High-efficiency carbon-absorbing tower

A carbon absorption tower, high-efficiency technology, applied in the separation of dispersed particles, purification with alkaline earth compounds, chemical instruments and methods, etc., can solve the problems of insufficient clarification effect, large equipment investment, low carbon dioxide utilization rate, etc. Utilization rate, reliable operation cost, absorption effect of fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

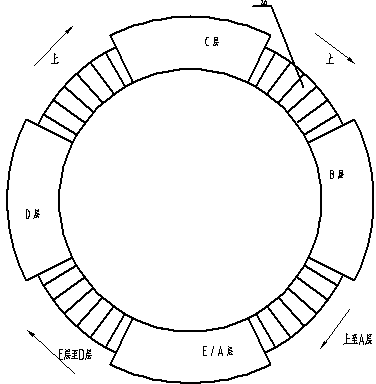

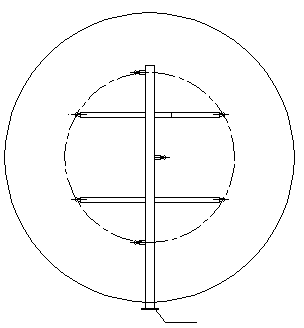

[0034] Such as Figure 1~5 As shown, the present invention mainly includes a tower shell (body), a flue gas extraction and discharge system, a packing system, a spray absorption system, a demister system, a cleaning system, a monitoring system and a material conveying system.

[0035] The body of the tower is divided into five areas, namely A, B, C, D, and E. Among them, the boiler flue gas extraction and discharge system is divided into two types: flue gas inlet and flue gas outlet. The flue gas inlet is set at the lower half of the tower body, and the flue gas outlet is set at the top of the tower. Boiler flue gas transmission power comes from the boiler induced fan system, flows from bottom to top, and finally flows out from the air outlet at the top of the tower, and returns to the inlet of the boiler chimney through the pipe. In line with the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com