Arsenic removal device with monitoring and regenerating functions and use method thereof

A technology of functional and detection reagents, applied in the field of water treatment, can solve the problems of large amount of solid waste, high cost of use, difficult to regenerate, etc., and achieve the effect of reducing the amount of solid waste generated, fully contacting, and reducing material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

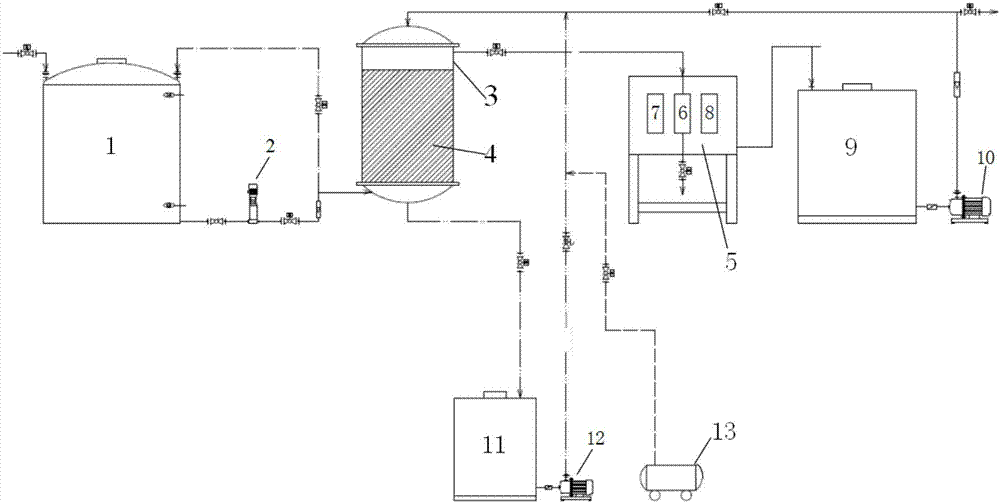

Embodiment 1

[0033] In this embodiment, the cloth-like arsenic-absorbing fiber material used to make the inner core is activated carbon fiber cloth modified by magnesium ferrite nanoparticles (magnesium ferrite nanoparticles in the cloth-like arsenic-absorbing fiber material account for 15wt%), and the cloth-like arsenic The porosity of the adsorption fiber material is 65%, the average pore diameter of macropores is 5-50 μm, and the average pore diameter of micropores is 0.005-0.2 μm. Put the Ф200mm×1000mm arsenic removal inner core into the shell to make a fixed-bed arsenic processor, which is connected with the arsenic-containing water tank to be treated and the desorption regeneration system. A rapid arsenic detection reagent column and a 100ppb and 500ppb contrast column are installed side by side, wherein the arsenic rapid detection reagent column is connected to the water outlet of the fixed bed arsenic processor.

[0034] The arsenic-containing wastewater with a pH value of 6.5 and ...

Embodiment 2

[0037] In this embodiment, the cloth-like arsenic-absorbing fiber material used to make the inner core is a glass fiber non-woven fabric loaded with nano-metatitanic acid (nano-metitatanic acid in the cloth-like arsenic-absorbing fiber material accounts for 11.2wt%, and the cloth-like arsenic adsorbing fiber material accounts for 11.2 wt%. The porosity of the arsenic adsorption fiber material is 75%, the average pore diameter of macropores is 10-100 μm, and the average pore diameter of micropores is 0.01-0.5 μm. The arsenic removal inner core of Ф200mm×1000mm is put into the shell to make a fixed bed arsenic treatment The fixed bed processor is connected with the arsenic-containing water tank to be treated and the desorption regeneration system. The arsenic rapid detection reagent column and the 100ppb and 500ppb contrast columns are installed side by side, and the arsenic rapid detection reagent column is connected with the fixed bed arsenic processor. the water outlet connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com