Treatment method of waste mash of cane sugar factory

A treatment method and technology for waste mash, which are applied in the fields of food industry wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. Or the technology is immature, the by-products do not have a stable market, etc., to achieve the effect of easy promotion, good environmental protection and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

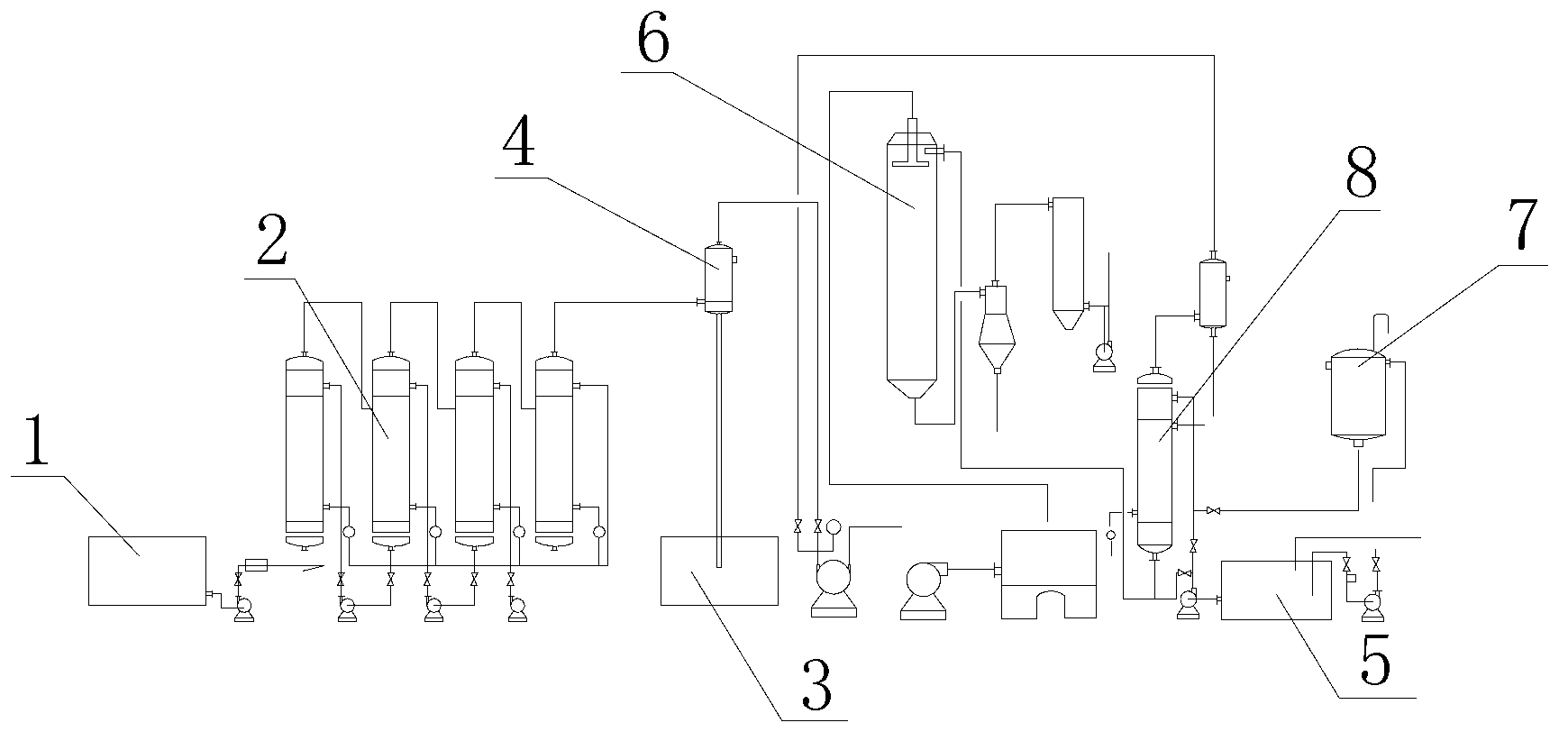

[0041] Such as figure 1 The treatment method of the waste mash of the shown sugarcane sugar factory:

[0042] (1) Pre-treatment: Measure the molasses alcohol waste mash discharged from the alcohol workshop into 1 and adjust the pH to 5.5 with ammonium bicarbonate;

[0043] (2) Primary concentration: Send the waste mash obtained in step (1) with a pH of 5.5 into a four-effect vacuum falling film evaporator 2 with an evaporation pressure of 450kpa to evaporate to a waste mash with a mass concentration of 40%. , the cooling water produced after its evaporation is put into the cooling water pool 3 and then recycled to the fermentation workshop of the sugar factory;

[0044] (3) Cooling and sedimentation and thick slurry drying: the primary concentrated liquid obtained in step (2) is transported to the separator 5 through the cooler 4 for sedimentation and separation for 24 hours. After separation and sedimentation, a supernatant liquid and a lower thick slurry are formed in the s...

Embodiment 2

[0047] Such as figure 1 The treatment method of the waste mash of the shown sugarcane sugar factory:

[0048] (1) Pretreatment: Measure the molasses alcohol waste mash discharged from the alcohol workshop into 1 and adjust the pH to 6 with ammonium bicarbonate;

[0049] (2) Primary concentration: Send the waste mash obtained in step (1) with a pH of 6 to a four-effect vacuum falling film evaporator 2 with an evaporation pressure of 475kpa to evaporate to a waste mash with a mass concentration of 45%. , the cooling water produced after its evaporation is put into the cooling water pool 3 and then recycled to the fermentation workshop of the sugar factory;

[0050](3) Cooling and sedimentation and thick slurry drying: The primary concentrate obtained in step (2) is transported to the separator 5 through the cooler 4 for sedimentation and separation for 25 hours. After separation and sedimentation, a supernatant liquid and a lower thick slurry are formed in the separator , the ...

Embodiment 3

[0053] Such as figure 1 The treatment method of the waste mash of the shown sugarcane sugar factory:

[0054] (1) Pre-treatment: Measure the molasses alcohol waste mash discharged from the alcohol workshop into 1 and adjust the pH to 6.5 with ammonium bicarbonate;

[0055] (2) Primary concentration: Send the waste mash obtained in step (1) with a pH of 6.5 into a four-effect vacuum falling film evaporator 2 with an evaporation pressure of 500kpa to evaporate to a waste mash with a mass concentration of 50%. , the cooling water produced after its evaporation is put into the cooling water pool 3 and then recycled to the fermentation workshop of the sugar factory;

[0056] (3) Cooling and sedimentation and thick slurry drying: the primary concentrated liquid obtained in step (2) is transported to the separator 5 through the cooler 4 for sedimentation and separation for 26 hours. After separation and sedimentation, a supernatant liquid and a lower thick slurry are formed in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com