Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

183 results about "Sugar factory" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Industrialized production method of primitive brown sugar

ActiveCN103993106ARetract lowPromote recoverySugar crystallisationPurification by physical meansSlagMicrofiltration

The invention discloses an industrialized production method of primitive brown sugar. The method comprises the steps of with cane sugar factory mixed juice as a raw material, adding lime milk to regulate the pH value to 5.8-6.6; sieving and filtering; heating, floating and removing floating slag; removing impurities through microfiltration; evaporating and concentrating to obtain syrup with the concentration of 60-65-degree Bx; boiling sugar at the temperature of 125-130 DEG C at normal pressure to obtain syrup with the concentration of 95-98-degree Bx; sanding and forming to realize industrialized production of the primitive brown sugar. When used for producing brown sugar, the industrialized production method disclosed by the invention is safe and reliable in production process, high in mechanization degree, capable of realizing large-scale production of the primitive brown sugar and stable in product quality.

Owner:GUANGXI UNIV +1

Fertilizer for fruit trees and production method of fertilizer

InactiveCN105254452ARich in nutrientsHigh in nutrientsBio-organic fraction processingOrganic fertiliser preparationSucroseNutrition

The invention discloses a fertilizer for fruit trees and a production method of the fertilizer. The fertilizer is prepared from raw materials in parts by weight: 35 to 45 parts of chicken manure, 30 to 40 parts of filter mud in sugar factory, 20 to 30 parts of agricultural residues powder, 20 to 25 parts of tea seed cake, 10 to 15 parts of rice husk powder, 10 to 20 parts of vinegar residue, 5 to 8 parts of fulvic acid potassium, 155 to 175 parts of urea, 125 to 135 parts of potassium sulfate, 55 to 65 parts of potassic-magnesian fertilizer, 85 to 90 parts of calcium superphosphate, 2 to 3 parts of ammonium molybdate, 10 to 15 parts of lignin, 6 to 8 parts of animo acid chelated copper and boron, 7 to 9 parts of sucrose complexed manganese and calcium, 3 to 5 parts of diaminoferric xanthohumate and 4 to 6 parts of zinc lignosulfonate. The fertilizer prepared by the production method disclosed by the invention is abundant in nutrition, can be used for meeting nutrient requirement of the fruit trees, improving growth speed of the fruit trees and improving the yield and the quality of the fruit trees, and is beneficial for promoting the growth of the fruit trees; in addition, by using the fertilizer, the properties of soil can be improved, and soil loosening is promoted; after the fertilizer is applied, a good control effect for diseases and insect pests of the fruit trees can be realized.

Owner:DAXIN PRODIVITY PROMOTING CENT

Heavy metal contaminated soil improving agent and preparation method thereof

ActiveCN105542781AIncrease surface areaStrong electrostatic attractionOrganic fertilisersSoil conditioning compositionsPotassiumSoil conditioner

The invention discloses a heavy metal contaminated soil improving agent and a preparation method thereof, wherein the heavy metal contaminated soil improving agent includes the following components in parts by weight: 45-55 parts of cloud ear fungus residues, 25-35 parts of plant ash, 15-25 parts of silkworm excrement, 20-30 parts of quick lime, 20-30 parts of medical stone, 5-10 parts of chitosan, 5-8 parts of fumed silica, 200-250 parts of filter mud from a sugar factory, 5-7 parts of potassium fulvate, 3-5 parts of bone meal, and 80-100 parts of water. The prepared soil improving agent has good improvement effect, can reduce the content of heavy metals in the soil in a long time, moreover, makes full use of the waste, saves resources and reduces pollution to the environment.

Owner:百色市雅芒农业科技有限责任公司

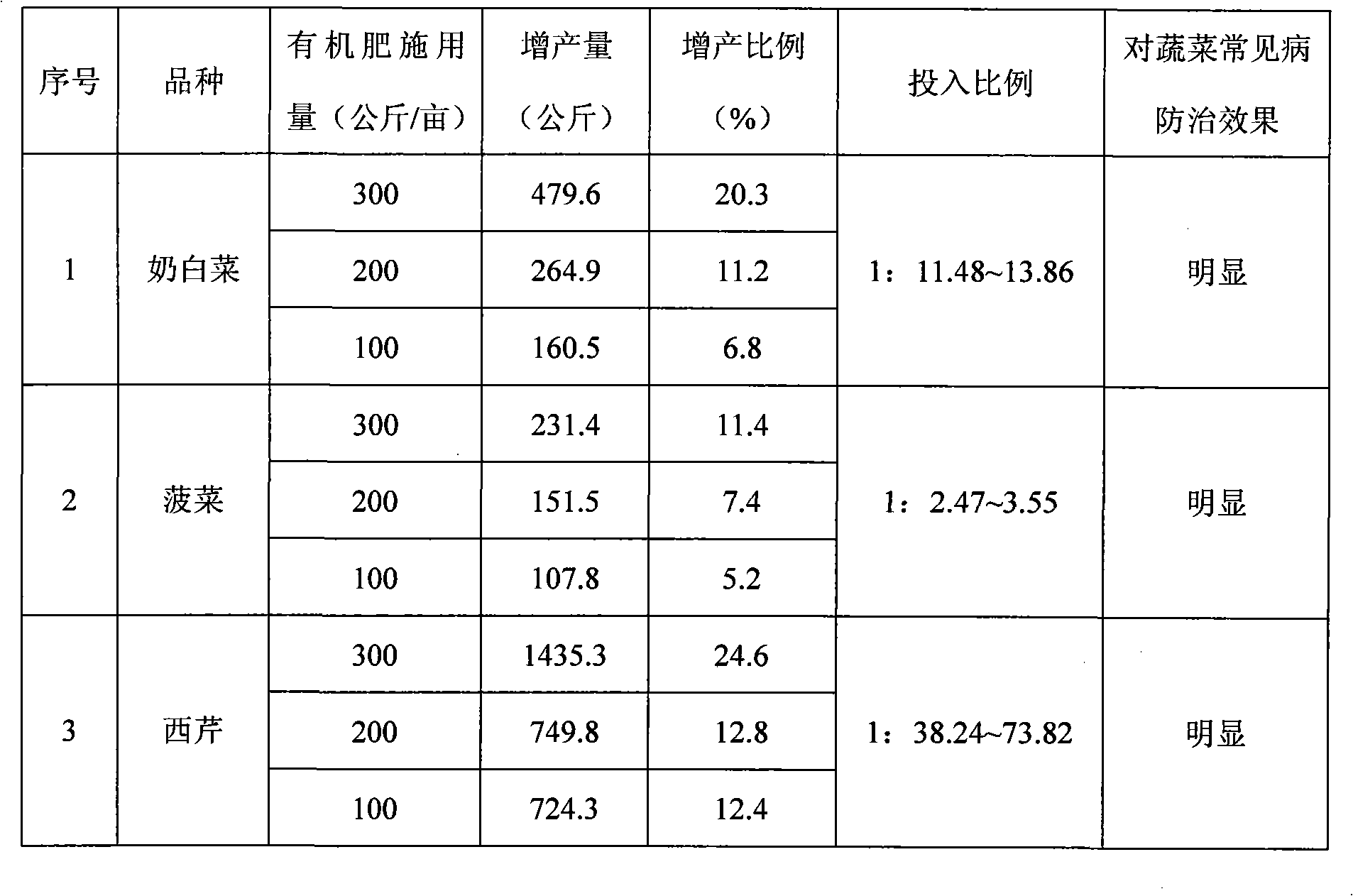

Production method for organic fertilizer

InactiveCN103304283ANon-perishableRoot Rot PreventionBio-organic fraction processingOrganic fertiliser preparationSludgeRoot rot

The invention discloses a production method for an organic fertilizer. The production method can be used for mixing excrements of herbivore animals and plasters or plant ashes and coal ashes which are obtained by combusting lime sludge of a sugar factory or manioc waste and bagasse of a starch factory and quickly converting organic waste into available organic fertilizers by a zymophyte ecological method. According to the method provided by the invention, the stack fertilizer preparing time can be shortened, and the labor and the time can be saved. By using the organic fertilizer produced by the method, a perfect root environment can be constructed, so that rot diseases can be avoided; plants can fully realize the functions of absorbing the fertilizers, and crops can quickly grow up; the physical property and the chemical property as well as the microbial state of the soil are thoroughly balanced, so that the soil can be forever kept in an optical state for culturing crops. The organic fertilizer produced by the invention can be mixed with other trace elements, a plant growth promoter, chemical fertilizers and the like to prepare a composite fertilizer. Beneficial microflora can be added for further treatment; the non-toxic and harmless microorganism fertilizer can be compounded.

Owner:WUZHOU CITY YIYUAN FERTILIZER CO LTD

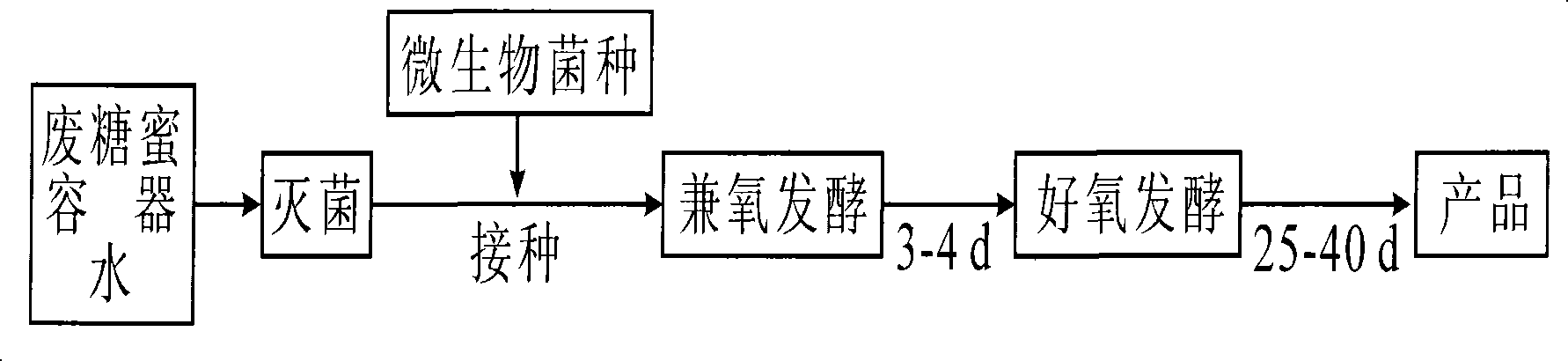

Method for producing biological leaf fertilizer by using waste molasses of sugar plant

The invention discloses a method for using waste molasses of sugar factory to produce biological leaf fertilizer, which comprises disinfecting a fermentation vessel via boiled water, boiling waste molasses to kill bacterials and grafting microbe strains as aerobic bacteria, yeast and actinomycetes at 35DEG, preparing fermentation materials as 20-30kg of waste molasses, 0.3-1kg of grafting microbe and 20-30kg of sterile water, arranging the fermentation material into a fermentation vessel, mixing uniformly via a disinfection rod, covering 2-3 gauze layers on the mouth of the vessel, culturing and fermenting, starting aeration each day from the fourth day as 30min at morning and 30min at afternoon until there is dense wine aroma. The invention uses aerobic bacteria, yeast and actinomycetes as grafting microbe strains to process mixed fermentation at suitable temperature, facultative and aerobic conditions to convert organics as sugar into useful compositions as glucose, alcohol, amino acid, nucleic acid and vitamin B.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

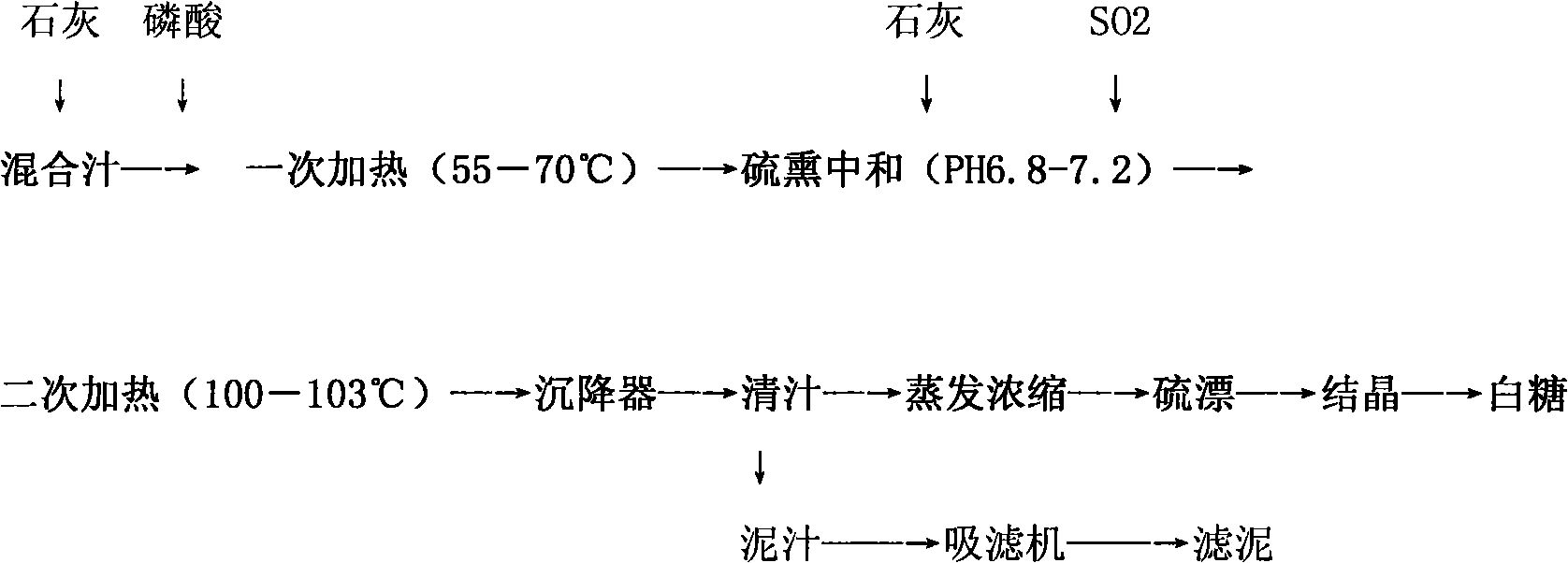

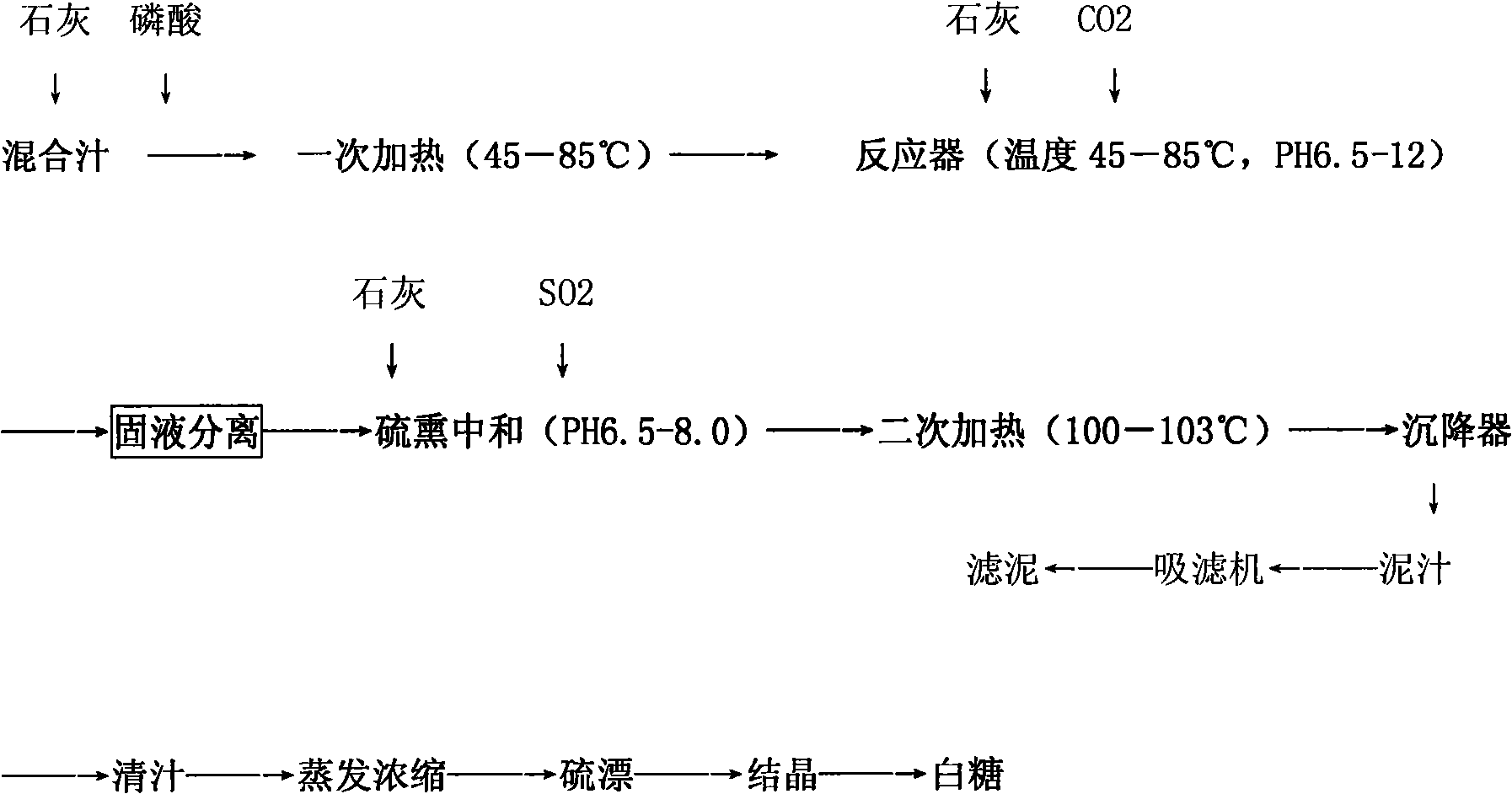

Clarification method for sugarcane juice

InactiveCN101280344AEmission reductionReduce residual sulfur dioxidePurification using alkaline earth metal compoundsSugar caneCarbonation

The invention discloses a clarification method for cane expressed juice, which is an improvement for sulfurous acid method manufacturing technique of a cane sugar factory. The cane juice is conveyed into a reactor after the first heating, and carbonation is performed through adding lime and carbon dioxide; solid-liquid separation can be performed to the carbonation cane juice to remove solid impurity, and the stoving liming neutralization treatment is performed to the obtained clear juice taking sulfur dioxide and lime as clarificant; the stoving liming neutralization treatment can be also performed to the turbid carbonation cane juice directly taking sulfur dioxide and lime as clarificant. The stoving liming neutralization cane juice is conveyed into a settler after the second heating, and the clear juice and the mud juice are separated. The clarification method has the advantages that the brenstone use level is reduced, the production cost is saved, the sulfur dioxide residual in white sugar is decreased greatly, the product quality is improved, the carbon dioxide discharge amount is reduced, the clear juice purity is increased by 1 to 1.5, the white granulated sugar color value is reduced by twenty percent, and therefore the environment problem does not exist.

Owner:南宁苏格尔科技有限公司

Efficient polycarboxylic acid water reducing agent with additional modified celluloses

InactiveCN105985052AGood dispersionReduce bleedingSolid waste managementPolyacrylamideSodium hydroxide

The invention discloses an efficient polycarboxylic acid water reducing agent with modified celluloses. The efficient polycarboxylic acid water reducing agent comprises, by weight, 240-250 parts of methyl-2-buten polyoxyethylene ether, 25.2-26.0 parts of acrylic acid, 1.6-1.65 parts of ammonium persulfate, 0.53-0.55 part of thioglycolic acid, 13-14 parts of lignin, an appropriate quantity of sodium hydroxide solution with the concentration of 10 wt%, an appropriate quantity of deionized water, 26-28 parts of graphene oxide, 5-7 parts of waste liquid from sugar factories, 7-8 parts of hydroxypropyl methyl celluloses, 2-3 parts of polyacrylamide, 3-4 parts of calcium chloride, 2-3 parts of triethanolamine, 5-6 parts of carbon black, 19-22 parts of building brick residues and 1-1.2 parts of silane coupling agents kh550. The efficient polycarboxylic acid water reducing agent has the advantages that components such as the hydroxypropyl methyl celluloses, the polyacrylamide and the carbon black are added into the efficient polycarboxylic acid water reducing agent in preparation procedures by the aid of a series of treatment processes, accordingly, the flowability and the frost resistance of concrete can be improved, and the dispersion resistance of products in water further can be improved.

Owner:ANHUI XINRUN NEW MATERIALS

Special organic/inorganic compound fertilizer for sugarcane produced by use of filter mud from sugar factory

InactiveCN103288522AIncrease profitImprove fertilizer efficiencyFertilizer mixturesAgricultural engineeringSugar mill

The invention discloses a special organic / inorganic compound fertilizer for sugarcane produced by use of the filter mud from a sugar factory. The special organic / inorganic compound fertilizer is prepared from the following raw materials in percentage by weight: 4.17-42.87% of urea, 11.52-60.87% of calcium superphosphate or calcium magnesium phosphate, 3.33-16.66% of potassium chloride and 25.0-37.5% of dry filter mud. The special organic / inorganic compound fertilizer is prepared by the following steps of: (1) stacking the filter mud for natural fermentation; rotting the stacked filter mud for ripening from top to bottom; spreading the rotten filter mud; drying in the sunlight until the water content is 15-25%, and grinding the filter mud by a grinder; adding nitrogen, phosphorus and potash fertilizer into the filter mud after fermentation and grinding according to the proportion of the raw materials; mixing and then grinding, granulating, drying, cooling and screening; and packaging to obtain a finished product. The special organic / inorganic compound fertilizer disclosed by the invention has the advantages of long fertilizer efficiency, soil improvement, soil fertility improvement, avoidance of soil hardening and the like, can effectively improve the yield per unit by 0.5-1.0 ton of sugarcane and the sugar content of the sugarcane by 0.5-1.0%, and also can improve the utilization rate of the chemical fertilizer by 3-5%.

Owner:云南中蔗农业科技有限责任公司 +1

Floating method of brown granulated sugar dissolved by a-wash

The invention discloses a floating method for A-wash remelting brown granulated sugar, in the method, A-wash is added while remelting brown granulated sugar to enable the purity of mixed syrup to reach or near the purity of rough syrup, and then the mixed syrup is treated by the syrup floating method. Not only the product quality is guaranteed, the color value is lowered and reducing sugar, color elements and impurities are removed, but also the back boiling amount of low purity materials is increased, the rearward shift of the materials is reduced, the yield and the purity of waste molasses are effectively lowered to achieve the purposes of improving the yield of white granulated sugar, increasing the product recovery and improving the economic benefits of the sugar factories.

Owner:GUANGXI YONGXINHUA SUGAR GROUP

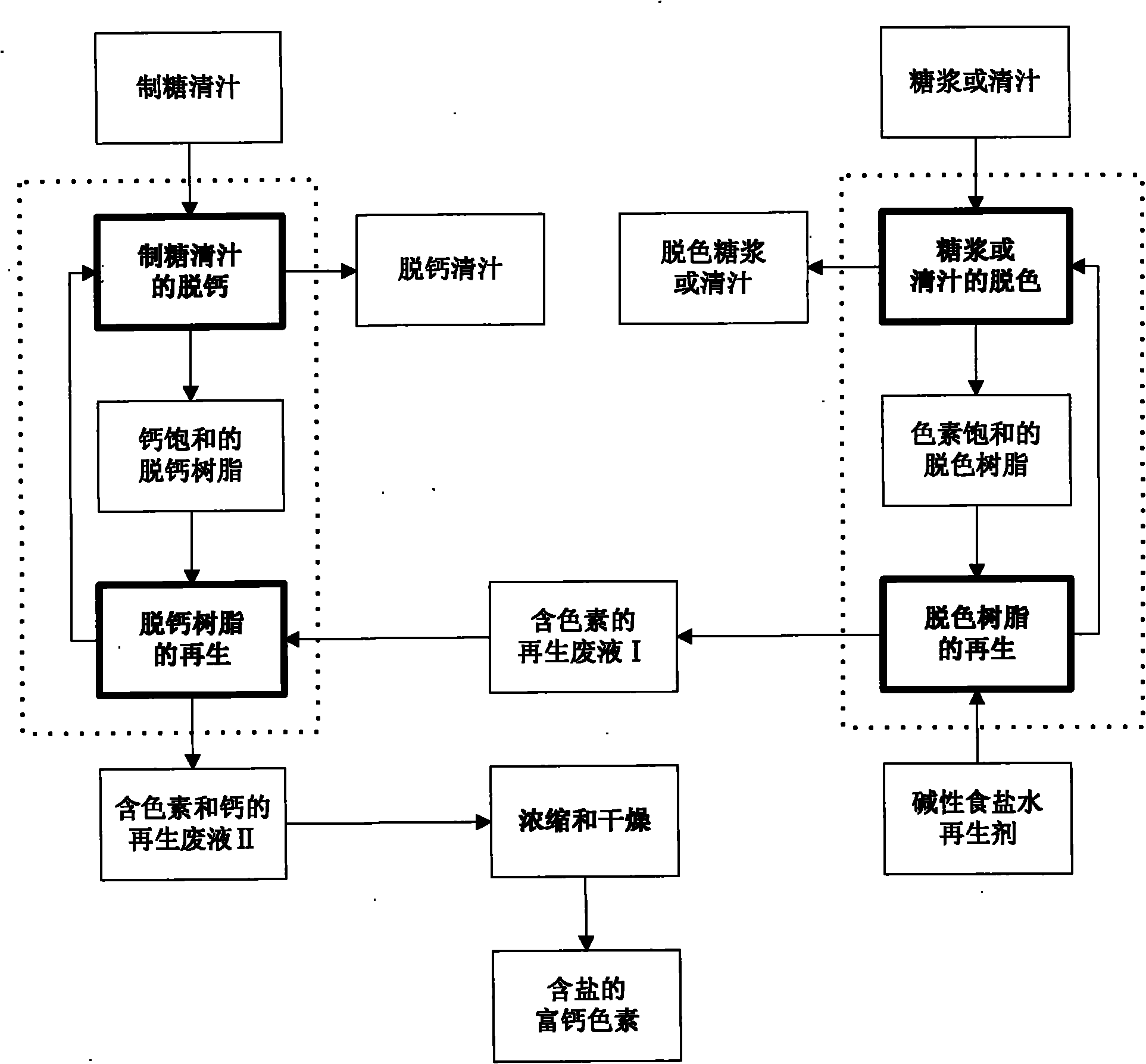

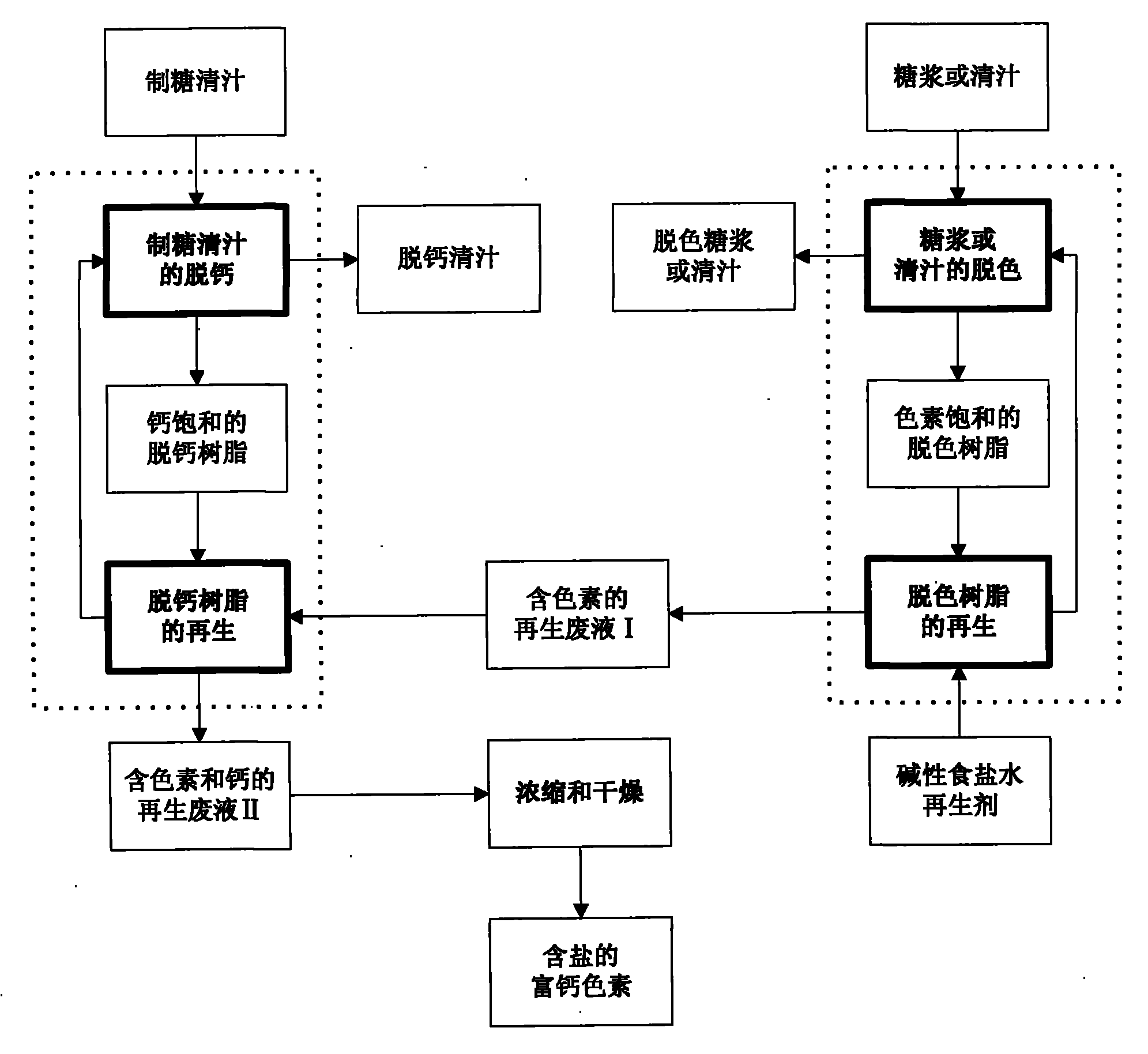

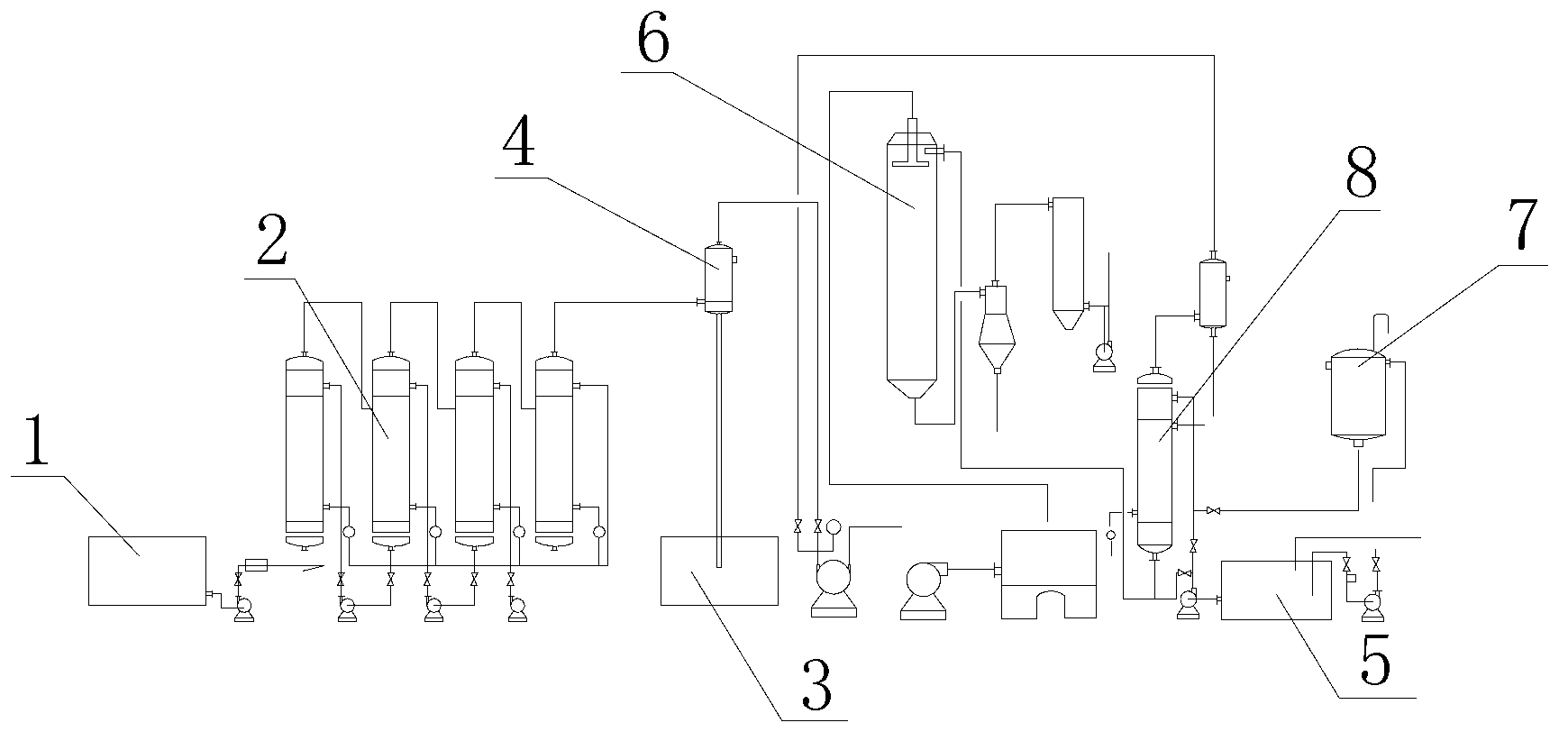

Method for regenerating sugar making decolorized and decalcified resin and method for recycling regeneration waste liquid

ActiveCN102031315AEmission reductionHigh regeneration ratePurification using ion-exchange materialsNatural dyesLiquid wasteEvaporation

The invention discloses a method for regenerating sugar making decolorized and decalcified resin, which comprises the following steps of: (1) decolorizing syrup or clear juice to obtain decolorized resin and decolorized syrup or clear juice; (2) regenerating the decolorized resin to obtain regenerated decolorized resin and decolorized resin regeneration waste liquid I; (3) decalcifying sugar making clear juice to obtain decalcified resin and decalcified clear juice; and (4) regenerating the decalcified resin, namely regenerating the decalcified resin by using the regeneration waste liquid I to obtain regenerated decalcified resin and decalcified resin regeneration waste liquid II. The invention also discloses a method for recycling the regeneration waste liquid II, which is used for preparing a calcium-rich pigment with anti-oxidation activity. The method is suitable for the cleaning or clarifying process of the syrup (juice) in a beet or cane sugar factory, is particularly suitable for decolorizing and decalcifying the sugar making clear juice and the syrup, has the main characteristics of reducing the using amount of a regenerant and the scaling of an evaporator, saving the evaporation energy of an evaporating pot, recycling non-sugar components in the syrup (juice), such as the pigment, calcium and the like, along with safe processing technology, and is environmental-friendly.

Owner:广东华糖实业有限公司

Method for preparing fertilizer from cane sugar factory filter mud

InactiveCN104341177AGood physical propertiesOdorlessCalcareous fertilisersBio-organic fraction processingRare-earth elementPotassium

The invention relates to a cane sugar factory waste filter mud recycling technology. According to the invention, a conditioning agent is added into filter mud that is not subjected to a drying treatment; the mixture is mixed by stirring, and is subjected to a reaction, such that a powdery or granular mixed fertilizer with excellent physical properties is prepared; proper amounts of nitrogen, phosphorus, potassium and rare earth elements, and a plant growth regulator are further added, such that various binary and ternary composite fertilizers comprising the rare earth element or growth regulator can be obtained. Therefore, mud-like smelly filter mud is turned into the odorless powdery or granular fertilizer, such that an environment pollution problem caused by the filter mud is solved. The method is in accordance with the principles of local material, local processing, local use, and turning waste into treasure. The method has significant economic and social benefits.

Owner:陈亮亮

Fertilizer special for guava and production method of fertilizer

InactiveCN104829399AImprove qualityProportion content is reasonableFertilizer mixturesRoot growthPhosphate

The invention discloses fertilizer special for guava and a production method of the fertilizer. The fertilizer comprises, by weight, 30-50 parts of decomposed organic fertilizer, 15-20 parts of potassium dihydrogen phosphate, 2-8 parts of urea, 12-18 parts of plant ash, 10-15 parts of lime and 1-3 parts of trace element fertilizer, wherein the decomposed organic fertilizer is the product obtained by adding strains into sisal hemp residues, sugar factory alcohol waste liquid, sugarcane filtered mud and bagasse pith to perform fermentation; the trace element fertilizer includes iron, zinc and boron. The fertilizer special for guava has the advantages that the fertilizer is reasonable in nitrogen, phosphorus and potassium proportion and contains the trace element fertilizer; when the fertilizer is applied, shoot robustness can be achieved, flowering and fruiting can be promoted, soil can be improved, root growth can be promoted, guava quality can be increased at the same time, and guava tree yield can be increased.

Owner:杨芳

Agaricus blazei murill cultivating base stock

ActiveCN103467188AMeet training requirementsReduce manufacturing costFertilizer mixturesSludgeAgaricus blazei

The invention discloses agaricus blazei murill cultivating base stock, which is prepared from the following raw auxiliary materials in part by weight: 300-600 parts of bagasse, 300-500 parts of lime sludge, 0-100 parts of straws, 0-200 parts of corncobs, 0-10 parts of peanut bran, 5-20 parts of compound fertilizer, 10-50 parts of gypsum, 20-50 parts of lime and 0-5 parts of urea. According to the invention, two kinds of main secondary products as bagasse and lime sludge in the sugar industry are adopted to cultivate agaricus blazei murill, the formula is reasonable, the physical and chemical properties are reliable, and the requirement for cultivating agaricus blazei murill is completely met, the base stock has the advantages of improving comprehensive utilization of secondary products of sugar factories, reducing production cost of agaricus blazei murill and environmental pollution and facilitating the development of edible mushroom industry, and the biotransformation efficiency when the cultivating base stock is adopted to cultivate agaricus blazei murill reaches 38% above.

Owner:GUANGXI UNIV

Treatment method of waste mash of cane sugar factory

ActiveCN103319040AQuality improvementIncrease added valueClimate change adaptationBioloigcal waste fertilisersTreatment effectPotassium

The invention discloses a treatment method of waste mash of a cane sugar factory, belonging to the technical field of industrial wastewater treatment. The method comprises the following steps of: (1) pretreatment; (2) primary concentration; (3) cooling sedimentation and dense slurry drying; (4) secondary concentration and drying. The technical method disclosed by the invention has the advantages of small investment, simple equipment and easiness in popularization; the product after treatment is a high-quality high value-added (fully water-soluble) potassium humate product, and a new mode of treatment and profit enabling sustainable development is realized; the environmental protection treatment effect is good, water balance is realized through final water quality treatment, real zero emission is realized, and the problem of waste mash of a cane sugar factory can be solved fundamentally; energy is saved in operation, and the feasibility is high.

Owner:保山九隆酵母有限公司

Environment-friendly preparation method of beet pectin

The invention discloses an environment-friendly preparation method of beet pectin. According to the method, waste beet pulp of a beet sugar factory is taken as a raw material, and the method comprises the steps of firstly washing the beet pulp with distilled water, filtering, and then drying; preparing the beet pulp and the distilled water into a material solution with the liquid-solid ratio of (100:1)-(10:1), and placing under the conditions of an electrostatic field and an ultrasonic field to perform pretreatment, wherein the intensity of an electric field is 8-32kV and the ultrasonic intensity is 0.35-0.88W / cm<2>; extracting the pectin under subcritical water conditions, wherein the temperature is 100-300 DEG C, the pressure is 2MPa-20MPa, the pressure conversion period is 1-3 times, and the total extraction time is 5min-90min; filtering, concentrating, then precipitating with isopropanol, centrifuging, then further washing with isopropanol, and freeze-drying to obtain the beet pectin. The method disclosed by the invention has the characteristics of environmental friendliness, no pollution, short time of process flow, high product yield, stable nature and high edible safety.

Owner:SOUTH CHINA UNIV OF TECH

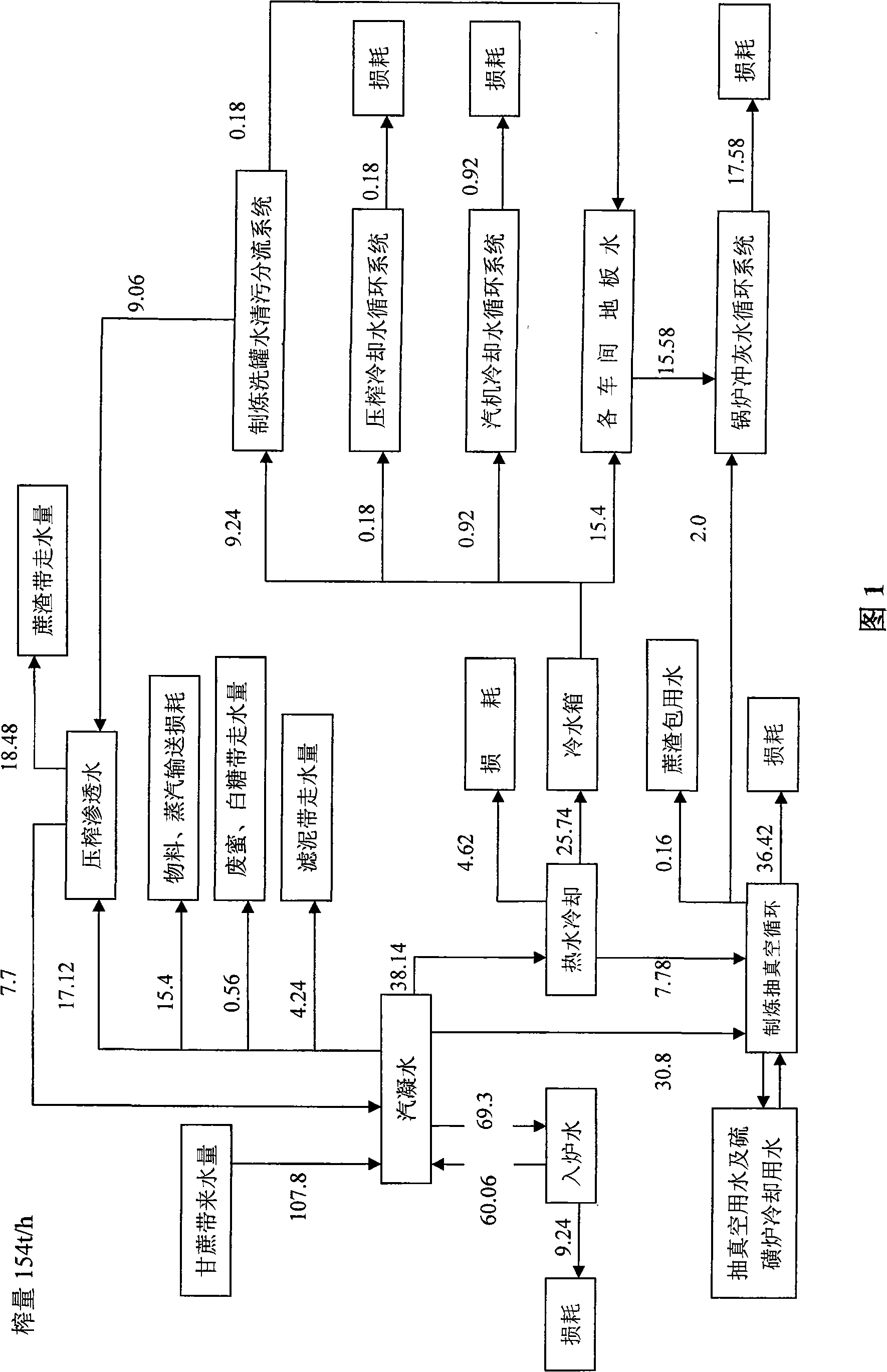

Cane sugar factory waste water zero discharge process

InactiveCN101266102ASave production waterAchieve water saving and emission reduction goalsFeed water supplyTrickle coolersWash waterBoiling process

The invention relates to a method of waste water zero draining for a cane sugar factory, comprising: using the condensed water form sugar boiling process and evaporation process as processes water of the whole factory; except for part of processes hot water, the rest condensate is cooled from about 80 deg C to room temperature and using in stead of new water; smelting washing tank water adopts a decontamination distributary system to process cleaning and shunting for wash-water of a heater, the wash-water of an evaporating pot and boiling tank water, and shunted clean water is used as washing water of an filter bottle of a pressure filter and pressing osmotic water, and sewage is drained into an ash-flushing water circulating system; the ash-flushing water adopts a gallet water curtain dust collector and a residue water separator to make up a closed-circulating system. The invention makes use of self-water of the cane to implement a closed-circulating production, so as to save a plurality of process water and realize the waste water zero draining to make economic and social benefits very remarkable.

Owner:陈志强

Method for improving sulfurous method production process in cane sugar factory

InactiveCN101818214AMake sure not to filter throughReduce sulfur dioxide contentPurification using adsorption agentsPurification by physical meansFiltrationImpurity

The invention discloses a method for improving a sulfurous method production process in a cane sugar factory. Active carbon is taken as an auxiliary clarifying agent to perform physical impurity removal and decoloration on serum, filtered serum, crude syrup or triose remelt syrup led out from the sulfurous method sugar production flow, and the secondary sulfur smoke process is eliminated further, so the problem of secondary sulfur smoke troubling the sugar industry for a long term is solved, the quality of whiter granulated sugar is improved fundamentally, and the high-quality whiter granulated sugar with low sulfur dioxide and low color number is produced. The method comprises the following steps of: leading the serum, filtered serum, crude syrup or triose remelt syrup out of the conventional production flow into a reactor; adding the active carbon accounting for 0.5 to 3 mass percent of the syrup in the reactor, reacting at the temperature of between 60 and 90 DEG C for 15 to 30 minutes, and performing physical adsorption, impurity removal and decoloration; and discharging sugar liquor after the adsorption from the reactor, and making purified serum, filtered serum, crude syrup or triose remelt syrup subjected to secondary filtration and solid-liquid separation by using a plate-and-frame filter press and a precision filter enter the conventional production flow again.

Owner:云南省轻工业科学研究院有限公司

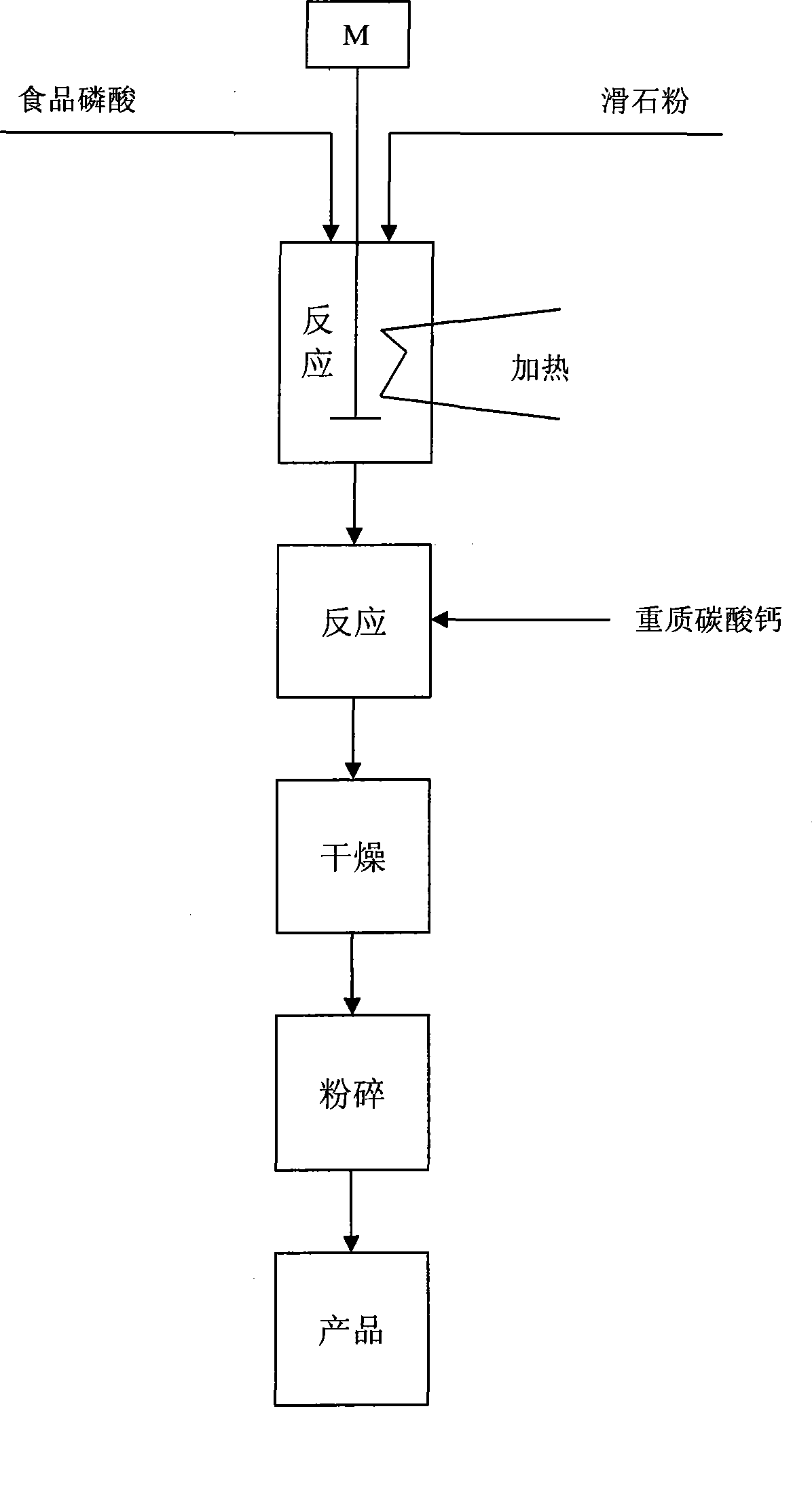

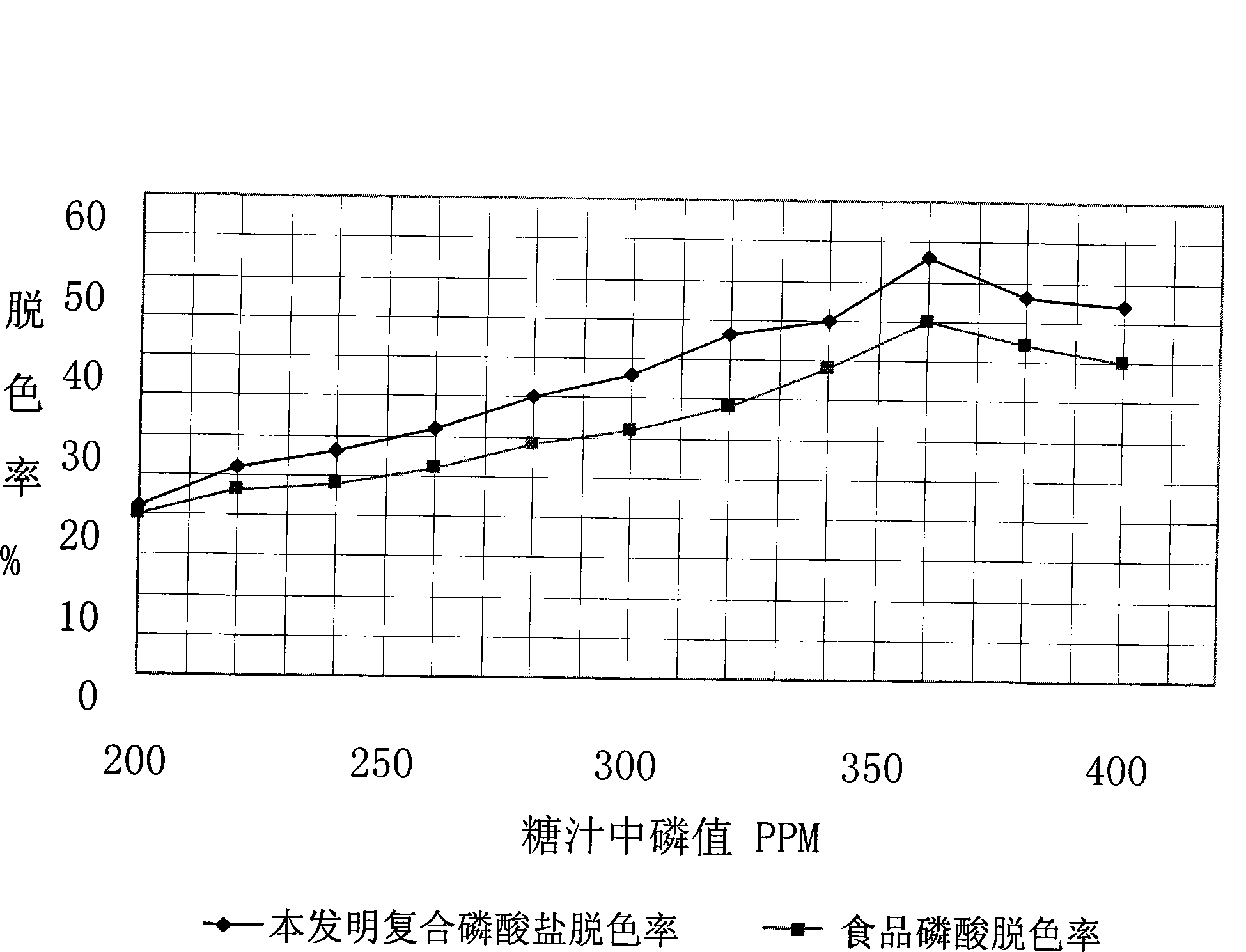

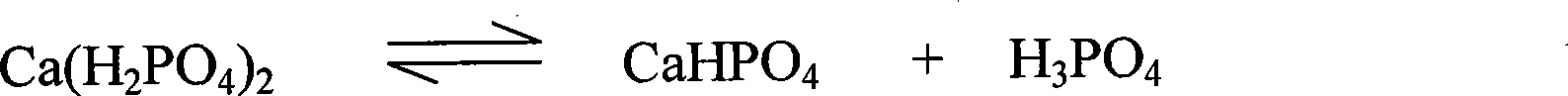

Composite phosphates sugar juice decoloring agent and preparation thereof

ActiveCN101440412AEasy to storeEasy to transportPurification by oxidation/reductionMonomagnesium phosphatePhosphate

The invention provides a composite phosphate sugar juice decoloring agent and a preparation method thereof, which belongs to the technical field of chemical engineering. The decoloring agent consists of the following four components: (1) calcium biphosphate, (2) magnesium dihydrogen phosphate, (3) precipitated silica and (4) free phosphoric acid. The preparation method for the decoloring agent comprises the following steps: (1) talc is added to food-grade phosphoric acid hydrolysate and dissolved, so as to obtain a phosphoric acid aqueous solution which dissolves magnesium dihydrogen phosphate and disperses precipitated silica; and (2) heavy calcium carbonate powder is put into a mixer and added with the phosphoric acid aqueous solution in a step (1), and reaction evaporates the moisture of materials and progressively cures the materials, so as to obtain the composite phosphate sugar juice decoloring agent containing moisture. Compared with the food-grade phosphoric acid used by the prior sugar factories, the decoloring agent has the advantages of good decoloring effect, economical efficiency, convenience, no relation to dangerous chemicals, and the like.

Owner:YUNNAN JIANGLIN GROUP

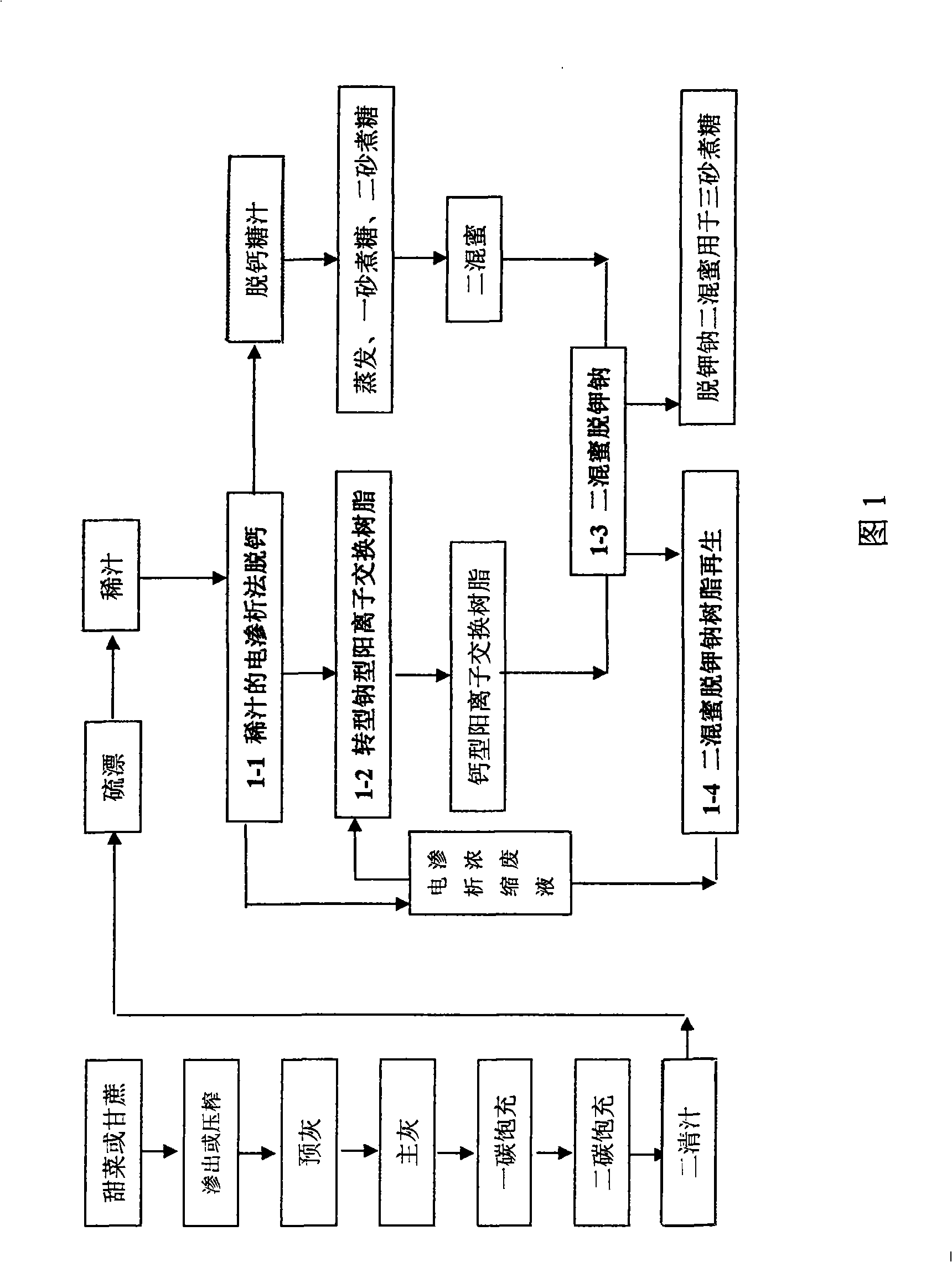

Regeneration method for di-mix honey de-kalium-sodium resin

InactiveCN101403017AReduce decalcification costsReduce Calcium ContentIon-exchanger regenerationPurification using ion-exchange materialsPotassiumIon-exchange resin

The invention discloses a regeneration method of secondary mixed honey de-potassium and de-sodium resin, which includes the following steps: Ca<2+> of dilute juice or secondary clarified juice is removed by an electrodialysis method; electrodialysis concentrated waste liquid is used for transforming Na<+> ionic exchange resin; the obtained Ca<2+> ionic exchange resin is used for removing potassium and sodium from the secondary mixed honey; the secondary mixed honey de-K<+> and de-Na<+> resin is regenerated effectively by the electrodialysis concentrated waste liquid. Therefore, after the reaction is carried out again and again, the Ca<2+> in the dilute juice or the secondary clarified juice is exchanged with K<+> and Na<+> in the secondary mixed honey by passing over an evaporating pot under the condition of not consuming extra calcium salt, and the K<+> and Na<+> in the secondary mixed honey are reduced and at the same time, the concentration of the Ca<2+> of the dilute juice is reduced from 200 to 300mg / l to less than 10mg / l. The invention can be applied to the de-potassium and de-sodium of the secondary mixed honey and the decalcification of the clarified juice of sugar factories, with regenerants thereof coming from the electrodialysis concentrated waste liquid, thus realizing the coupling of the decalcification of the clarified juice and the de-potassium and de-sodium of the secondary mixed honey. The invention has the advantages of low cost, high efficiency, easy industrialization and continuous production, and the like.

Owner:SOUTH CHINA UNIV OF TECH +1

Multiple organic humic acid spraying liquid fertilizer and preparation method

InactiveCN101289339AWide variety of sourcesAbundant resource storageBio-organic fraction processingClimate change adaptationDiseaseFlora

The invention relates to a multielement organic humic acid watering liquid fertilizer and a preparation method thereof. The weight percentage of main materials are as follows: 40 to 45 percent of waste mash, 15 to 20 percent of coal powder, 17 to 25 percent sugar mire, 20 to 25 percent of straws or bagasse, 0.5 to 1 per thousand of molasses, 1 to 1.5 per thousand of ferrous sulfate and 1.5 to 3 per thousand of fermentation strain. The main materials of the invention come from the waste of sugar factories, agricultural production and coal mining. The method is low in production cost and relatively simple in production process and technical equipment, and products are safe and reliable with no residue and no heavy metal beyond standard, so the multielement organic humic acid watering liquid fertilizer is suitable for developing organic agriculture, ecological agriculture, green agriculture and harmless agriculture and has significant ecological, economic and social benefits. Furthermore, the multielement organic humic acid watering liquid fertilizer can balance agricultural soil flora, flora, nutrition, acid base and ecology and has considerably good manurial effect and good control efficiency to plant diseases and insect pests such as downy mildew, powdery mildew, black spot, leaf blight, mosaic diseases, black shank, aphids, cutworms, soft rot and virus diseases and the like. in the practical application.

Owner:李保忠

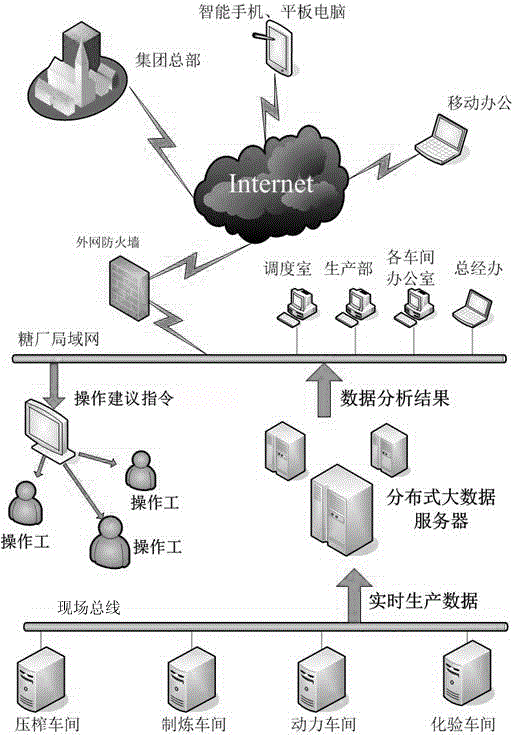

Intelligent material dispatching system based on large data in sugar factory

The invention provides an intelligent material dispatching system based on large data in sugar factory, whose system structure adopts a three-tier system of lower computer -> the server-> the client, and uses a real-time communication network formed by the field bussing technology, the local area network and the wide area network communication technology to form a distributed monitoring system.The intelligent dispatching system can establish an operation strategy model for material dispatching according to the theory of sugar production and the experience data provided by the skilled workers, and collect the parameters of the production process, the laboratory analysis data and the manual instruction in real time, which will transmitted to the operator's smart phone, tablet computer and computer for reference through the conditions judgment system, automatic generation of operational instructions, and the computer network. The system can complete single dispatching task, develop a batch of dispatching plans, and achieve tracing management of dispatching instruction, thereby greatly the processing efficiency of production management personnel is improved and control of the overall production becomes easier.

Owner:广西宏智科技有限公司

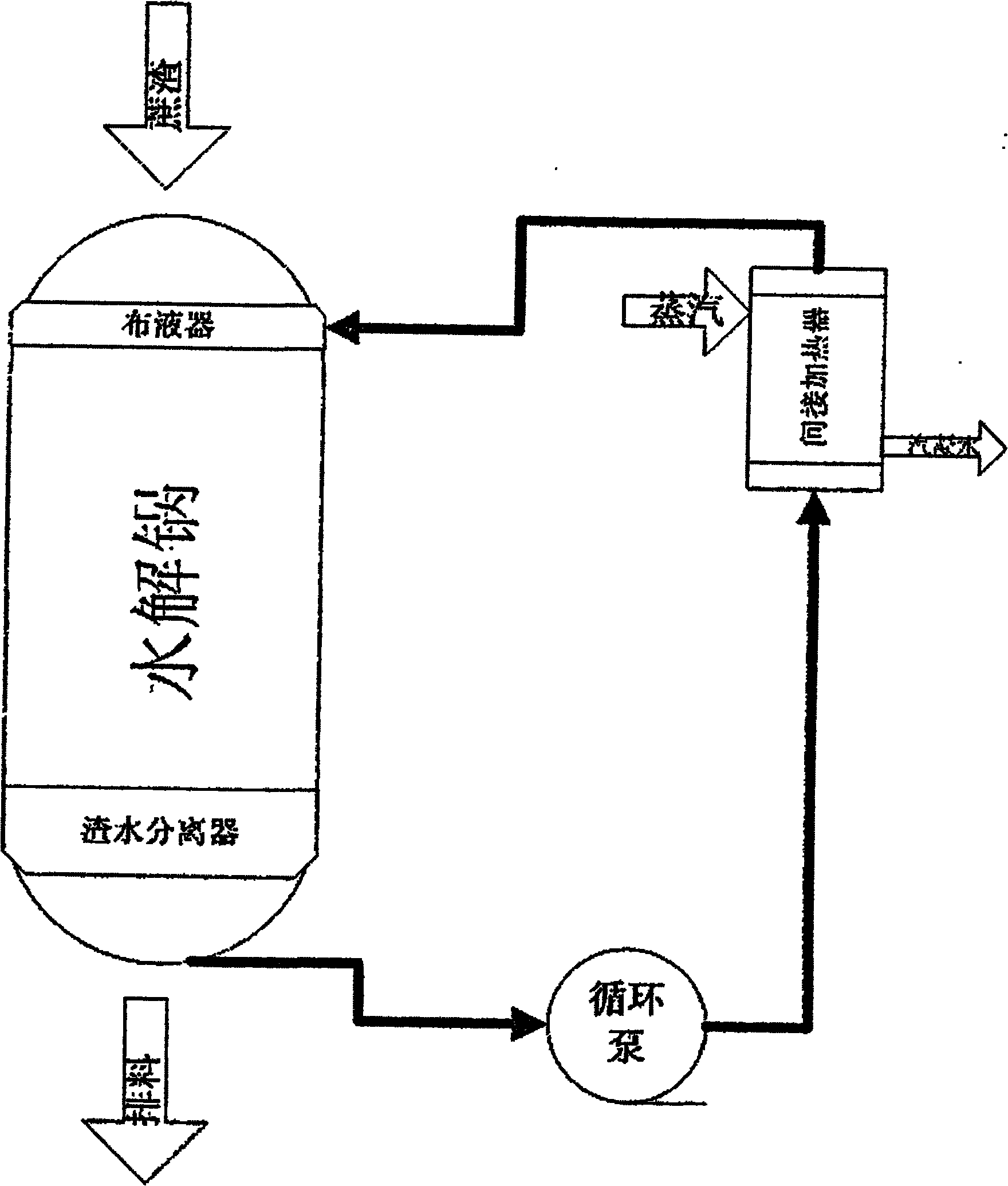

Hydrolysis method for producing xylose from bagasse

InactiveCN101818215AImprove hydrolysis efficiencyQuality improvementSaccharides productionEvaporationHydrolysis

The invention discloses a hydrolysis method for producing xylose from bagasse. The bagasse in a cane sugar factory is taken as a raw material; an indirect heating forced circulation system is adopted, in the temperature rise process, a circulating pump pumps out liquid subjected to bagasse-water separation in a hydrolysis pot, and the liquid is indirectly heated; and the liquid is returned to the pot through a distribution system so as to ensure the uniformity and completeness of heat transfer and mass transfer of each part of material in the hydrolysis pot. In the method, dialysis hydrolysis is performed first and then series hydrolysis is performed; the solid matter concentration in the hydrolysis liquid is over 4.0 percent and is improved by 20 to 25 percent than that of the traditional hydrolysis process; and the steam consumption of an evaporation system in the subsequent station is reduced by 15 to 25 percent, the energy consumption of the subsequent station is reduced, and the economic benefit is obvious.

Owner:云南省轻工业科学研究院有限公司

Method for preparation of bagasse-grafted methyl methacrylate copolymer by solid-phase method

The invention discloses a method for preparation of a bagasse-grafted methyl methacrylate copolymer by a solid-phase method. The method comprises the steps: exposing bagasse after sugar rolling in a sugar refinery to the sun, then passing through an 80-200 mesh sieve, adding an alkaline liquor with the mass fraction of 1%-5%, carrying out a high-speed stirring reaction for 1-4 hours at the temperature of 50-80 DEG C, washing, and drying to be used as activating-treated bagasse; charging materials in a reaction kettle according to a ratio of the activating-treated bagasse, an initiator, a monomer and deionized water of 1:0.05-0.15:0.1-1:0.1-1, carrying out a constant-temperature reaction for 30-60 minutes at the temperature of 50-80 DEG C, and thus obtaining a crude product of the bagasse-grafted methyl methacrylate copolymer; and by a Soxhlet extractor, separating and purifying to obtain the pure bagasse-grafted methyl methacrylate copolymer. The method not only has the advantages of high product grafting ratio, simple operation, low reaction temperature, no solvent pollution and simple post-treatment, but also is lower in product comprehensive production costs and wide in application.

Owner:SOUTH CHINA UNIV OF TECH

A cane sugar factory production command and dispatching system and an operating method thereof

PendingCN107463152AComplete efficientlyReliable completionTotal factory controlProgramme total factory controlAutomatic controlComputer science

The invention provides a cane sugar factory production command and dispatching system. The system is characterized in that a field control platform monitors operating parameters of each production line section of a sugar factory and controls real-time operating states of production line sections according to dispatching decision instructions; an OPC server collects the operating parameters and sends the dispatching decision instructions; a data storage server stores the operating parameters; a command and dispatching platform checks the operating parameters and issues the dispatching decision instructions, wherein a dispatching decision module runs on the command and dispatching platform. The invention also provides an operating method of the system. The method comprises the steps that: firstly a production plan input module generates a current production plan; secondly, a production execution comparison module obtains a matching parameter chain; thirdly, an operating parameter comparison module determines an execution parameter chain; fourthly, the dispatching decision module calculates regulation and control parameters and converts the same into dispatching decision instructions; fifthly, the command and dispatching platform issues the dispatching decision instructions; sixthly, the field control platform controls operating states of production line sections to complete the production plan. Thus, reasonable and efficient remote automatic control is achieved.

Owner:GUANGDONG PROVINCIAL BIOENGINEERING INST (GUANGZHOU SUGARCANE IND RES INST)

Microwave-assisted extraction method of beet pectin

The invention discloses a microwave-assisted extraction method of beet pectin. The method comprises the following steps: 1) pretreating dried beet pellets: crushing, screening, cleaning, heating by using microwave for enzyme deactivation, and drying; 2) mixing the pretreated dried beet pellets with sodium hexametaphosphate solution, extracting beet pectin by using microwave, and filtering to acquire extracting solution; 3) decoloring and concentrating the extracting solution, adding absolute ethyl alcohol into the concentrated solution for precipitation, and collecting the precipitate to acquire solid pectin. The extraction method of the beet pectin overcomes the defect of heavy use of acid solvent in a traditional technology; the acquired pectin has high purity, small damage to molecular structure and no solvent residues; waste beet pellets in a beet sugar factory can be efficiently recycled and the added value of products is greatly improved; meanwhile, the method is simple and efficient in process and easy for industrialization.

Owner:SHIHEZI UNIVERSITY +1

Novel technique for quality-preservation treatment of sugar plant circulation cooling water

InactiveCN101182088AHighlight substantive featuresSignificant progressWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentFiltration membraneCooling tower

The invention relates to a treatment technology and equipment of circulating cooling water of a sugar factory juice steam condensing system. The technology process includes steps as follows: firstly, pH value of the circulating cooling water is regulated to be neutralized through alkaline materials; secondly, circulating water in a circulating a circulating water tank is rotated; the third step is to cool mixed steam condensing water after fetching a part of heat and supplement the circulating water in the circulating water tank; and fourthly, a part of the cooling water which has circulated for many times is heated to be at the temperature of about 65 degree Celsius after being filtered through an ultra-filtration membrane system and is sent to the press to be used as pressing infiltration water, or a part of the cooling water which has circulated for many times is sent to a boiler to be used as ash water, and the circulating water is recharged again through the settlement and the filtration. The equipment includes the circulating water tank, a cooling tower, a condenser, the ultra-filtration system, a heat exchanger, a boiler water membrane dust removing and ash sluicing system and a sediment pool. The invention can ensure the circulating cooling water to be not metamorphic and stink. The mixed steam condensing water and the part of the cooling water which has circulated for many times are ensured to be utilized reasonably. A large quantity of production water is saved for sugar manufacturing factories. No sewage is discharged. The investment is saved. And the invention has the advantages of low operating cost and stable operation.

Owner:广西工院糖业科技有限责任公司 +1

Process for preparing halophyte organic fertilizer using marine culture sludge

InactiveCN1546435AReduce pollutionReduce the amount of applicationClimate change adaptationSewage/sludge fertilisersHalophyteSucrose

A process for preparing plant fertilizer through mariculture comprises the steps of, air-drying mariculture sludge and the pond sludge in cane sugar factories, subjecting the cultivation sludge to eluting desalinization, mixing the eluted sludge with the air-dried pond sludge by the mass ratio of 2:5, controlling humidity between 50%-60% (mass ratio), agitating and ventilating 5-15 minutes each day, fermenting 20 days at 35 deg. C-45 deg. C, air-drying to obtain the halophytic vegetation fertilizer.

Owner:NANJING AGRICULTURAL UNIVERSITY

High-efficiency carbon-absorbing tower

InactiveCN103418225AIncrease profitWell mixed absorption reactionPurification using alkaline earth metal compoundsDispersed particle separationProcess engineeringSugar refinery

The invention discloses main equipment: a high-efficiency carbon-absorbing tower, for recovering low-content CO2 of flue gas of a cane sugar factory boiler to be applied to a modified sugar manufacturing process by a sulfurous acid method. The high-efficiency carbon-absorbing tower comprises a tower shell, a boiler flue gas extraction and discharge system, a filling system, a spraying absorption system device, a demister system device, a cleaning system device, a monitoring system and a material conveying system. The high-efficiency carbon-absorbing tower is a high-efficiency forced absorption reactor; the utilization ratio of carbon dioxide is increased more quickly when compared with that of the traditional natural saturation equipment; a structure in the tower is designed innovatively and optimally, so that the gas liquid mixing ratio and the retention time are reasonable, the low-content carbon dioxide is gathered by the high-efficiency carbon-absorbing tower and reacts with lime milk to form calcium carbonate solution, emission is reduced, and the carbon dioxide can be recovered to be applied to an improved traditional sugar manufacturing process by the sulfurous acid method. The high-efficiency carbon-absorbing tower is characterized in that the structure is simple; the mounting is convenient; airflow resistance is small; the carbon dioxide is easy to gather and absorb; is the maintance is convenient;, the operation is reliable; the cost is low; the recovery rate of the carbon dioxide is high.

Owner:GUANGXI DAXIN COUNTY LEIPING YONGXIN SUGAR

Boiler chimney dust collection system and dust collection method

InactiveCN104399337ASimple structureLow costLighting and heating apparatusUsing liquid separation agentEngineeringNational standard

The invention relates to the technical field of dust collection, and discloses a boiler chimney dust collection system and a dust collection method. The system comprises a water drain device, a spraying device, a water pump, a sampler, a detector and a controller, wherein the water drain device is mounted at the bottom of a chimney and is positioned below an air inlet pipeline; the spraying device is mounted in the chimney and is positioned above the air inlet pipeline; the spraying device is connected with the water pump outside the chimney; the sampler is mounted in the chimney and is positioned above the spraying device; the sampler is connected with the detector mounted outside the chimney; the detector is connected with the controller; the controller is connected with the water pump. The boiler chimney dust collection system is particularly suitable for a boiler chimney of a sugar factory; the spraying device is arranged in the chimney; meanwhile, the sampler and the detector are used for monitoring the concentration of smoke dust discharged from the chimney in real time, and the flow of the spraying device can be adjusted in time according to the concentration of the smoke dust from the chimney, so that the smoke can be in effective contact with spraying water, and the dust collection effect is enhanced; therefore, the concentration of the smoke dust discharged by the boiler chimney meets the national standard.

Owner:广西糖业集团红河制糖有限公司

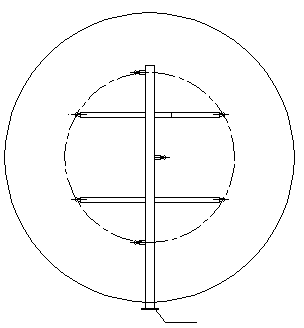

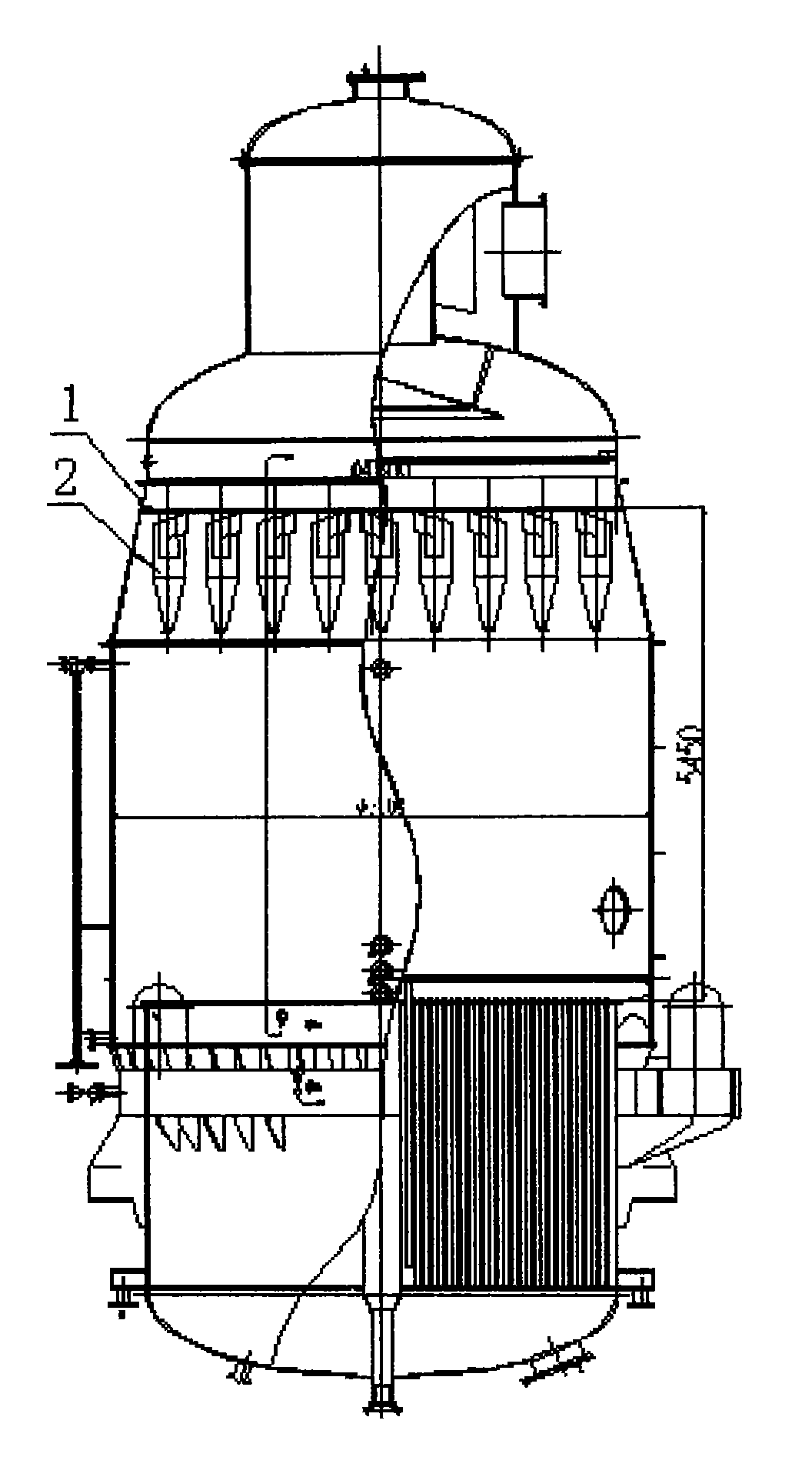

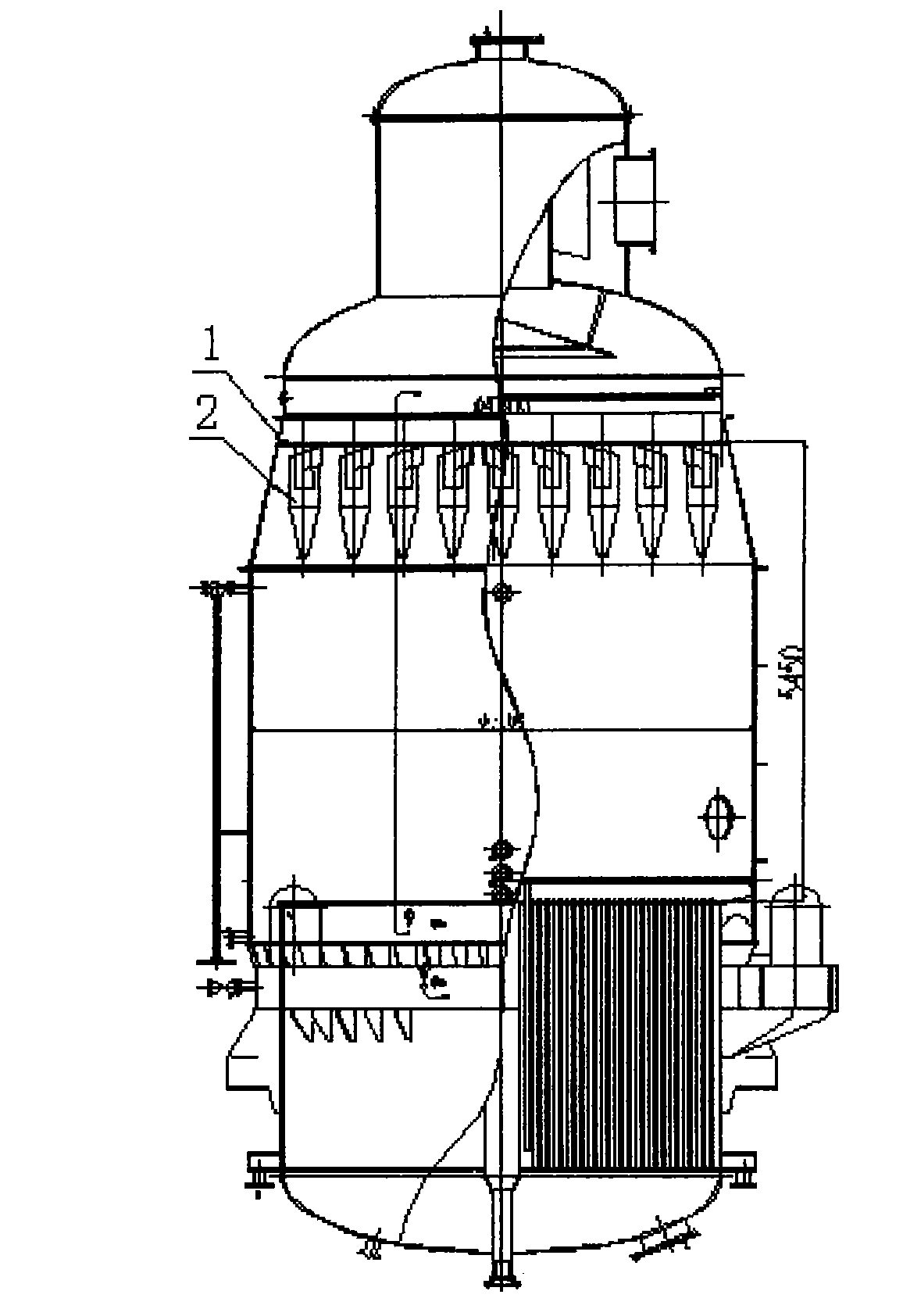

Whirlwind type separation juice extracting method and equipment

InactiveCN101812547ASimple structureSmall footprintSugar juice boiling/evaporationDual effectSoft water

The invention relates to an evaporation and sugar boiling method and equipment in a cane sugar factory, in particular to an entrainment separation juice extracting method and a device. The device consists of a plurality of whirlwind separators, wherein the whirlwind separators are uniformly distributed on the top of an evaporation tank, juice steam enters into air inlets of a whirlwind juice extracting device in the tangential line direction at high speed, under the effect of the centrifugal force, liquid drips in the juice steam are thrown to the device wall to be separated, and the liquid drips flow back into the tank through U-shaped pipes arranged at the bottom of the whirlwind separators, so the liquid drips are prevented for being converted into fog again because of the steam flow impact, clean juice steam is discharged to the top from center pipes of the whirlwind separators, and the goal of separation is reached. The sugar loss of the evaporation tank and a sugar boiling tank is avoided, and the invention has the juice extracting effects that the sugar content of dual effect condensing water is reduced from a range between 100 ppm and 150 ppm to a range between 25 ppm and 40 ppm, and the boiler soft water standard is reached.

Owner:GUANGXI JIRAN TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com