Granular compounded organic fertilizer and preparation method thereof

A technology of organic fertilizer and granule, which is applied in the field of granule compound organic fertilizer and its preparation, can solve the problems of organic matter environmental pollution, etc., and achieve the effects of low cost, improved utilization rate, and appropriate proportion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

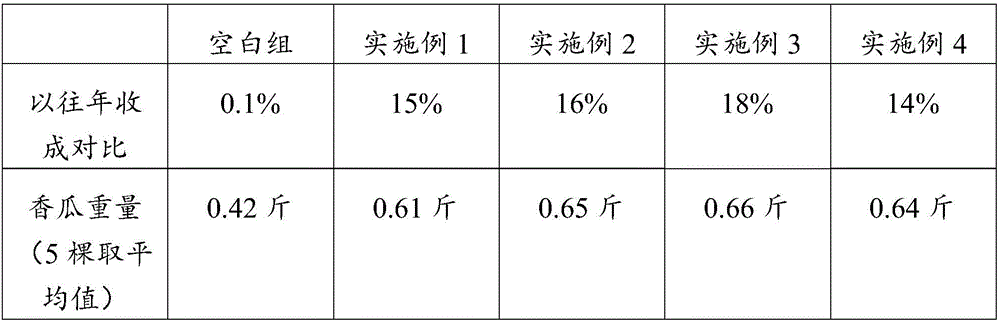

Examples

Embodiment 1

[0035] A granular compound organic fertilizer, comprising the following raw materials in parts by weight: 60 parts of chicken manure, 50 parts of cassava dregs, 12 parts of sugar factory filter mud, 10 parts of medicinal dregs, 40 parts of white mud, 5 parts of potassium fulvic acid, inorganic 5 parts of fertilizer, 5 parts of biological bacteria, 5 parts of fermentation bacteria, 5 parts of compound additives;

[0036] The inorganic fertilizer is composed of urea, potassium chloride, calcium hydrogen phosphate, monoammonium phosphate, ammonium sulfate and ammonium chloride, and the weight ratio of nitrogen, phosphorus and potassium in the inorganic fertilizer is 15:8:8;

[0037] The preparation method of the granular compound organic fertilizer consists of the following steps:

[0038] (1) blending the fermented bacteria with water into a fermented liquid;

[0039] (2) Take chicken manure, cassava dregs, sugar factory filter mud, medicine dregs and white mud respectively acc...

Embodiment 2

[0047] A granular compound organic fertilizer, comprising the following raw materials in parts by weight: 80 parts of pig manure, 30 parts of cassava dregs, 25 parts of sugar factory filter mud, 5 parts of medicinal dregs, 60 parts of white mud, 1 part of potassium fulvic acid, inorganic 10 parts of fertilizer, 1 part of biological bacteria, 10 parts of fermentation bacteria, 1 part of compound additive;

[0048] The inorganic fertilizer is composed of urea, potassium chloride, calcium hydrogen phosphate, monoammonium phosphate, ammonium sulfate and ammonium chloride, and the weight ratio of nitrogen, phosphorus and potassium in the inorganic fertilizer is 15:3:12;

[0049] The preparation method of the granular compound organic fertilizer consists of the following steps:

[0050] (1) blending the fermented bacteria with water into a fermented liquid;

[0051] (2) Take pig manure, cassava residues, sugar factory filter mud, medicinal residues and white mud respectively accord...

Embodiment 3

[0059] A granular compound organic fertilizer, comprising the following raw materials in parts by weight: 70 parts of cow dung, 40 parts of cassava dregs, 20 parts of sugar factory filter mud, 6 parts of medicinal dregs, 50 parts of white mud, 3 parts of potassium fulvic acid, inorganic 8 parts of fertilizer, 3 parts of biological bacteria, 8 parts of fermentation bacteria, 4 parts of compound additives;

[0060] The inorganic fertilizer is composed of urea, potassium chloride, calcium hydrogen phosphate, monoammonium phosphate, ammonium sulfate and ammonium chloride, and the weight ratio of nitrogen, phosphorus and potassium in the inorganic fertilizer is 15:6:9;

[0061] The preparation method of the granular compound organic fertilizer consists of the following steps:

[0062] (1) blending the fermented bacteria with water into a fermented liquid;

[0063] (2) Take cow dung, cassava dregs, sugar factory filter mud, medicinal dregs and white mud respectively according to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com