A kind of catalytic hydrolysis pretreatment method for industrial park wastewater

A technology for catalytic hydrolysis and industrial wastewater, applied in water/sewage treatment, water/sewage multi-stage treatment, oxidized water/sewage treatment, etc. achieve the effect of enhancing biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

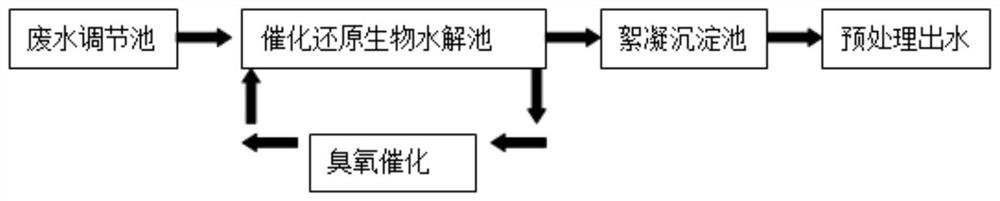

Method used

Image

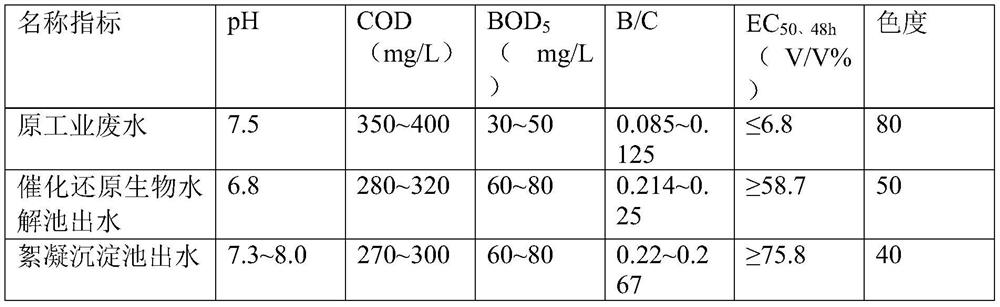

Examples

specific Embodiment approach 1

[0021] Embodiment 1: This embodiment is a method for catalytic hydrolysis pretreatment of wastewater in industrial parks, which is completed according to the following steps:

[0022] 1. First add the catalytic reduction filler and the biohydrolysis filler into the catalytic reduction biohydrolysis tank, and then add the pretreated industrial wastewater into the catalytic reduction biohydrolysis tank for degradation through the water inlet at the lower part of the catalytic reduction biohydrolysis tank;

[0023] 2. First add the ozone catalytic filler into the ozone catalytic reaction tank, then pump the upper layer liquid of the industrial wastewater in the catalytic reduction biological hydrolysis tank into the ozone catalytic reaction tank, and add hydrogen peroxide into the ozone catalytic reaction tank at the same time. Oxidation, the industrial wastewater in the ozone catalytic reaction tank flows back into the catalytic reduction biological hydrolysis tank from the water...

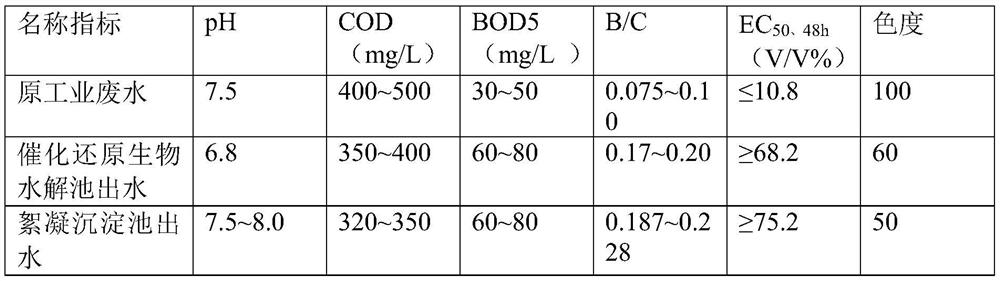

specific Embodiment approach 2

[0033] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the pretreated industrial wastewater described in Step 1 is prepared according to the following steps: adding the industrial wastewater into the wastewater regulating tank, and adjusting the pH of the industrial wastewater to 6.5 to 7.5, the pretreated industrial wastewater is obtained; the hydraulic retention time in the wastewater conditioning tank is 8h, and the perforated aeration stirring method is used for stirring.

[0034] Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0035] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the catalytic reduction filler described in step 1 is made of iron powder, copper powder, nickel powder, manganese powder and activated carbon powder after being mixed and soaked and then sintered. , the diameter is 2cm-4cm; the stacking height of the catalytic reduction filler in the catalytic reduction biological hydrolysis tank is 0.3m-0.5m, accounting for 5% to 8% of the volume of the catalytic reduction biological hydrolysis tank.

[0036] Other steps are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com