Whirlwind type separation juice extracting method and equipment

A cyclone separator and equipment technology, which is applied to the mist separation of boiled sugar and the evaporation field of sugar cane plants, can solve the problems of poor separation effect, not much popularization and application, fog generation, etc. The effect of less investment and less power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

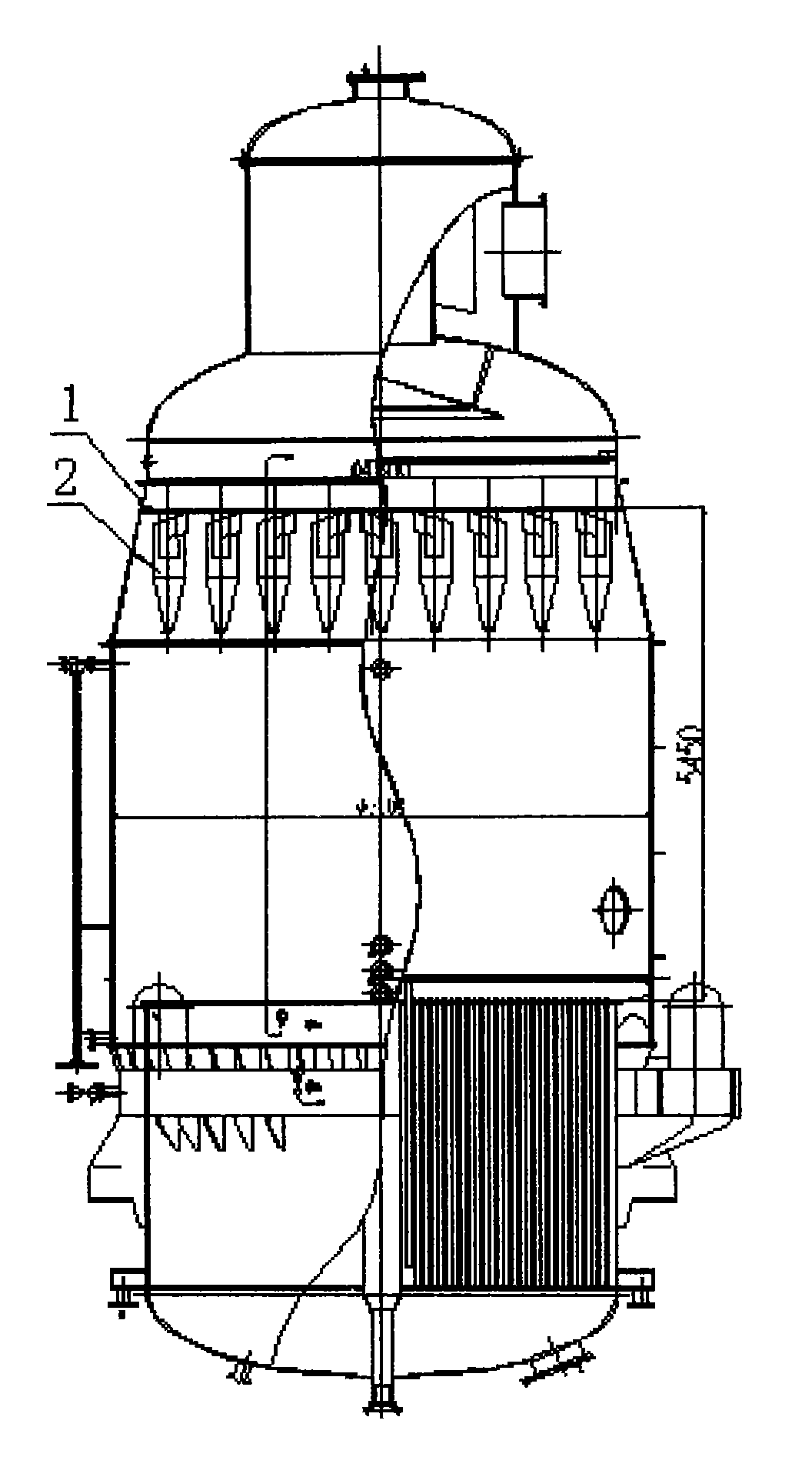

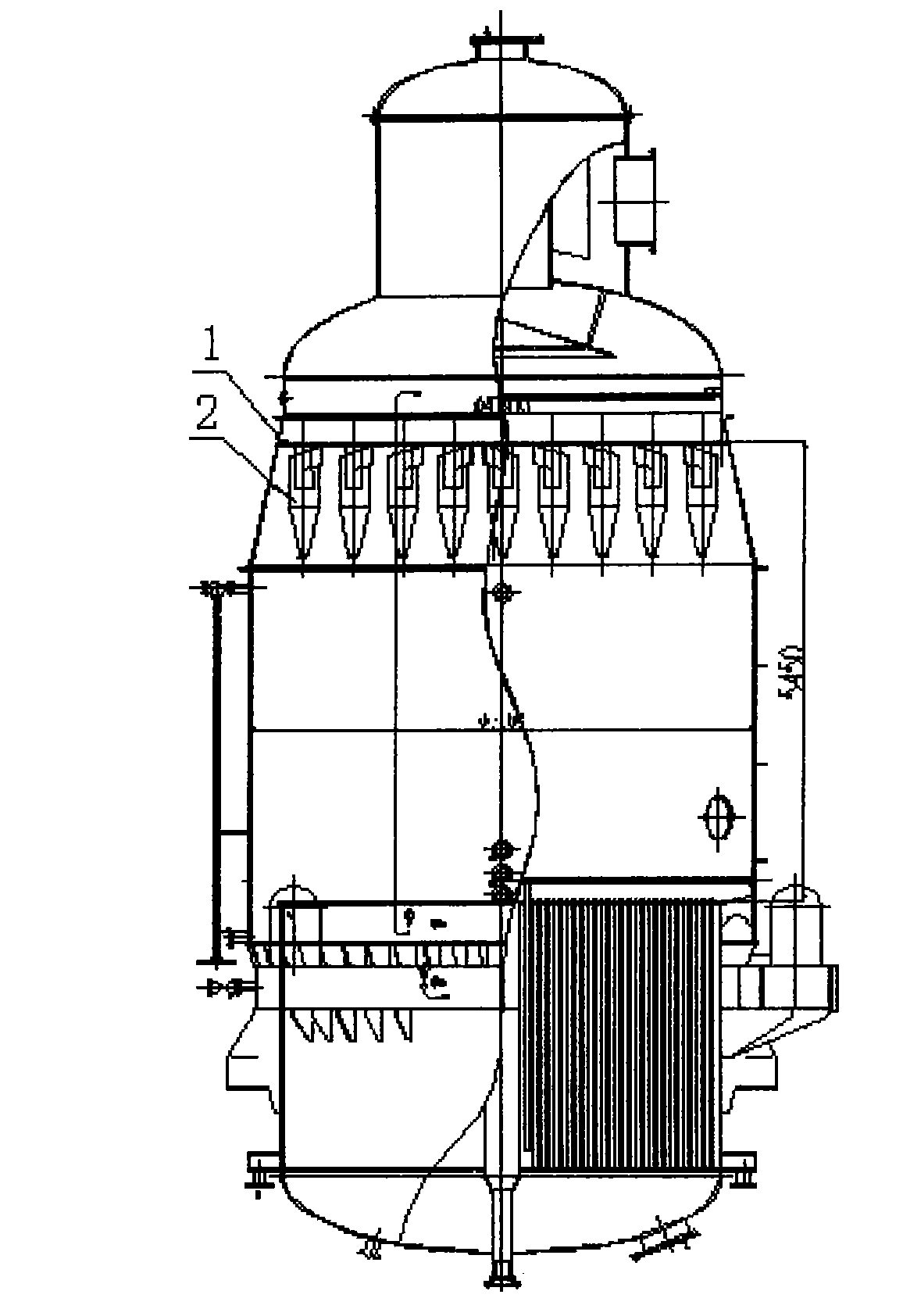

[0032] Find out from accompanying drawing 1, the present invention is fixed on the tank top sealing flower plate 2 by several cyclone separators 1 uniform distribution. The number of cyclones depends on the size of the tank.

[0033] The tank body and the cyclone separator 1 can be made of stainless steel, and the inner wall of the body is smooth without welds, and the overall shape is kept round. The upper part of the cyclone separator 1 has a central pipe 4 and a steam inlet 8, a cylindrical body 5, a conical body 6, a U-shaped pipe 7, and a slag outlet 9.

[0034] One end of the central tube 4 is connected to the cylindrical body 5, which is the inlet of clean juice vapor, and the other end is welded and fixed to the tank top sealing flower plate 2, which is the outlet of clean juice vapor.

[0035] The steam inlet 8 is rectangular, seamlessly welded on the cylindrical body 5, and its welding position is at the same level as the upper end line of the cylindrical body.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| drag coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com