Biosolid-sludge mixed ceram site

A biological sludge and mixed technology, applied in the field of light materials, can solve the problems of high production cost, agglomeration, difficult control of burning process, etc., and achieve the effect of low cost, wide source of raw materials and remarkable energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solutions of the present invention will be further specifically described below through specific examples; but the present invention is not limited to these examples.

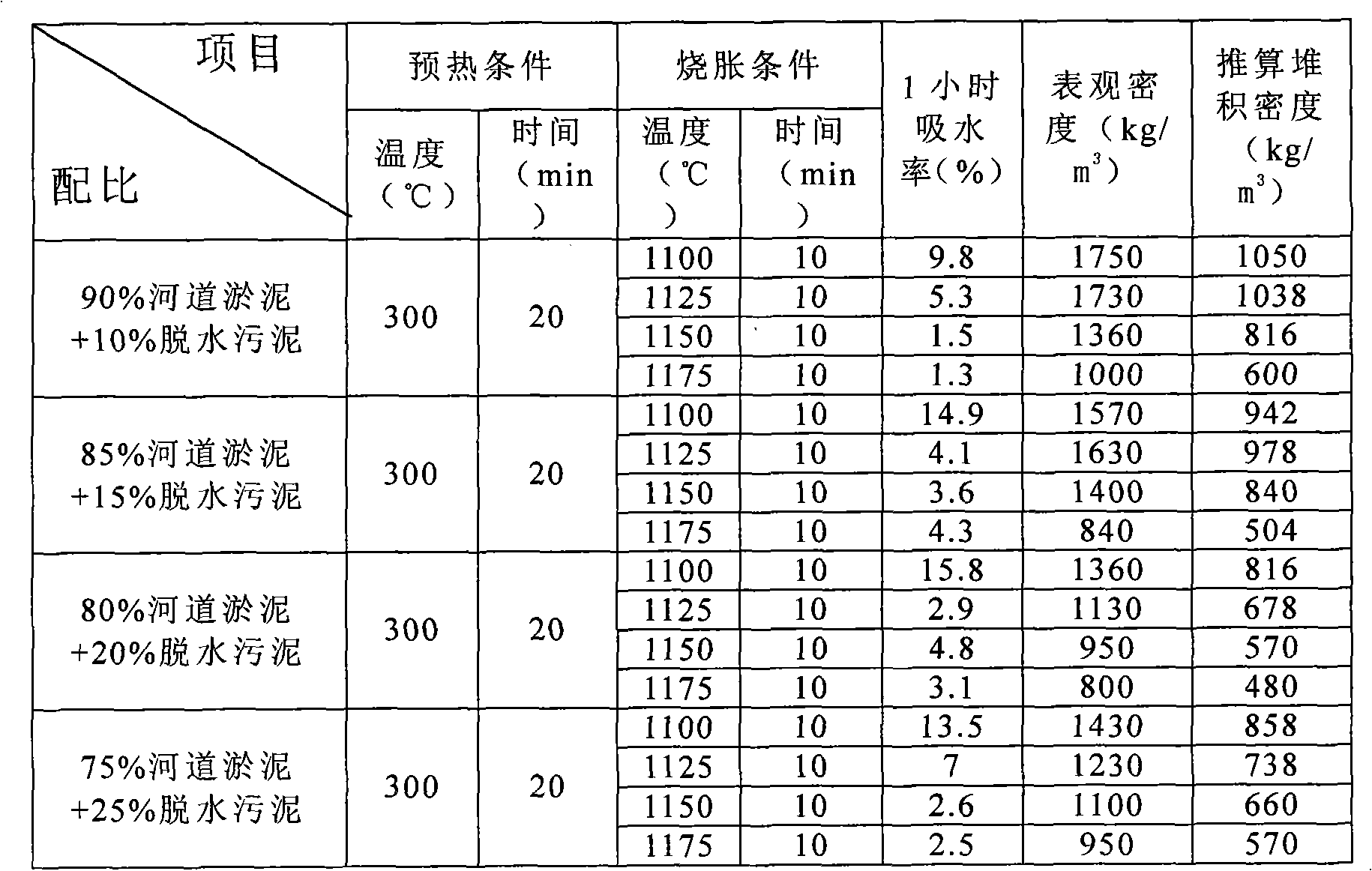

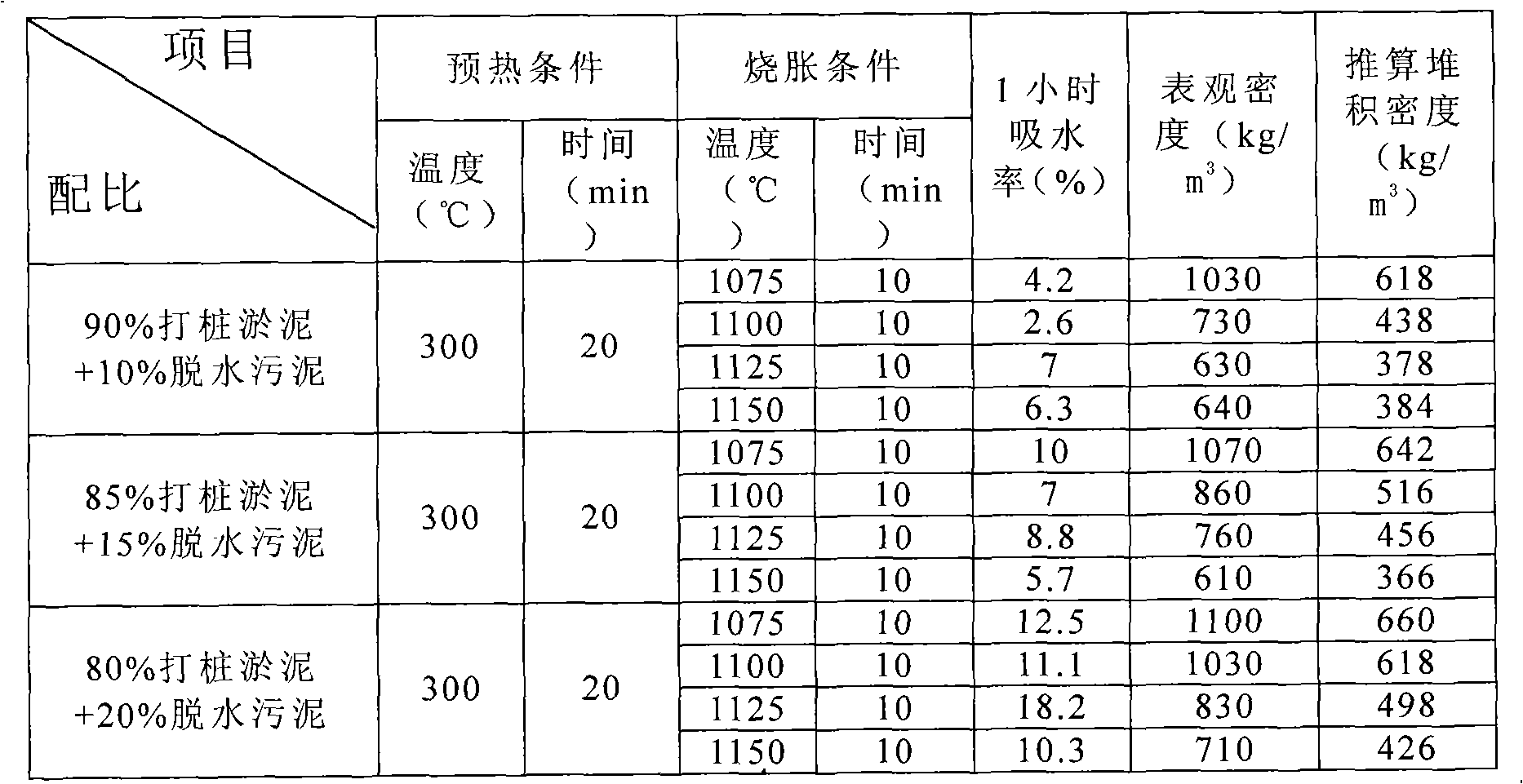

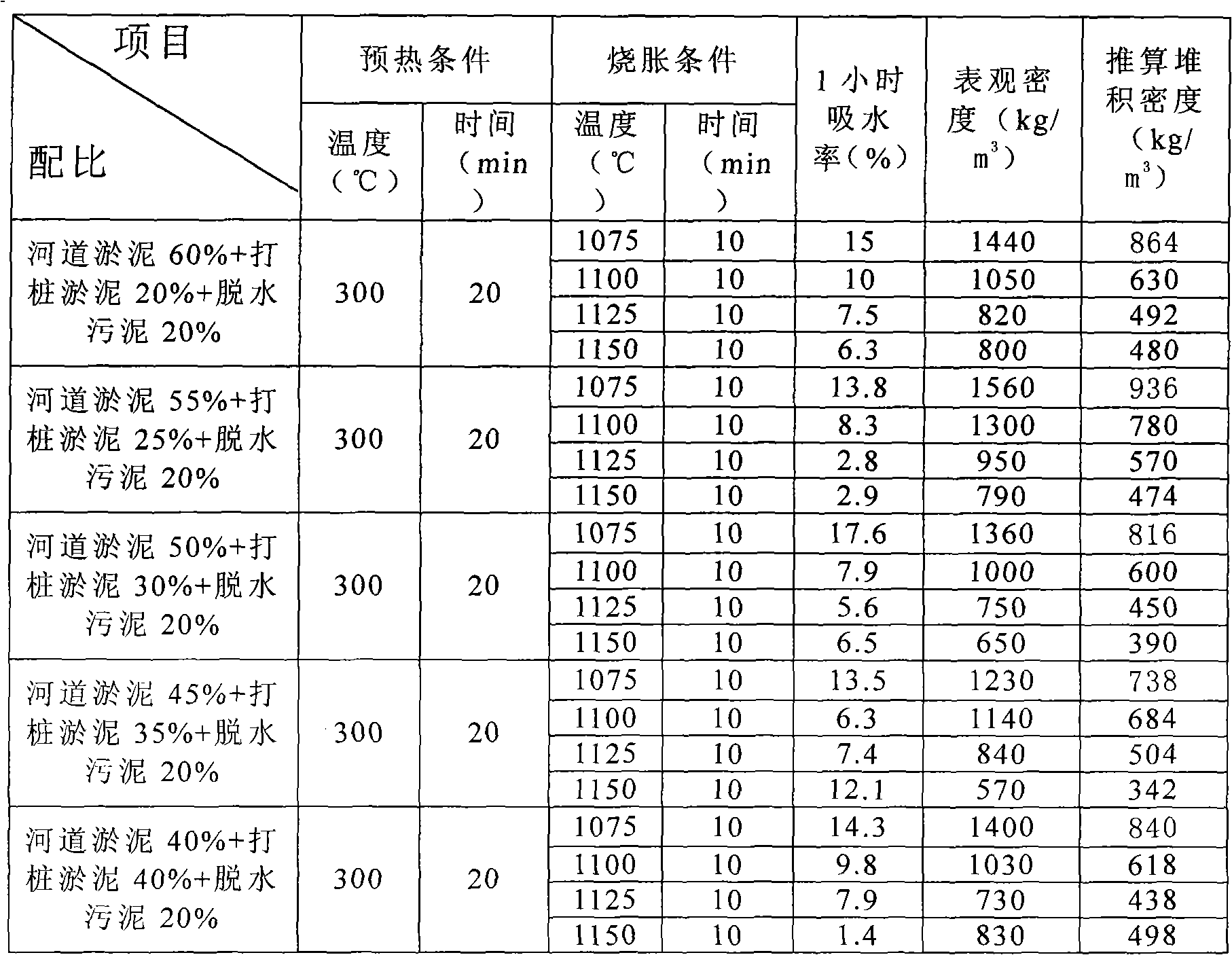

[0047] Table 5: The parts by weight of biological sludge and sludge prepared from ceramsite in Examples 1-12

[0048]

[0049] What used in the embodiment 1-12 is the river course silt in the Jiaojiang area of Taizhou City, Zhejiang Province, the piling silt in Taizhou City, Zhejiang Province, and the biological sludge produced by Jiaojiang Sewage Treatment Plant in Taizhou City, Zhejiang Province. The chemical composition and weight percent thereof of described river course silt are:

[0050] SiO 2 : 48.27%; Al 2 o 3 : 12.57%;

[0051] Fe 2 o 3 : 4.94%; CaO: 3.81%;

[0052] MgO: 2.52%; Loss on ignition: 7.19%;

[0053] The rest are impurities.

[0054] The chemical composition and weight percent thereof of described piling silt are:

[0055] SiO 2 : 60.7%; Al 2 o 3 : 15.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com