Hydrolysis method for producing xylose from bagasse

A technology for sugar cane bagasse and sugar cane sugar, which is applied in the directions of sugar production, sugar production, application, etc., can solve the problems of unstable hydrolysis process control, low xylose content in the hydrolyzate, low equipment utilization rate, etc., and achieves significant economic benefits. , The effect of stable acid concentration and increased pot loading coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

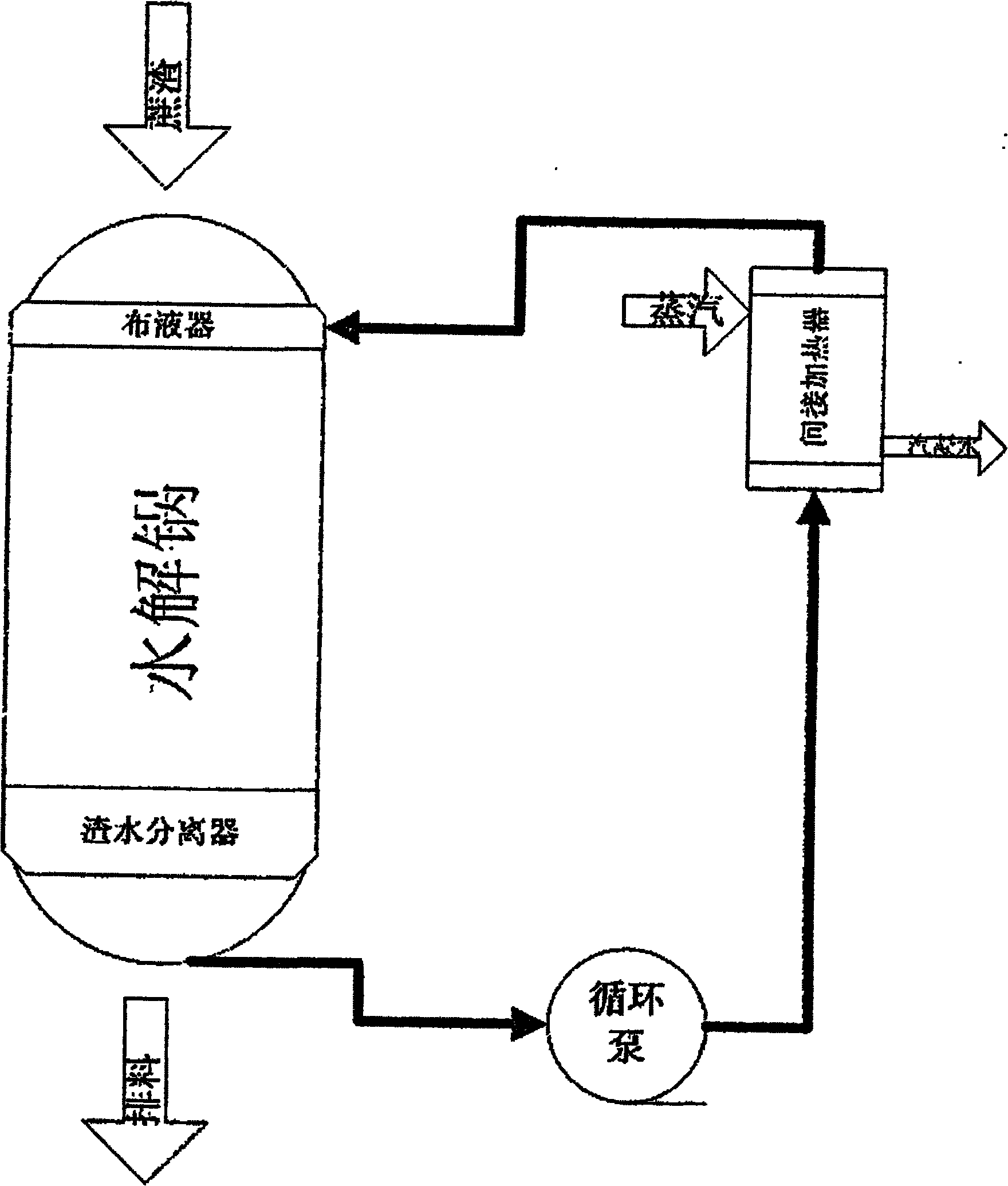

Image

Examples

Embodiment

[0015] (1) Preparation of catalyst solution

[0016] A certain amount of water or dilute hydrolyzate is injected into a water tank, and a certain amount of hydrochloric acid or sulfuric acid is added to prepare a catalyst solution with a concentration of 3-10%.

[0017] (2) Charge hydrolysis

[0018] Add bagasse into the hydrolysis pot, the volume of bagasse is greater than 85% of the capacity of the hydrolysis pot, add the prepared catalyst solution in a ratio of 1:5 to 7 by mass, heat up the hydrolysis pot, start the forced circulation pump at the same time, turn on the heater to The steam valve is heated, kept at 115-130° C., kept warm for 60-90 minutes, and the hydrolysis ends.

[0019] (3) Nesting

[0020] After the hydrolysis is completed, turn off the forced circulation pump, turn off the steam inlet valve of the heater, use the residual pressure in the hydrolysis pot to discharge the material out of the discharge pool, and enter the next section for processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com