System and method for recovering acid and alkali from high-salt-content deacidification wastewater

A technology for recovering acid-base and high-salt content, which is applied in chemical instruments and methods, gaseous effluent wastewater treatment, water pollutants, etc. It can solve the problems of inability to reuse resources and high comprehensive disposal costs, and achieve the realization of resource recovery. Effective utilization, reduction of solid waste generation, improvement of energy saving and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

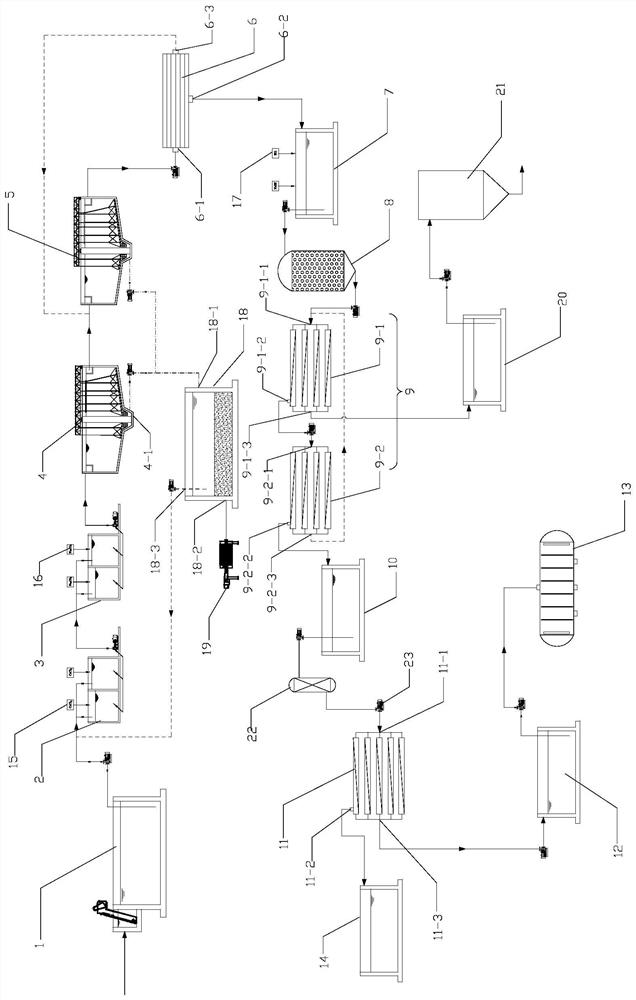

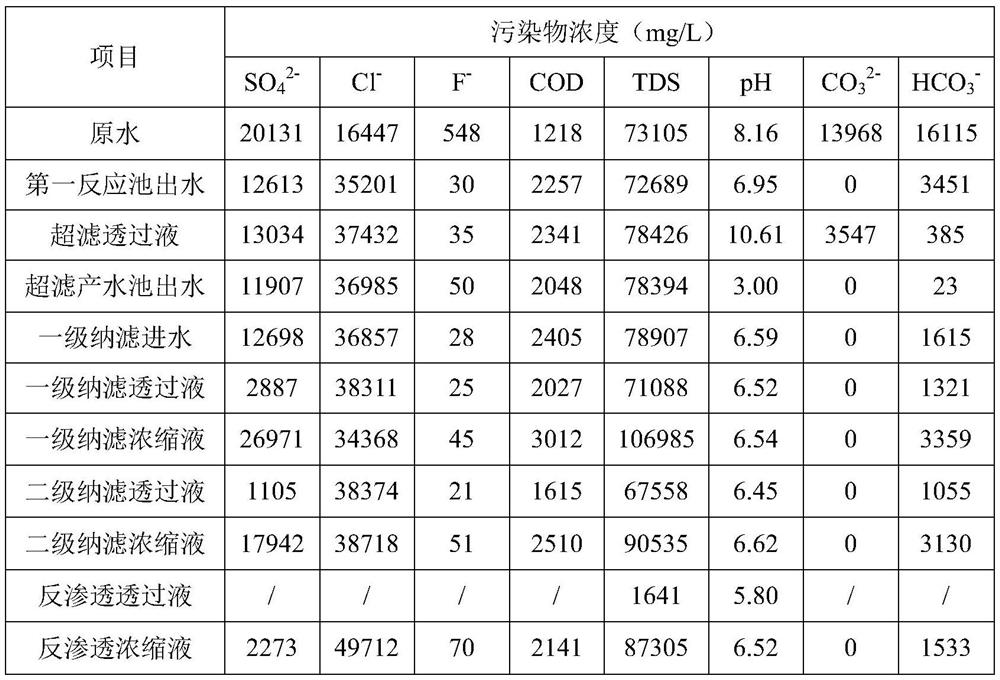

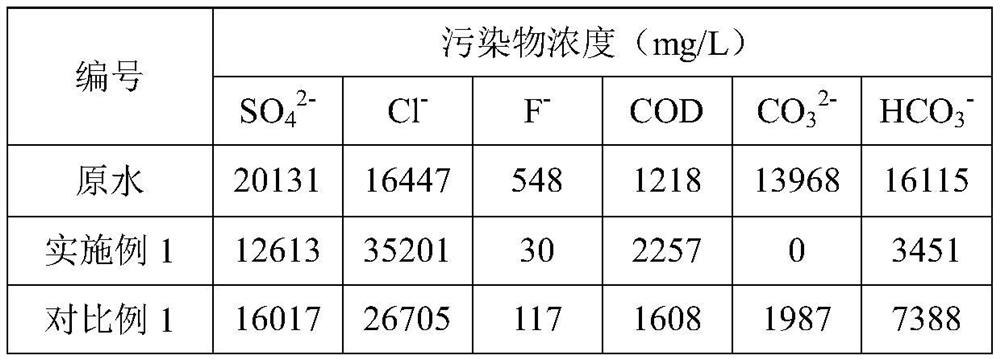

[0050] A method for reclaiming acid and alkali from high-salt deacidification wastewater using the above-mentioned system, comprising the steps of:

[0051] (1) The deacidification wastewater enters the first reaction tank after being homogenized by the homogenization tank, and CaCl is added 2 To react, CaCl 2 The dosage is 14kg / m 3 Deacidification wastewater, residence time 25min;

[0052] (2) The effluent of the first reaction tank enters the second reaction tank, adding 30wt% Na 2 CO 3 solution to react, Na 2 CO 3 The dosage of the solution is 7.6L / m 3 Deacidification wastewater, residence time 25min;

[0053](3) After the effluent of the second reaction tank passes through the sedimentation tank and the concentration tank for precipitation, the supernatant enters the ultrafiltration system for ultrafiltration. The operating pressure of the ultrafiltration device is 2.4MPa, and the influent flow rate is 30m 3 / h;

[0054] (4) The permeate after ultrafiltration ente...

Embodiment 2

[0060] The preparation method of the nanofiltration membrane in the primary and secondary nanofiltration device in embodiment 2 is:

[0061] A) ZrCl with a molar ratio of 1:1.5 4 and 2-aminoterephthalic acid dissolved in DMF, ZrCl 4 The mass volume ratio of DMF and DMF is 1g:120mL; add hydrochloric acid, ultrasonically disperse for 25min, then heat to 130°C for hydrothermal reaction for 30h, and after cooling to room temperature, filter, wash and dry the product to obtain a metal-organic framework material; the added hydrochloric acid The mass concentration is 36%, and the volume ratio of added hydrochloric acid to DMF is 1:55;

[0062] B) Add the metal organic framework material and N-methylimidazole to ethanol, and stir for 14 hours under the protection of nitrogen; then add 3-bromopropylamine hydrobromide, and reflux for 30 hours under the protection of nitrogen; wherein, the metal organic framework material, N- The mass ratio of methylimidazole and 3-bromopropylamine hyd...

Embodiment 3

[0068] A method for reclaiming acid and alkali from high-salt deacidification wastewater using the above-mentioned system, comprising the steps of:

[0069] (1) The deacidification wastewater enters the first reaction tank after being homogenized by the homogenization tank, and CaCl is added 2 To react, CaCl 2 The dosage is 8kg / m 3 Deacidification wastewater, residence time 20min;

[0070] (2) The effluent of the first reaction tank enters the second reaction tank, adding 40wt% Na 2 CO 3 solution to react, Na 2 CO 3 The dosage of the solution is 5L / m 3 Deacidification wastewater, residence time 20min;

[0071] (3) After the effluent of the second reaction tank passes through the sedimentation tank and the concentration tank for precipitation, the supernatant enters the ultrafiltration system for ultrafiltration. The operating pressure of the ultrafiltration device is 2.0MPa, and the influent flow rate is 30m 3 / h;

[0072] (4) The permeate after ultrafiltration enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com