valve and a filter element cleaning structure, wherein the filter element assembly is arranged inside the filter shell, a water inlet and a water outlet are formed in the filter shell, a water inlet pipe is arranged at the water inlet, and a water inlet valve is arranged on the water inlet pipe; the water outlet pipe is arranged at the water outlet and is provided with a water outlet valve; and the water inlet is positioned below the water outlet. According to the filtering device, the filter element cleaning structure is arranged, the filter element assembly can be cleaned and regenerated, the problem that an original filter element cannot be recycled is solved, the filtering device is adopted for filtering, long-term operation can be achieved, the filter element does not need to be frequently replaced, and the filtering device has the advantages of reducing the maintenance frequency, reducing the solid waste output of the filter element and reducing filter element solid waste quantity. And the device is suitable for radioactive water filtration of the nuclear power station.

Owner:AT&M ENVIRONMENTAL ENG TECH CO LTD

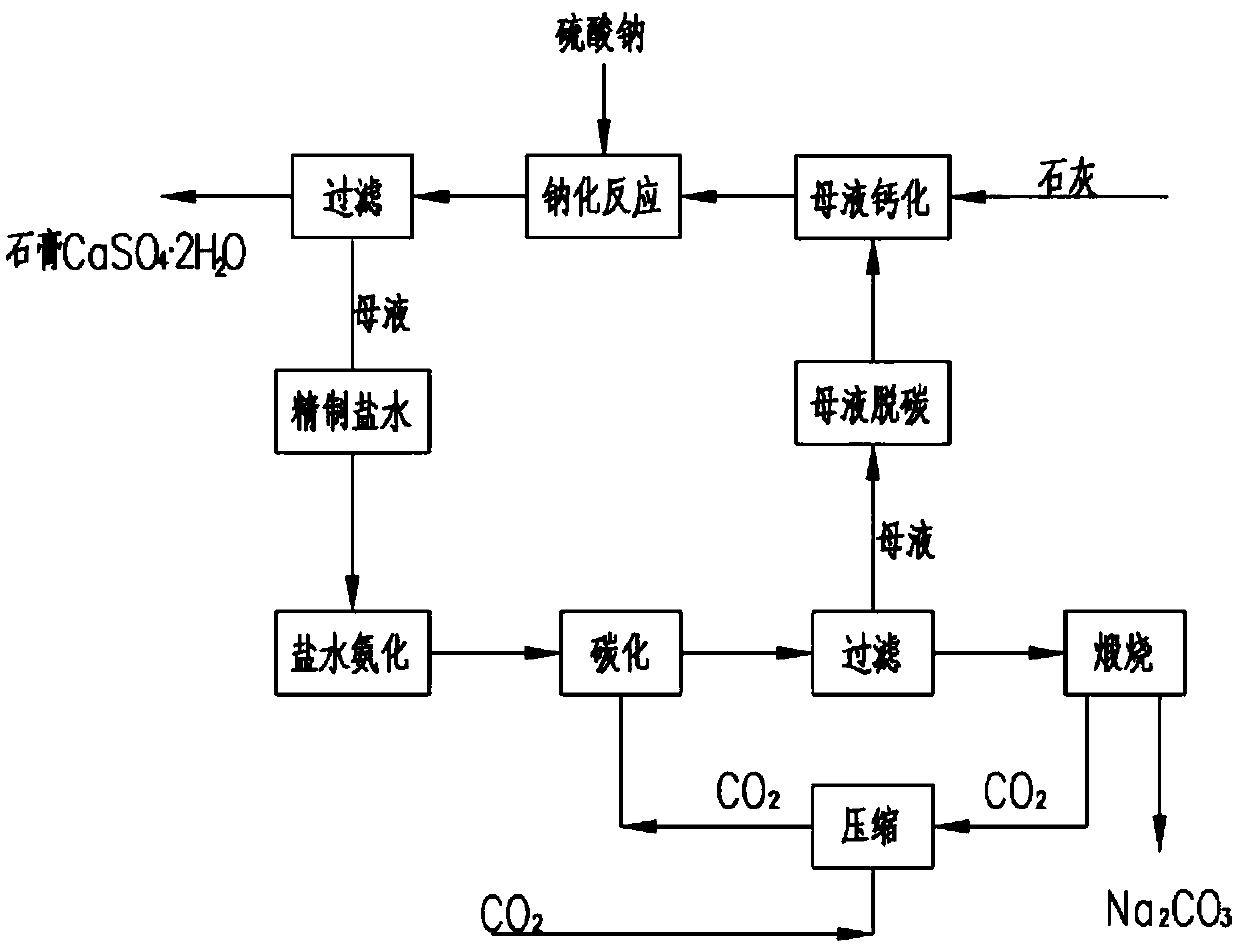

Technological method for preparation of sodium carbonate from sodium sulfate

The invention relates to a technological method for preparation of sodium carbonate from sodium sulfate. Sodium sulfate and limestone are adopted as the main raw materials, chlorine ions and ammonia are adopted as the intermedia of the process, and the main products are sodium carbonate and gypsum. The method provided by the invention uses sodium sulfate as the main raw material to produce sodiumcarbonate, the process does not involve ammonia distillation procedure, the system does not discharge wastewater, and the consumption of steam and new water is reduced, great changes occur to the technological process and basic principles, and the raw material utilization rate reaches 98% or above. The method provided by the invention reduces energy consumption, realizes recycling of resources, does not produce wastewater, and can change the existing sodium carbonate production, and at the same time provides a new way for deepening utilization of sodium sulfate and enterprises producing sodiumsulfate waste salt.

Owner:SHAANXI KEYUAN ENVIRONMENTAL PROTECTION & ENERGY SAVING TECH +1

Method for extracting hemicellulose from waste paper

The invention discloses a method for extracting hemicellulose from waste paper, the method specifically comprises the following steps: 1) dispersing and beating the waste paper into waste paper pulp by using a hydrapulper, and filtering to remove non-paper pulp impurities; (2) dipping the waste paper pulp filtered in the step (1) in a 5-20% sodium hydroxide solution for 0.5-4 hours to obtain a material A; 3) performing solid-liquid separation treatment on the material A to obtain impregnated waste paper and impregnation liquid, and collecting the impregnation liquid as a material B; 4) pretreating the material B with a filter bag, then treating with a nanofiltration membrane to obtain a concentrated solution and a filtrate, and collecting the concentrated solution as a material C; 5) adding acid into the material C to obtain a precipitate which is a material D; 6) treating the material D with a ceramic membrane to obtain a concentrated solution and a filtrate, adding pure water for dialysis, collecting the concentrated solution as a material E, and 7) drying the material E to obtain the hemicellulose dry powder. The method has the advantages of high efficiency, low cost, no generation of three wastes, small influence on the environment and the like.

Owner:SHANGHAI CHANGFA NEW MATERIAL CO LTD

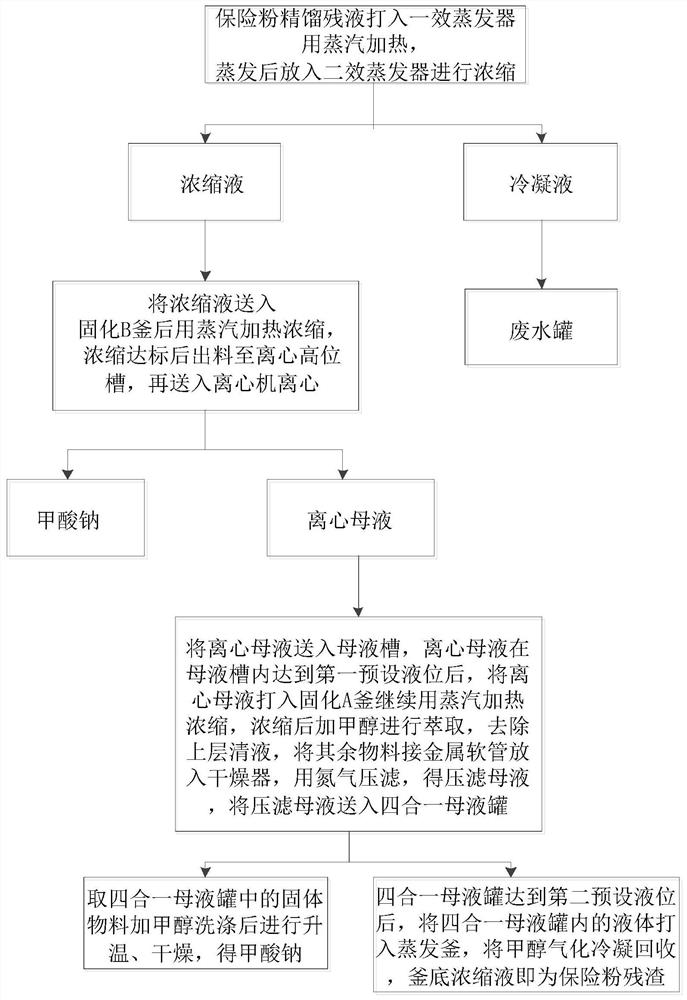

Method for reducing residue output in sodium hydrosulfite production process

PendingCN113527086AReduced residue generationReduce solid waste generationOrganic compound preparationHydroxy compound preparationMother liquorMethanol

The invention discloses a method for reducing residue output in a sodium hydrosulfite production process, the method comprises the following steps: S1, pumping sodium hydrosulfite rectification residual liquid into a first-effect evaporator, heating with steam, evaporating, and concentrating in a second-effect evaporator to obtain concentrated liquid and condensate; s2, feeding the concentrated solution into a curing kettle B, heating and concentrating with steam, discharging to a centrifugal head tank, feeding into a centrifugal machine, and centrifuging to obtain sodium formate and centrifugal mother liquor; s3, pumping the centrifugal mother liquor into a curing kettle A, continuously heating and concentrating with steam, adding methanol for extraction after concentration, removing supernatant liquid, connecting other materials with a metal hose, putting the other materials into a dryer, carrying out pressure filtration with nitrogen to obtain pressure filtration mother liquor, and treating the pressure filtration mother liquor to obtain sodium formate; s4, after the four-in-one mother liquor tank reaches a second preset liquid level, pumping liquid in the four-in-one mother liquor tank into an evaporation kettle, gasifying methanol, condensing and recycling so that a kettle bottom concentrated solution is sodium hydrosulfite residues. The method has the beneficial effect of reducing the generation amount of residues.

Owner:HUBEI YIHUA CHEMICAL INDUSTRY CO LTD

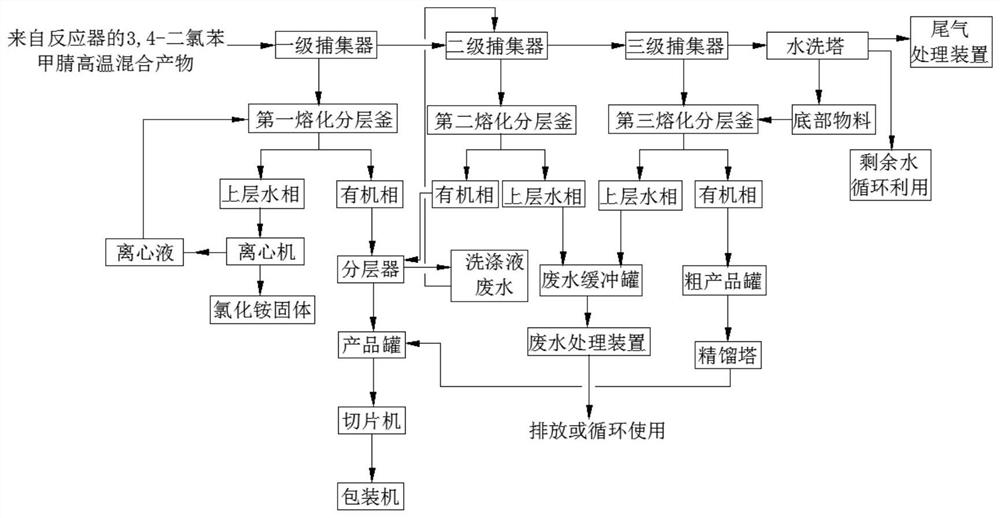

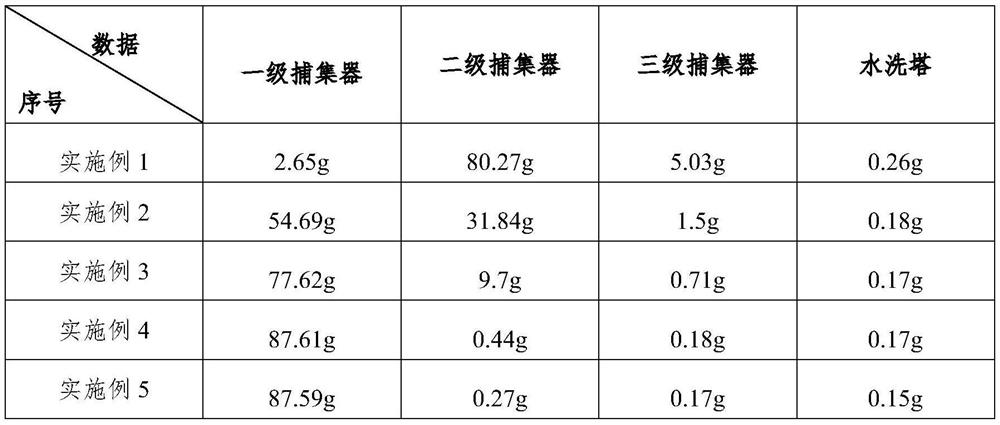

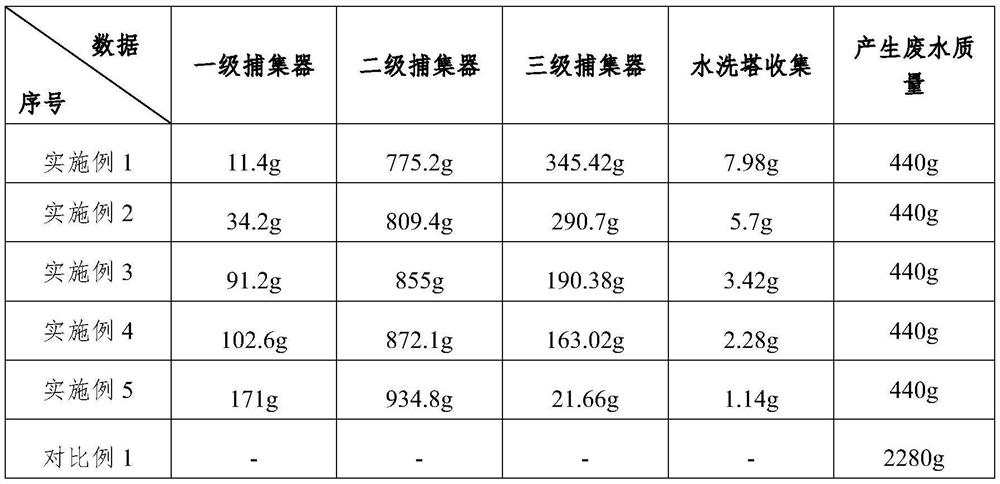

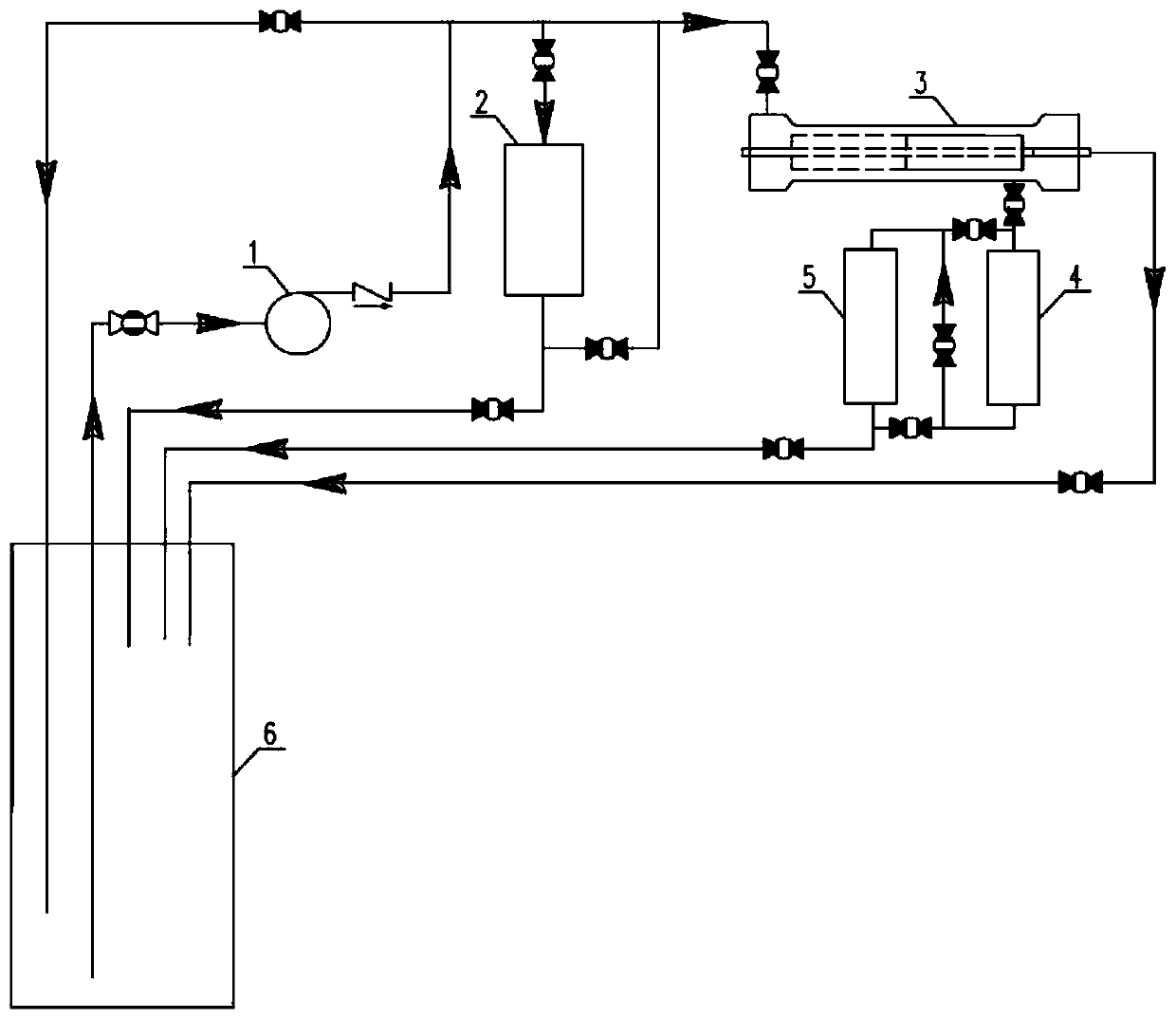

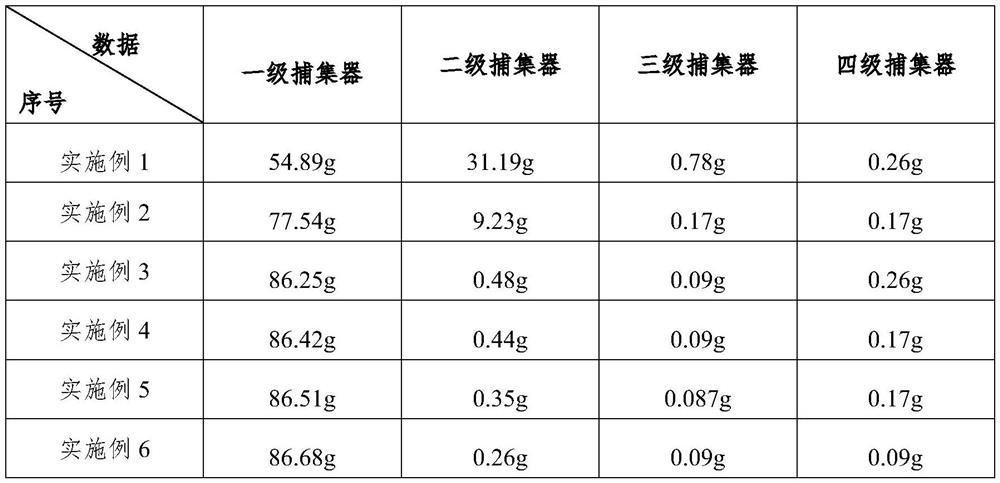

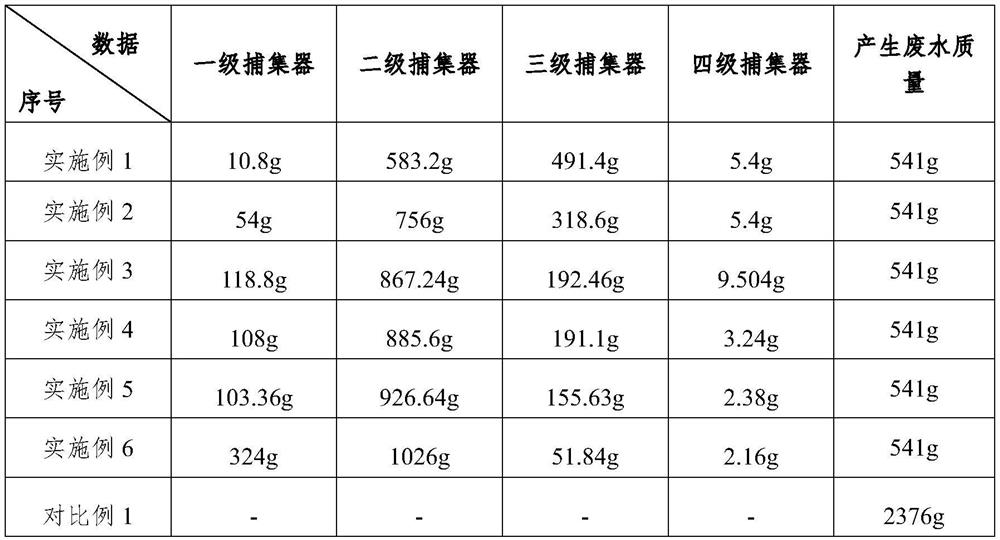

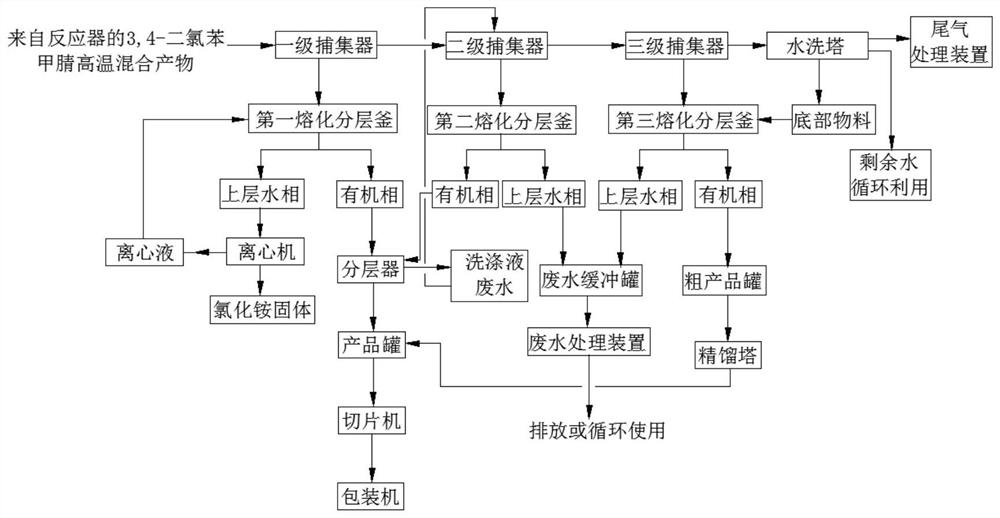

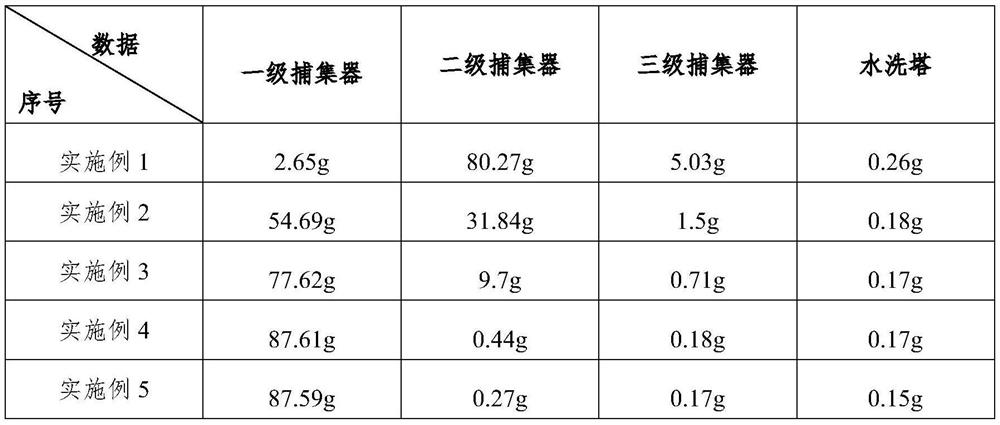

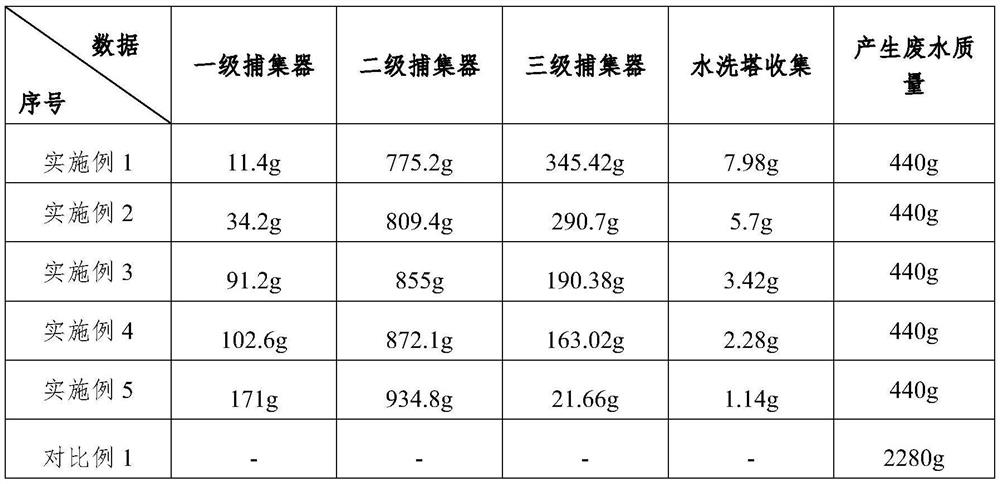

A trapping device and process for the production of 3,4-dichlorobenzonitrile

ActiveCN111957063BSimple structural designHigh feasibilityPreparation by hydrocarbon ammoxidationCarboxylic acid nitrile purification/separationEconomic benefitsProcess engineering

Owner:常州新日催化剂股份有限公司

Device and method used for cobalt source storage source well water processing

PendingCN110164578AEfficient removalRealize automatic cycleRadioactive decontaminationActivated carbon filtrationIon exchange

The invention discloses a device and a method used for cobalt source storage source well water processing. The device comprises a pump, an active carbon filter, a membrane processing system, and a two-stage multi-medium mixed ion exchange column. Compared with the prior art, the advantages are that: the membrane processing system is adopted for condensation of extremely low concentration radionuclide or other ionic state impurities in well water, and an obtained concentrated solution is delivered through the two-stage multi-medium mixed ion exchange column, so that resin adsorption rate on radionuclide and impurities in unit time is accelerated, efficiency is increased, solid waste generation amount is reduced, and a problem in the prior art that only pure physical separation can be realized using the membrane processing system. Design of the distribution position of inlet water, reflux water, produced water, and concentrated water in well water is capable of realizing well water automatic circulation, and solving a problem that effective purifying of bottom precipitate is impossible to realize; and the device and the method can be both used for routine source well water purifyingand source well water pre-decommissioning fine processing, and the target of the invention is achieved.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

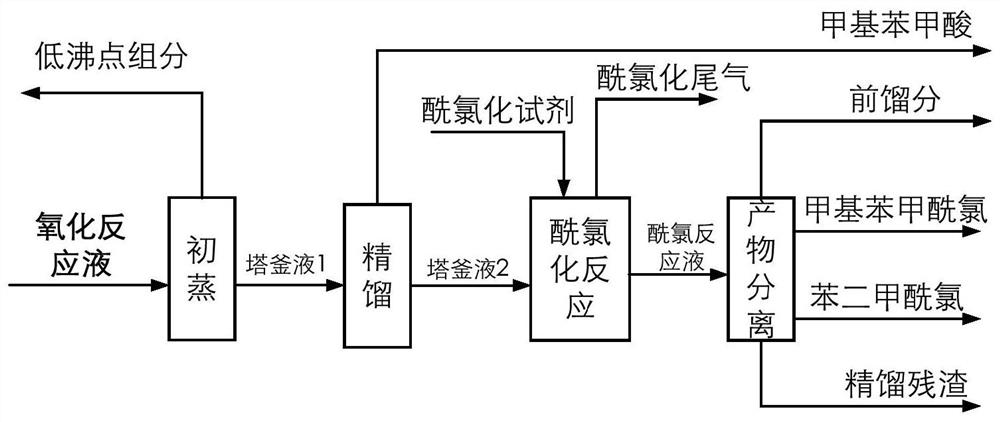

A method for co-producing methylbenzoic acid, methylbenzoyl chloride and phthaloyl chloride

ActiveCN108117486BHigh concentration of production industryRaw materials are easy to getOrganic compound preparationCarboxylic compound separation/purificationBenzoic acidXylylene

The invention discloses a method of co-producing methyl benzoic acid, methylbenzoyl chloride and phthaloyl dichloride. The method comprises the following steps: (1) continuously introducing xylene, acatalyst and oxygen-containing gas into an oxidizing reactor to react to obtain an oxidized reaction solution; (2) rectifying and separating the oxidized reaction solution to obtain a low-boiling-point component and an initial evaporative tower bottom; (3) rectifying the initial evaporative tower bottom to obtain a methyl benzoic acid product and a tower bottom; (4) carrying out an acylating chlorination reaction on the tower bottom and an acylating chlorination reagent to obtain an acyl chloride reaction solution; and (5) rectifying and separating the acyl chloride reaction solution to separately obtain methylbenzoyl chloride and phthaloyl dichloride products. The method provided by the invention has the advantages of being simple in process, small in equipment investment, green and environment-friendly and good in comprehensive economical benefit.

Owner:JIANGXI KEYUAN BIOPHARM

Method for directly smelting ferrovanadium nitride or ferrovanadium with high-temperature vanadium slag without chemical process

ActiveCN113621864BProduction process is environmentally friendlyReduce energy consumptionProcess efficiency improvementElectric arc furnaceNitrogen gas

The invention provides a method for directly smelting ferrovanadium nitride or ferrovanadium with high-temperature vanadium slag without chemical process, which includes blowing vanadium-containing molten iron from the bottom or side of the furnace when it is close to the end point of vanadium extraction in the process of blowing vanadium in the converter Reductant, iron oxide in the reduction slag; after the semi-steel is produced, add the reducing agent from the top of the vanadium extraction furnace to continue reducing the iron oxide in the vanadium slag, and pour the high-temperature vanadium slag directly into the intermediate frequency induction furnace or electric arc furnace or through the heat preservation slag The tank is poured into the intermediate frequency induction furnace or electric arc furnace, and the vanadium and beneficial metal elements in the vanadium slag are deeply reduced by controlling the reduction temperature in the intermediate frequency induction furnace or electric arc furnace, and ferrovanadium nitride or ferrovanadium is obtained by controlling the amount of nitrogen blown at the bottom . The present invention uses high-temperature vanadium slag as raw material to directly produce ferrovanadium nitride, and can also produce ferrovanadium alloys of different grades, without the need for chemical land, and the production process is green and environmentally friendly, does not produce chemical waste water, and the energy consumption is significantly lower than that of traditional vanadium chemical processes. The process is short.

Owner:张计辉

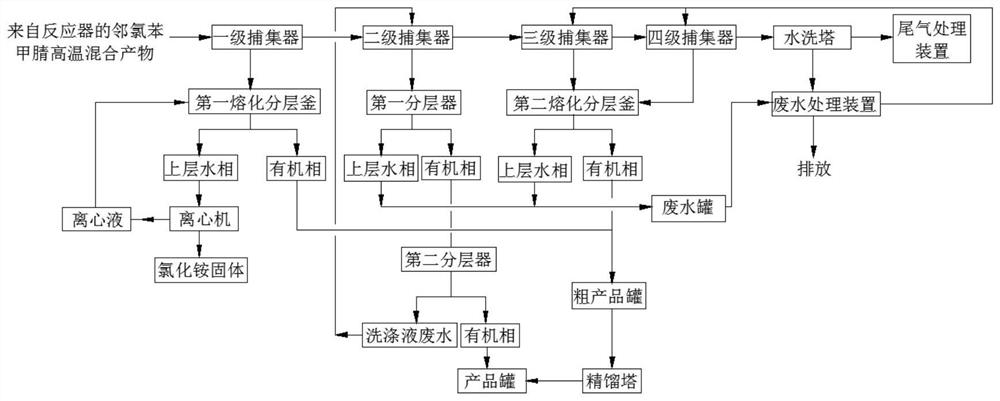

A kind of trapping device and process for the production of o-chlorobenzonitrile

ActiveCN111978210BReduce usageReduce productionCarboxylic acid nitrile purification/separationChlorobenzeneEconomic benefits

The invention discloses a trapping device and process for production of o-chlorobenzonitrile. The device is simple and reasonable in structural design, high in implementation feasibility and high in practicability, 90% or above of ammonium chloride is captured through a first-stage catcher by a dry capture method, 70% or above of the o-chlorobenzonitrile is captured through a second-stage catcherby a dry capture method,, the first-stage catcher makes full use of latent heat of vaporization of water, and the usage amount of spray liquid-water is small. Besides, about 30% of crude o-chlorobenzonitrile products captured by a third-stage catcher and a fourth-stage catcher is molten with hot water, dehydrated, rectified and purified to obtain an o-chlorobenzonitrile liquid pure product, and the tar generation amount and the solid waste generation amount in the rectification process are small. Compared with a traditional multi-stage wet capture method, the loss amount of the o-chlorobenzonitrile is reduced. Besides, the investment cost of rectification equipment is reduced by more than half, the rectification energy consumption is equivalent to 30% of that of the traditional method, andthe economic benefits are good.

Owner:常州新日催化剂股份有限公司

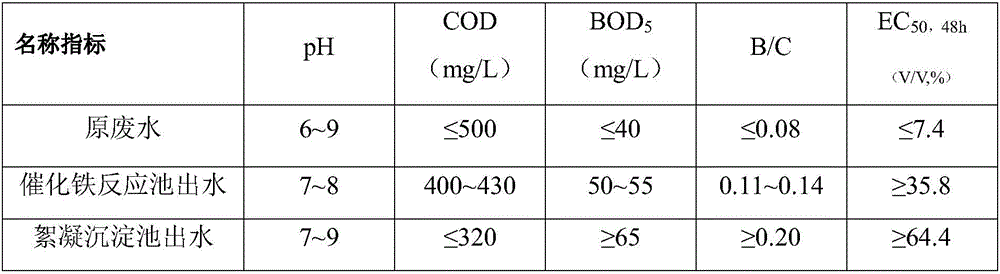

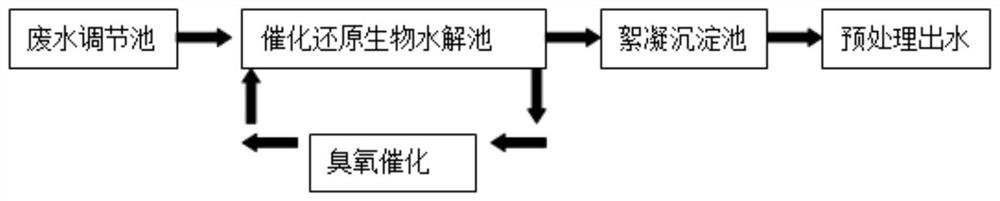

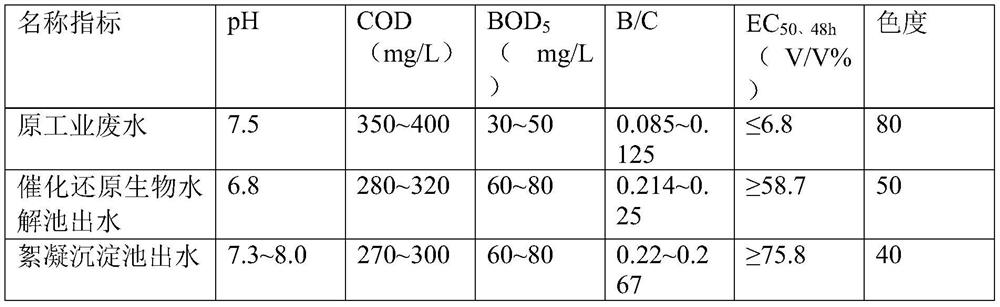

A kind of catalytic hydrolysis pretreatment method for industrial park wastewater

ActiveCN111410376BImprove biodegradabilityLow biological toxicityWater treatment compoundsMultistage water/sewage treatmentIndustrial waste waterPretreatment method

A catalytic hydrolysis pretreatment method for industrial park wastewater relates to the technical field of industrial wastewater treatment. In order to solve the problems of traditional industrial park wastewater pretreatment, the invention has poor pretreatment effect, cumbersome acid-base adjustment, large amount of oxidative pretreatment, large amount of sludge and unstable operation. Method: 1. Add packing and pretreated industrial wastewater into the catalytic reduction biological hydrolysis tank, add ozone catalytic packing and hydrogen peroxide into the ozone catalytic reaction tank, and pump the upper layer liquid of the industrial wastewater in the catalytic reduction biological hydrolysis tank to the ozone catalytic reaction Catalytic oxidation is carried out in the tank, and the industrial wastewater in the ozone catalytic reaction tank is returned to the catalytic reduction biological hydrolysis tank; the industrial wastewater flows into the flocculation sedimentation tank through the water outlet, the pH is adjusted to 7-8.5, polyacrylamide is added, and precipitation is completed to complete the industrial wastewater. Catalytic hydrolysis pretreatment. The invention can obtain a method for catalytic hydrolysis pretreatment of industrial park wastewater.

Owner:工大环境股份有限公司

Trapping device and process for production of 3,4-dichlorobenzonitrile

ActiveCN111957063ASimple structural designHigh feasibilityPreparation by hydrocarbon ammoxidationFractional distillationEconomic benefitsProcess engineering

The invention discloses a trapping device and process for production of 3,4-dichlorobenzonitrile. The device is simple and reasonable in structural design; the implementation feasibility is high, thepracticability is high, more than 90% of ammonium chloride and more than 8% of 3,4-dichlorobenzonitrile are captured by a first-stage catcher through a dry capture method, more than 76% of 3,4-dichlorobenzonitrile is captured by a second-stage catcher through a dry capture method, latent heat of vaporization of water is fully utilized by the first-stage catcher, and the usage amount of spray liquid-water is small; besides, about 15% of the 3,4-dichlorobenzonitrile crude product collected by a third-stage catcher and a bath tower is dissolved by hot water, dehydrated, rectified and purified toobtain a liquid pure product of 3,4-dichlorobenzonitrile. The generation amount of coke oil and solid waste during the rectification process is low. Compared with a traditional multi-stage wet capturemethod, the consumption of 3,4-dichlorobenzonitrile is reduced, the investment cost of rectification equipment is reduced by more than half, the rectification energy consumption is equivalent to 15%of that of the traditional method, and the economic benefit is good.

Owner:常州新日催化剂股份有限公司

A kind of processing method of pouring pole plate of lead-acid battery

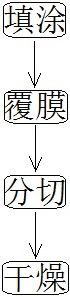

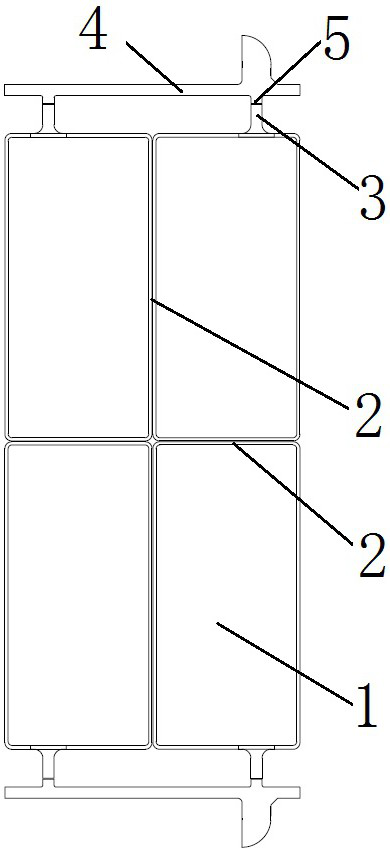

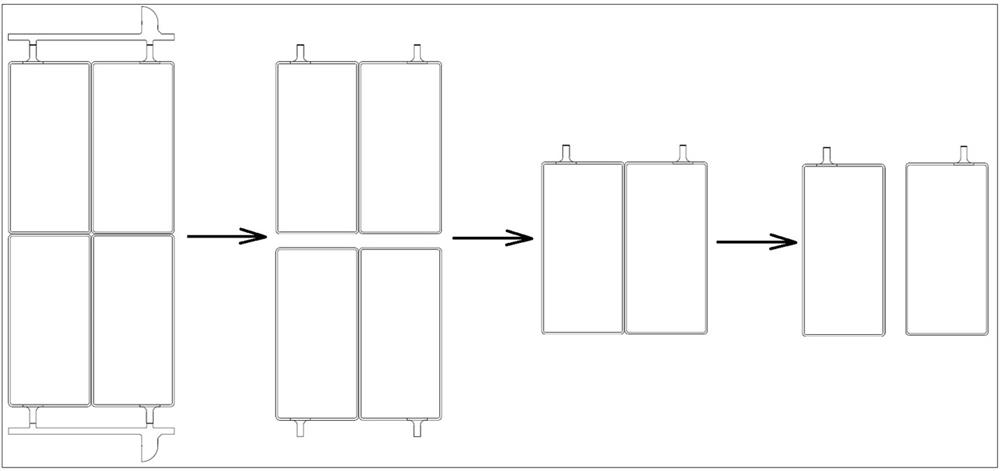

ActiveCN112151772BReduce the number of people involved in leadReduce wasteLead-acid accumulator electrodesStructural engineeringMechanical engineering

The invention relates to a processing method for pouring polar plates of lead-acid batteries, which relates to a processing and forming method for the polar plates of lead-acid batteries. A method for processing lead-acid battery pouring plates, the steps of which are as follows: (1) filling and coating, filling and coating lead paste on large grids that have not been cut to form wet plates; (2) coating, The surface of the wet electrode plate filled with lead paste is folded in half and coated on both sides (the center line of the film is folded in half, and the film covers the upper surface and the lower surface of the grid at the same time); The plate is continuously cut; (4) Drying, the surface of the small piece of wet plate after cutting is dried. The large uncut grid is a matt grid, and the grid can be cut into 4 finished plates of equal size, and there are concave cutting grooves between the finished plates for convenient Slitting is carried out; tabs are respectively provided at both ends of the grid, and each of the two tabs is connected by poured side strips.

Owner:江苏永达电源股份有限公司

A processing process of a maternal liquid pigmentation during the production of magnesium sulfate

ActiveCN110921691BGood depigmentation effectReduce solid waste generationIon-exchange process apparatusOrganic compound preparationOrganic chemistryMagnesium sulphate heptahydrate

The invention discloses a process for treating mother liquid pigment in magnesium sulfate production, relates to the technical field of chemical decolorization, and comprises the following process steps: (1) resin column preparation; (2) pigment adsorption; (3) pigment analysis. The present invention adopts the resin method, first absorbing the organic pigment in the magnesium sulfate mother liquor to the resin, and then decomposing it with a solvent, recovering the solvent, and reusing the resin; not only greatly reducing the amount of solid waste generated, but also simple process operation, the magnesium sulfate mother liquor Excellent depigmentation effect.

Owner:安徽皖东树脂科技有限公司

A wastewater treatment control method that promotes the effect of advanced oxidation

ActiveCN110451681BReduce secondary pollutionGuaranteed response speedWater contaminantsMultistage water/sewage treatmentOxidizing agentWastewater disposal

The invention discloses a wastewater processing control method for promoting the advanced oxidation effect, and belongs to the field of wastewater processing. The method comprises following steps: (1)detecting the kinds and corresponding mole concentrations of heavy metal ions in wastewater; (2) adding an oxidizing agent into wastewater to carry out an advanced oxidation treatment, wherein the addition amount of the oxidizing agent is determined based on the content of heavy metal ions in the wastewater; (3) detecting the effluent of the step (2), and stopping the advanced oxidation treatment, if the COD concentration is not greater than 50 mg / L and the TOC concentration is not more than 20 mg / L; if not, carrying out a further advanced oxidation treatment. The method has the advantages that the actual water quality is taken into account, the oxidation reaction efficiency is maximized, the medicaments are effectively saved at the same time, and the operation cost is reduced therefore.

Owner:NANJING UNIV +1

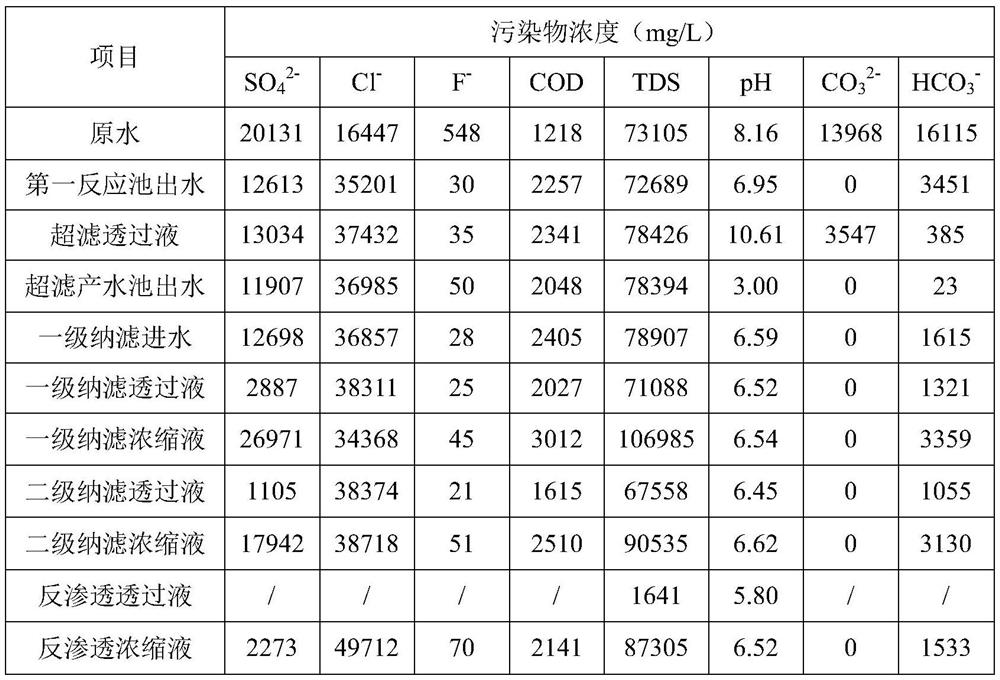

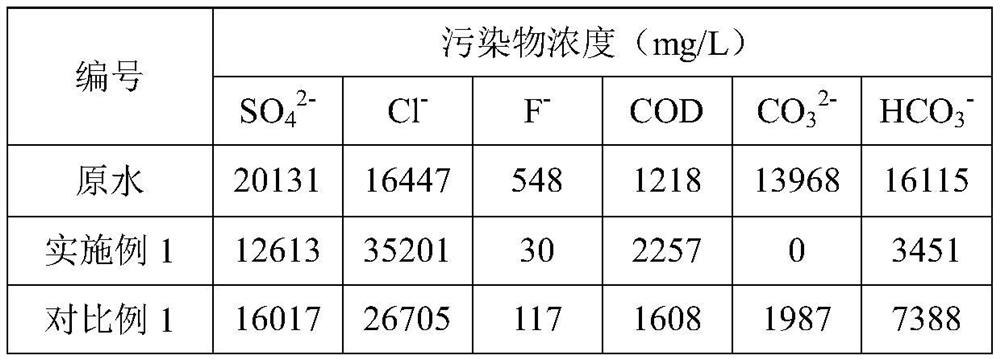

System and method for recovering acid and alkali from high-salt-content deacidification wastewater

PendingCN113698025ARealize resource utilizationReduce solid waste generationWater contaminantsWaste water treatment from gaseous effluentsEnvironmental chemistryUltrafiltration

The invention discloses a system for recovering acid and alkali from high-salt-content deacidification wastewater. The system is characterized by comprising a homogenizing tank, a first reaction tank, a second reaction tank, a sedimentation tank, a concentration tank, an ultrafiltration device, an ultrafiltration water producing tank, a nanofiltration device, a nanofiltration water producing tank, a reverse osmosis device, a reverse osmosis concentrated water tank and a bipolar membrane electrodialysis device which are connected in sequence, a CaCl2 dosing device is arranged over the first reaction tank, a Na2CO3 dosing device is arranged over the second reaction tank, and a hydrochloric acid dosing device is arranged above the ultrafiltration water producing tank. According to the method, NaCl in the deacidification wastewater can be effectively separated through cooperation of chemical reaction and membrane treatment devices with different levels of precision, and NaOH and HCl are prepared through electrodialysis, so that acid and alkali can be recycled from the deacidification wastewater, the resource utilization of the deacidification wastewater is realized, the solid waste output is reduced, and the energy conservation and emission reduction degree is improved.

Owner:浙江省环保集团有限公司

Treatment method of waste acid in titanium dioxide production process

PendingCN113336275AReduce solid waste generationSulfate/bisulfate preparationFerroso-ferric oxidesOxideSodium sulfate

The invention relates to the field of waste treatment, in particular to a method for treating waste acid in a titanium dioxide production process. The invention aims to solve the problem that a large amount of solid waste is generated due to the fact that waste acid generated in titanium dioxide production by a sulfuric acid method is neutralized by quicklime. The implementation process of the method comprises the steps of adding quick lime into waste acid according to a certain mass ratio, uniformly mixing to generate calcium sulfate precipitate, and separating the precipitate through a settling pond; and adding a sodium hydroxide or potassium hydroxide solution with a certain concentration into the residual solution according to a certain proportion to obtain iron hydroxide precipitates, filtering the precipitates, centrifugally separating and then drying at a certain temperature to obtain magnetic ferroferric oxide, wherein the residual aqueous solution can be concentrated to prepare sodium sulfate or potassium sulfate and can also be reused in the rinsing process. The method can greatly reduce the solid waste generation amount in titanium dioxide production, can generate remarkable economic benefits, and has a wide application prospect.

Owner:NANKAI UNIV

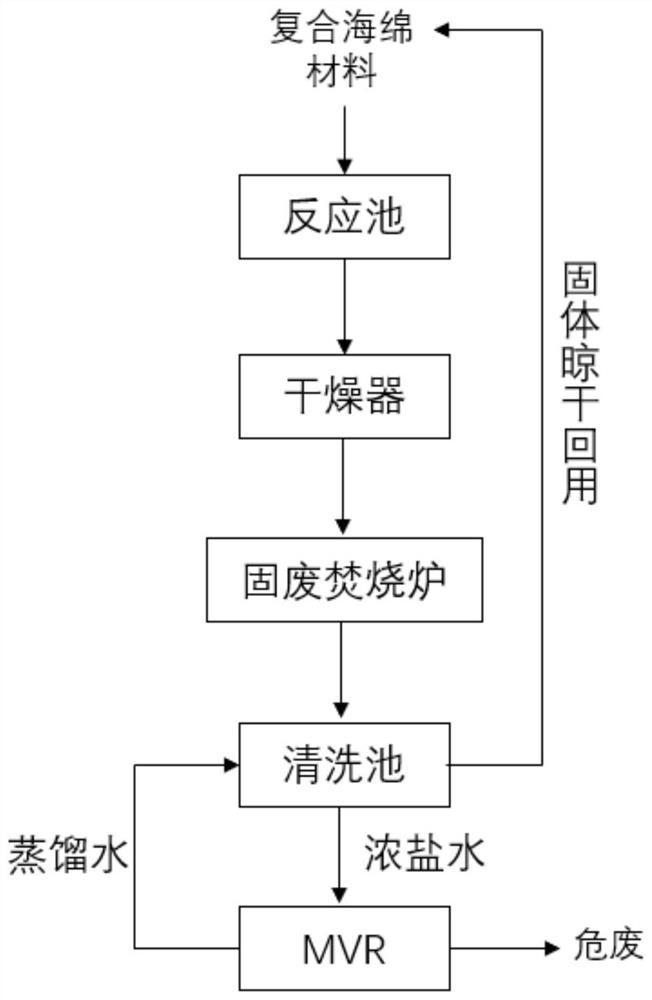

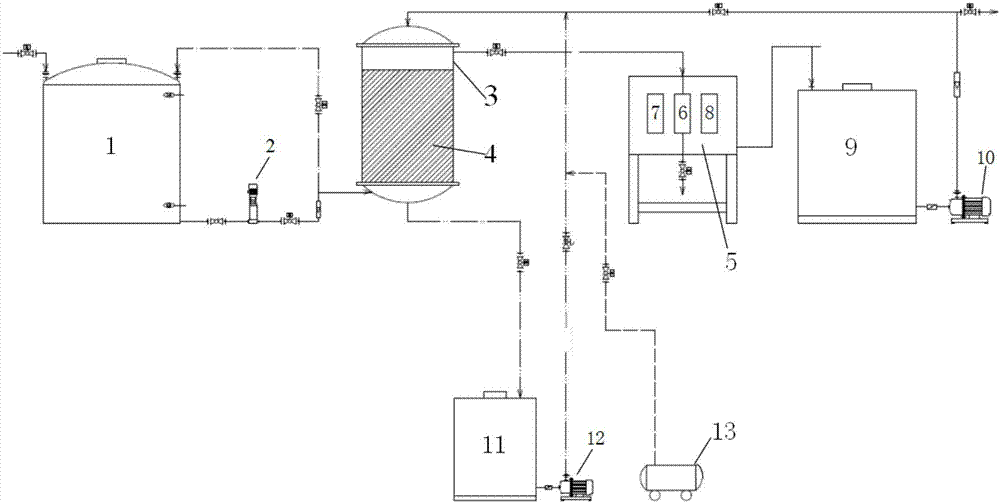

Composite sponge material and preparation method thereof, and application of composite sponge material in treatment of high-salt high-calorific-value wastewater

ActiveCN113511694ANo pollution in the processNot easy to reverse osmosisSpecific water treatment objectivesWater contaminantsMolten saltWastewater disposal

The invention relates to a composite sponge material and a preparation method thereof, and application of the composite sponge material in treatment of high-salt high-calorific-value wastewater. The composite sponge material is formed by mixing an inorganic drying agent and an organic curing coagulant, can efficiently cure wastewater, and overcomes the problems that special wastewater is difficult to treat, treatment cost is high and secondary pollution is caused. A using method of the composite sponge material comprises the following steps: uniformly mixing wastewater and the composite sponge material to a semi-solid state, and conducting drying to obtain solid waste; and incinerating the solid waste. The composite sponge material is suitable for treatment of the high-salt high-calorific-value wastewater, good in effect, mild in incineration conditions and short in incineration time, and the solid waste obtained after incineration is powdery, so the problem that incineration equipment is damaged by molten salt in a direct incineration process of the high-calorific-value wastewater can be effectively solved; and a drying agent in the material can be recycled, and treatment cost is low.

Owner:南京乐透思高新材料科技有限公司

Arsenic removal device with monitoring and regenerating functions and use method thereof

InactiveCN106946307AGood water permeabilityUniform water flowWater treatment parameter controlOther chemical processesFiberControl system

The invention belongs to the technical field of water treatment and particularly provides an arsenic removal device with monitoring and regenerating functions and a use method thereof. The arsenic removal device consists of a main body, a regenerating device, a monitoring system and a power control system, wherein the main body is a fixed bed processor equipped with an inner core made from a cloth-shaped arsenic adsorption fiber material. The arsenic removal device is characterized in that the cloth-shaped arsenic adsorption fiber material is adopted to manufacture the arsenic removal inner core, the arsenic removal inner core is formed by rolling the cloth-shaped arsenic adsorption fiber material around a central shaft, the arsenic removal inner core is cylindrical, is tight in interlayer lamination and is vertically mounted in a housing, and no gap exists between the layers of the cloth-shaped arsenic adsorption fiber material or between the arsenic removal inner core and the inner wall of the housing; the regenerating system consists of a regenerated liquid tank, a pump valve and a pipeline; and the monitoring system consists of a quartz column with a rapid arsenic detection reagent and comparison columns. The arsenic removal device has the advantages of excellent water permeability, high arsenic removal efficiency, easy desorption regeneration and the like, can monitor the arsenic concentration of water in real time and provides instructions for desorption regeneration while ensuring that the effluent meets the discharge standard.

Owner:江阴和悦鑫环保科技有限公司

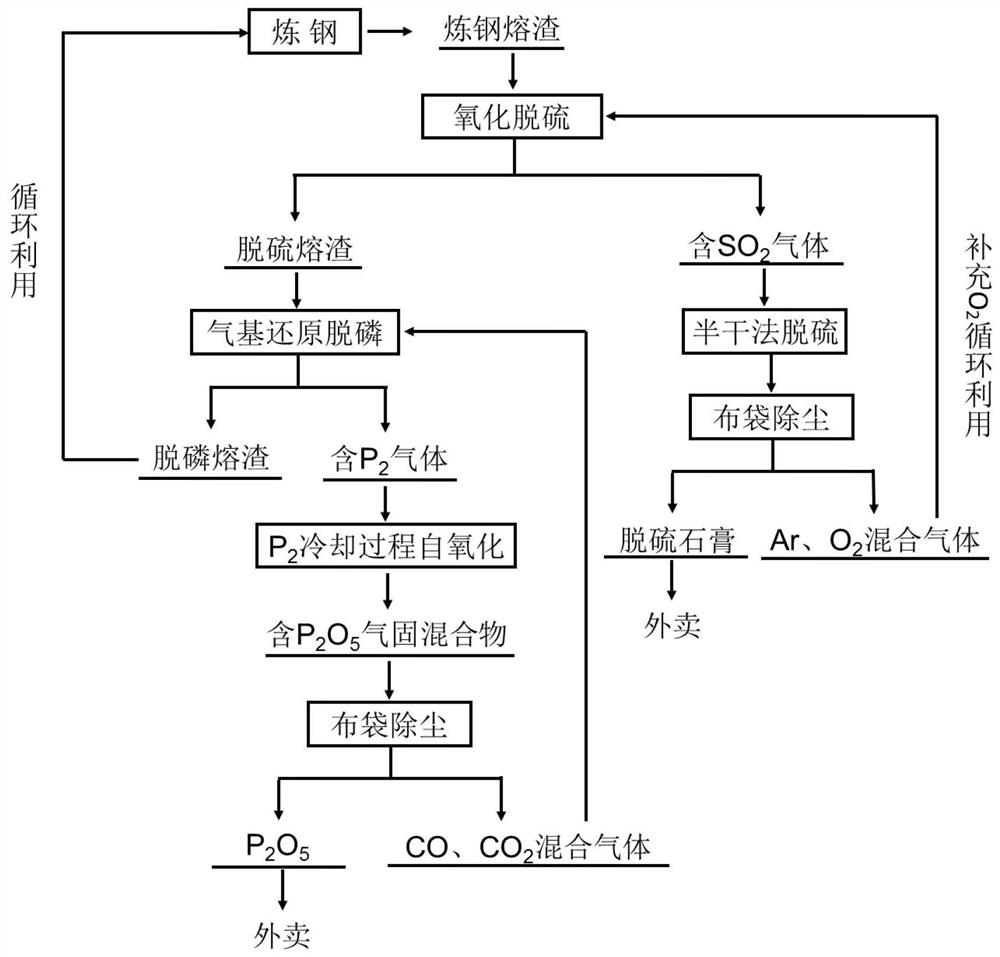

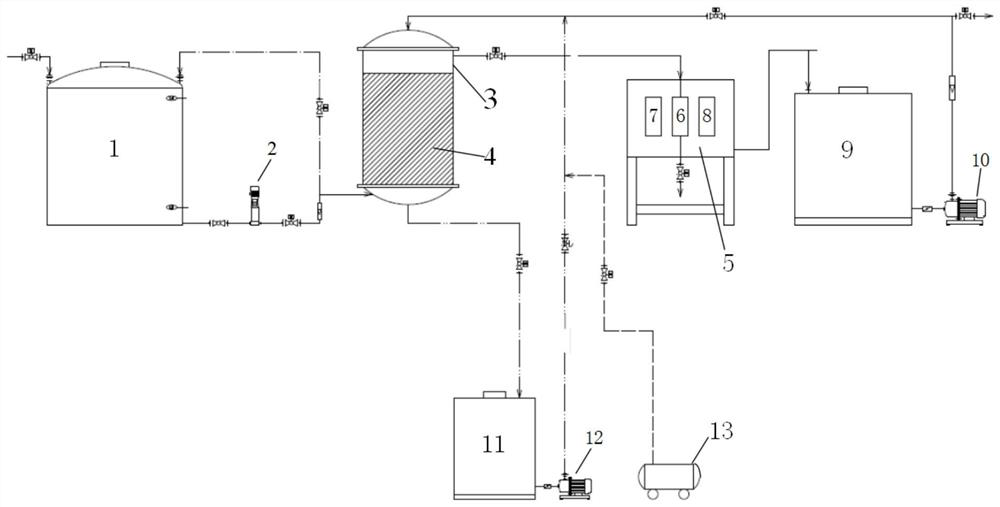

A steel slag treatment method using oxidation desulfurization and reduction dephosphorization two-step method

ActiveCN110184399BComposition is stableReduce the reductive dephosphorization temperatureRecycling and recovery technologiesProcess efficiency improvementSteelmakingMolten steel

The invention relates to a steel slag treatment method using a two-step method of oxidation desulfurization and reduction dephosphorization, belongs to the technical field of iron and steel metallurgy and resource utilization, and solves the problem of enrichment of sulfur and phosphorus in the existing steel slag recycling technology. The steel slag treatment method using the two-step method of oxidation desulfurization and reduction dephosphorization includes S1. Oxidative desulfurization of steel slag; passing Ar and O into molten steel slag 2 The mixed gas, the SO obtained by oxidation 2 Overflow and remove from the slag phase, the removal rate of S is 82-97%; S2. The desulfurized steel slag obtained in step S1 is subjected to gas-based reduction dephosphorization; the reducing gas is CO and CO 2 The mixed gas, the removal rate of phosphorus reaches more than 80%, and the P obtained by reduction 2 Spilled and removed from the slag. The invention can completely solve the problem of removing sulfur and phosphorus in steel slag, greatly improve the recycling rate of steel slag, realize the full utilization of steel slag, S and P, reduce the cost of steelmaking, increase the utilization value of sulfur and phosphorus, and have broad application prospects.

Owner:钢研晟华科技股份有限公司

An arsenic removal device with monitoring and regeneration functions and its application method

InactiveCN106946307BGood water permeabilityUniform water flowWater treatment parameter controlOther chemical processesFiberPower control system

The invention belongs to the technical field of water treatment and particularly provides an arsenic removal device with monitoring and regenerating functions and a use method thereof. The arsenic removal device consists of a main body, a regenerating device, a monitoring system and a power control system, wherein the main body is a fixed bed processor equipped with an inner core made from a cloth-shaped arsenic adsorption fiber material. The arsenic removal device is characterized in that the cloth-shaped arsenic adsorption fiber material is adopted to manufacture the arsenic removal inner core, the arsenic removal inner core is formed by rolling the cloth-shaped arsenic adsorption fiber material around a central shaft, the arsenic removal inner core is cylindrical, is tight in interlayer lamination and is vertically mounted in a housing, and no gap exists between the layers of the cloth-shaped arsenic adsorption fiber material or between the arsenic removal inner core and the inner wall of the housing; the regenerating system consists of a regenerated liquid tank, a pump valve and a pipeline; and the monitoring system consists of a quartz column with a rapid arsenic detection reagent and comparison columns. The arsenic removal device has the advantages of excellent water permeability, high arsenic removal efficiency, easy desorption regeneration and the like, can monitor the arsenic concentration of water in real time and provides instructions for desorption regeneration while ensuring that the effluent meets the discharge standard.

Owner:江阴和悦鑫环保科技有限公司

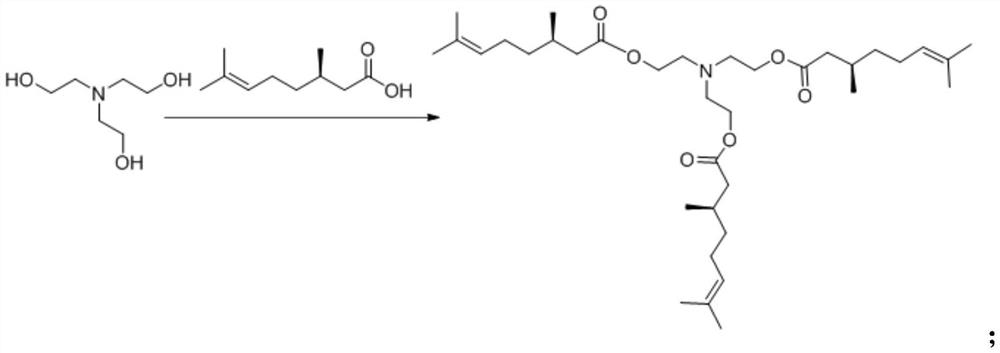

Catalyst and preparation method, hydrotreating method of vanillin tar

ActiveCN110479257BReduce solid waste generationImprove economyOrganic chemistryOrganic compound preparationCesium compoundPtru catalyst

The invention relates to a catalyst, a preparation method and a hydrotreating method of vanillin tar. The catalyst comprises a cesium-containing compound, Pd / TiO 2 and Pt / TiO 2 The hydrotreating method of vanillin tar is as follows: in ethanol solvent, using vanillin tar as reaction raw material, directly catalyzing hydrocracking to recover guaiacol. The method is simple to operate, green and environmentally friendly. On the one hand, the residual vanillin and 5-aldehyde-based vanillin by-products in the vanillin tar are cracked and recovered, and at the same time, tars such as vanillin dimerization and deep oxidation are added again. Hydrogen cracking into high value-added guaiacol products. It not only reduces the treatment cost of solid waste, but also has better economic benefits.

Owner:WANHUA CHEM GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com