Device and method used for cobalt source storage source well water processing

A well water and source storage technology, which is applied in the field of cobalt source storage well water treatment devices, can solve the problems of low radioactivity concentration, poor purification effect, solid waste, and low decontamination factor, so as to avoid ineffective purification , Reduce solid waste generation and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

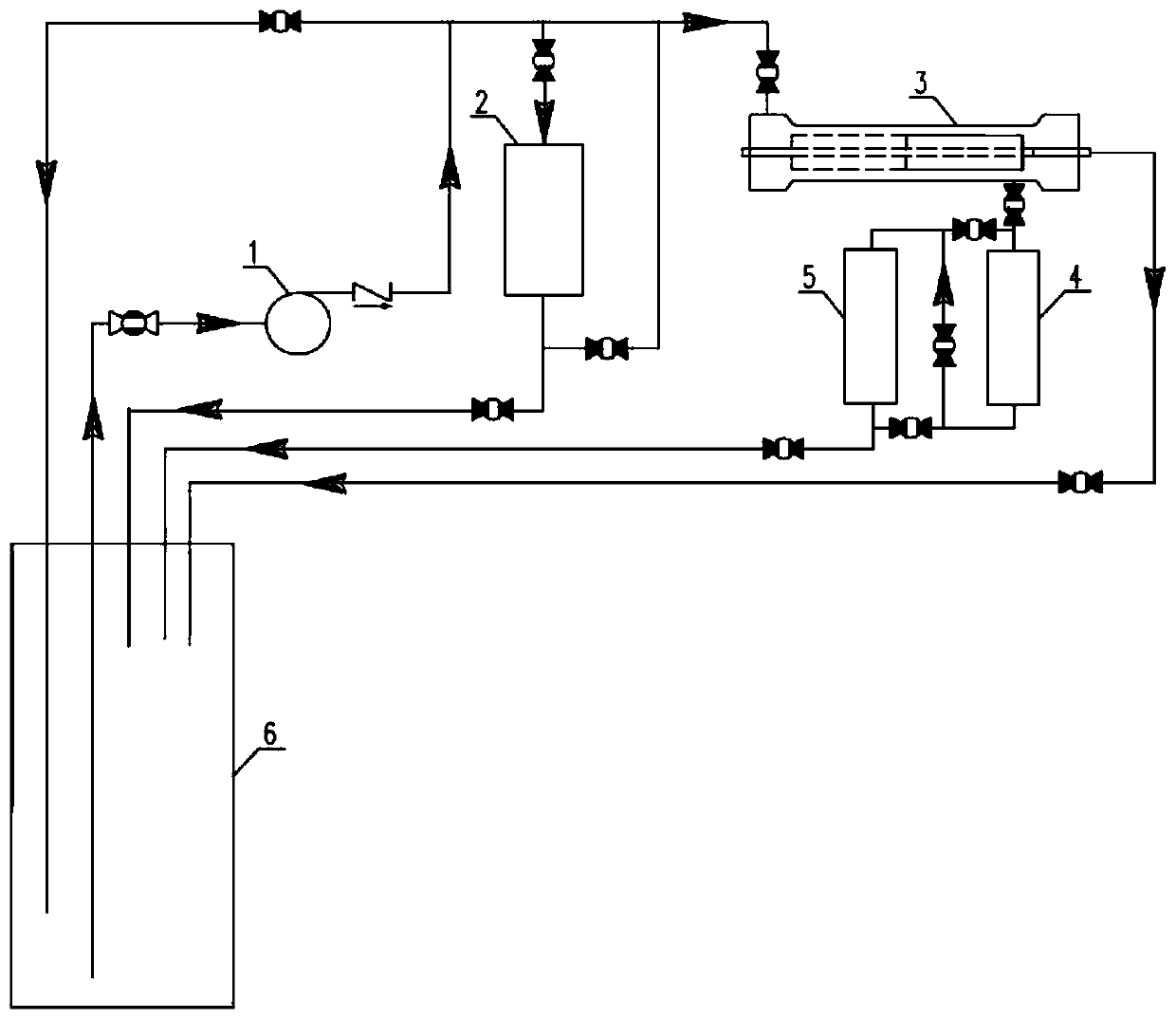

[0025] Such as figure 1 Shown, the present invention is used for the device of cobalt source storage source well water treatment, and it comprises pump 1, activated carbon filter 2, membrane treatment system 3, primary ion exchange column 4 and secondary ion exchange column 5; Pump 1 The input end is arranged at the bottom of the cobalt source storage source well 6, and the output end of the pump 1 enters the membrane treatment system 3 and returns to the middle part of the cobalt source storage source well 6 respectively through the activated carbon filter 2, and the output end of the membrane treatment system 3 passes through in turn. The primary ion exchange column 4 and the secondary ion exchange column 5 flow back to the upper part of the cobalt source storage well 6 .

[0026] In this embodiment, the layer height of the activated carbon filter 2 is 300-1500mm.

[0027] In this embodiment, the membrane treatment system 3 is a seawater membrane system or a nanofiltration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com