A kind of trapping device and process for the production of o-chlorobenzonitrile

A technology of o-chlorobenzonitrile and process, which is applied in the field of trapping devices for the production of o-chlorobenzonitrile, can solve the problems of difficult cooling of circulating spray water, high cost of wastewater treatment, and large amount of wastewater treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

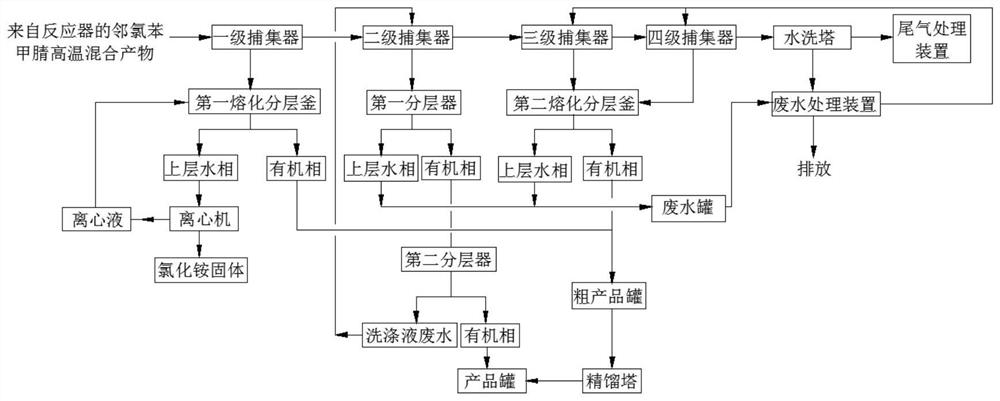

[0034] A trapping device for the production of o-chlorobenzonitrile, comprising a primary trap, a secondary trap, a tertiary trap, a quadruple trap, a rectification tower, a product tank, and a waste water treatment device and tail gas treatment device, the o-chlorobenzonitrile high-temperature mixed product from the reactor enters the primary trap through the feed inlet of the primary trap, and the gas outlet at the top of the primary trap is connected to the The feed port of the secondary trap is connected, the gas outlet at the top of the secondary trap is connected with the feed port of the tertiary trap, the gas outlet at the top of the tertiary trap is connected with the The feed inlet of the four-stage trap is connected, and the gas outlet on the top of the four-stage trap is connected with the tail gas treatment device;

[0035] The discharge port at the bottom of the primary trap is connected to the feed port of the first melting layered tank, the discharge port above...

Embodiment 2

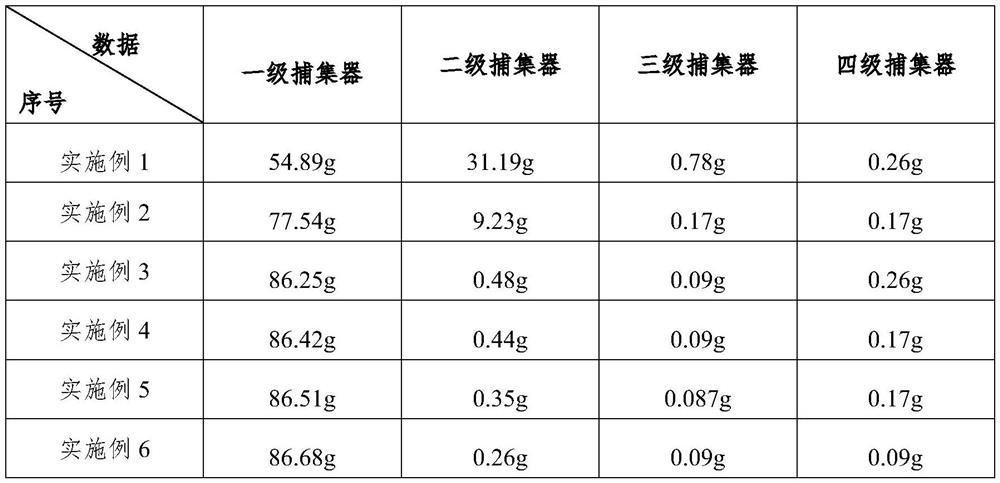

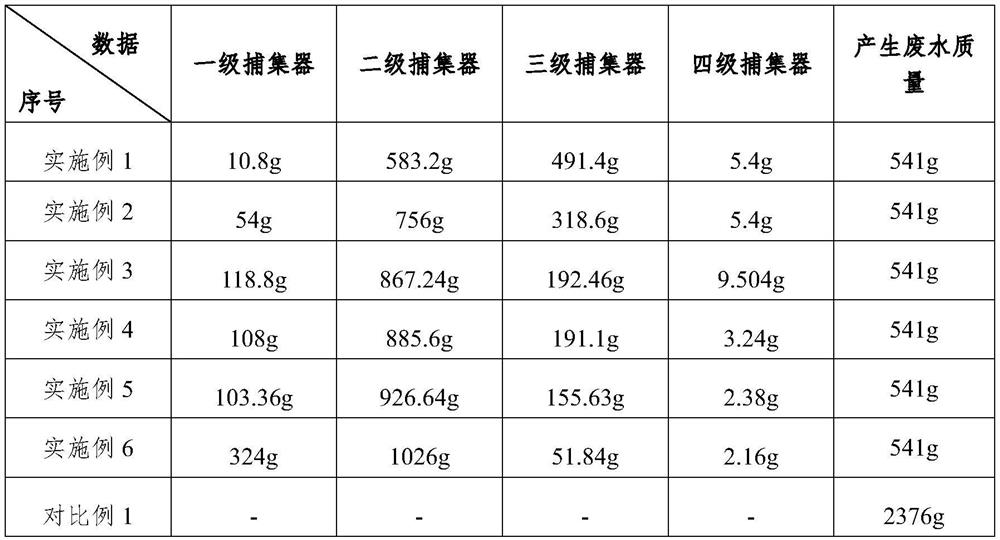

[0051] The difference between embodiment 2 and embodiment 1 is that (two) trapping section:

[0052] S1: The high-temperature mixed product of o-chlorobenzonitrile from the reactor enters the primary trap. At this time, the spray device accurately sprays the refrigerant inside the primary trap according to the temperature of the inlet of the primary trap and the inlet air volume. The eluate was evaporated and cooled, and 77.54g of ammonium chloride solid and 54g of o-chlorobenzonitrile liquefied condensation were precipitated in the primary trap, and the solid-liquid mixture produced in the primary trap was dissolved and washed with 500g hot water at 50°C. layer, in which the upper aqueous phase is cooled and then centrifuged to separate the ammonium chloride solid product and centrifugate, which is used as a solvent for the solid-liquid mixture produced in the primary trap, and the lower organic phase is sent to the rectification tower for purification to obtain purity ≥99.5%...

Embodiment 3

[0058] The difference between embodiment 3 and embodiment 1 is that (two) trapping section:

[0059] S1: The high-temperature mixed product of o-chlorobenzonitrile from the reactor enters the primary trap. At this time, the spray device accurately sprays the refrigerant inside the primary trap according to the temperature of the inlet of the primary trap and the inlet air volume. Evaporate and cool down the eluent, 86.25g of ammonium chloride solid and 118.8g of o-chlorobenzonitrile liquefaction condensation are precipitated in the primary trap, and the solid-liquid mixture produced in the primary trap is dissolved and washed in 500g hot water at 50°C Layering, wherein the upper aqueous phase is cooled and centrifuged to separate the ammonium chloride solid product and centrifugate, the centrifugate is used as a solvent for the solid-liquid mixture generated in the primary trap, and the lower organic phase is sent to the rectification tower for purification to obtain The liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com