Biochar pulp prepared from garbage leachate serving as raw material and preparation process thereof

A technology of landfill leachate and biochar, applied in the direction of liquid carbon-containing fuel, fuel, petroleum industry, etc., can solve the problems of global environmental damage, arduous tasks, and great difficulty, and achieve effective utilization, low ash content, and easy loading and unloading Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Landfill leachate described in the present invention is the biochar slurry prepared by raw material, and it comprises the following components by weight percentage:

[0056] Biochar 40% Landfill Leachate 38%

[0057] Methanol 20% High temperature sand 1%

[0058] Additive 1%. .

[0059] The preparation process of the biochar slurry prepared from the above-mentioned garbage leachate is as follows: the above-mentioned percentage of biochar and high-temperature sand are transported to the feeding mechanism, and at the same time, the garbage leachate and additives are mixed through the computer metering system. After the primary grinding and crushing by the drum mill, the additive is metered again and the methanol is metered into the planetary mill for secondary grinding and crushing, and then enters the homogenization tank, and after homogenization, it is filtered through a filter. Finally, the finished biochar slurry is obtained and loaded into storage tanks.

[0060]...

Embodiment 2

[0066] In this embodiment, the landfill leachate is a biochar slurry prepared from raw materials, which includes the following components by weight percentage:

[0067] Biochar 53% Landfill Leachate 28%

[0068] Methanol 16% High temperature sand 2%

[0069] Additive 1%.

[0070] The preparation process and other features of this embodiment are consistent with Embodiment 1.

Embodiment 3

[0072] In this embodiment, the landfill leachate is a biochar slurry prepared from raw materials, which includes the following components by weight percentage:

[0073] Biochar 45% Landfill Leachate 30%

[0074] Methanol 18% High temperature sand 1.5%

[0075] Domestic sludge 5% additive 0.5%.

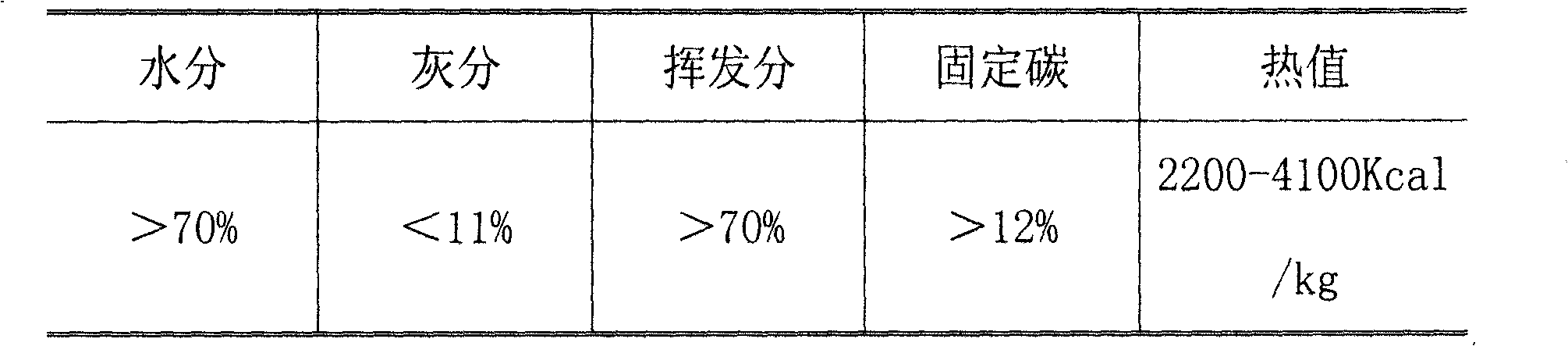

[0076] Compared with Example 1, an appropriate amount of domestic sludge has been added in this implementation. According to the analysis of the sludge discharged from the urban sewage treatment plant, the organic content of the primary sludge is between 55-70%, and the organic content of the activated sludge is between 70-70%. Between 85%, this kind of sludge has a fine particle size, and the calorific value of organic matter is 2200-4000 kcal / kg dry sludge. The specific indicators are shown in the table below.

[0077] Domestic Sludge Characteristics Data Sheet

[0078]

[0079] Therefore, the organic matter contained in sludge generally has a high calorific value, but due to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com