Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

146results about How to "Realize the purpose of turning waste into treasure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for comprehensively utilizing useful substances in shrimp and crab skin

ActiveCN104140474AImprove production yieldRealize the purpose of turning waste into treasureAnimal feeding stuffFermentationBiotechnologyEngineering

The invention relates to a method for comprehensively utilizing useful substances in shrimp and crab skin. The method is characterized by mainly comprising the steps that first, mineral substances, protein, pigment and chitin in the shrimp and crab skin are recycled; second, the chitin is degraded with an enzymatic method to prepare N-acetyl-D-glucosamine; third, enzymolysis waste residues are applied. Due to the method, the useful substances in the shrimp and crab skin are extracted and recycled step by step, raw materials can be fully utilized, the problem that leftovers of products in the shrimp and crab industry are contaminated is solved, and resources are saved to the maximum extent.

Owner:NANJING UNIV OF TECH

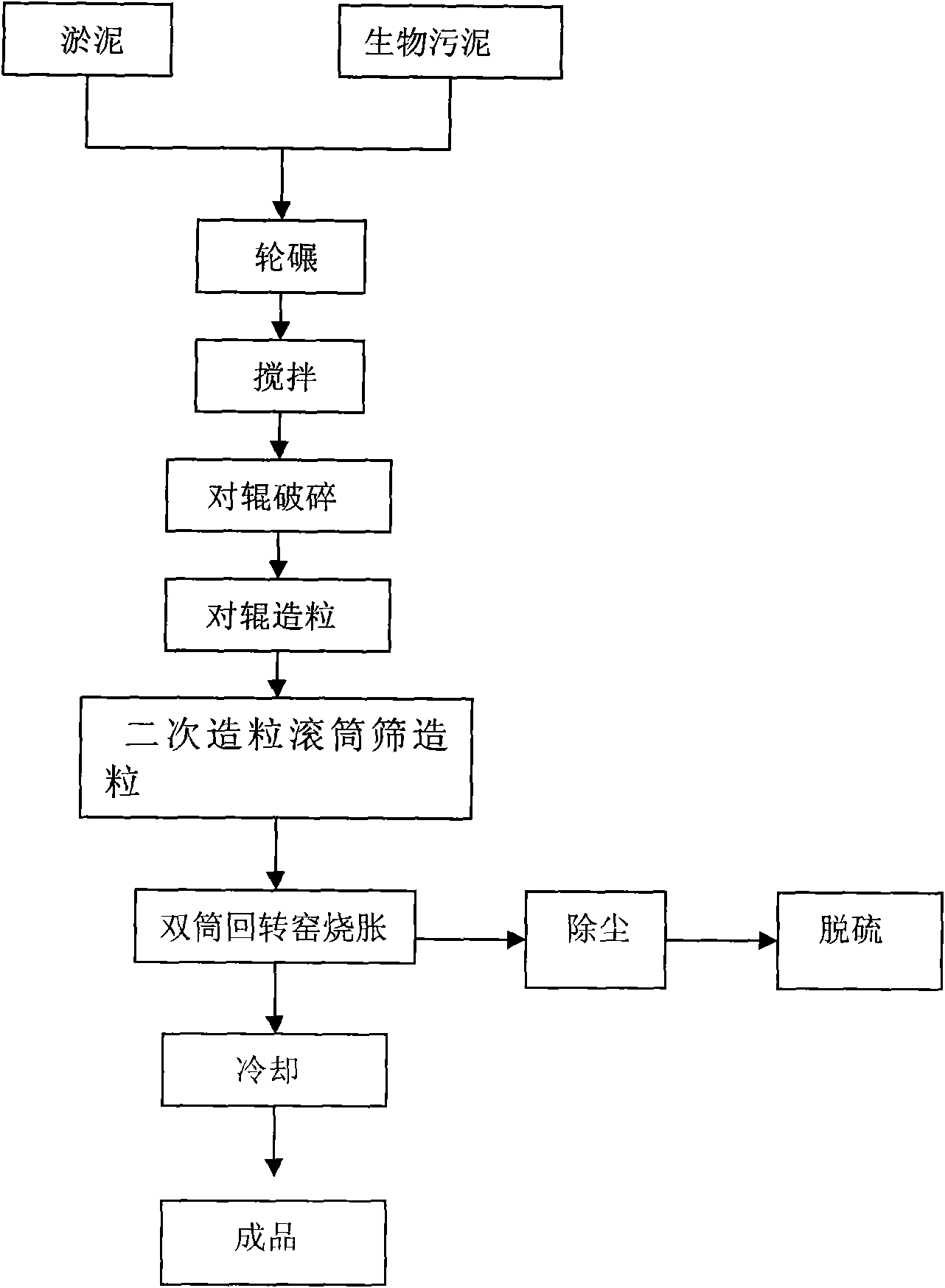

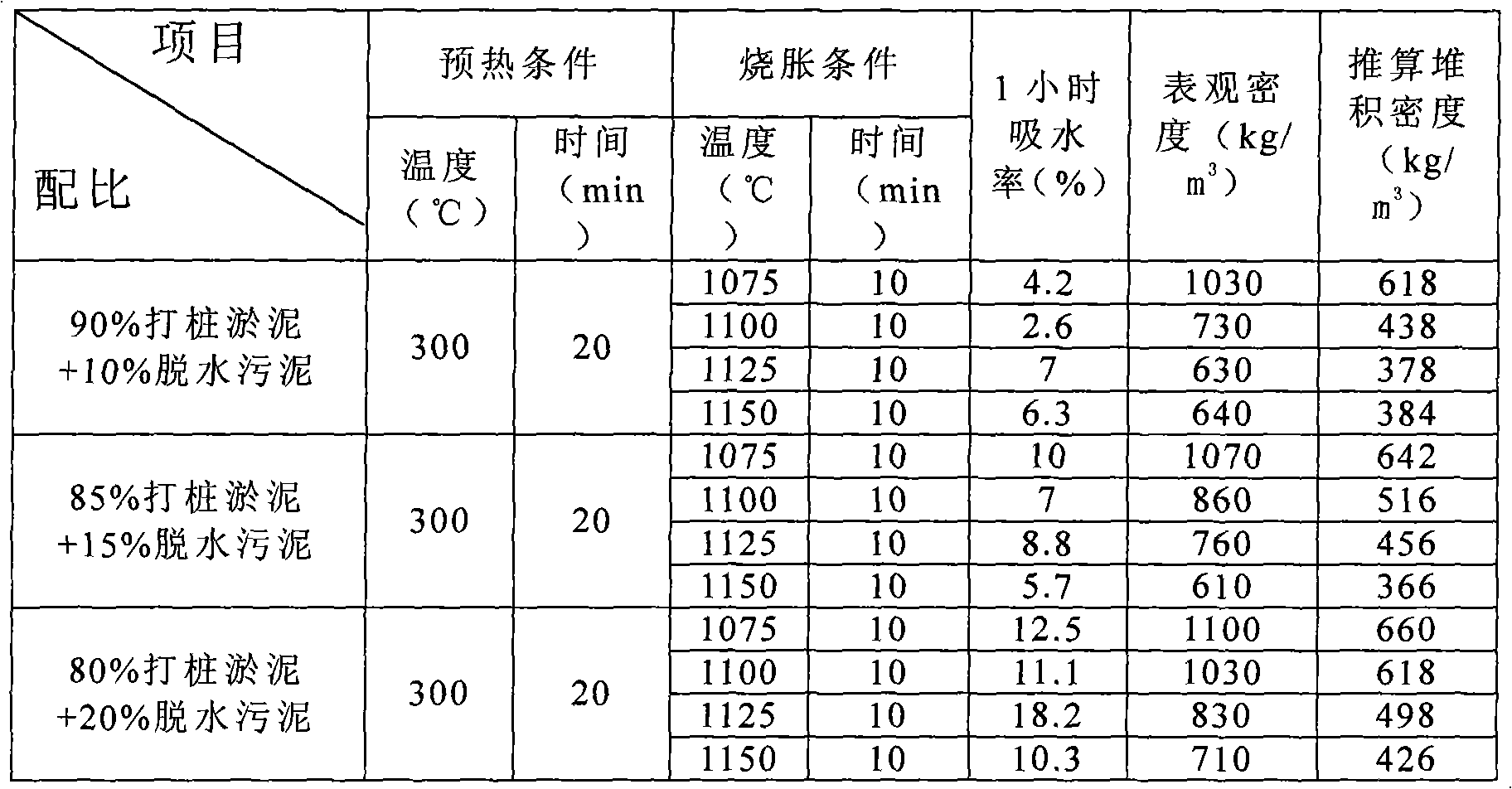

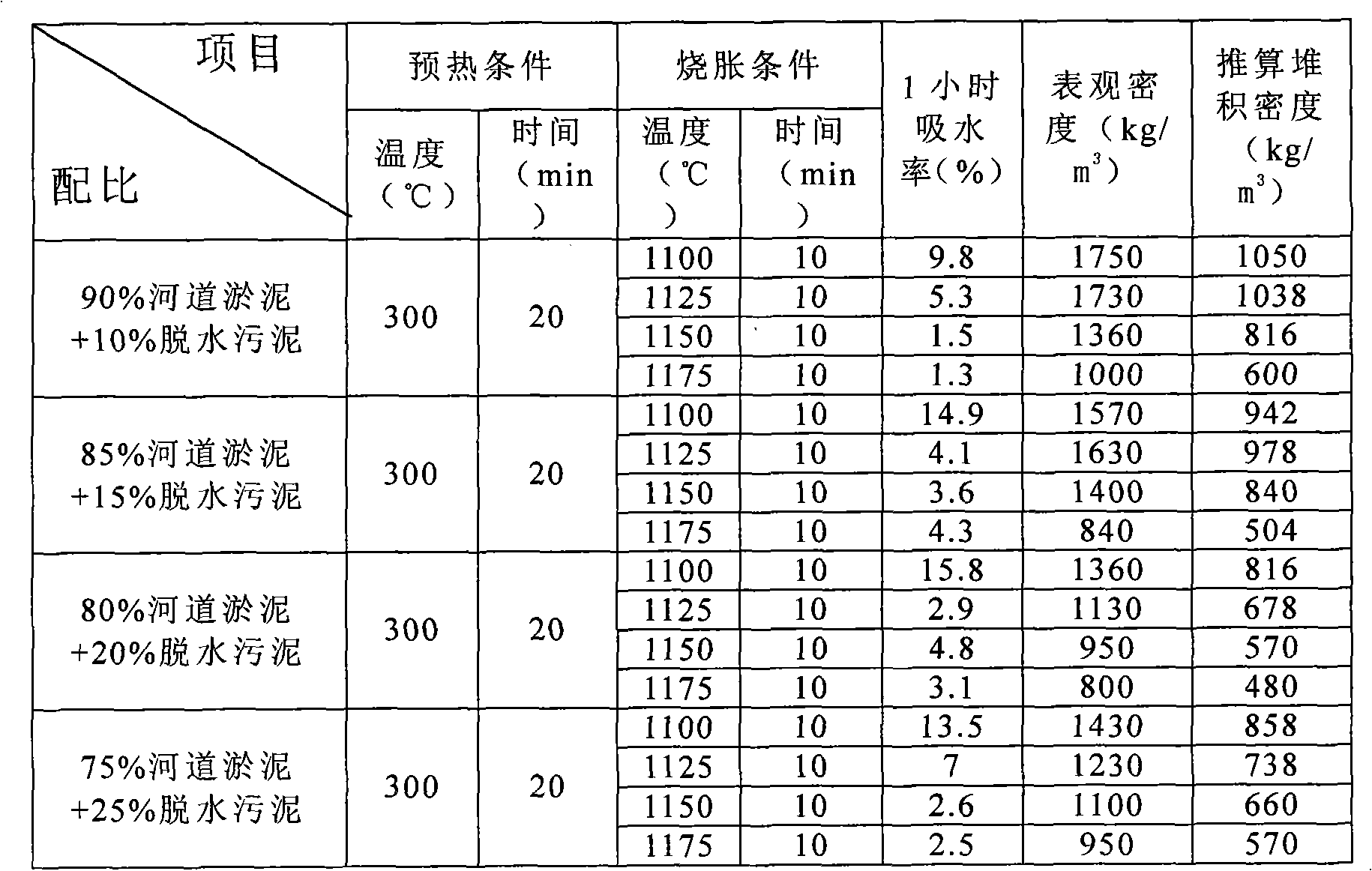

Preparing method of ceram site fully using biosolid and sludge

ActiveCN101585714AGood energy saving effectSelf weight effect is goodSolid waste disposalCeramicwareIndustrial wasteSludge

This invention discloses a preparing method of ceram site fully using biosolid and sludge, including steps as follows: a, mixing materials; b, preparing particles; c, sintering at temperature of 1000-1300 degrees centigrade after pre-heating for 5-20 minutes; cooling at temperature of 50-200 degrees centigrade for 10-30 minutes after sintering, thereby preparing finished ceram site product. Accordingly, this invention makes effective use of urban mud, and changes industrial waste solid into valuable; further, this utilyit model is low in preparation cost and suitable for large-scaled production.

Owner:ZHEJIANG FANGYUAN BUILDING MATERIALS TECH

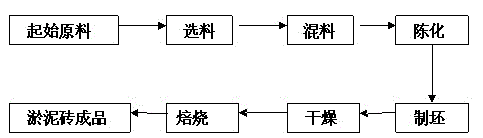

Mud brick fired by environment-friendly comprehensive utilization of wastes and preparation method thereof

InactiveCN103183499AReduce moisture contentAvoid toxic leachingCeramic materials productionClaywaresBrickSludge

The invention belongs to the field of waste resource environment-friendly utilization, and particularly relates to a mud brick fired by environment-friendly comprehensive utilization of wastes and a preparation method thereof. The mud brick comprises the following components by weight percent: 35-65 percent of dredging silt, 5-15 percent of sludge, 15-25 percent of domestic waste incineration slag, 10-25 percent of fly ash and 1-5 percent of quicklime, wherein the dredging silt is in large rivers, lakes, rivers or sea and has the water content of less than or equal to 80 percent and the clay component content of more than or equal to 30 percent; the sludge is generated after water treatment in a sewage treatment plant and has the clay component content of more than or equal to 30 percent; the domestic waste incineration slag and the fly ash are active wastes generated by incineration of domestic wastes; and quicklime is common quicklime II. The invention has the advantages that various wastes are comprehensively utilized in an environment-friendly manner and changed into valuables to avoid secondary pollution, and the social and economic benefits are remarkable. The mud brick can be extensively used in municipal engineering and construction engineering, protects the environment and saves resources.

Owner:HOHAI UNIV

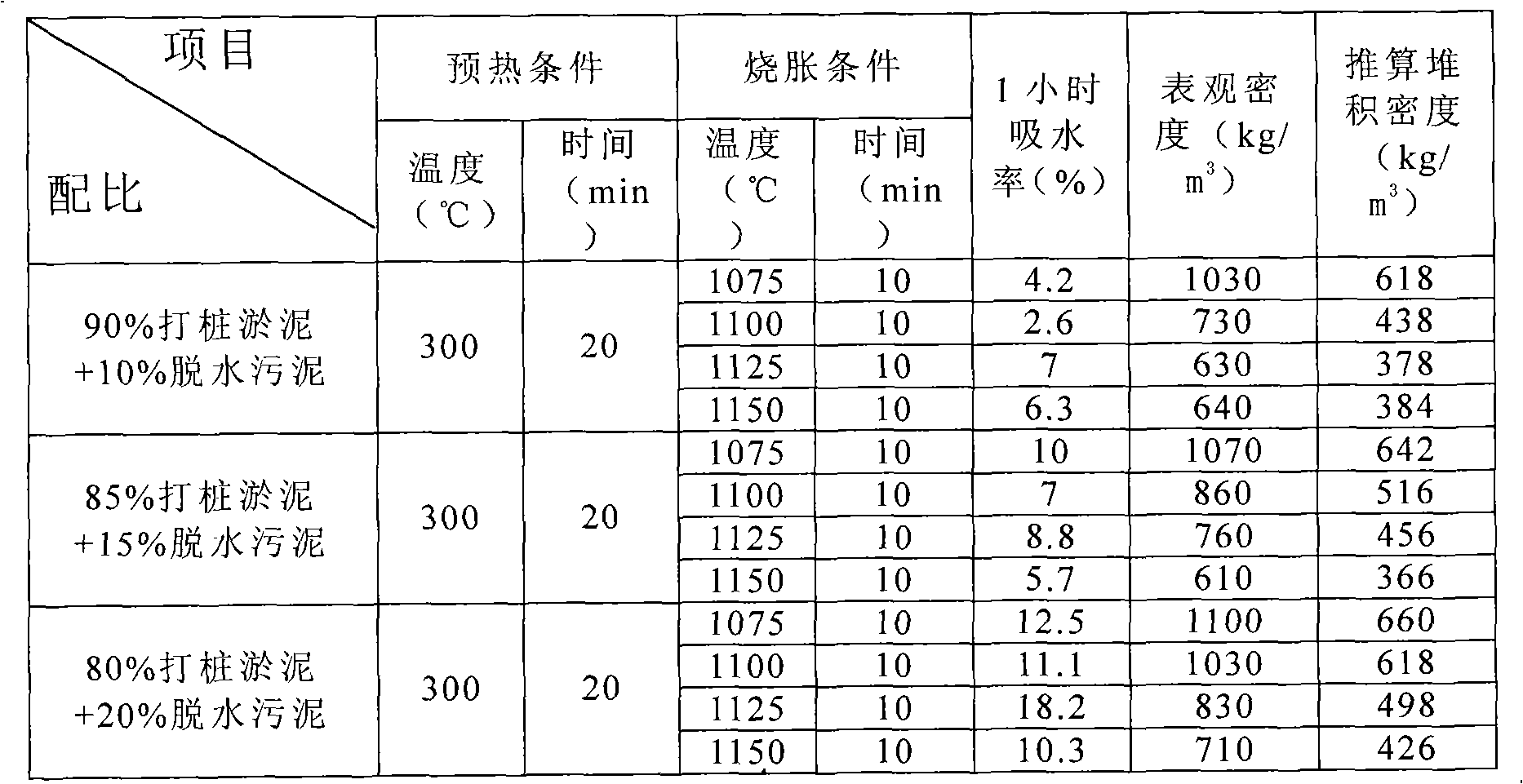

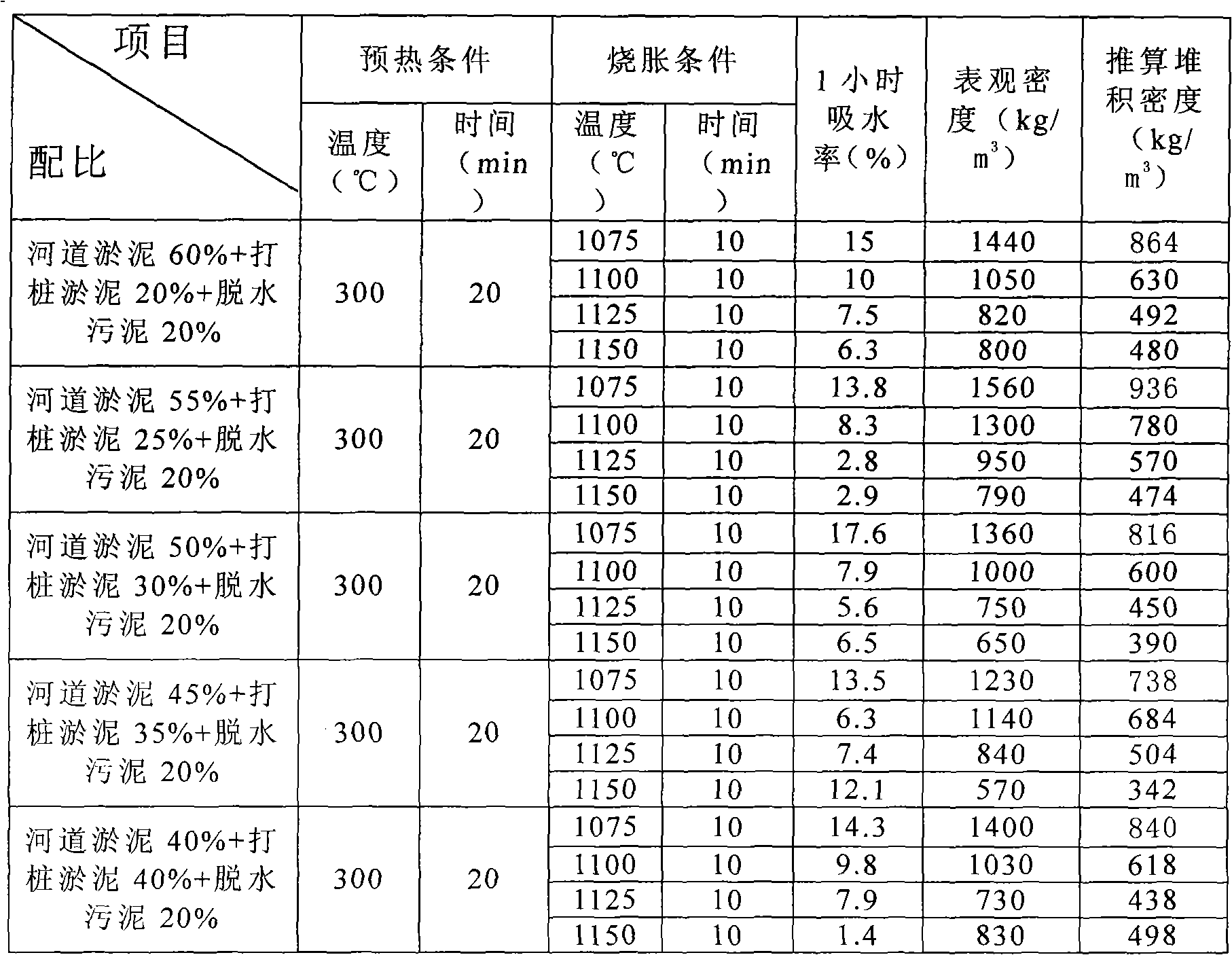

Biosolid-sludge mixed ceram site

ActiveCN101585672AImprove protectionEfficient use ofSolid waste disposalSludgeToxic industrial waste

This invention discloses biosolid-sludge mixed ceram site, belonging to the technical field of light materials. The biosolid-sludge mixed ceram site is prepared using raw materials as follows: biosolid of 10-30 parts by weight, and sludge of 70-90 parts by weight, wherein the biosolid is dehydrated mud and the sludge is river sludge and / or piling sludge. Accordingly, the mixed ceram site makes effective use of urban mud, and changes industrial waste solid into valuable; further, this utility model is wide in raw material source and is relatively low in cost.

Owner:ZHEJIANG FANGYUAN BUILDING MATERIALS TECH

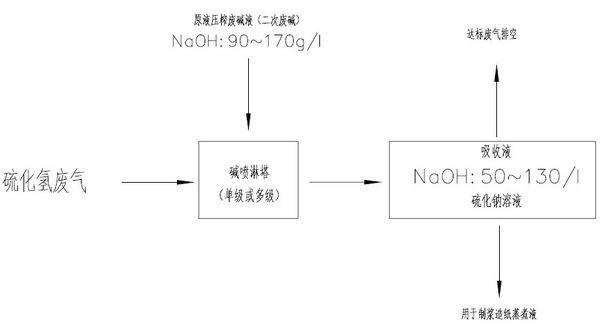

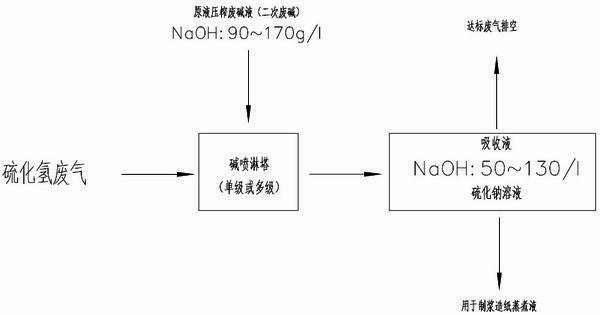

Method for recycling hydrogen sulfide waste gas

InactiveCN102512937ASolve pollutionFix security issuesDispersed particle separationPulp gases treatmentFiberFiltration

The invention relates to the field of waste gas recovery in viscose fiber industry, in particular to a method for recycling hydrogen sulfide waste gas. The method mainly includes the steps: A, squeezing alkali fibers to generate waste alkali liquor, and subjecting the waste alkali liquor to membrane filtration to obtain secondary waste alkali liquor; B, utilizing the secondary waste alkali liquor as alkali absorption liquor, and jointly delivering the secondary waste alkali liquor and the hydrogen sulfide waste gas generated during viscose fiber production to an alkali spray tower; and C, utilizing drained alkali spray absorption liquor as digestion liquor for sulfate pulping, and delivering Na2S (sodium sulfide) obtained by reaction and the rest of NaOH (sodium hydroxide) liquor to a pulping process. The method has the advantages that the method is high in hydrogen sulfide waste gas absorption efficiency and large in treatment quantity in unit time, the problems of environmental pollution and potential production safety hazards due to hydrogen sulfide waste gas emission are solved, and the purposes of treating waste with waste and turning the waste into wealth are realized by the aid of the waste alkali liquor generated by squeezing the alkali fibers.

Owner:YIBIN HIEST FIBER +2

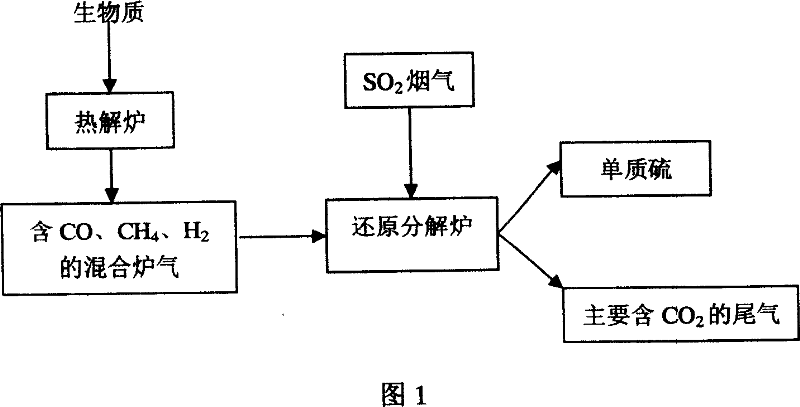

Method for deacidizing low sulfur dioxide concentration by using gas produced by biomass pyrolysis

InactiveCN101036853AEmission reductionRealize the purpose of treating waste with wasteDispersed particle separationCarburetting by solid carbonaceous material pyrolysisReductive decompositionFlue gas

The invention relates to a process for reducing SO2 to elemental sulfur in flue gas by using biomass pyrolysis gas, which belongs to the desulfurization technic field. The pyrolysis reaction for the biomass is carried out in a pyrolysis oven to generate a mixed pyrolysis gas used as desulfurizer which mainly comprises CO, CH4, and H2, the prepared catalyst is filled in a reductive decomposition oven, the mixed pyrolysis gas and the flue gas containing low-concentration SO2 are introduced into the reductive decomposition oven to have a reduction reaction at temperature of between 600DEG C and1000DEG C for 1h to 3h, the volume percentage of the SO2 gas from reductive decomposition oven can be up to 0.006% to 0.65%, and the desulfurization percent can be up to 80% to 98%, thereby realizing waste reutilization.

Owner:KUNMING UNIV OF SCI & TECH

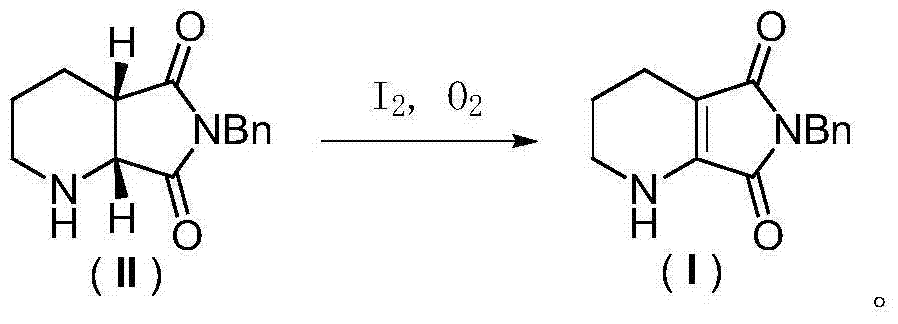

Racemization method of (1R, 6S)-8-benzyl-7, 9-dioxo-2, 8- diazabicyclo (4, 3, 0) nonane

The invention relates to the field of a medical technology, and discloses a racemization method of (1R, 6S)-8-benzyl-7, 9-dioxo-2, 8- diazabicyclo (4, 3, 0) nonane. The method comprises the steps of (1) in ether solvent or polar aprotic solvent, carrying out oxidative dehydrogenation on the (1R, 6S)-8-benzyl-7, 9-dioxo-2, 8-diazabicyclo (4, 3, 0) nonane by taking elemental iodine and oxygen as co-oxidant to prepare 6-benzyl-5, 7-dioxo-1, 2, 3, 4-tetrahydron-pyrrolo (3, 4-b) pyrrole; (2) in ester solvent or alcohol solvent, carrying out catalytic hydrogenation on oxidative product by taking Pd / Al2O3 as a catalyst to obtain the racemic cis-8-benzyl-7, 9-dioxo-2, 8-diazabicyclo (4, 3, 0) nonane. The method is simple in technology, convenient to operate, mild in reaction conditions, etc.

Owner:SHAOXING UNIVERSITY

Soilless culture method for wild old stump potted landscape

InactiveCN102217519ALow costRealize the purpose of turning waste into treasureAgriculture gas emission reductionCultivating equipmentsSocial benefitsBiology

The invention discloses a soilless culture method for a wild old stump potted landscape. The method comprises the following steps of: culturing an old stump in a special cement pit, frequently spraying the old stump to promote old roots to root and germinate, periodically changing water and exposing the roots to enable the old roots to slowly adapt to grow in water, unearthing the old stump, transferring the old stump to a water filled container, and completing soilless culture of the old stump by adopting a common soilless culture technology, wherein in the soilless culture process, soilless potted landscape culture of the old stump is completed by adopting a conventional potted landscape pruning technology. The method is low in cost, and realizes the social benefit of changing wastes into valuable.

Owner:高贯友

Harmless treatment system and method for municipal waste incineration

ActiveCN102294340AShort dry burn timeIncineration realizedSievingScreeningEnvironmental engineeringTreatment system

The invention relates to a refuse treatment system, especially to a harmless treatment system for city refuse burning, and a method thereof. The harmless treatment system for the city refuse burning has the following structure that: the rear of a screening system is connected with a hand-picking system; the hand-picking system is connected with an incinerator; a refuse outlet end of the screeningsystem is connected with a biomass pool; a high temperature gas outlet end of the incinerator is connected with a gas purification treatment system; a gas outlet end of the gas purification treatmentsystem is connected with a reutilization apparatus. According to the present invention, the process is simple; the residual heat can be used for heat supplying, power generation and the like; the system has characteristics of low investment, low operating cost and no environmental pollution.

Owner:李东国 +1

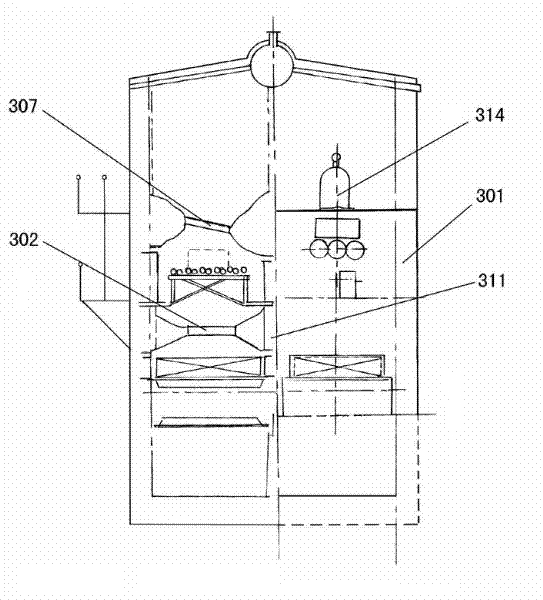

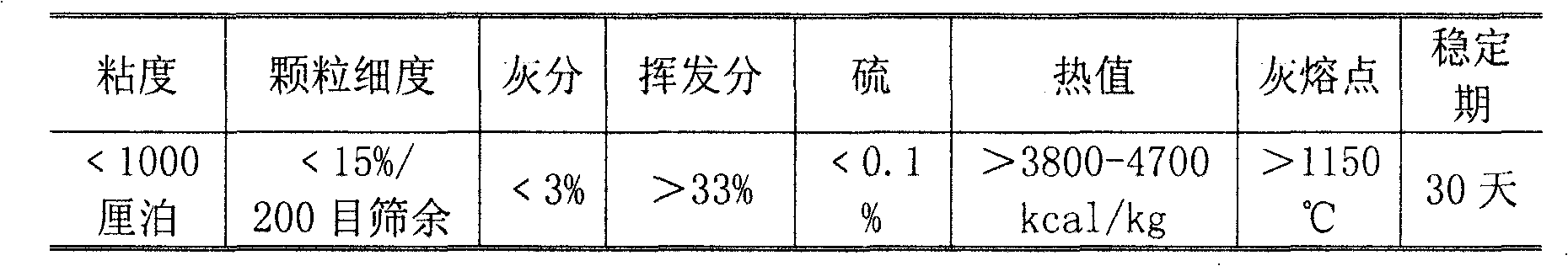

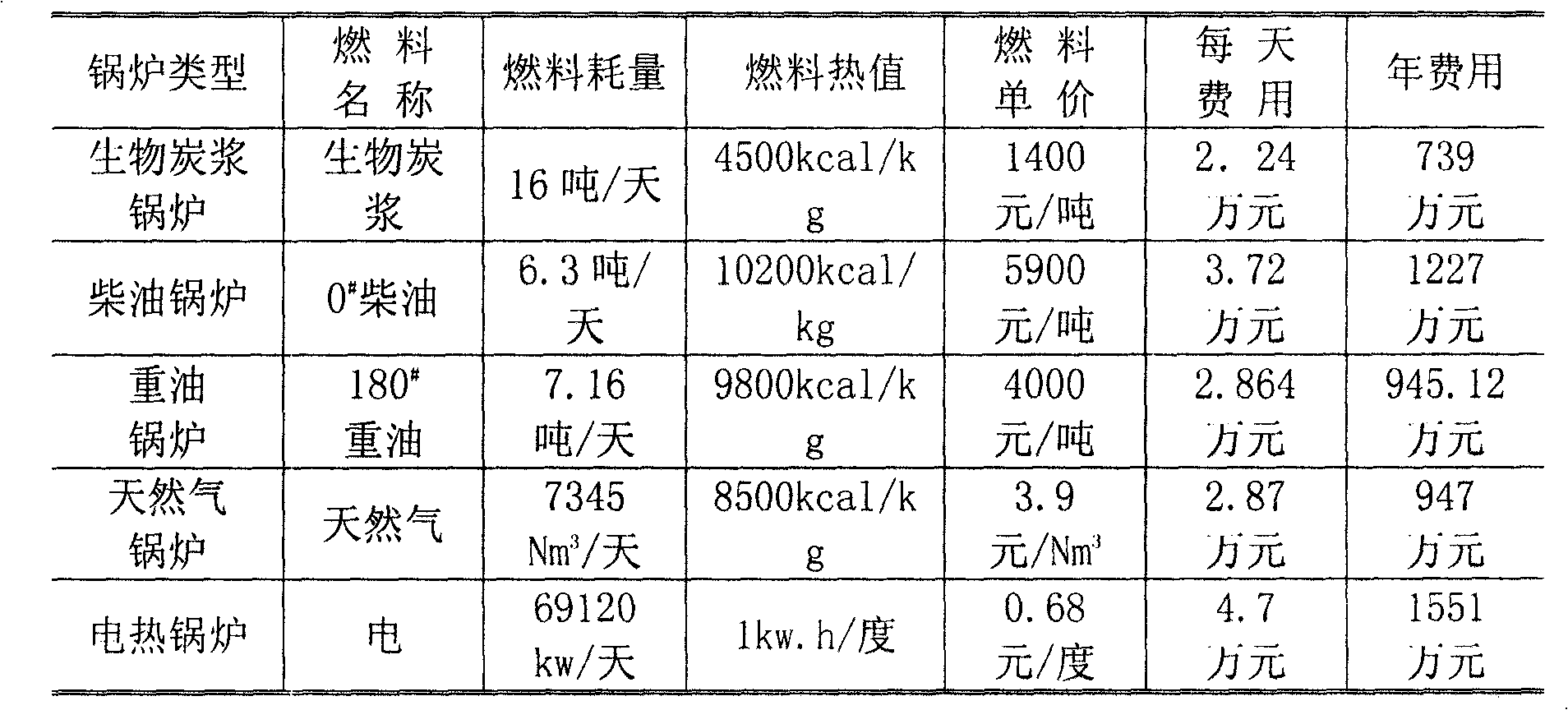

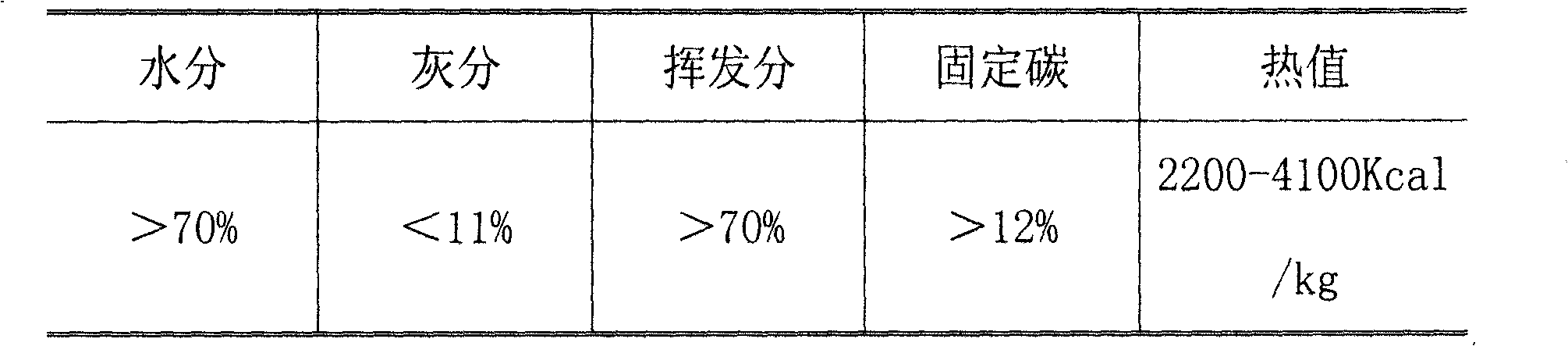

Biochar pulp prepared from garbage leachate serving as raw material and preparation process thereof

ActiveCN101787312AEmission reductionLow in sulfur and nitrogenLiquid carbonaceous fuelsPower stationEnvironmental engineering

The invention discloses a biochar pulp prepared from garbage leachate serving as a raw material and a preparation process thereof, and aims to provide the biochar pulp prepared from the garbage leachate serving as the raw material and the preparation process thereof, which have the advantages of the combination of energy saving and emission reduction and environmental management and low cost. Thepreparation process comprises the following steps of: mixing biochar, the garbage leachate, methanol, high-temperature sand and additives serving as raw materials; and crushing, homogenizing and filtering the mixed raw materials to prepare the biochar pulp. The biochar pulp is used for replacing fuel oil so as to effectively save energy and reduce fuel cost, plays a good part in managing urban environment, and fulfills the aims of promoting economic and environmental health and sustainable development. The biochar can be widely applied in the fields of substitute oil firing such as industrialboilers, power station boilers, industrial furnaces and the fields of urban environment management and the like.

Owner:珠海中水环保科技有限公司

Soilless culture method for potted landscape of orchid

InactiveCN102499040ARealize the purpose of turning waste into treasureConvert to Secondary ReuseAgriculture gas emission reductionCultivating equipmentsPlant cultivationBotany

The invention discloses a soilless culture method for potted landscape of orchid. The soilless culture method comprises the steps as follows: cultivating a plant of the orchid in a purpose-made cement pit, promoting rooting of the plant through frequently spraying and adding nutrition, enabling the plant to adapt to growing in water through the technology of changing water periodically and exposing the root, taking the plant out of soil, transplanting the plant into a container holding water, and accomplishing soilless culture of the orchid by adopting the general soilless culture technology; and during the process of soilless culture, soilless potted landscape culture of plants of the orchid is accomplished by adopting the technology of root exposure and nutrition adding of the conventional potted landscape. The method has the advantages that the cost is low, and a new orchid culture method is realized compared with the traditional soil culture of orchid.

Owner:高贯友

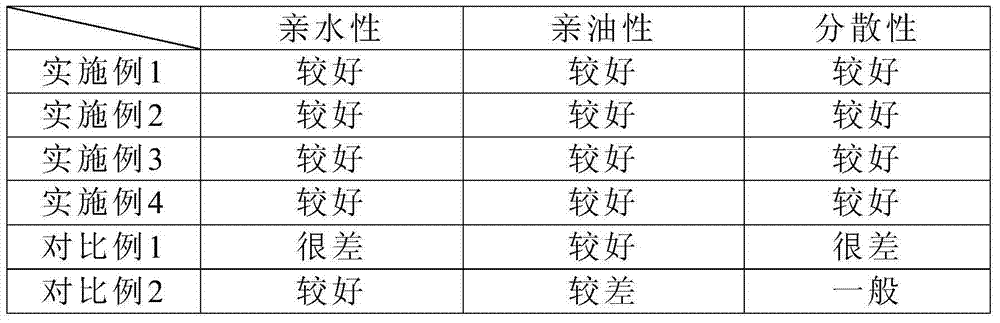

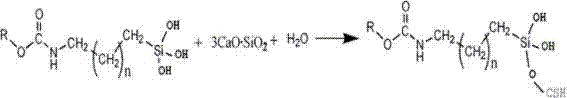

Hydrophilic and oleophilic polytetrafluoroethylene micro-powder and preparation method thereof

InactiveCN103923264AHas the function of hydrophilic and lipophilicEasy to prepareDispersityTetrafluoroethylene

The present invention relates to hydrophilic and oleophilic polytetrafluoroethylene micro-powder and a preparation method thereof. According to the hydrophilic and oleophilic polytetrafluoroethylene micro-powder, in a solvent, in the presence of 5-10 parts of a surfactant, 1-3 parts of concentrated H2SO4, and 1-3 parts of a polymerization inhibitor, 15-30 parts of polytetrafluoroethylene micro-powder crushed through electron beam irradiation, 25-50 parts of a water-soluble monomer and 40-80 parts of an oil-soluble monomer are grafted to prepare the hydrophilic and oleophilic polytetrafluoroethylene micro-powder. According to the present invention, the water-soluble monomer and the oil-soluble monomer are grafted on the polytetrafluoroethylene micro-powder, such that the polytetrafluoroethylene micro-powder maintains the original excellent performance, further has functions of hydrophilicity and lipophilicity, has good dispersity, and can be uniformly blended with other materials.

Owner:ZHEJIANG GREEN NEW MATERIALS

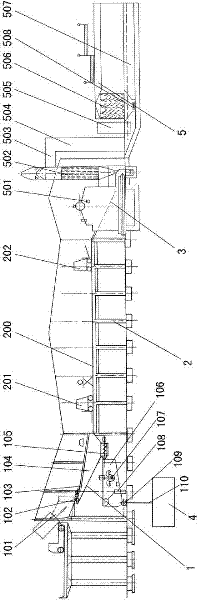

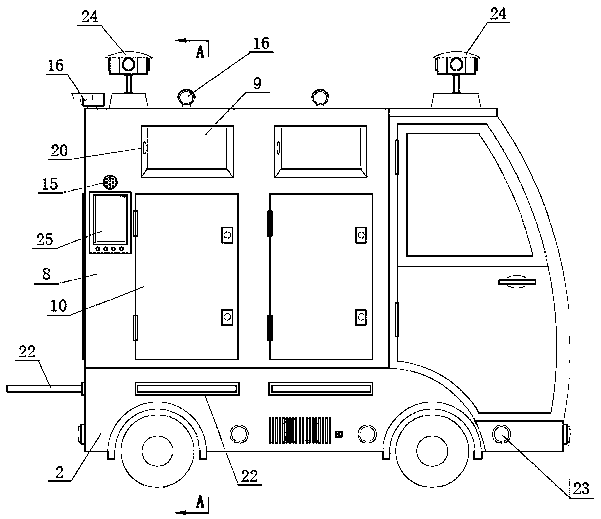

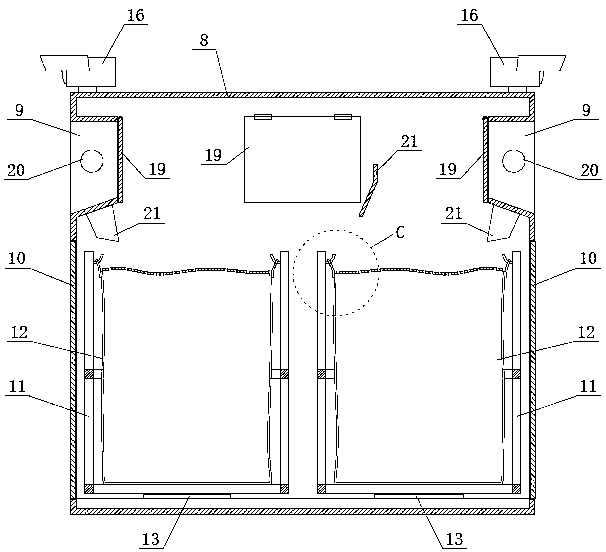

Unmanned garbage collection and storage vehicle and garbage collection and storage method capable of realizing full coverage in area

The invention relates to an unmanned garbage collection and storage vehicle and garbage collection and storage method capable of realizing full coverage in an area. Based on driverless technology, Internet of Things technology and internet technology, the collection and storage vehicle can move arbitrarily in a planning area through an automatic driving function of the collection and storage vehicle, and users in the area can throw garbages anywhere at any time without moving, so that full coverage in the area is realized. At the same time, the unattended type collection and storage vehicle combines scaled centralized management and operation, incomes of common people are ensured by score accumulation and integral audit, and the common people are guided to actively carry out garbage classification, so that the problem in traditional garbage recycling industry is thoroughly solved. In addition, the collection and storage method is simple in procedure, convenient to carry out and convenient to promote and operate.

Owner:潍坊美好生活环保科技有限公司

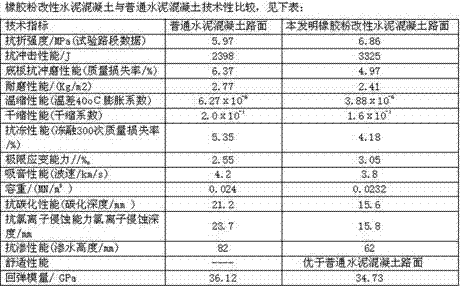

Rubber powder modified cement concrete pavement and manufacturing method thereof

ActiveCN107188488AEffective digestionExtended service lifeIn situ pavingsSolid waste managementCelluloseWear resistant

The invention discloses a rubber powder modified cement concrete pavement and a manufacturing method thereof. The rubber powder modified cement concrete pavement is characterized by being prepared from the following raw materials in parts by weight: 25 to 30kg / m<3> of rubber powder, 300 to 330kg / m<3> of 425 cement, 550 to 590kg / m<3> of river sand, 1080 to 1180kg / m<3> of broken stone, 135 to 165kg / m<3> of water, 5 to 7kg / m<3> of water reducing agents, 3 to 4kg / m<3> of phthalic ester coupling agents, 2 to 3kg / m<3> of rubber latex, 3 to 4kg / m<3> of hydrophobic modification cellulose, 15 to 20kg / m<3> of lignin, 80 to 110kg / m<3> of granulitic blast-furnace ore slag powder and the like. The raw materials are effectively mixed to obtain the concrete. The rubber powder modified cement concrete pavement has the characteristics that the properties of anti-folding intensity, anti-impact performance, bottom plate anti-impact and anti-abrasion performance, wear-resistant performance, temperature shrinkage, dry shrinkage performance, freezing resistance performance, ultimate strain capability, noise reducing performance, volume weight, corrosion resistance and the like of the rubber powder modified cement concrete pavement are superior to those of the ordinary cement concrete pavement; the later-stage maintenance cost is lower than that of the ordinary cement concrete pavement, and the like.

Owner:广西航务建设工程有限公司

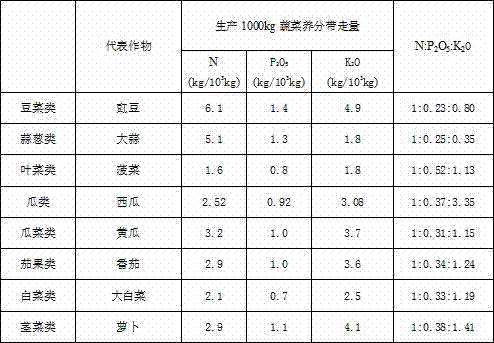

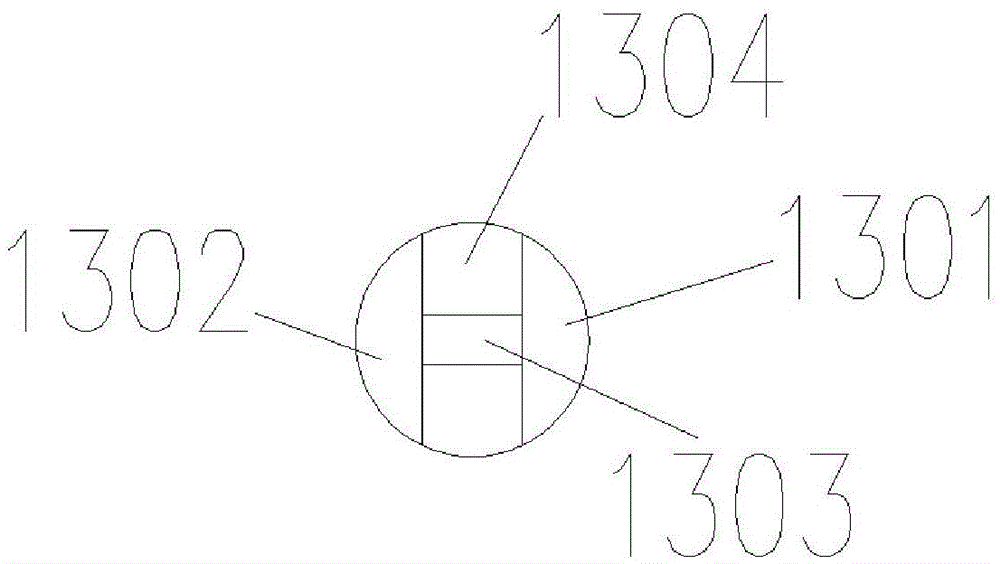

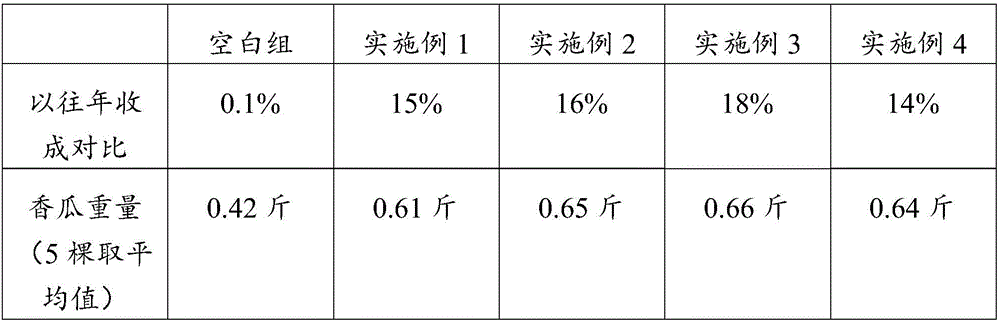

Special organic base fertilizer and preparation method thereof

ActiveCN104163666AWide variety of sourcesLow costBio-organic fraction processingOrganic fertiliser preparationAgricultural scienceOrganic base

The invention provides a special organic base fertilizer and a preparation method thereof. The organic base fertilizer is prepared from the following raw materials in percentage by weight: 25% of sugarcane top, 15% of bagasse, 5% of peanut hull meal, 7% of cattle manure, 5% of horse manure, 5% of plant ash, 3% of mushroom slag, 3% of bean pulp, 5% of protein sludge, 3% of vinasse, 3% of vinegar vinasse, 10% of biogas slurry, 3% of river course silt, 7% of water, 0.8% of rice bran and 0.2% of organic fertilizer baking powder. The special organic base fertilizer has the advantages of wide raw material sources and low cost, can improve the soil structure, and has the functions of preserving the moisture and fertility, enhancing the soil permeability, promoting the growth and development of plants and increasing the yield.

Owner:惠州海大川凯肥料有限公司

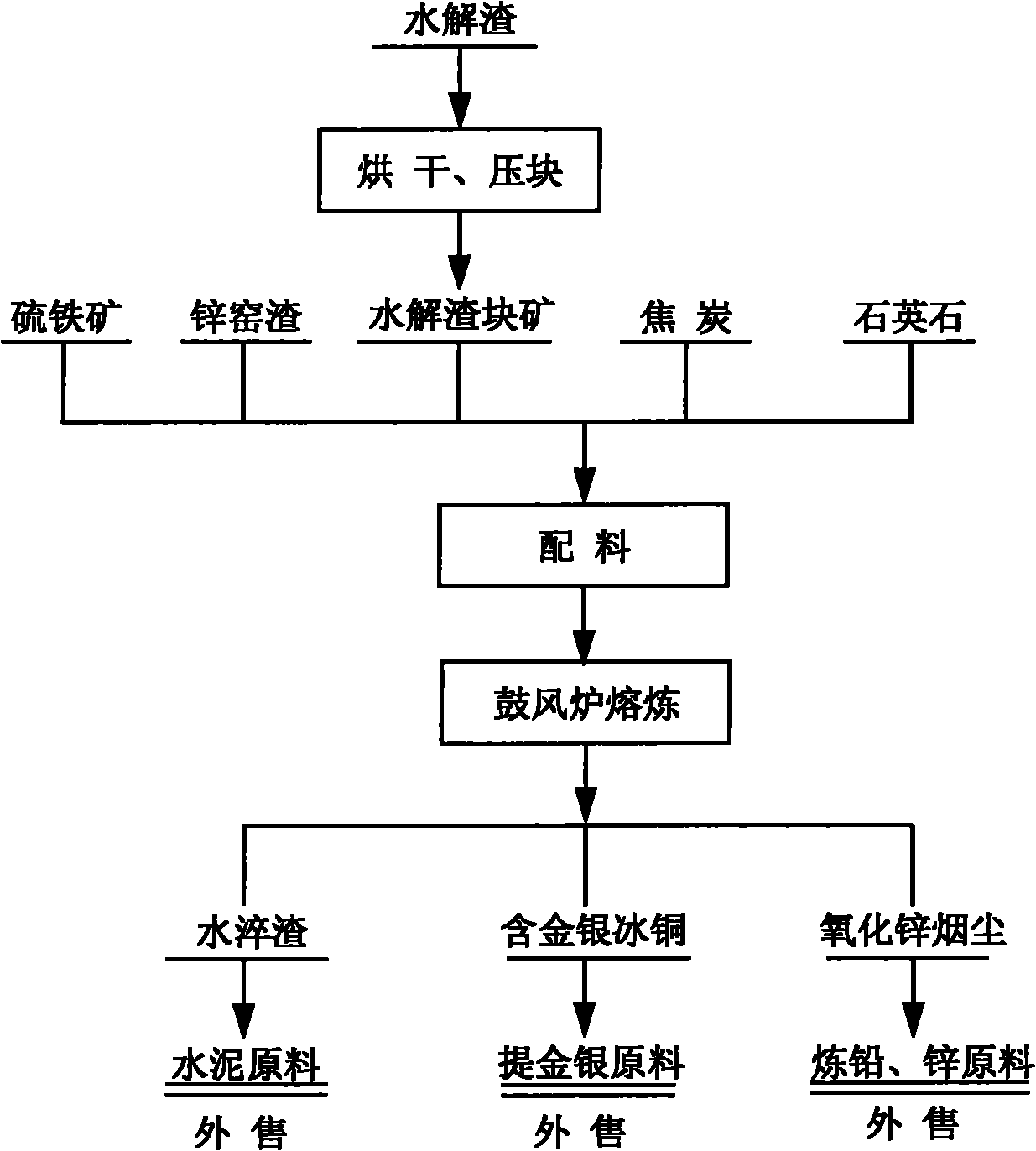

Method for simultaneously smelting hydrolysis slag, pyrite and zinc kiln slag by using blast furnace

ActiveCN101812594AHigh recovery rateReduce productionBlast furnace detailsCement productionBriquetteZero emission

The invention relates to a method for simultaneously smelting hydrolysis slag, zinc kiln slag and pyrite by using a blast furnace, which belongs to the technical field of metal smelting. The method comprises the following steps: a, taking a proper amount of hydrolysis slag, drying the hydrolysis slag with hot air to meet the moisture requirement of 6 to 14 percent, then briquetting the hydrolysis slag, and naturally drying the briquette for 10 to 16 hours for later use; b, taking 55 to 71 percent of zinc kiln slag of which over 80 percent meets the initial granularity requirement of 10 meshes, adding 9 to 20 percent of hydrolysis slag briquette, 13 percent of coke, 3 to 5 percent of quartzite and 4 to 7 percent of pyrite into the zinc kiln slag, naturally mixing the five materials and then smelting the mixture in the blast furnace; c, smelting the mixture in the blast furnace, wherein the smelting temperature is between 600 and 1,350 DEG C, the smelting period is 40 to 80 minutes, the material column height is 1.5 to 1.8 meters and the volume of blast is 7,000 to 8,000 m<3> / h; and d, reclaiming the gold and sliver-containing copper matte obtained after smelting to obtain a raw material for smelting copper, reclaiming zinc and lead valuable elements in the soot to directly obtain raw materials for smelting zinc and lead, and directly using water granulated slag as a raw material for producing cement. The method has the advantages of simultaneously obtaining the copper matte, the water granulated slag and the soot serving as primary products through one process, realizing efficient separation and zero emission of the valuable elements, along with environmental protection.

Owner:云南云铜锌业股份有限公司

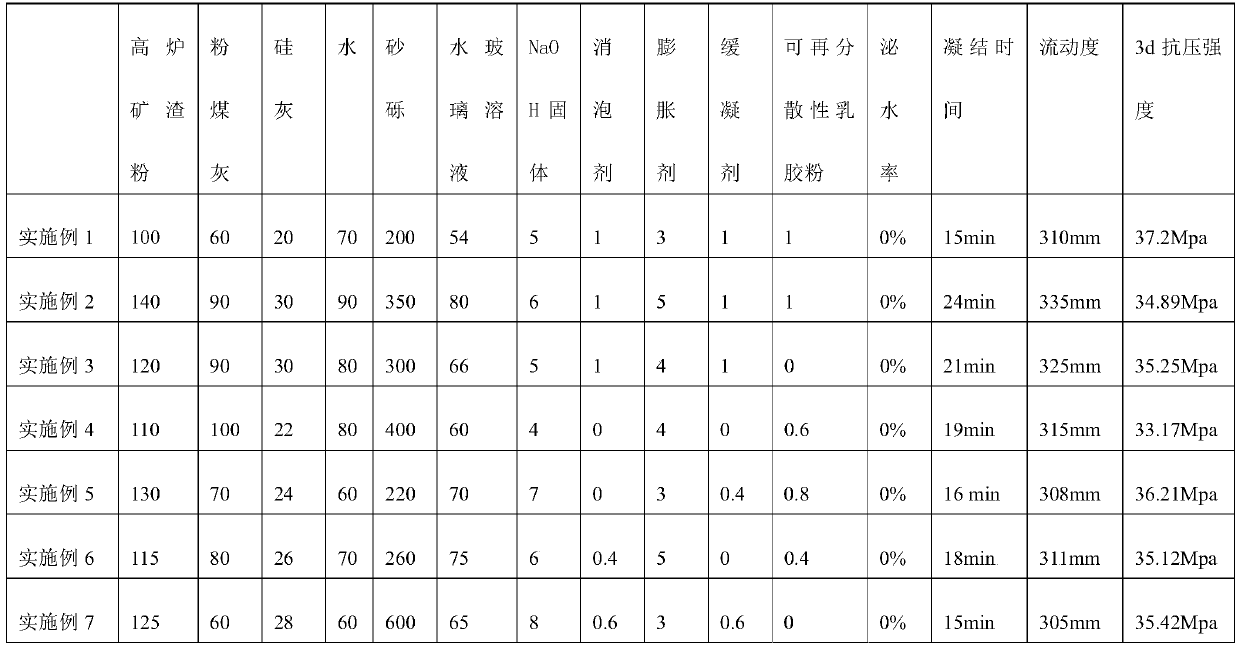

Uncemented geopolymer grouting material and preparation method thereof

he invention discloses an uncemented geopolymer grouting material and a preparation method thereof. Gravel is used as a supporting material to improve the overall strength of the material, blast furnace slag powder, fly ash and silica fume are added, and the silica ash mainly composed of SiO2 can optimize the pore structure and reduce the porosity of the system; a water glass solution and NaOH are used to dissolve and rejoin active silicon, aluminum and calcium substances in the fly ash and slag powder in order to form hydration products which are C-S-H hydrated calcium silicate and C-S-A-Hhydrated calcium aluminosilicate, and a solution composed of the water glass solution and NaOH is used to firstly react the fly ash with alumina in the slag powder in order to ensure the increase of the reinforcing material after the calcium oxide removal, so the utilization rates of the blast furnace slag powder and the fly ash are effectively improved, and the working performances of the grouting material are improved. The grouting material prepared in the invention has the advantages of good fluidity, low bleeding ratio, high concretion rate, effectiveness in utilization of the industrial wastes which are slag powder and fly ash, and realization of the purpose of changing industrial wastes into valuables.

Owner:CHANGAN UNIV

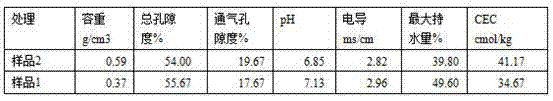

Leaf vegetable cultivation matrix and preparation method thereof

ActiveCN104261958AFull of nutritionImprove germination rateBio-organic fraction processingBioloigcal waste fertilisersFermentationVermiculite

The invention belongs to the field of agriculture, especially belongs to the field of plant seedling growing and discloses a leaf vegetable cultivation matrix and a preparation method thereof. Aiming at filling in gap of use of fermentation bed waste padding in a leaf vegetable cultivation matrix, the invention provides a method for preparing a leaf vegetable cultivation matrix from fermentation bed waste padding and the leaf vegetable cultivation matrix obtained by the method. The leaf vegetable cultivation matrix is prepared from fermentation bed waste padding, vermiculite, perlite and vegetable garden soil by mixing. The leaf vegetable cultivation matrix and the preparation method realize recovery and recycle of fermentation bed waste padding thereby realizing change of waste into valuables.

Owner:南京沃优生物肥业有限公司

Inorganic coagulant and preparation method thereof

InactiveCN107935143AImprove adsorption capacityLow costWater contaminantsWater/sewage treatment by flocculation/precipitationIron saltsHazardous substance

The invention provides an inorganic coagulant and a preparation method thereof. The inorganic coagulant is prepared from major raw materials including steel slag and pulverized fuel ash according to amass ratio of 8:2. The preparation method mainly comprises the following steps of raw material pretreatment, acidification treatment, alkalization treatment, mixing and drying. Through the technicalscheme, a large number of solid wastes are utilized; the environment is protected; the raw material sources are enlarged; the material cost is reduced; through acidification treatment and alkalizationtreatment, a multicomponent iron salt and aluminum salt mixed coagulant is obtained; the respective advantages of two coagulants are fully realized; the flocculation effect is improved; high adsorption capacity is realized, so that a better removal effect is achieved on hazardous substances such as chroma, macromolecular organic compounds and heavy metal ions.

Owner:BAOTOU IRON & STEEL GRP

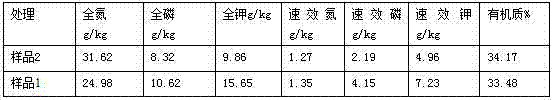

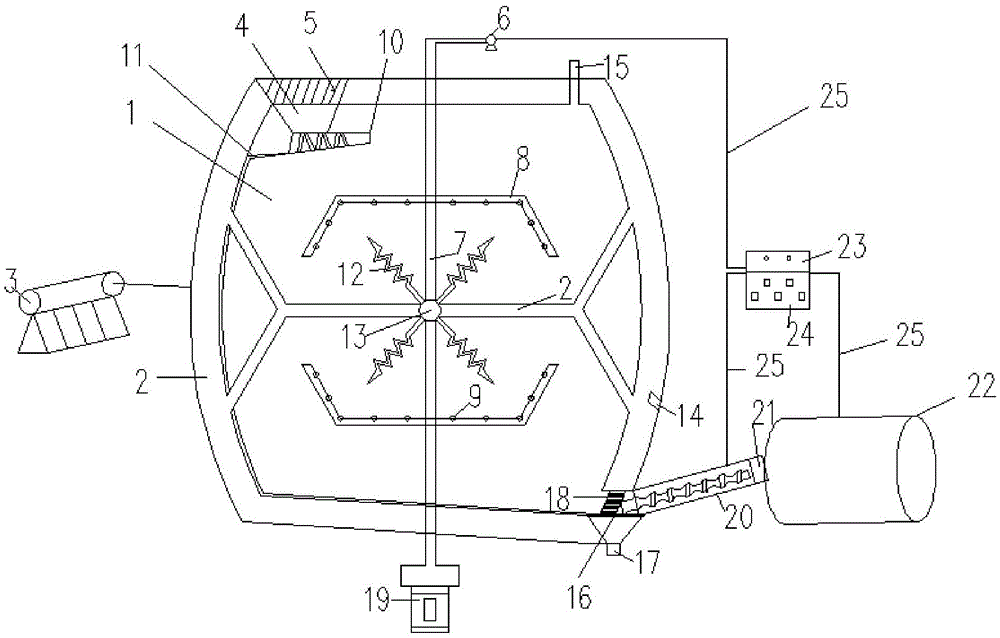

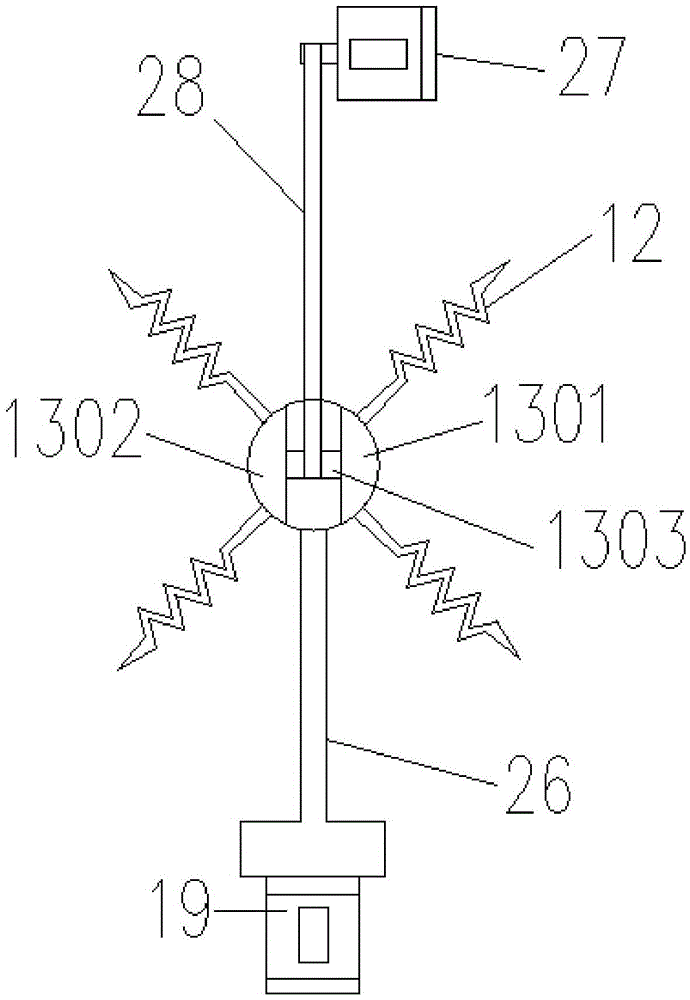

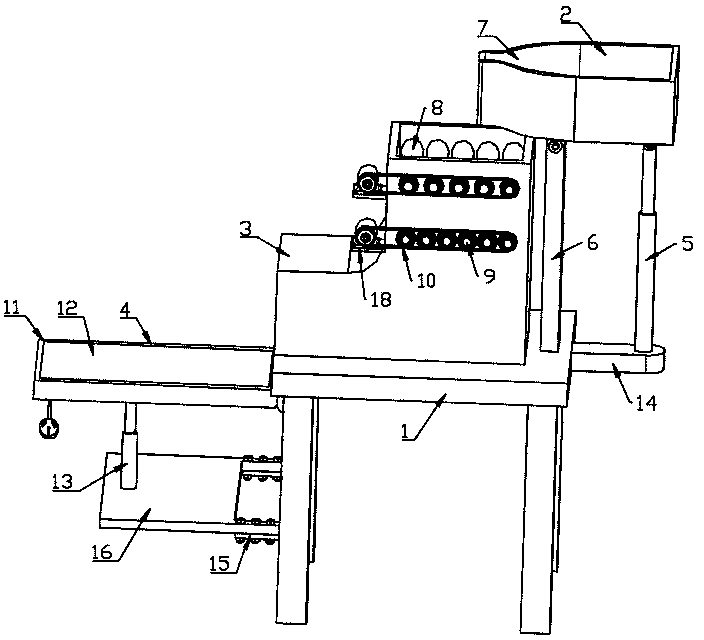

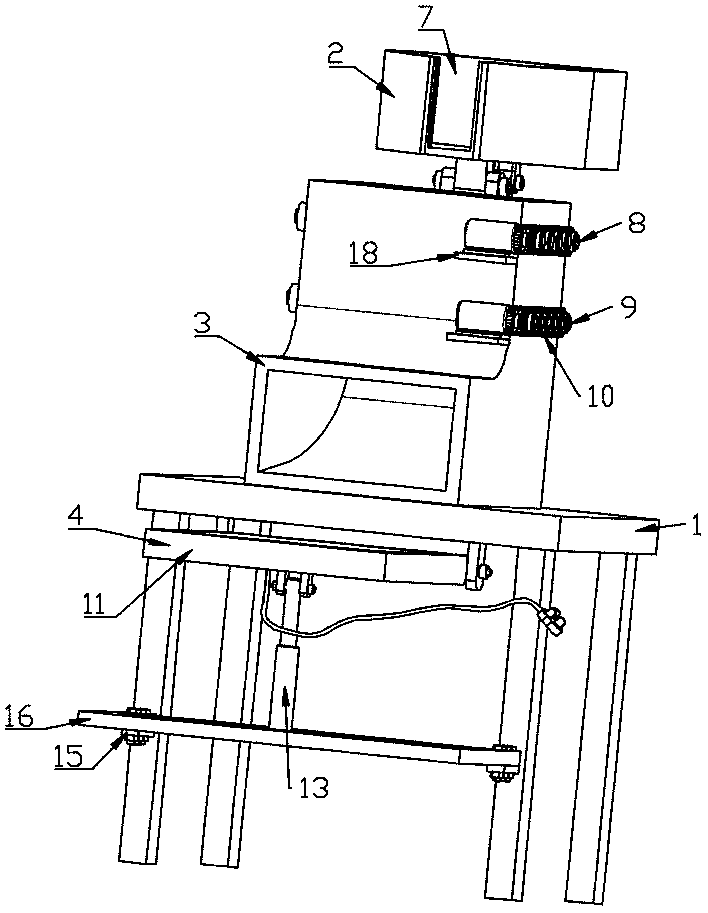

Household garbage fermentation and fertilizer making device and method

ActiveCN105461367AAvoid blockingBlocking implementationClimate change adaptationOrganic fertilisersFermentationScrew conveyor

The invention discloses a household garbage fermentation and fertilizer making device and method. A device body is a fermentation bin. A feed inlet and an air outlet are formed in the upper portion of the fermentation bin. A feeding baffle is arranged at the feed inlet. The lower portion of the fermentation bin is provided with a liquid outlet used for draining percolate and a discharge outlet used for outputting fermented materials. A breaking device is arranged in the fermentation bin and composed of a plurality of sets of breaking blades distributed in a cross shape, and has two perpendicular rotary dimensionalities. Household garbage to be treated passes through a spiral conveying machine through the feed inlet to enter the fermentation bin where a hot water pipeline is laid, is broken and fermented and then enters a dehydration pelleting and drying system from the position of a discharge baffle. According to the household garbage fermentation and fertilizer making device and method, breaking, stirring, heating, fermentation, dehydration pelleting and drying are integrated, garbage is converted into fertilizer, the energy is nature is effectively utilized, the running cost is reduced, the resources are effectively utilized while the environment problem is solved, the garbage is made profitable, and a new approach for effectively treating household garbage is provided.

Owner:ZHEJIANG UNIV

Granular compounded organic fertilizer and preparation method thereof

InactiveCN106748522AFertilization is convenientLong storage timeBio-organic fraction processingDi-calcium phosphate fertilisersCompound organicLivestock manure

The invention discloses a granular compounded organic fertilizer which comprises the following raw materials in parts by weight: 60-80 parts of livestock manure, 30-50 parts of manioc wastes, 12-25 parts of sugar plant filter mud, 5-10 parts of medicine dregs, 40-60 parts of white mud, 1-5 parts of potassium fulvic acid, 5-10 parts of an inorganic fertilizer, 1-5 parts of biological bacteria, 5-10 parts of fermentation bacterial and 1-5 parts of a compound aid, wherein the weight ratio of nitrogen and phosphorus to potassium in the inorganic fertilizers is 15:(3-8):(8-12). The invention further provides a preparation method of the granular compounded organic fertilizer. As the granular compounded organic fertilizer is prepared from agricultural wastes through two times of fermentation, wastes can be turned into wealth, and the problem of organic matter environment pollution can be solved; due to the addition of inorganic fertilizer components, and appropriate proportions of elements of nitrogen, phosphorus and potassium, a good fertilizer effect can be achieved, and nitration absorption of plants can be promoted; the prepared granular compounded organic fertilizer is good in organic fertilizer effect, is capable of loosening soil and powerfully ensures that high-yield, safe, high-quality and efficient agricultural products can be produced.

Owner:广西南宁奥浦森肥业有限公司

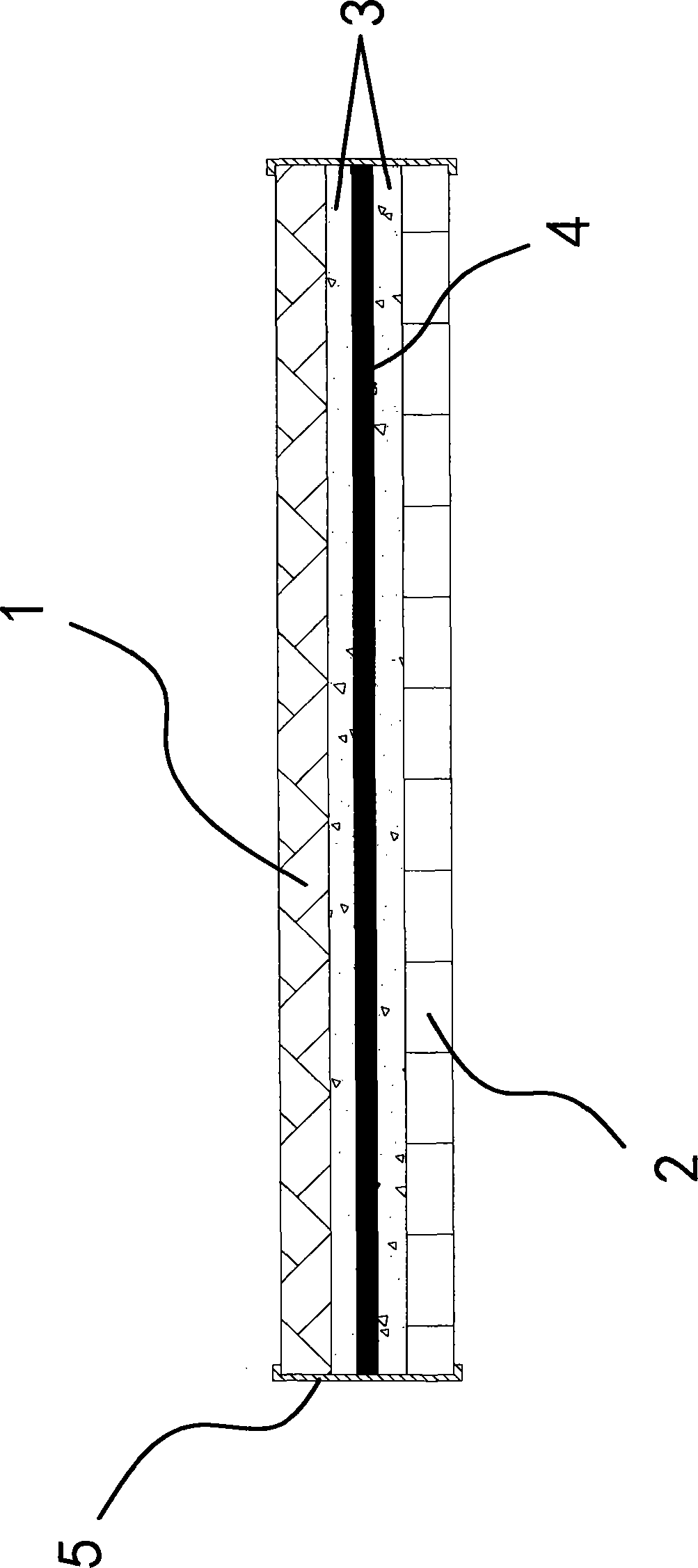

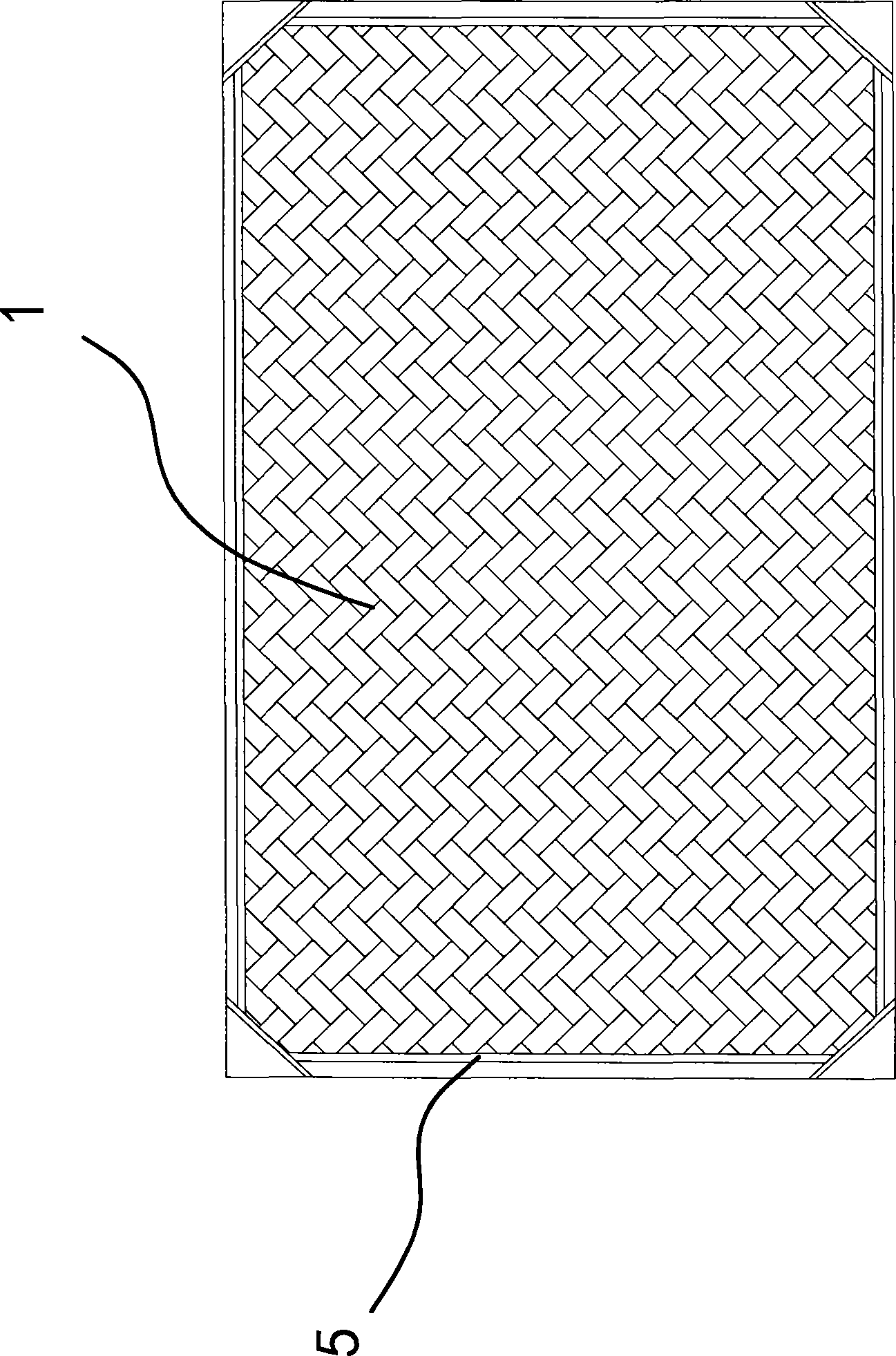

Processing technology and product of imitation vine and bamboo composite dual-purpose mat

The invention provides a processing technology and a product of an imitation vine and bamboo composite dual-purpose mat. The processing technology of the imitation vine and bamboo composite dual-purpose mat comprises the following steps of: a, pulping vegetation waste and making the pulped vegetation waste into semi-finished paper through a paper processing technology, slicing up and packaging core, then weaving to form an imitation vine mat main body and carrying out a press-polishing treatment; b, processing culm into bamboo canes, drying and weaving the bamboo canes into a bamboo mat main body; c, spraying environment friendly glue on the bottom surface of the imitation vine mat main body uniformly, paving a layer of gauze pad flatly, then paving the bamboo mat main body flatly and compacting; d, adopting double inserted line allocation, flanging by regarding the four 45-degree corners of the mat as oblique corners, and processing into a finished imitation vine and bamboo composite dual-purpose mat. The processing technology of the imitation vine and bamboo composite dual-purpose mat is simple, green and environment friendly; the produced imitation vine and bamboo composite dual-purpose mat is good in air permeability and hygroscopicity, is cool and comfortable and avoids causing skin sensibility.

Owner:NINGBO YINZHOU LIMING ARTS & CRAFTS

Method and device for preparing organic fertilizer by utilizing fecal sewage in urban septic tank

ActiveCN104628436AHigh quality processingEasy to processBio-organic fraction processingClimate change adaptationFecesWork in process

The invention discloses a method and a device for preparing an organic fertilizer by utilizing fecal sewage in an urban septic tank, belonging to the technical field of preparation of organic fertilizers. According to the technical key points, the method comprises the following steps: (1) collecting faeces, feces and sewage; (2) conveying and discharging the liquid dung mixture consisting of the faeces, feces and sewage into a faeces storage tank, adding quicklime powder, and stirring, so that the liquid dung mixture is subjected to solid-liquid separation; (3) standing, and discharging the intermediate dung sewage into a liquid pool for later use by virtue of a pipeline; (4) adding crop straw powder and the residual faeces and feces after the intermediate dung sewage is completely discharged, stirring and forming a semi-finished product; and (5) conveying the semi-finished product into a fermentation tank for fermenting for 15-25 days, packaging after the fermentation is ended, thereby obtaining the powdered organic fertilizer. The invention aims at providing a method and a device for preparing the organic fertilizer by utilizing the fecal sewage in the urban septic tank. According to the method and the device, the operation is easy and convenient, the urban dung sewage can be effectively treated, and the aim of changing wastes into valuable materials is achieved. The method and the device are used for manufacturing organic fertilizers.

Owner:张仲元

Preparation method of sugarcane leaf bio-fertilizer

InactiveCN103833430AGood fertilizer effectWide variety of sourcesBio-organic fraction processingOrganic fertiliser preparationAdditive ingredientFood flavor

The invention discloses a preparation method of a sugarcane leaf bio-fertilizer. The preparation method comprises the following steps: 1) adding brown sugar in water until the brown sugar is completely dissolved, then adding an EM (effective microorganisms) basic liquid to obtain an EM liquid; 2) evenly mixing the EM liquid, distiller's yeast and sugarcane leaf, stacking and compacting, and sealing with a plastic film or canvas for anaerobic fermentation for about 10 days in summer or about 15 days in winter until a stacking matter sends a distiller's yeast flavor or produces white and red mycelium to obtain the sugarcane leaf bio-fertilizer; wherein, the weight ratio of water to the brown sugar to EM basic liquid to distiller's yeast to sugarcane leaf is 30-50:0.5-2:0.5-2:50-200:400-800. The sugarcane leaf bio-fertilizer uses the sugarcane leaf as a main raw material which is wide in range of sources, the preparation method is simple and easy to control, and the prepared sugarcane leaf bio-fertilizer is free of inorganic fertilizer ingredients, and good in fertilizer efficiency, does not cause soil compaction, and can achieve the purpose of turning waste into treasure.

Owner:黄永成

Method for preparing edible fungus culture matrix from garlic straw wastes

InactiveCN102584354ALarge amount of processingRealize the purpose of turning waste into treasureClimate change adaptationBioloigcal waste fertilisersBiotechnologyAlliinase

The invention relates to a method for preparing an edible fungus culture matrix from garlic straw wastes. The method comprises the following steps of: putting the ground garlic straws into a steamer of a steam distillation device, spraying an alliinase-containing aqueous solution on the ground garlic straws, extracting garlic oil by a steam distillation method, and preparing the edible fungus culture matrix from the garlic straws from which the garlic oil is extracted. The garlic straw wastes are treated by the method, so that the wastes are recycled, and a natural garlic oil product can be obtained; and cost is low, the treatment capacity is high, obvious social and economic benefits are achieved, and industrial production can be implemented.

Owner:云南金雨庄生物科技有限责任公司

Method for utilizing sludge

ActiveCN105859317ASimple and easy to control textureHard textureSpecific water treatment objectivesCeramic materials productionBrickSludge

The invention belongs to the technical field of urban sewage treatment and particularly relates to a method for utilizing sludge. The method comprises: deodorizing sludge, and making it with bamboo charcoal, sepiolite, a foaming agent, potassium feldspar, expanded perlite, calcined kaolin, wollastonite powder and sodium dodecyl sulfate to obtain an insulation brick. The use of the method provides sludge resourceful utilization turning waste into wealth, and also provides new economic benefit, reducing economic burden for sludge treatment.

Owner:GUILIN RONGTONG TECH CO LTD

Method for preparing formaldehyde activated carbon adsorbent from ginkgo trees

InactiveCN108264043ALow costBroaden the fieldCarbon compoundsOther chemical processesActivated carbonWater vapor

The invention relates to a method for preparing a formaldehyde activated carbon adsorbent from ginkgo trees. The method comprises the steps that firstly, gingko trunks and branches are cut into smallpieces to be put into a carbonization furnace for carbonization, then, under high temperature, water vapor is used for performing repeated activation so that an abundant pore structure can be formed,the adsorption capacity is improved, and finally after drying is performed, packaging is performed to obtain the adsorbent. The ginkgo trees and branches which are not developed or utilized by peoplebasically are used for being developed into the novel formaldehyde activated carbon adsorbent, the application scenarios and fields are enlarged, and the purpose of recycling waste materials is achieved.

Owner:孝感市森茂激光数控设备有限公司

Method for preparing biodegradable polyurethane rigid foam from bamboo waste liquefaction products

InactiveCN101362818BRealize the purpose of turning waste into treasureReduce dependencePolymer sciencePolyethylene glycol

The invention discloses a method for preparing biodegradable rigid polyurethane foam with liquefaction products of bamboo waste, which comprises the following steps: 1 mass portion of crude glycerin / polyethylene glycol liquefying solvent and 0.02-0.04 mass portion of concentrated sulfuric acid are added into a reaction vessel, heated till the temperature reaches 120-180 DEG C after a reflux condensation tube is connected to the reaction vessel; 0.2-0.5 mass portion of crushed and dried bamboo waste is added, reacted for 90-180min with stirring, taken out and cooled and neutralized by MgO tillbeing neutral; 1 mass portion of liquefaction products of bamboo waste, 0.02-0.08 portion of a dibutyl tin dilaurate / triethylene diamine mixed catalyst, 0.02-0.06 portion of silicone oil, 0.02-0.1 portion of water and 0.1-0.15 portion of fire retardant are added into a container, premixed for 20-30s when stirred at 2,000r / min, added with sufficient PAPI with the molar ratio between isocyanato-NCOin PAPI and hydroxyl group-OH in bamboo waste liquefaction products being 0.6-1.2, stirred for 10s-15s at 1,000r / min, put into a mould, foamed with standing at room temperature, placed for slaking and mould separating at room temperature for 24h-72h after reaction. The method fully utilizes resources, reduces liquefaction cost, and has a mild reaction temperature and stable liquefaction products;the performance of obtained foam meets the national standard and biodegradability.

Owner:NANCHANG UNIV

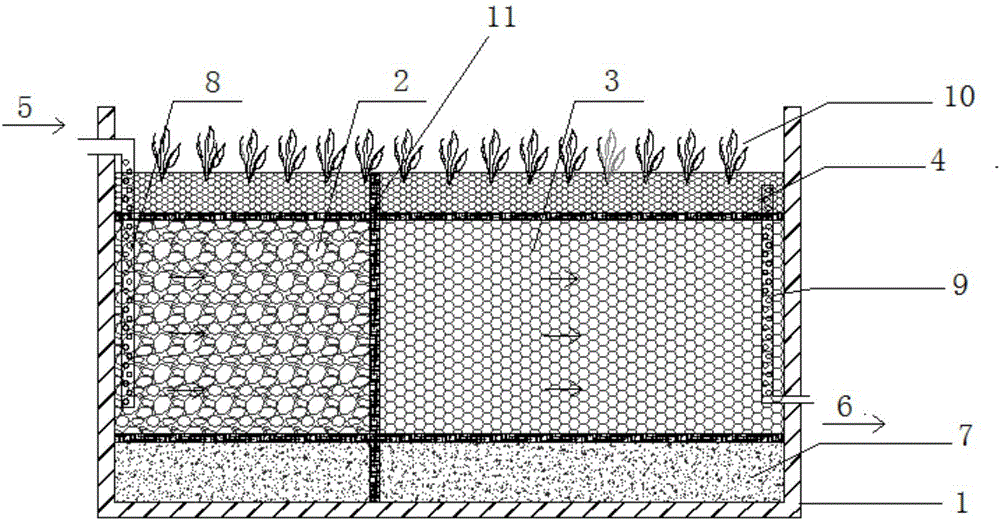

Substrate structural system of horizontal flow manual wet land

PendingCN106115927ASolve easy blockageImprove operational efficiencyBiological treatment apparatusSustainable biological treatmentWater flowEnvironmental engineering

The invention discloses a substrate structural system of a horizontal flow manual wet land, comprising an anti-seepage structure, an absorbent purifying module, a blockage preventive module and an ecological planting layer, wherein the anti-seepage structure forms a divided space open at the top; a water inlet is formed at one side of the divided space, a water outlet is formed at the other side; the absorbent purifying module and the blockage preventive module are sequentially arranged in the divided space along the direction of flow; and the ecological planting layer is arranged above the absorbent purifying module and the blockage preventive module. The substrate structural system effectively solves the problems of single substrates and susceptibleness to blockage of conventional wet lands, improves the operating efficiency and purifying effect of the wet land, makes the most of urban organic waste and garden waste, avoids waste of resources and realizes the purpose of changing waste into treasure. The substrate structural system has the advantages of wide source of materials, low cost, simplicity of construction and conservation of construction time and cost, and due to remarkable increases in operating efficiency and durability of the substrate, the later curing cost can be greatly reduced.

Owner:BEJING SUNSHINE LANDSCAPE CO LTD

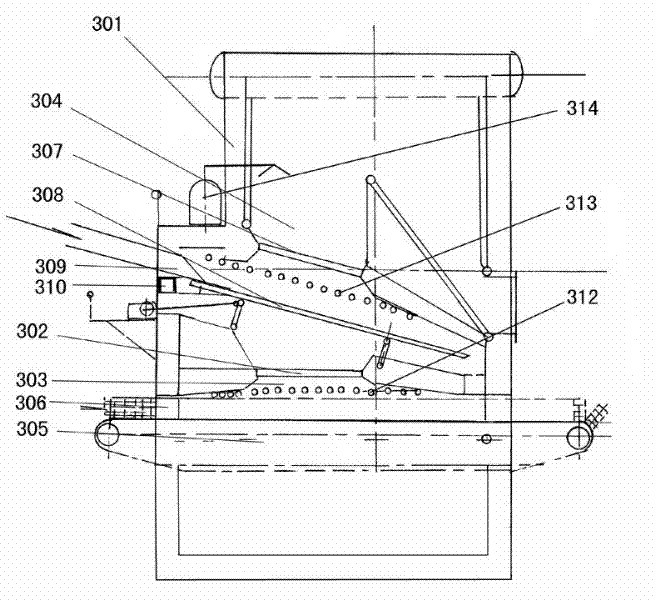

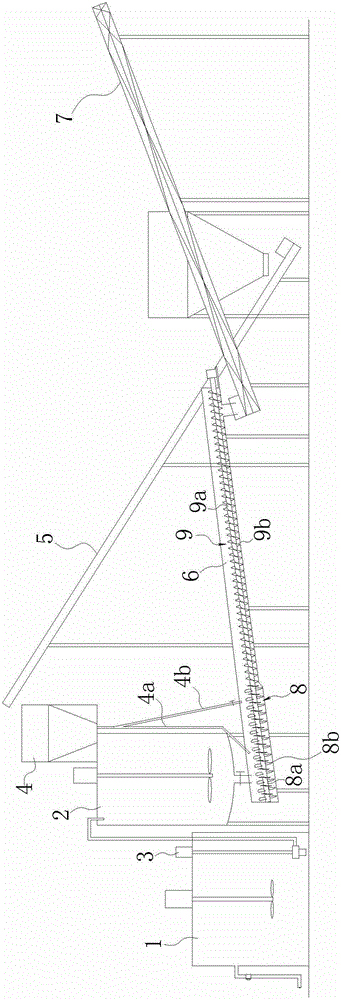

Recycling and utilizing system and method for granite solid waste

PendingCN109954540AAdjust feeding speedEasy to adjust tilt angleMagnetic separationGrain treatmentsPulp and paper industryWaste recycling

The invention relates to the technical field of granite waste recycling, in particular to a recycling and utilizing system and method for granite solid waste. The recycling and utilizing system comprises a support frame, a feeding mechanism, a crushing machine and an iron removing mechanism; the feeding mechanism is arranged at one end of the upper end face of the support frame; the crushing machine is arranged in the middle of the upper portion of the support frame; and the iron removing mechanism is arranged at the end, different from the feeding mechanism, of the upper portion of the support frame. According to the recycling and utilizing system and method for the granite solid waste, the inclination angle of a feeding hopper can be conveniently adjusted by adjusting the elongation of afirst electric pushing rod, and meanwhile the feeding speed of the granite solid waste is adjusted; through cooperative use of first crushing rolls and second crushing rolls, the granite solid wastecan be fully crushed, and good preparation is made for subsequent ceramic tile manufacturing; and broken scrap iron mixed in granite powder can be adsorbed through an electromagnetic adsorption plate,collection of the broken scrap iron is achieved, resources are saved, and meanwhile the purpose of changing waste materials into things of value is achieved.

Owner:SHANDONG UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com