Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

122results about "Pulp gases treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

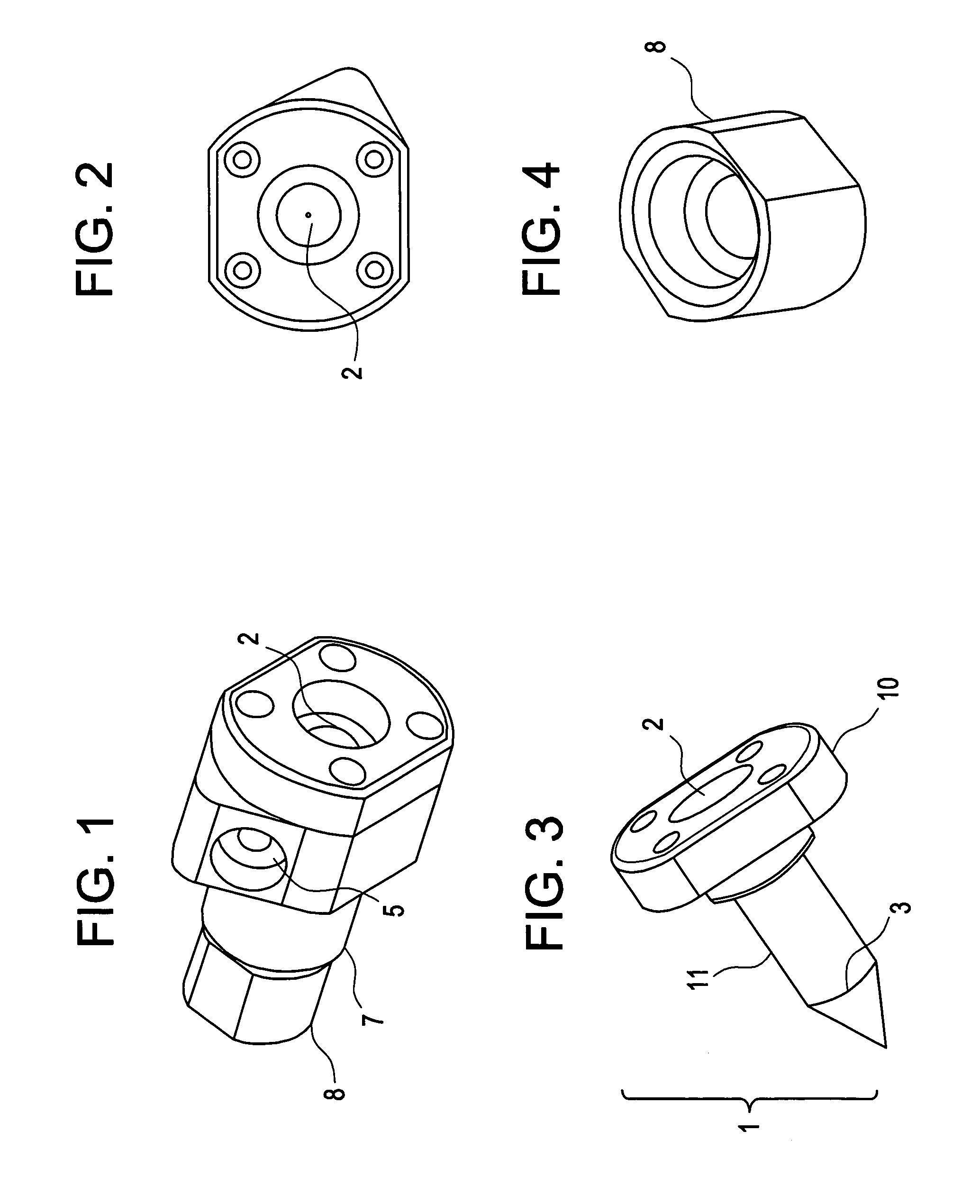

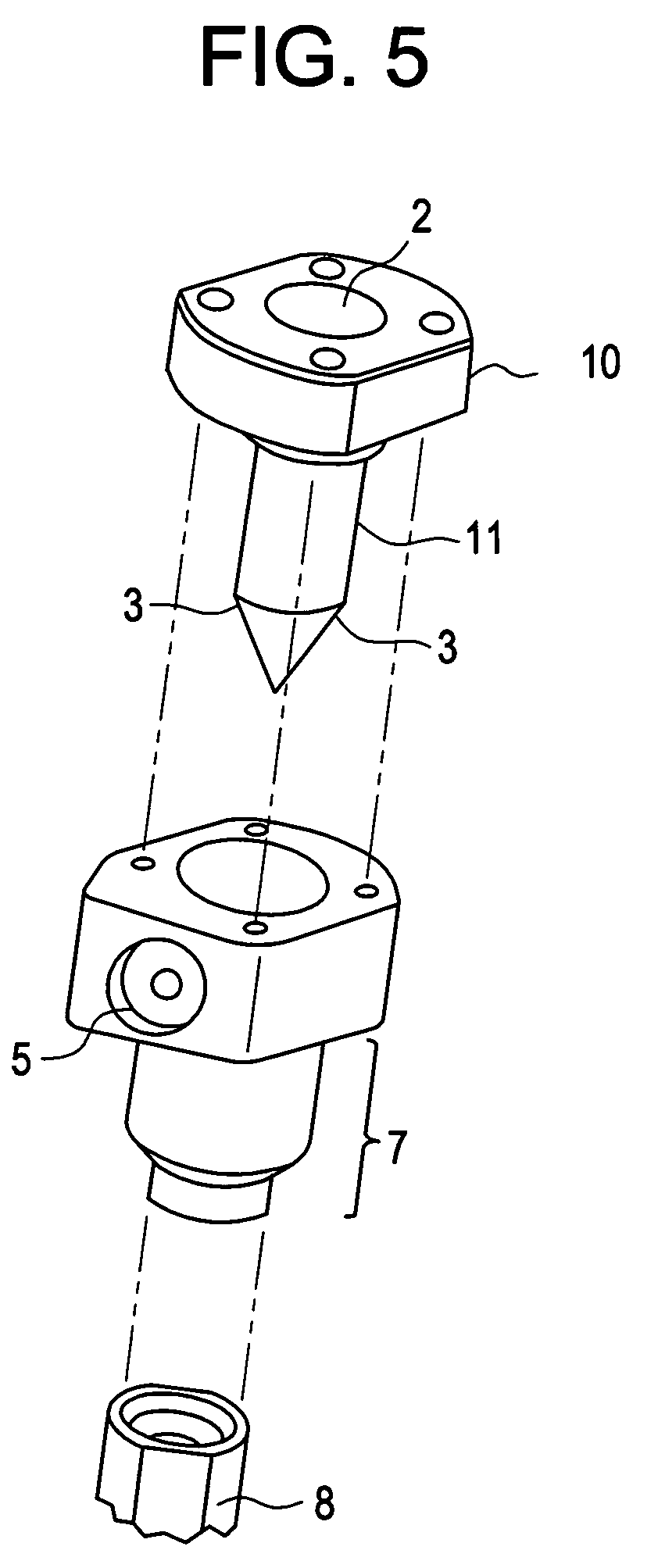

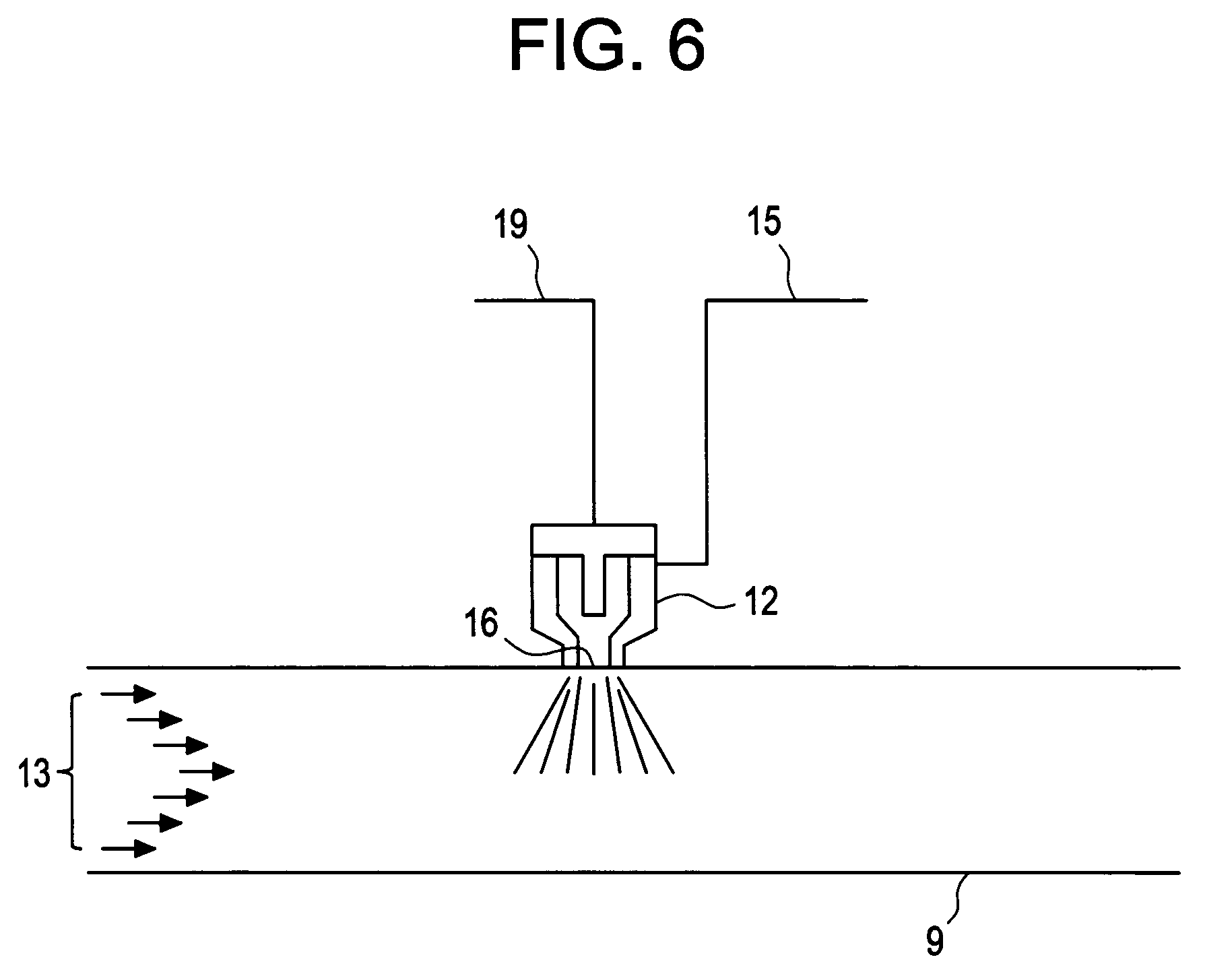

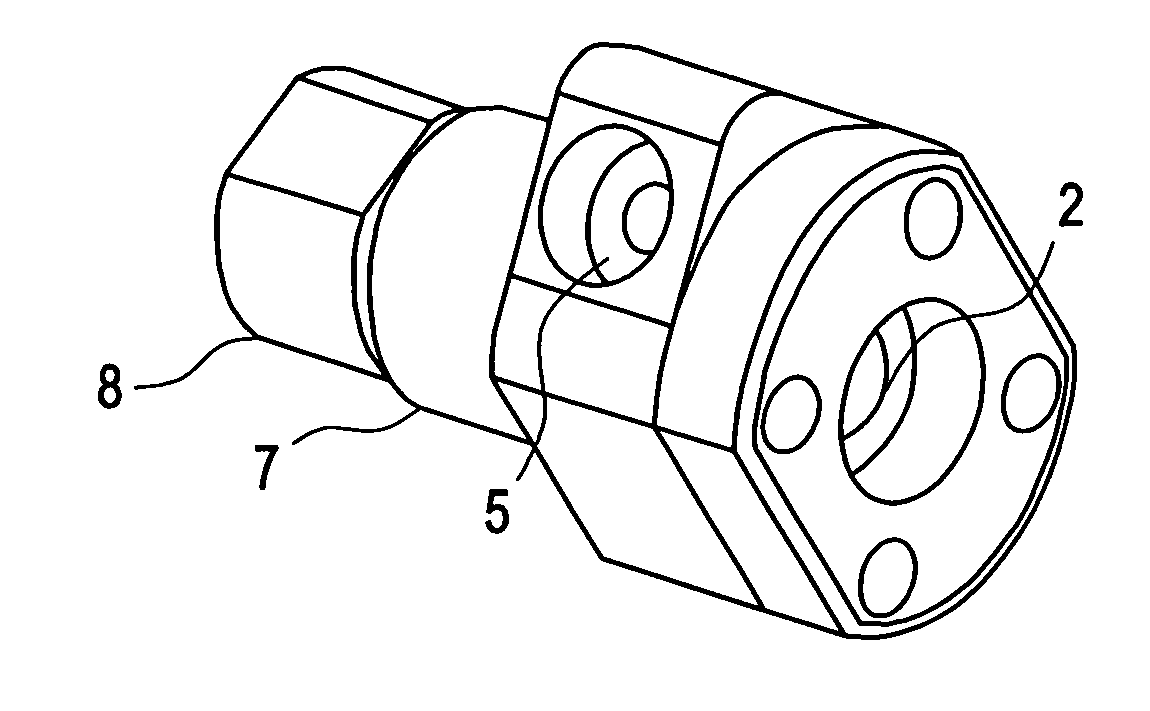

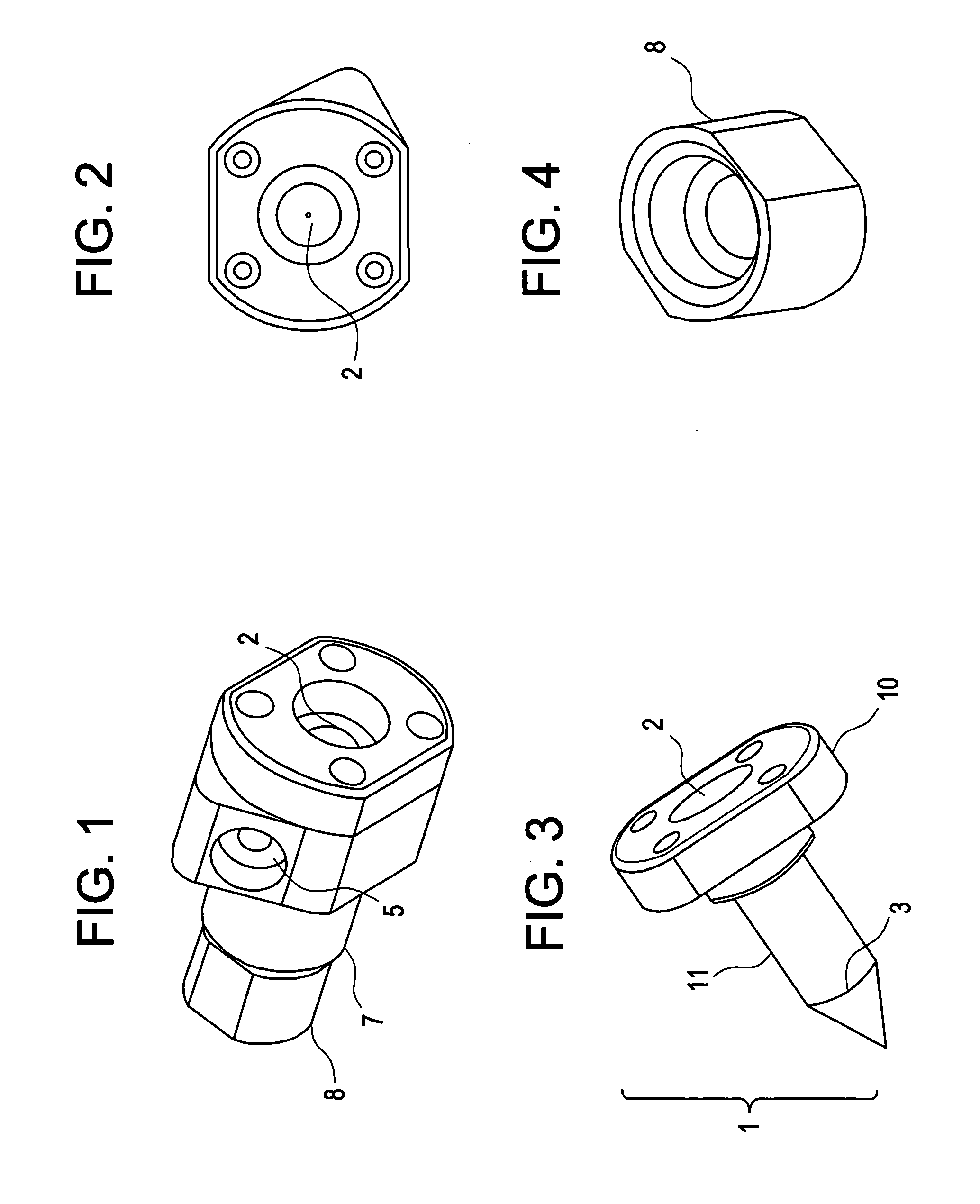

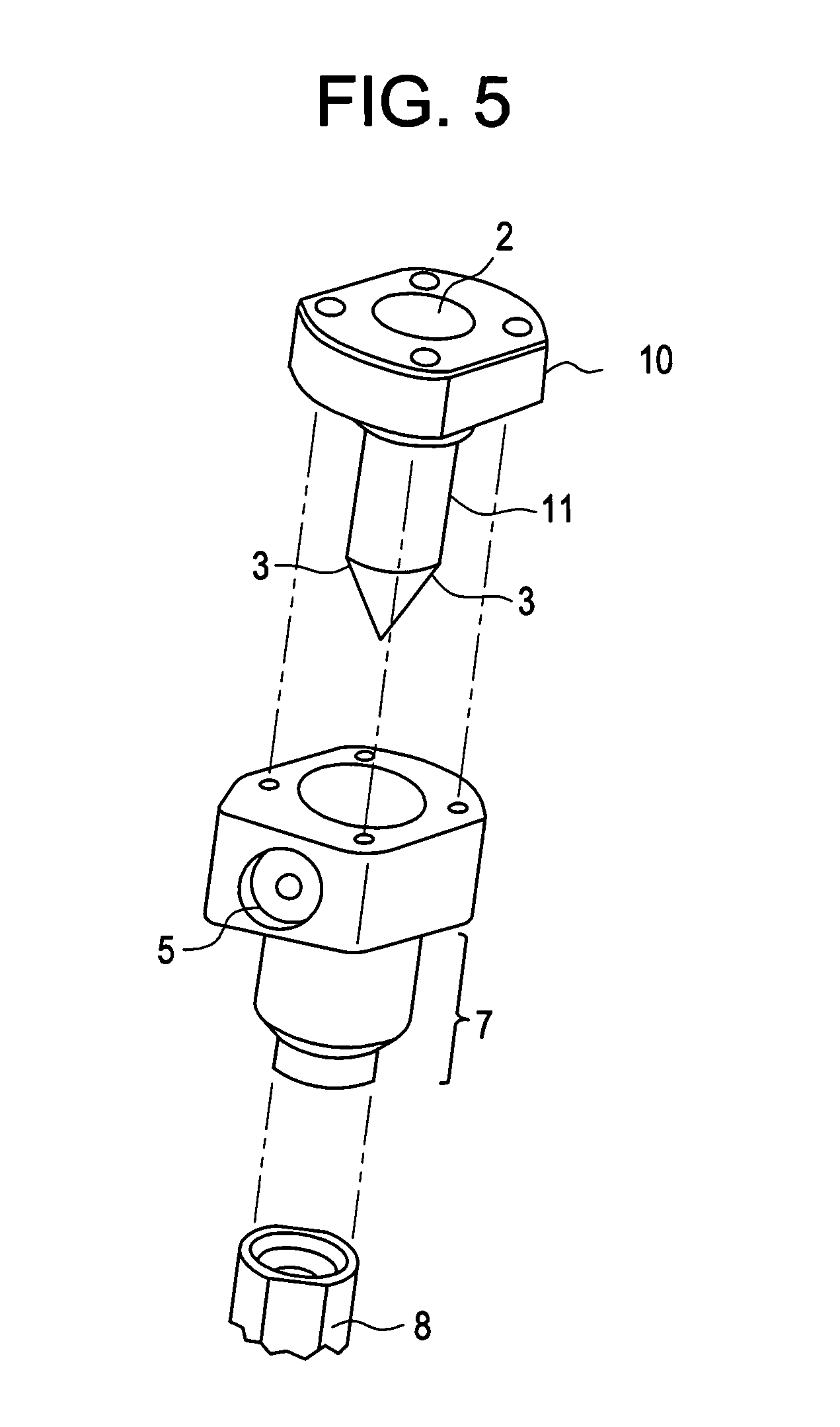

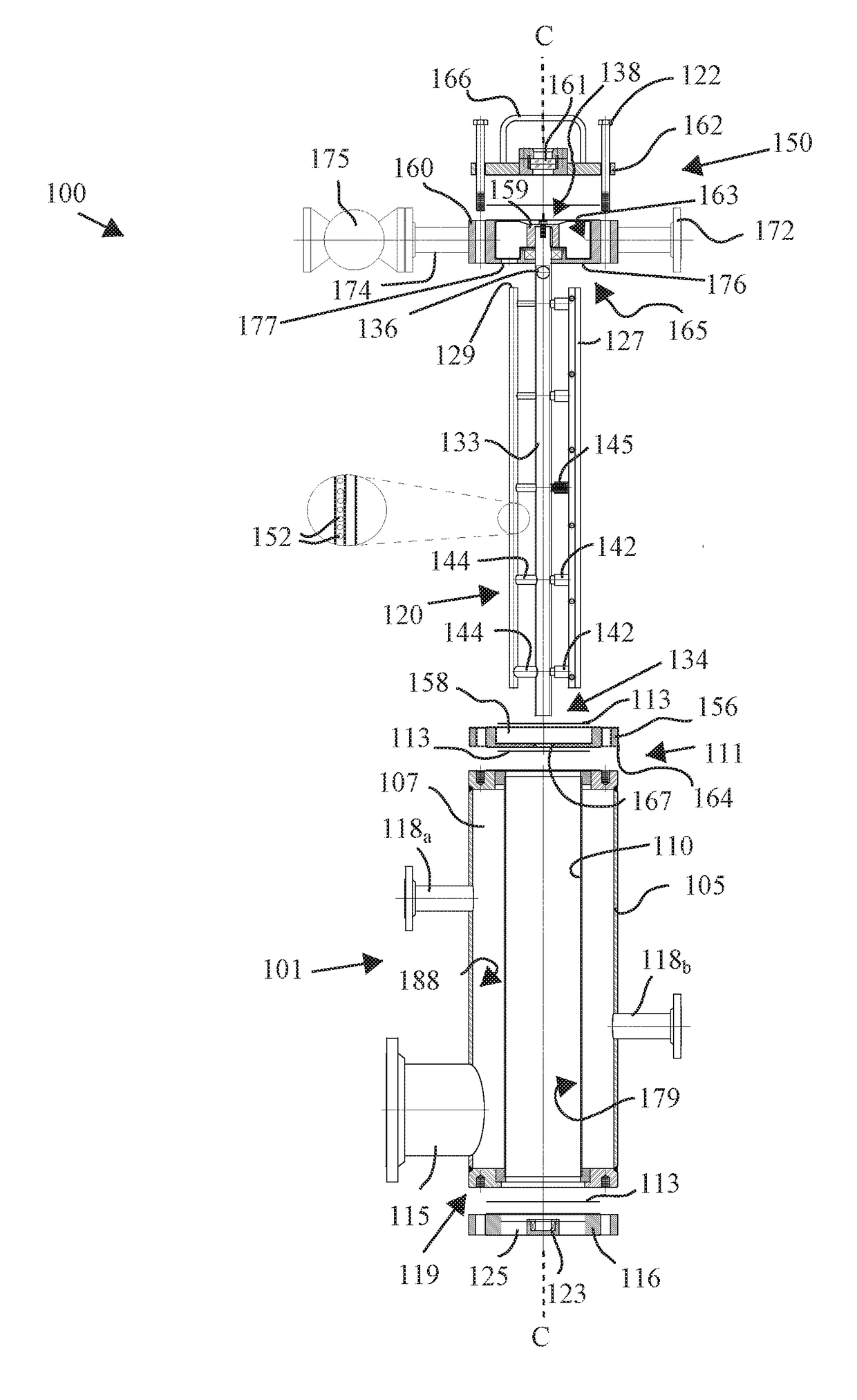

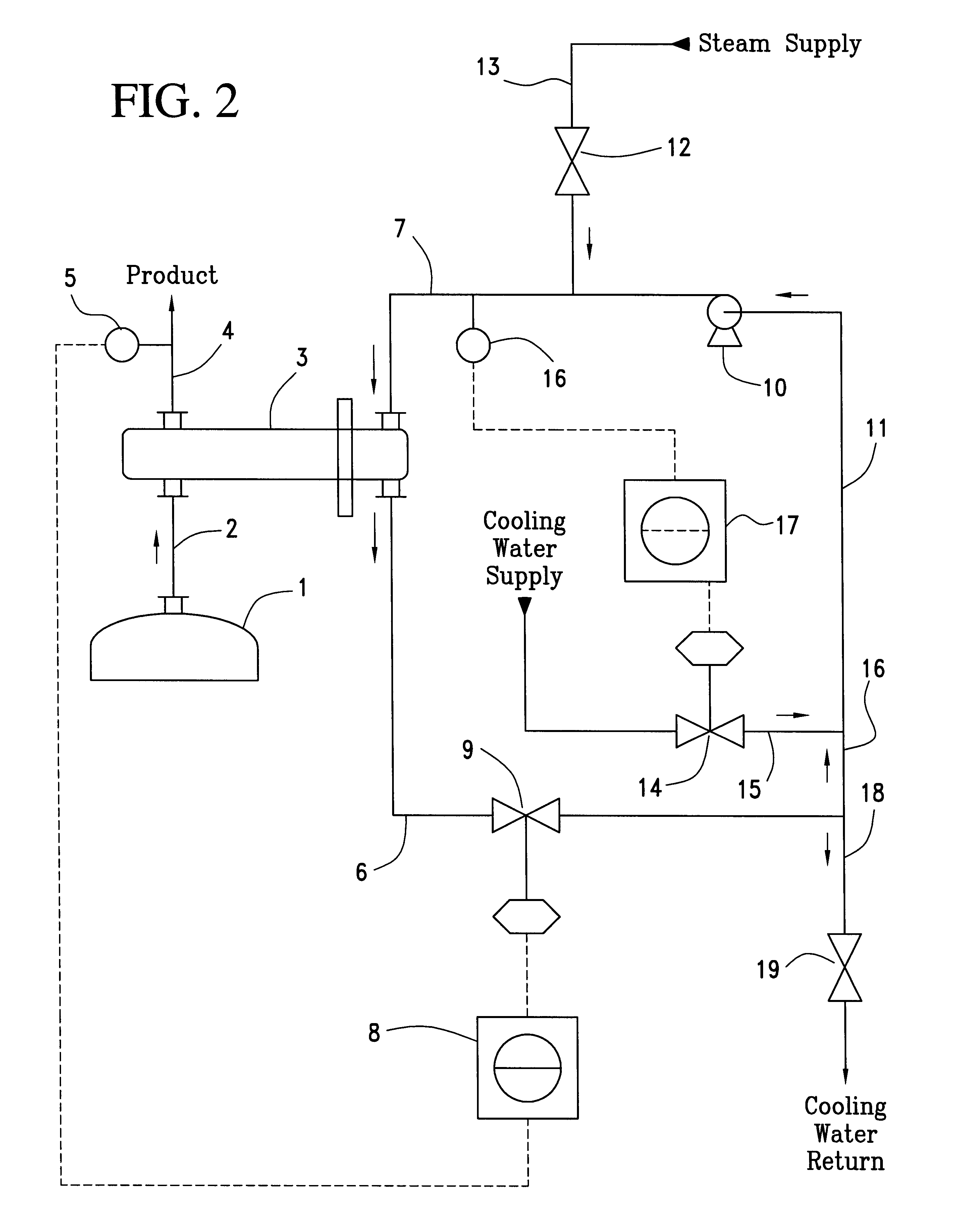

Method and arrangement for feeding chemicals into a process stream

An apparatus for feeding one or more chemicals into a process stream of a papermaking process is disclosed, as well as a method of utilizing the apparatus for feeding one or more chemicals into a process stream is disclosed.

Owner:ECOLAB USA INC

Detoxifying and Recylcing of Washing Solution Used In Pretreatment Of Lignocellulose-Containing Materials

ActiveUS20090056889A1Improve hydrolysis efficiencyImprove filtering effectWashing/displacing pulp-treating liquorsBiofuelsPre treatmentOrganic chemistry

The invention relates to a process of detoxifying pretreated lignocellulose-containing material comprising washing the pretreated lignocellulose-containing material in a washing solution and treating the used washing solution to remove an enzyme inhibitor and / or an inhibitor of a fermenting organism before recycling the used washing solution.

Owner:COFCO GROUP

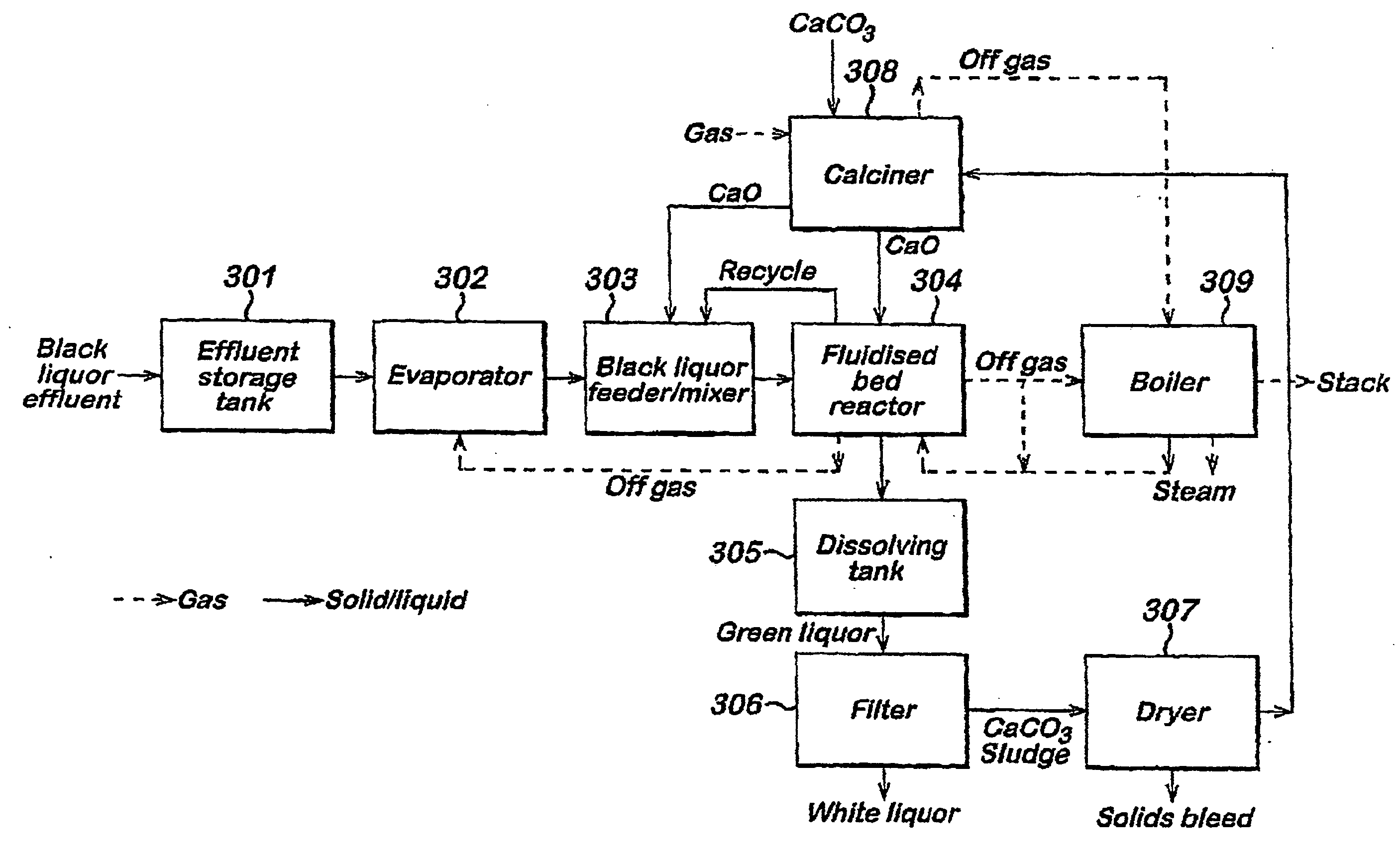

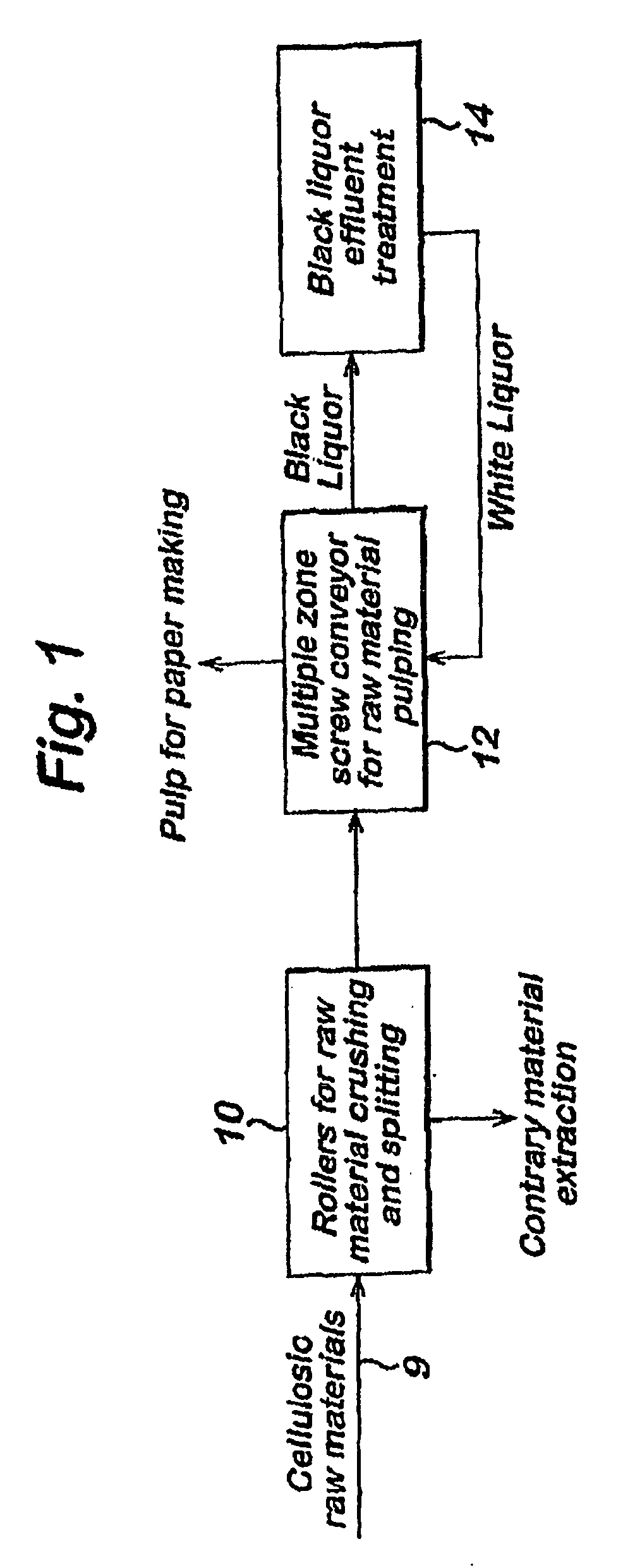

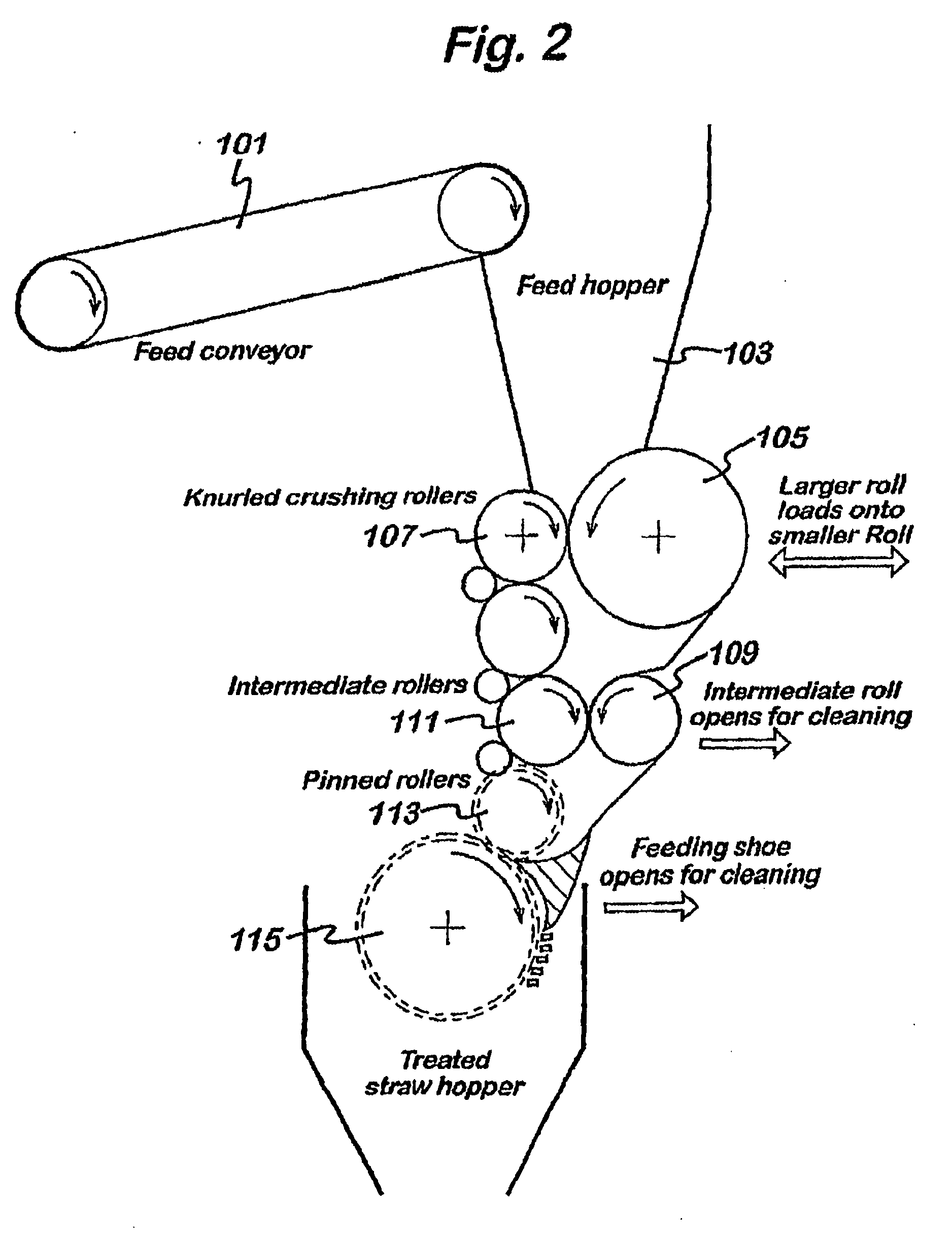

Methods for producing pulp and treating black liquor

InactiveUS20060201641A1Maintaining output qualityRaise the reaction temperaturePretreatment with water/steamPulp liquors combustionCalcium silicateOrganic content

A method is provided for treating black liquor particularly derived from non-wood pulp, by heating with an alkaline earth metal oxide in a toroidal fluidised bed reactor at a temperature of above 650° C. The method may be used alone or as part of a method of converting graminaceous raw material to pulp for paper or board, said method comprising (a) digesting said raw material with a white liquor based on sodium hydroxide and further comprising calcium hydroxide in an amount effective to substantially convert silica of said raw material to calcium silicate; (b) recovering pulp and black liquor substantially free of uncombined silica; (c) heating the black liquor in a fluidized bed reactor containing calcium oxide for catalysing conversion of organic content of said black liquor to gas and for providing recovered solids including sodium values of said white liquor and calcium oxide; and regenerating said white liquor using said recovered solids. The use of the above mentioned white liquor permits treatment of wheat straw, rice straw and other high-silica materials without resulting in a black liquor that is difficult to treat.

Owner:BIOREGIONAL MINIMILLS UK

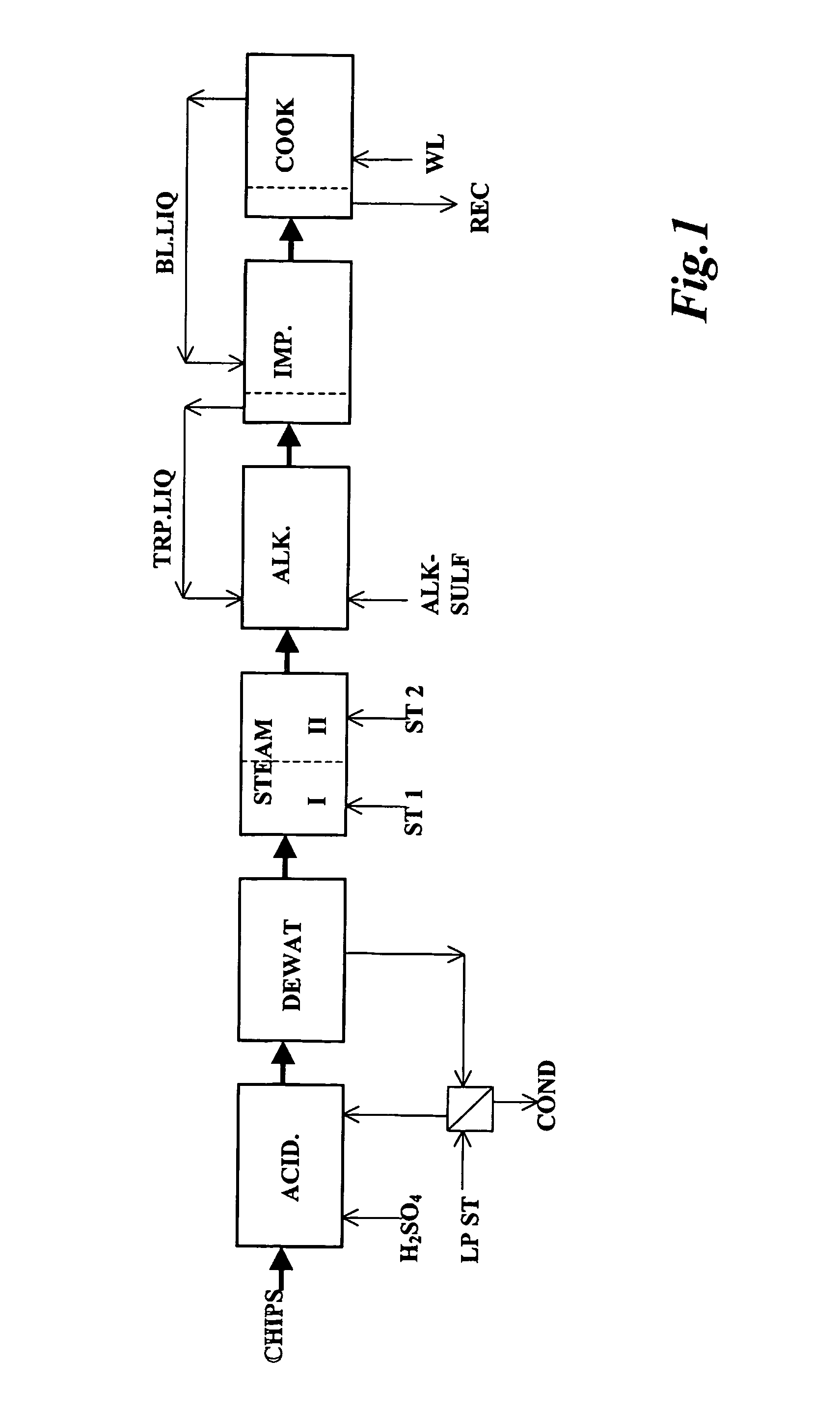

System and method for treatment of cellulose-containing material prior to pulp digestion

The invention relates to a process system and a method for preliminary treatment of disintegrated cellulose-containing material, preferably wood chips, prior to pulp digestion. The process system and the method according to the invention make use of a process vessel intended to function both as a so-called chip bin and as a pre-impregnation vessel. The characteristics of the invention are that a sloping steaming vessel is arranged downstream of the process vessel for the purpose of separating an excess of pre-impregnation liquid from the pre-impregnated cellulose-containing material, that the sloping steaming vessel is arranged for supplying steaming vapor which preferably has been generated by flashing of extraction liquor from a pulp digester, and that the sloping steaming vessel is connected to a chip chute communicating with a condenser for connection to a system for managing foul-smelling process gases. The invention can be applied in the production of pulp which is intended for paper manufacture or other applications where cellulose fibers are used.

Owner:METABO PAPER SWEDEN

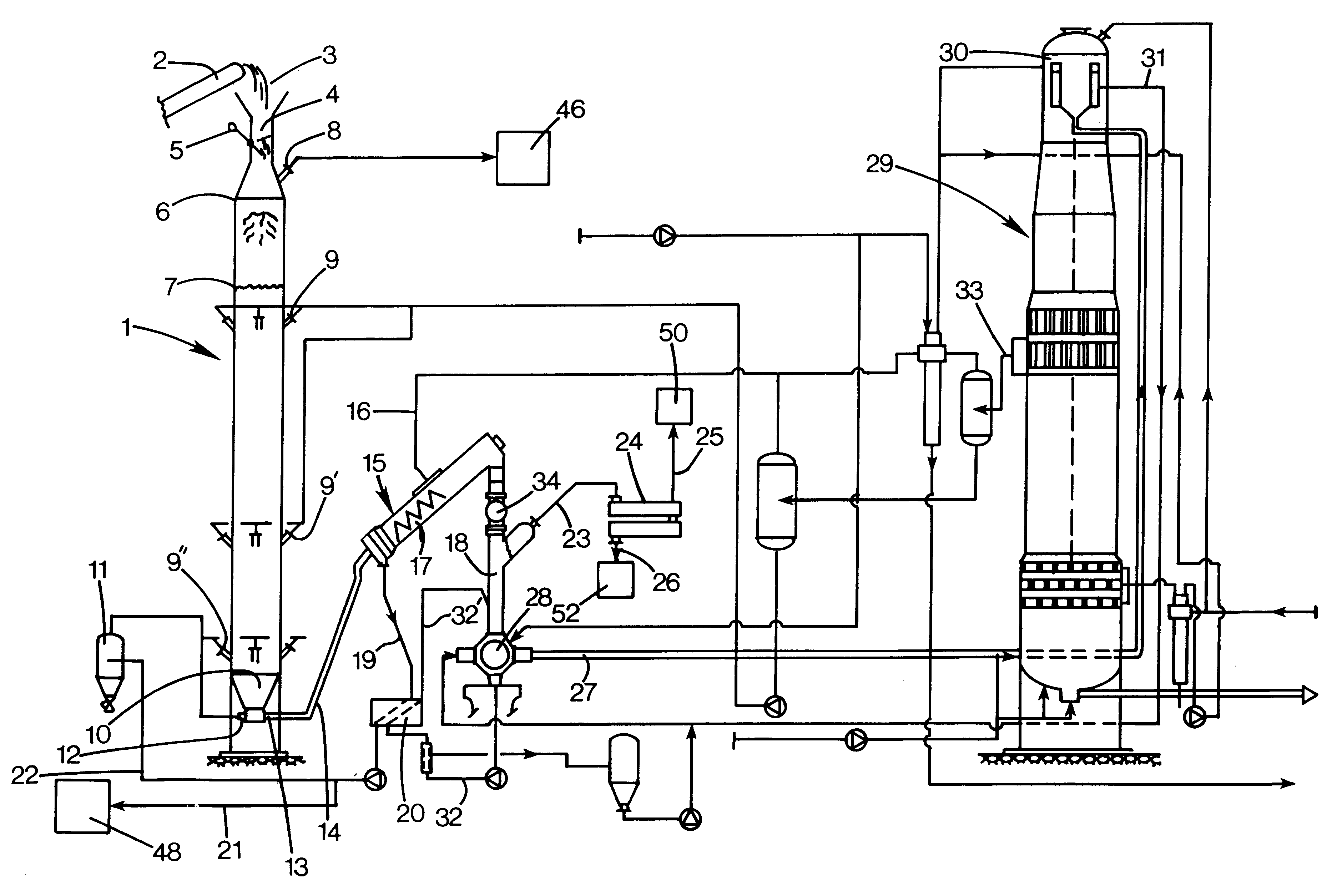

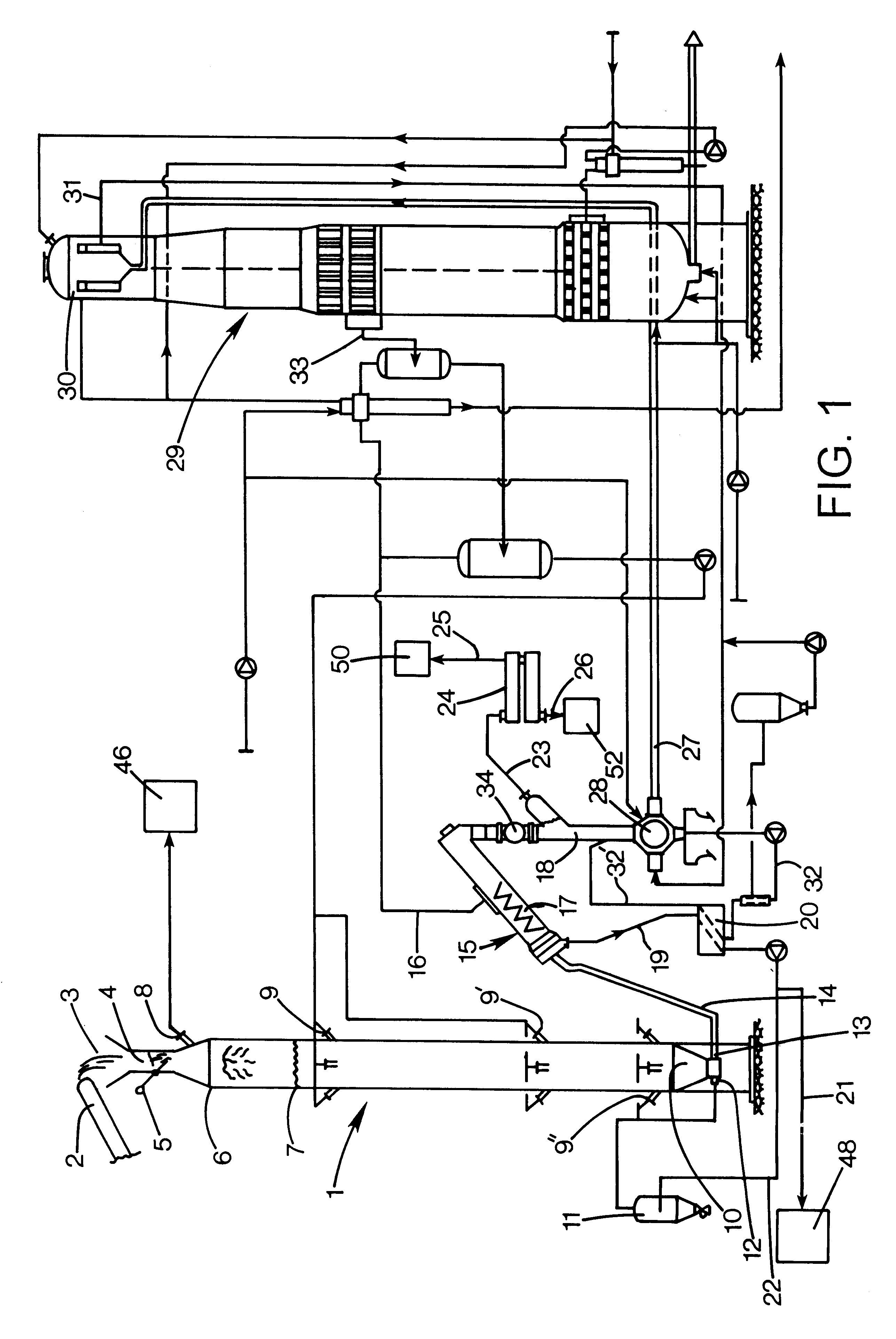

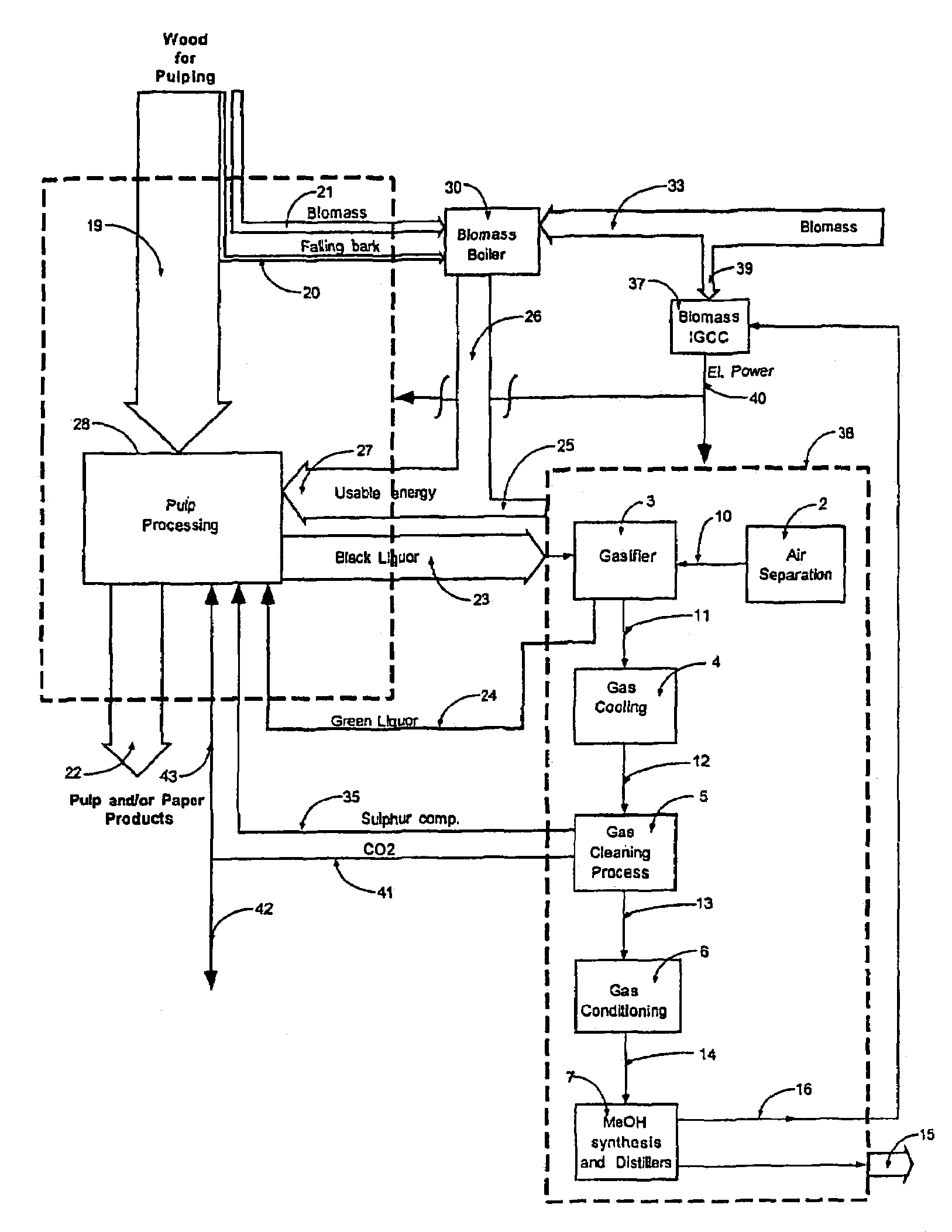

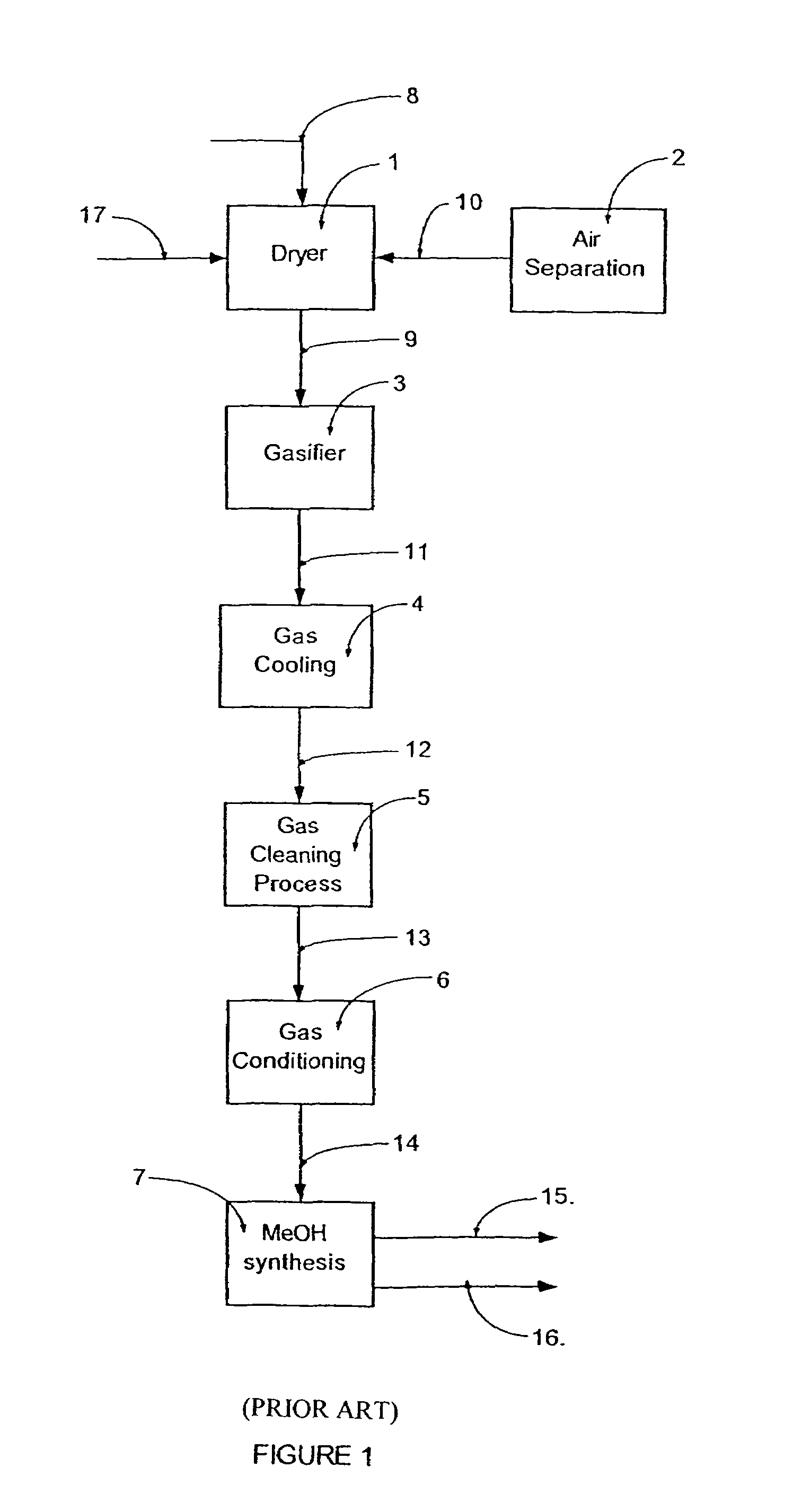

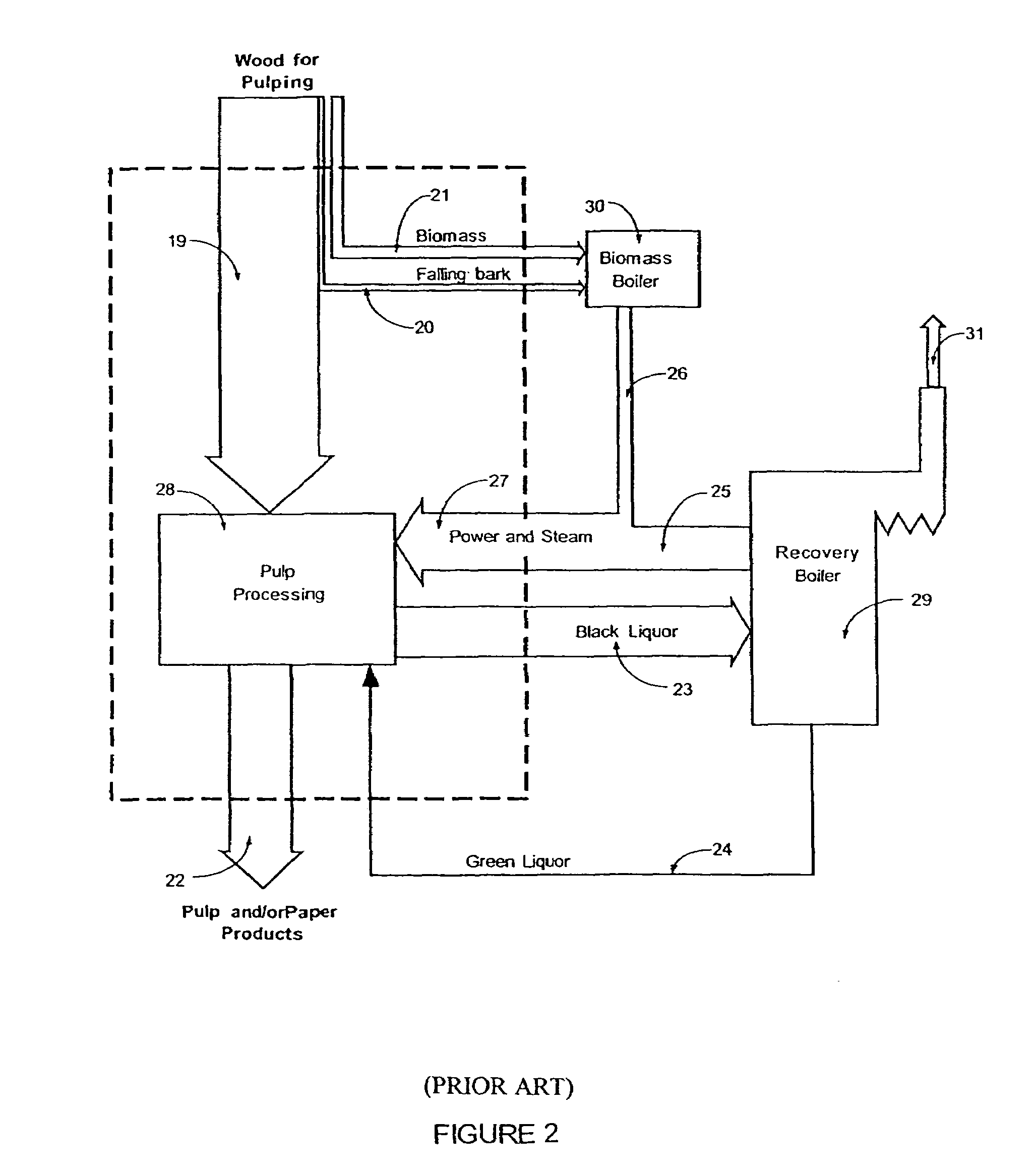

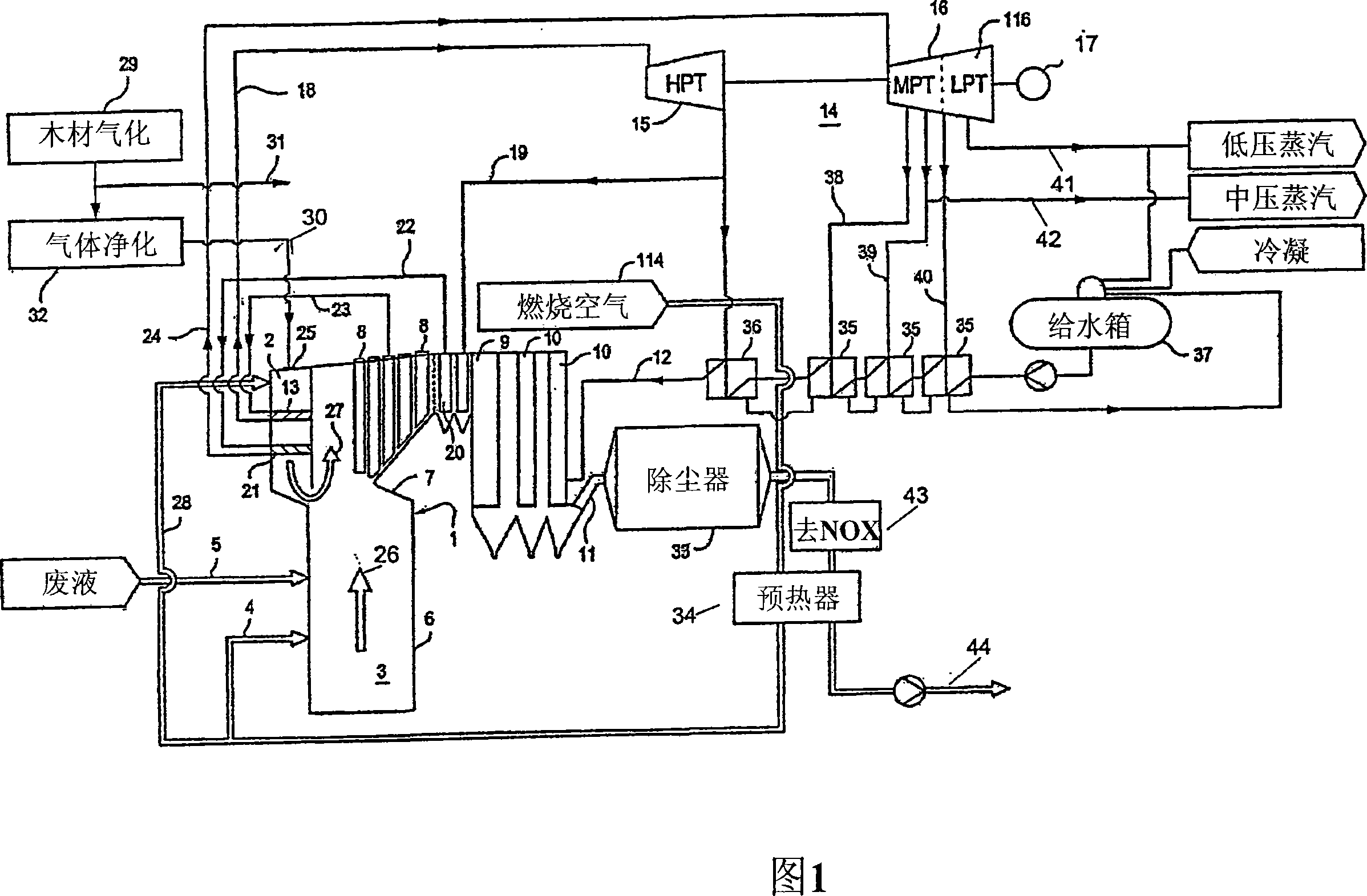

Process for production of synthesis gas in combination with the maintenance of the energy balance for a pulp mill

InactiveUS7294225B2Simpler andImprove energy savingPulp liquors combustionHydrocarbon from carbon oxidesEnergy balancingCombustion

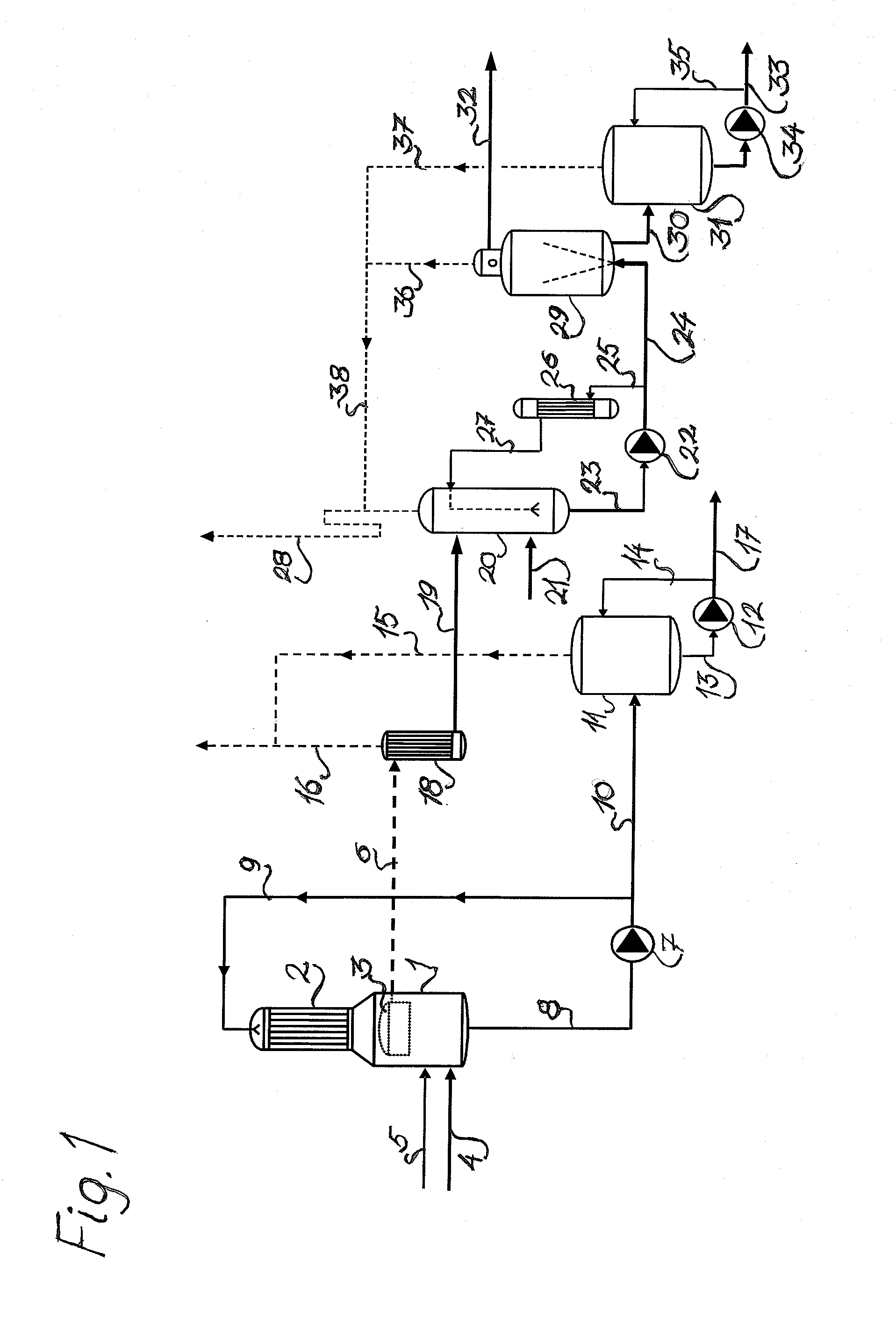

A process (44) for the production of pulp and paper (28), recycling of cooking chemicals (3, 29), combustion of biomass (30, 37) and generation of heat and electric energy (27, 40) comprising a pulp and paper mill (28), in that the part of the process which is recycling cooking chemicals is adjusted from combustion (29) to gasification (3) to generate synthesis gas (14); and that biomass is added (33, 39) in an amount sufficient for compensating of the decrease in heat and electricity generation as a consequence of the generation of synthesis gas (14).

Owner:CHEMREC AB

Removal of inorganic elements from wood chips

InactiveUS20050034823A1Less energy consumptionIncrease moisture contentWashing/displacing pulp-treating liquorsPretreatment with acid reacting compoundsProduction linePregnant leach solution

In a process of treating wood chips for reduction of the concentration of undesirable inorganic elements prior to cooking in a production line for chemical pulp, the wood chips, having entrapped air, are treated with an aqueous leaching liquor at elevated temperature and pressure, followed by draining at atmospheric pressure or below atmospheric pressure, the pressures being controlled to yield a moisture content in the wood chips as low as possible for adequate leaching result and behavior of the chips in a subsequent digester. The aqueous leaching liquor is e.g. pulp mill process water with a low content of undesirable inorganic components, such as bleach plant spent liquor or condensate. The aqueous leaching liquor drained from the treated wood chips may be purified and recycled back to the process.

Owner:STFI

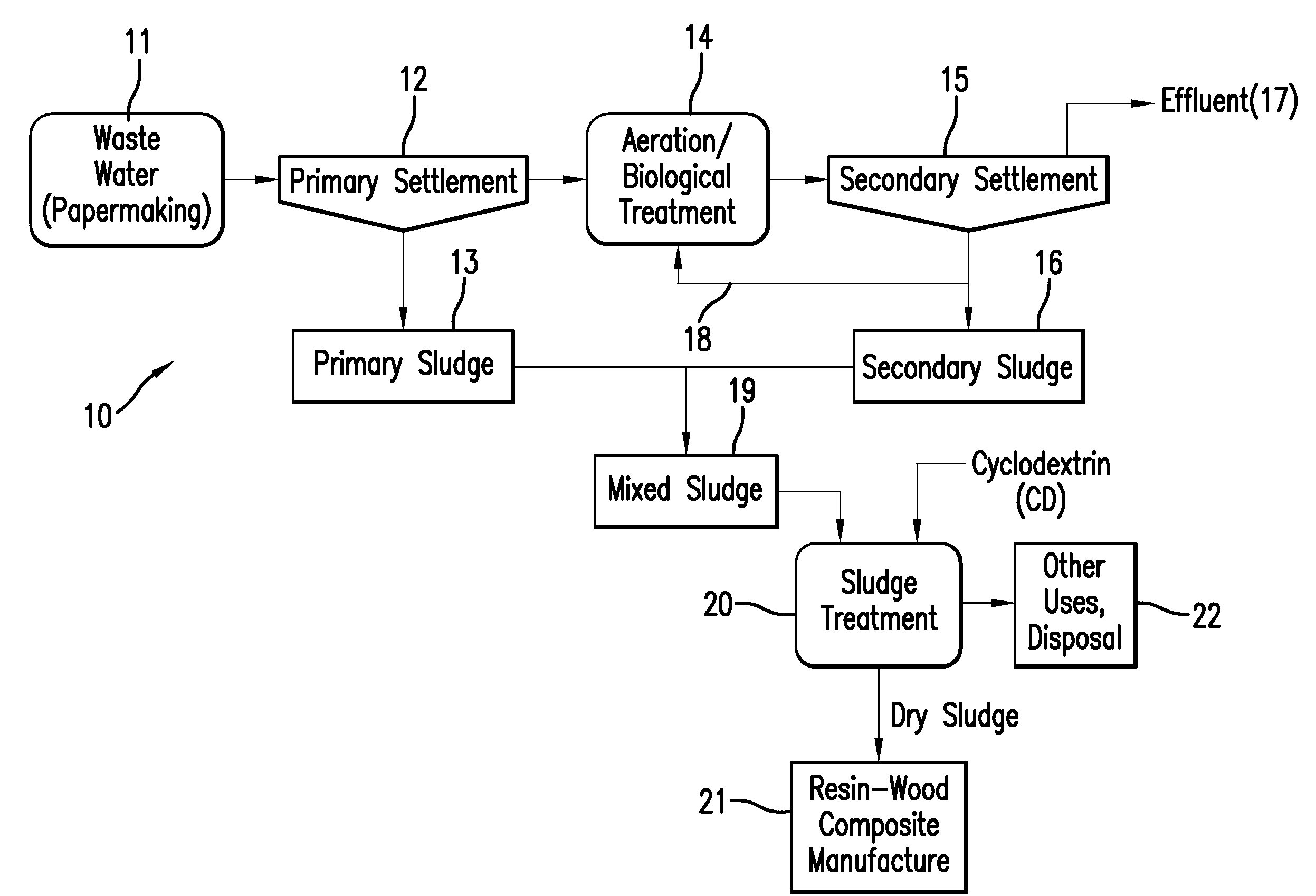

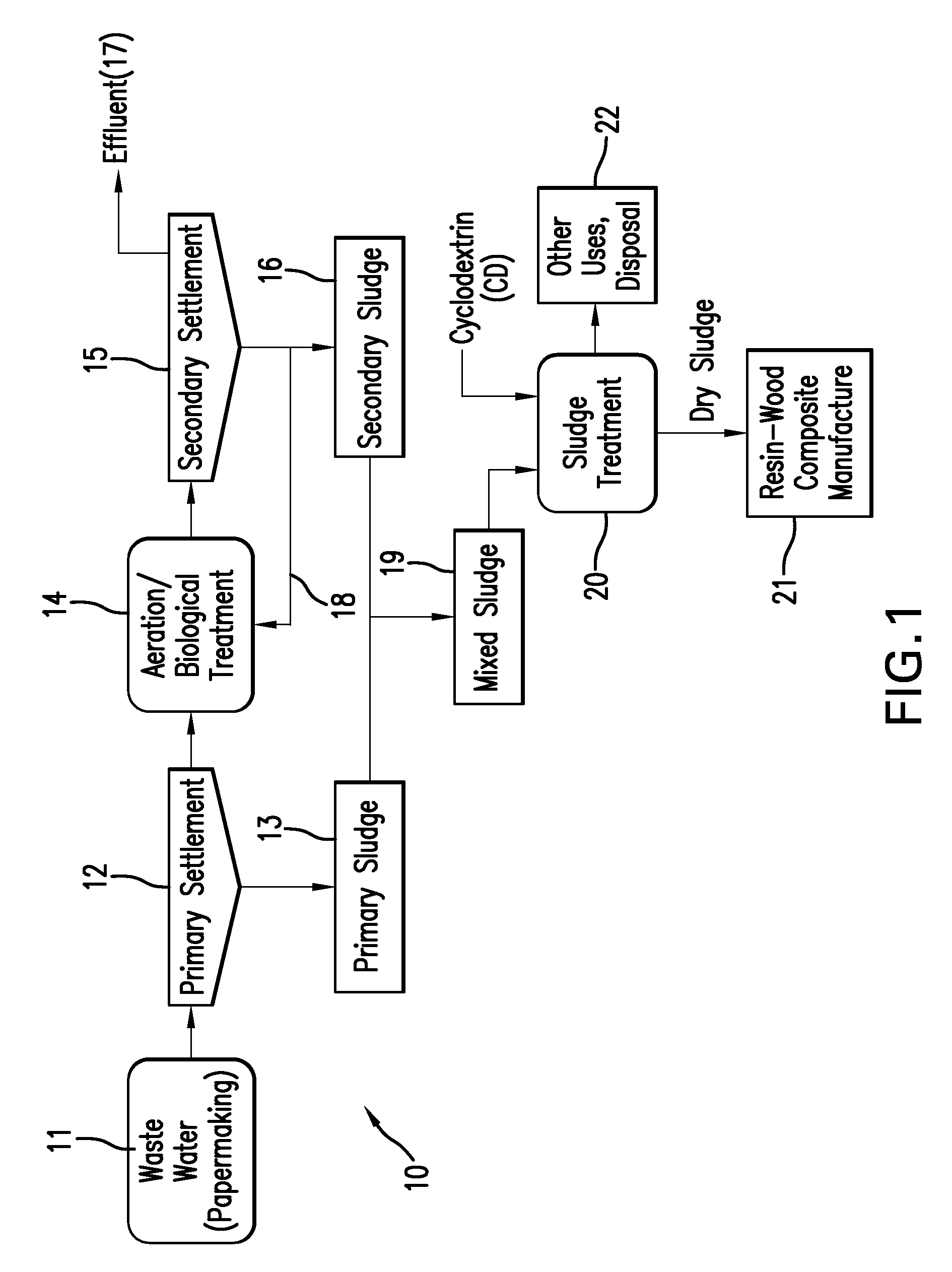

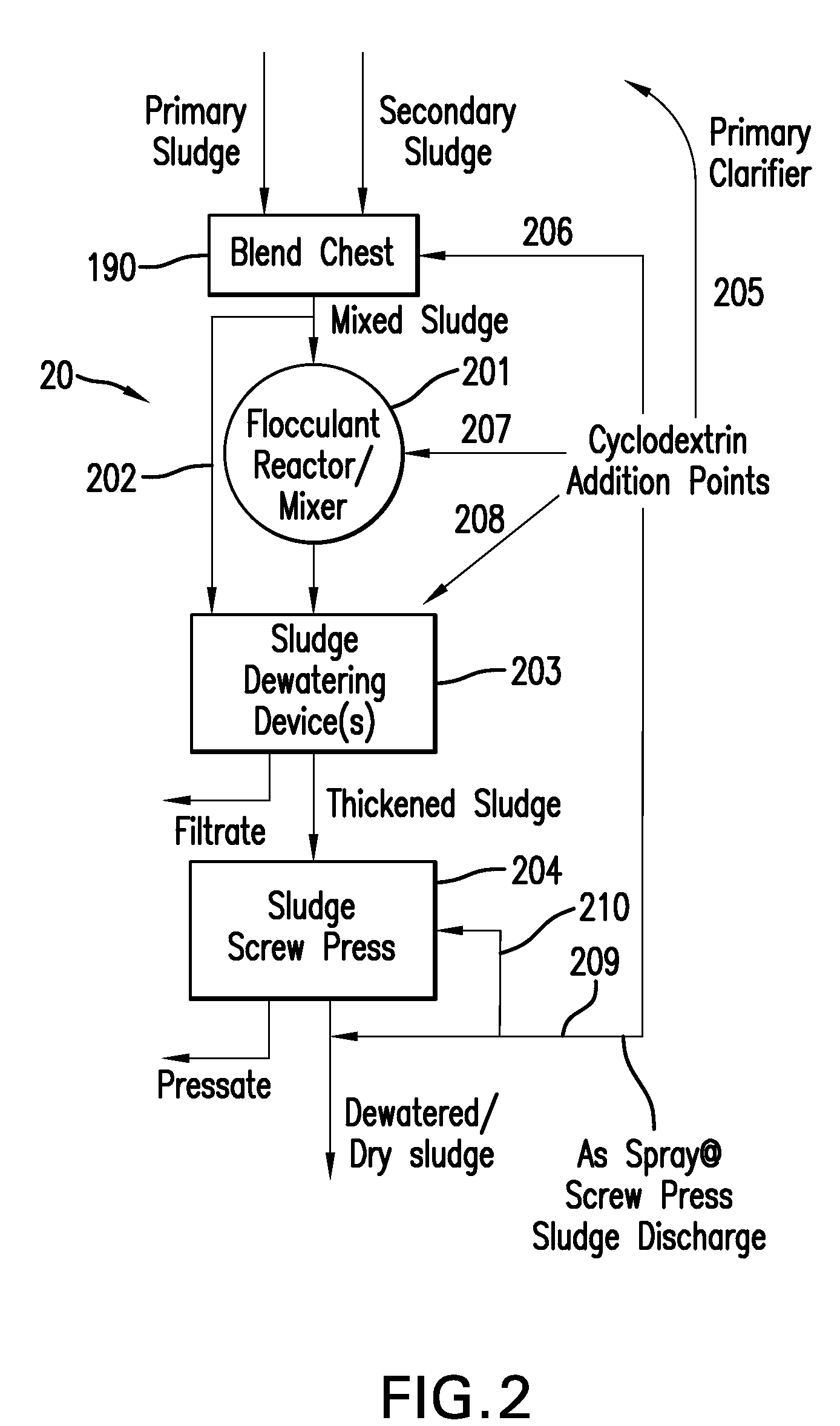

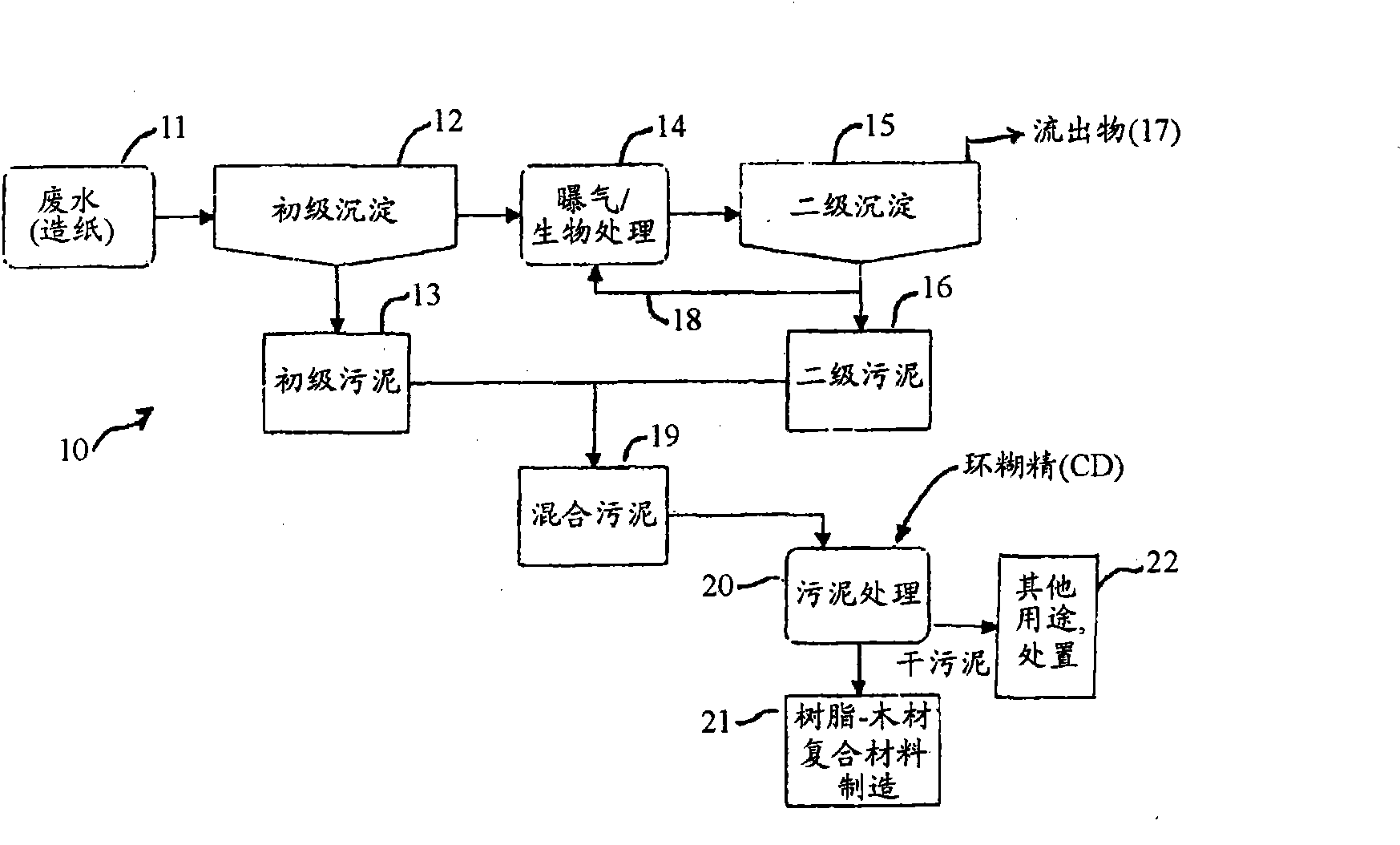

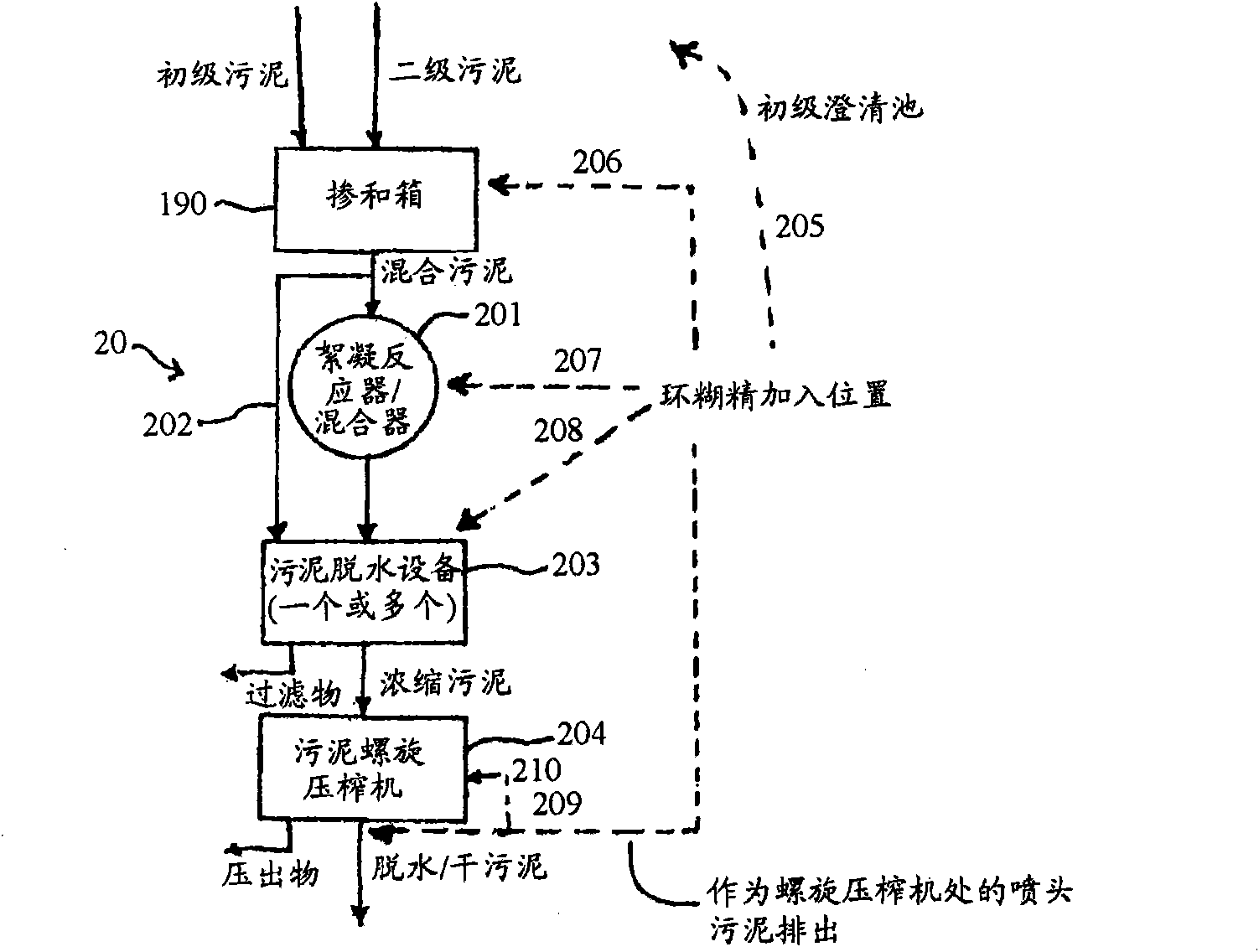

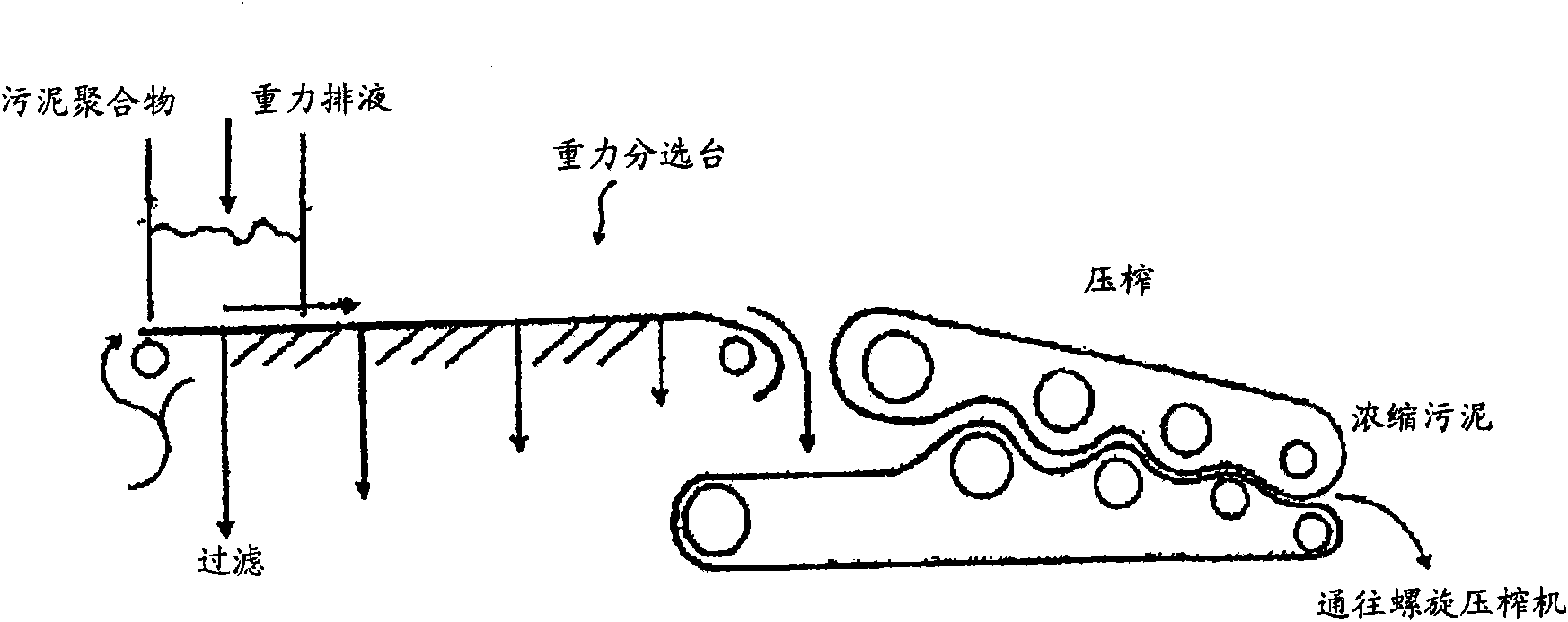

Use of Cyclodextrins For Odor Control In Papermaking Sludges, and Deodorized Sludge and Products

InactiveUS20090000752A1Easy and smooth transportationControl odorNon-fibrous pulp additionNatural cellulose pulp/paperSludgeOdor control

Methods to control and suppress odor in papermaking sludge are described. One method involves admixing sludge from a papermaking process and cyclodextrin to provide treated sludge with the cyclodextrin present in an effective amount to control odors in the treated sludge. The deodorized sludge may be used as a component of resin-wood composite products, such as composite decking materials, walls, flooring, casting forms, and the like.

Owner:BUCKMAN LAB INT INC

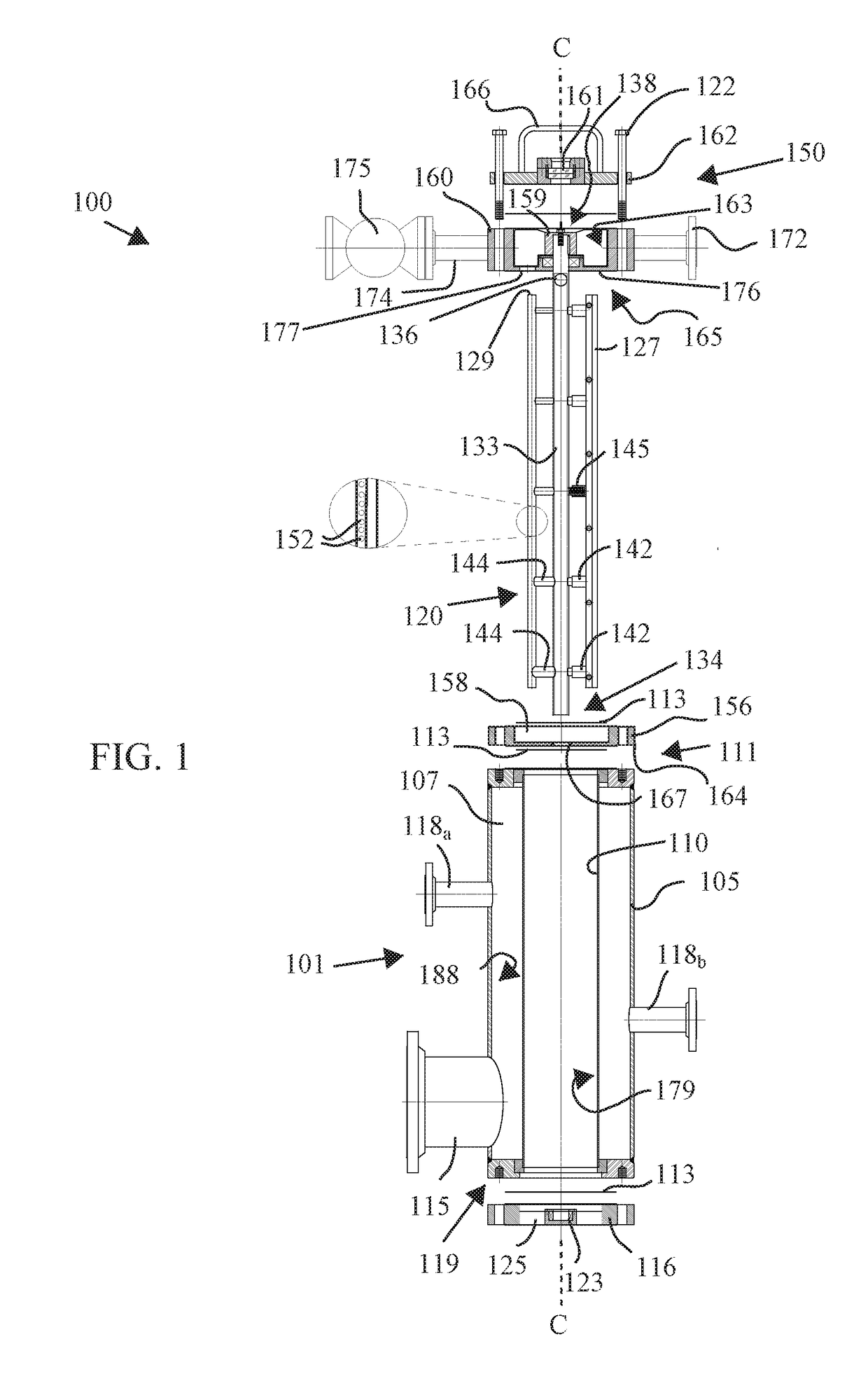

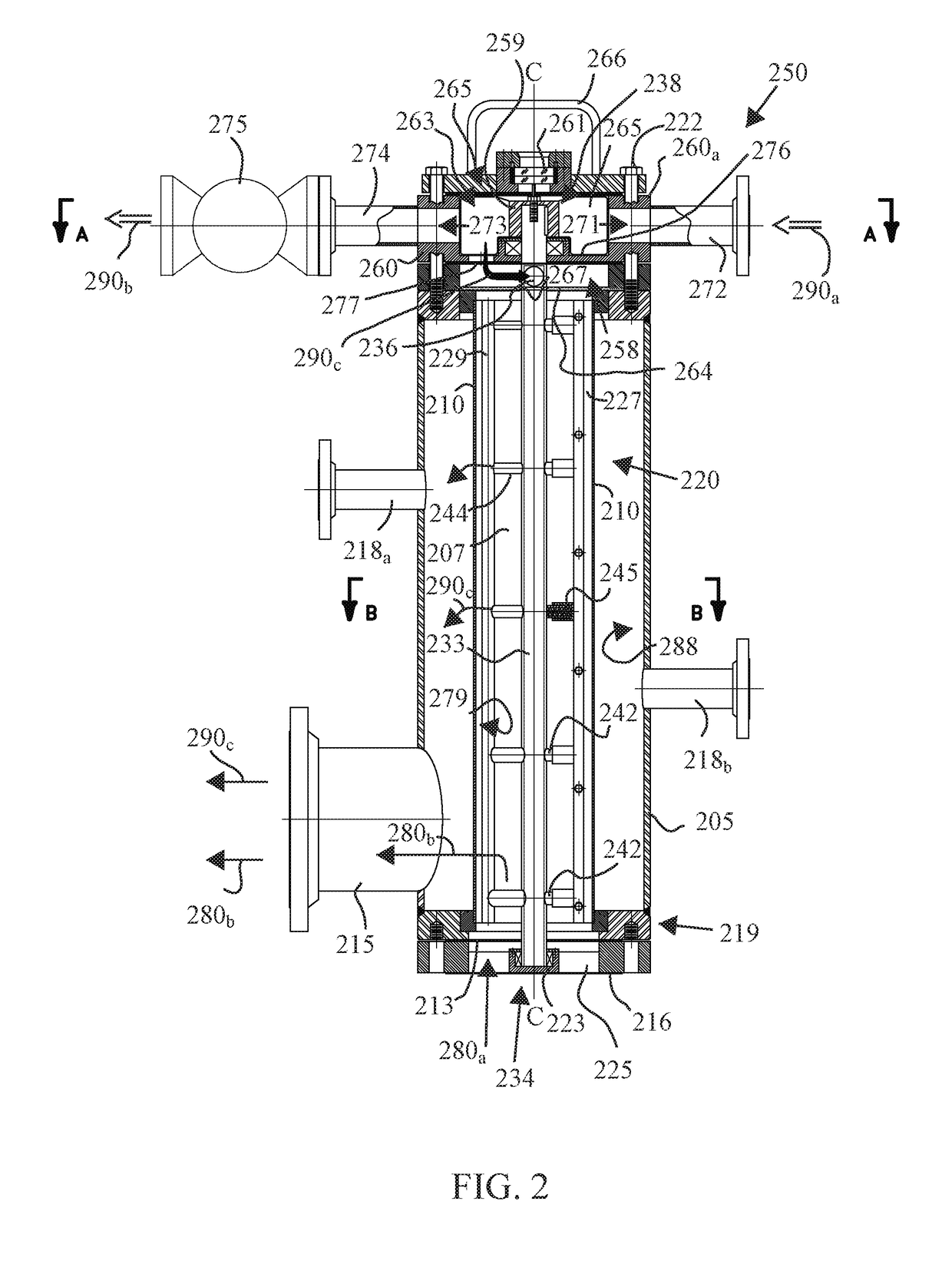

Method and arrangement for feeding chemicals into a process stream

An apparatus for feeding one or more chemicals into a process stream of a papermaking process is disclosed, as well as a method of utilizing the apparatus for feeding one or more chemicals into a process stream is disclosed.

Owner:ECOLAB USA INC

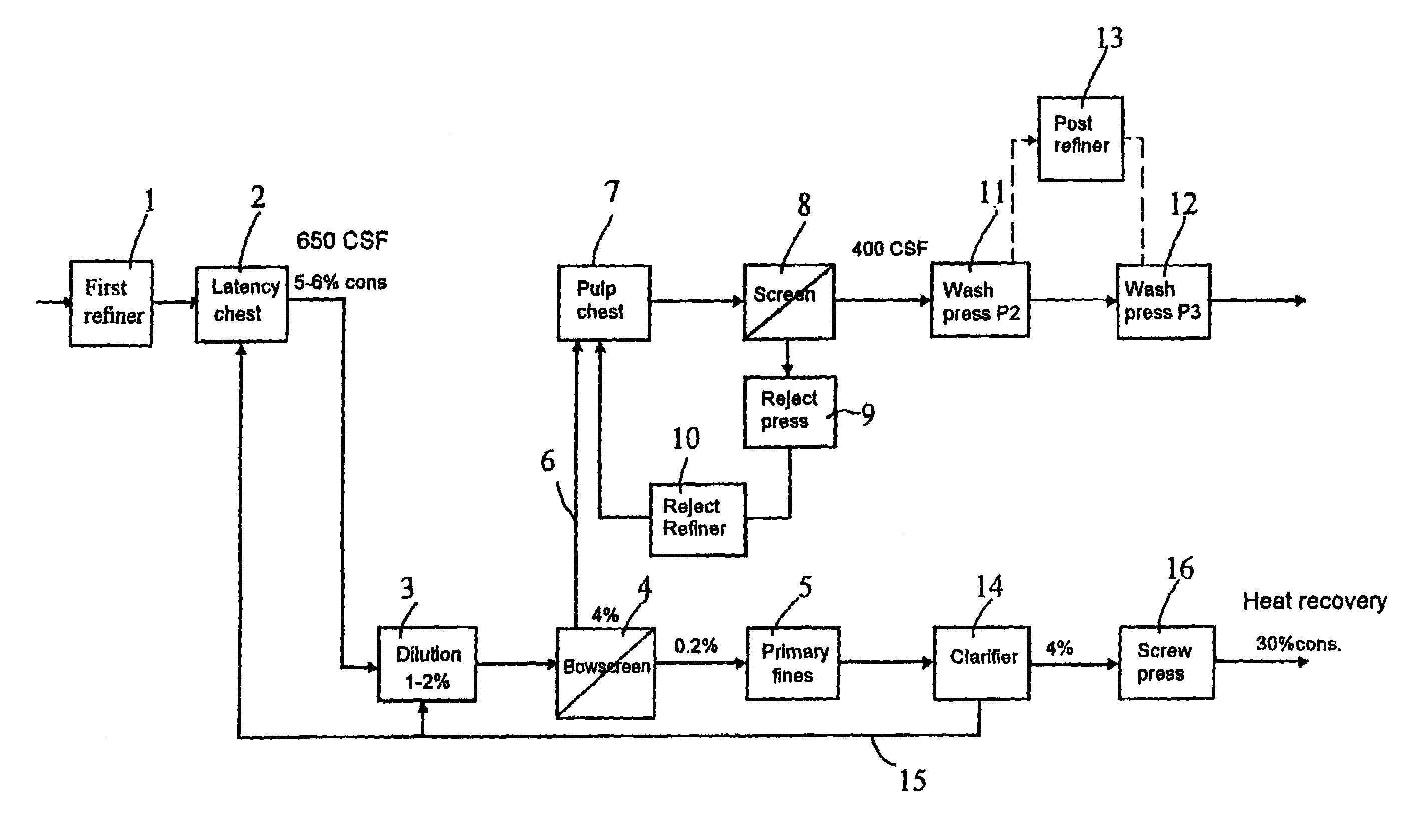

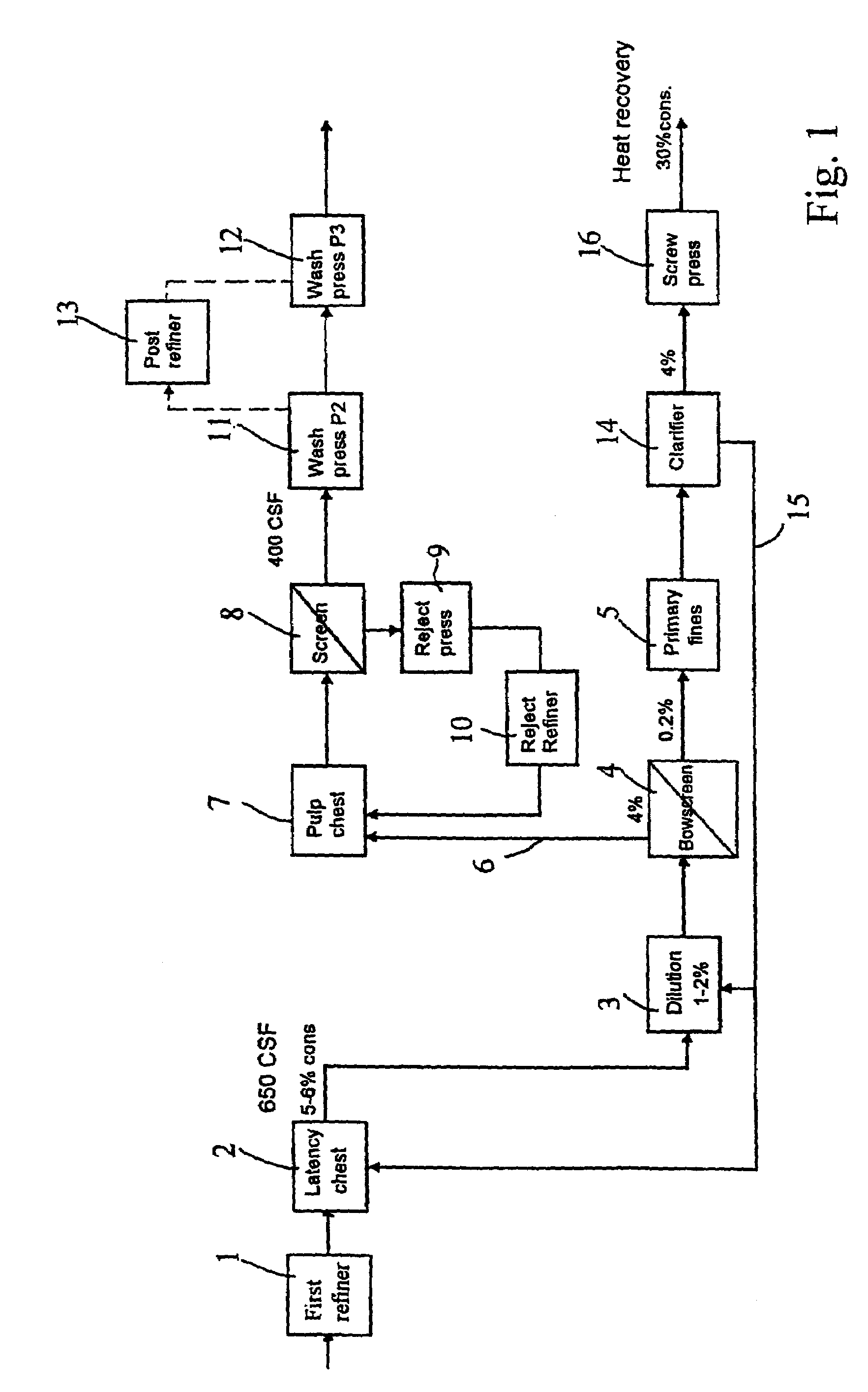

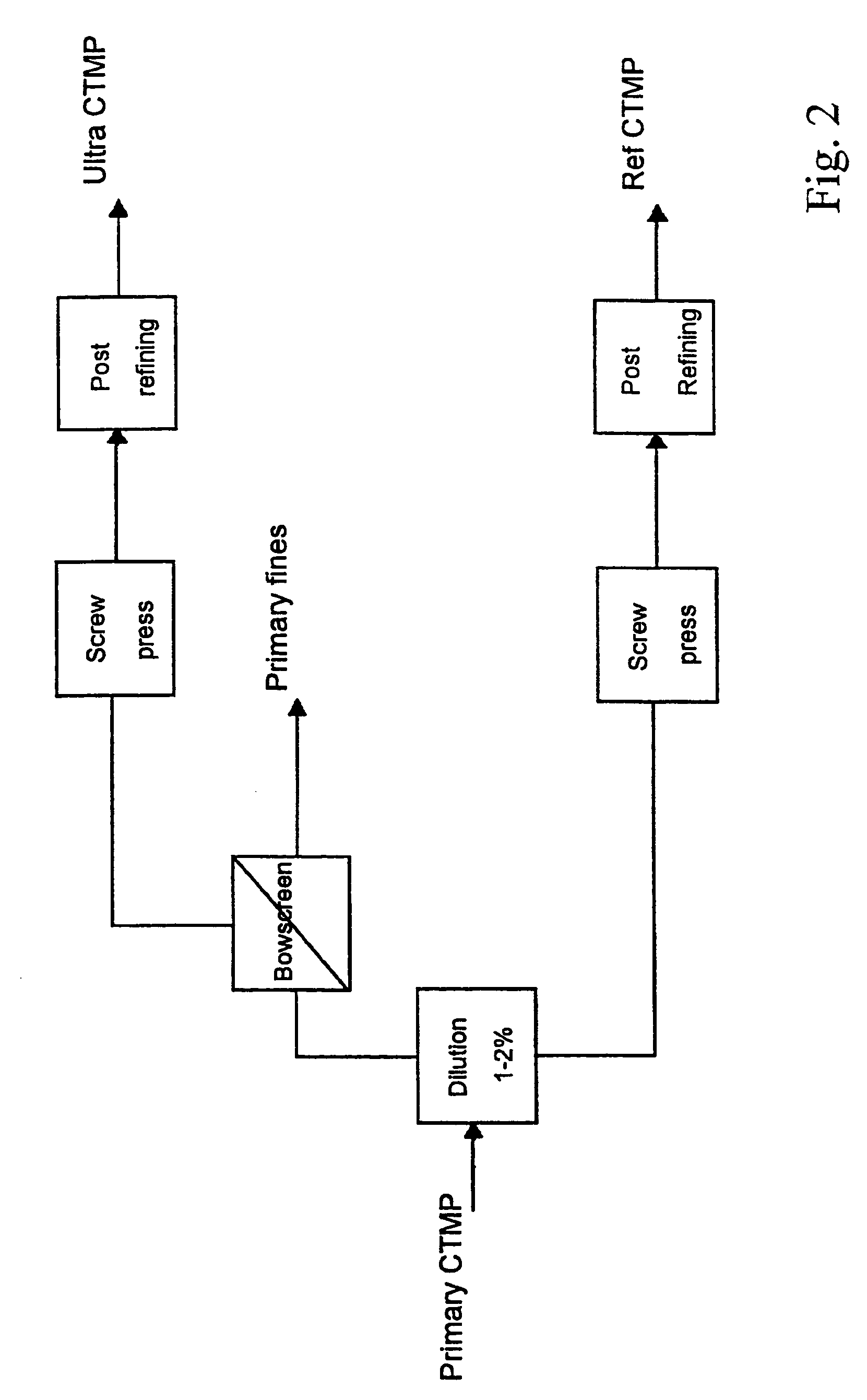

Method in connection with the production of mechanical pulp

InactiveUS7005034B1Reduce consumptionGood removal effectFats/resins/pitch/waxes removal in pulpDigestersCellulosePaperboard

A method in connection with the production of mechanical pulp from a cellulose containing material wherein the material is processed in at least one refining step to produce pulp. According to the invention, the pulp is fractionated (4), after a first refining step (1), in order to separate primary fines (5) from the pulp. The invention also relates to a mechanical pulp, produced by the method, and to a paperboard, which at least partly consists of such mechanical pulp.

Owner:STORA ENSO AB

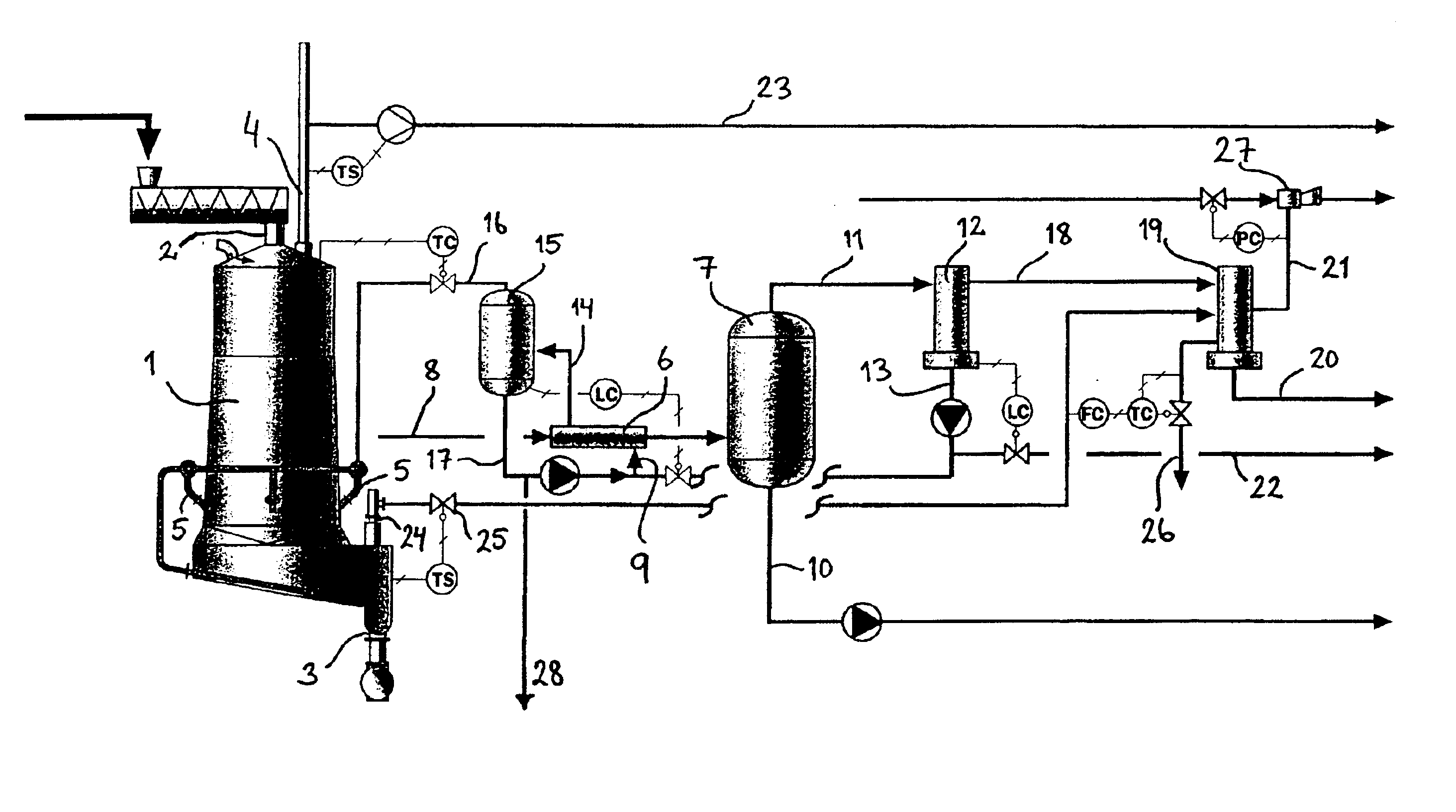

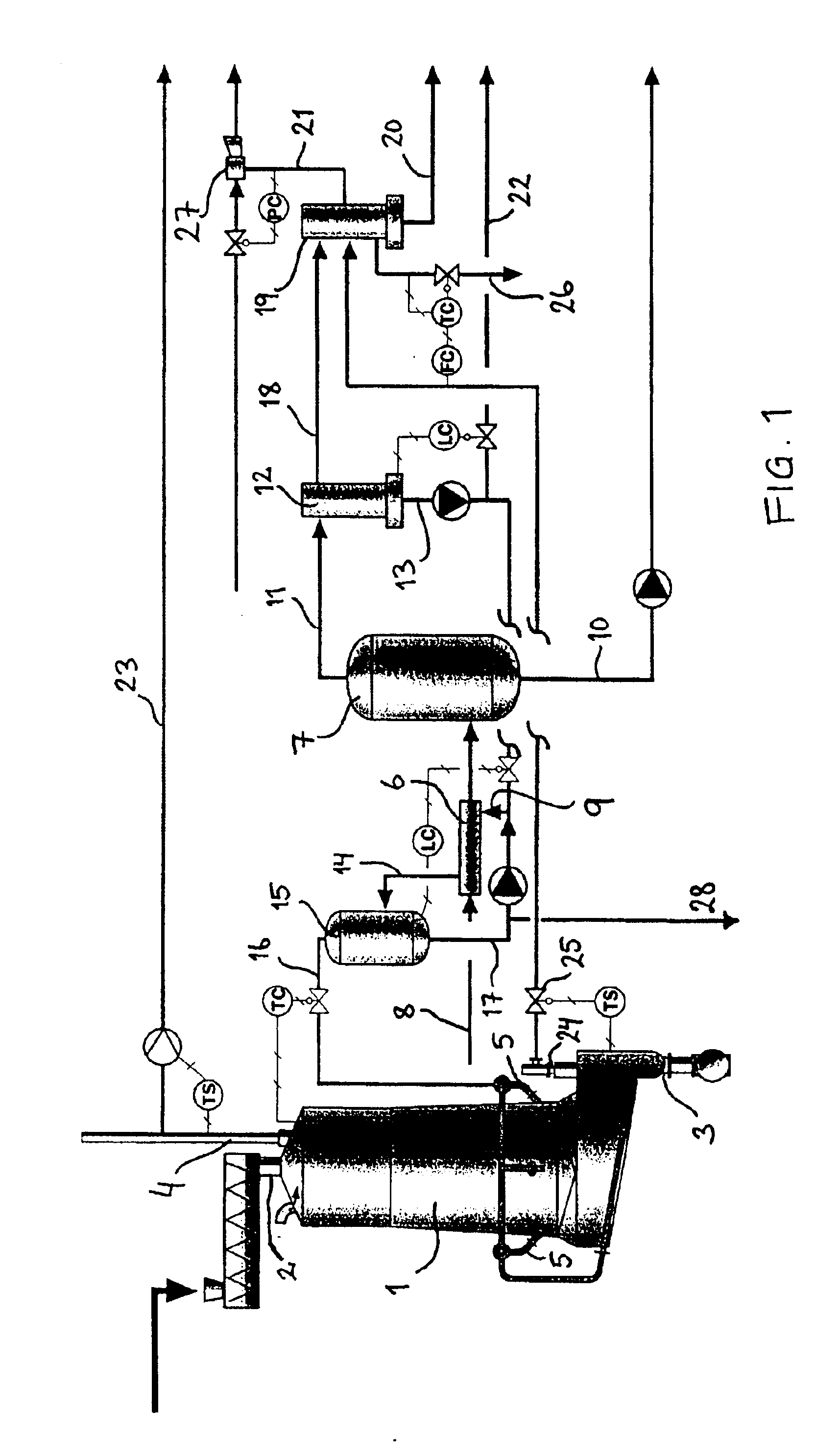

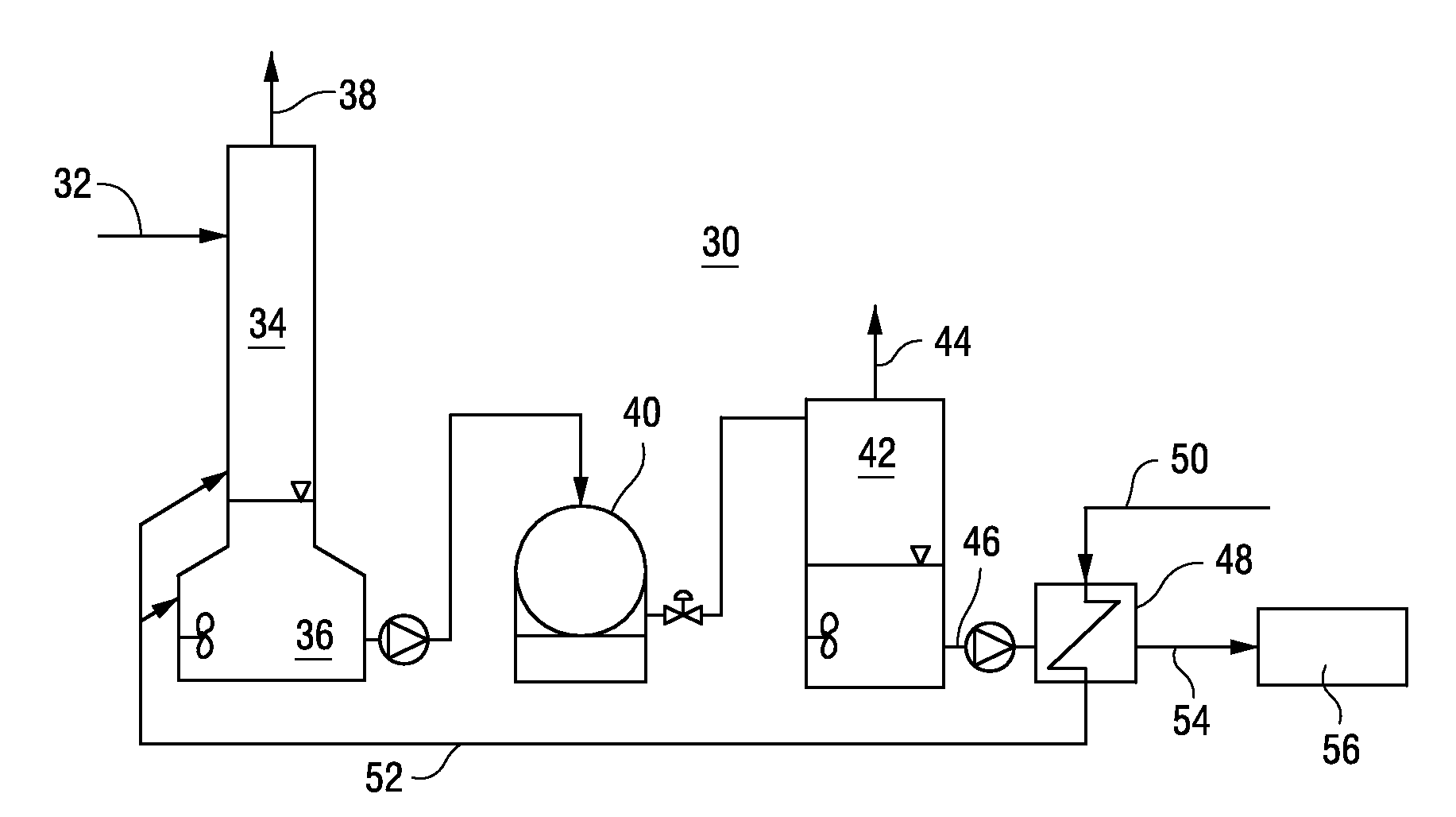

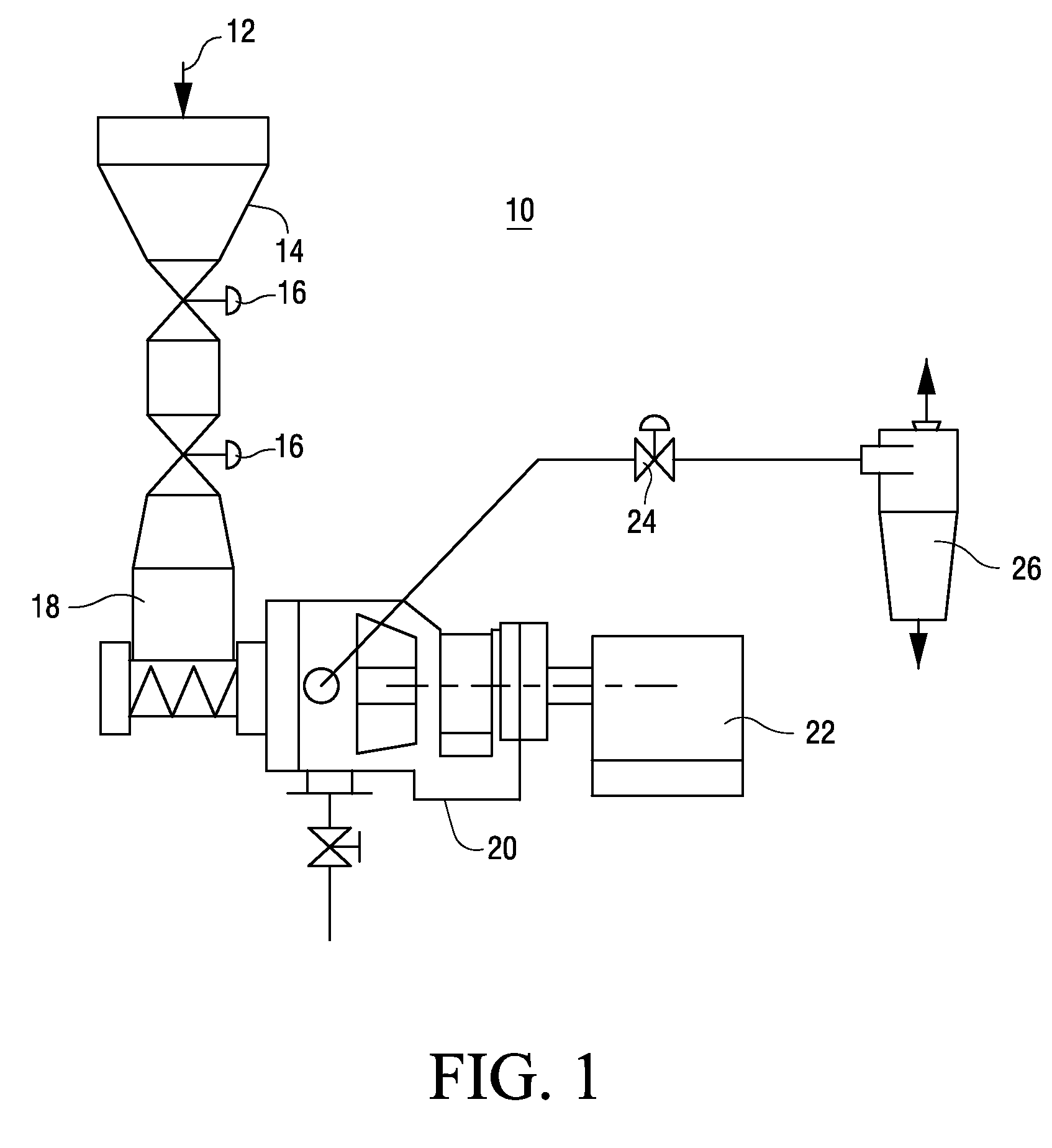

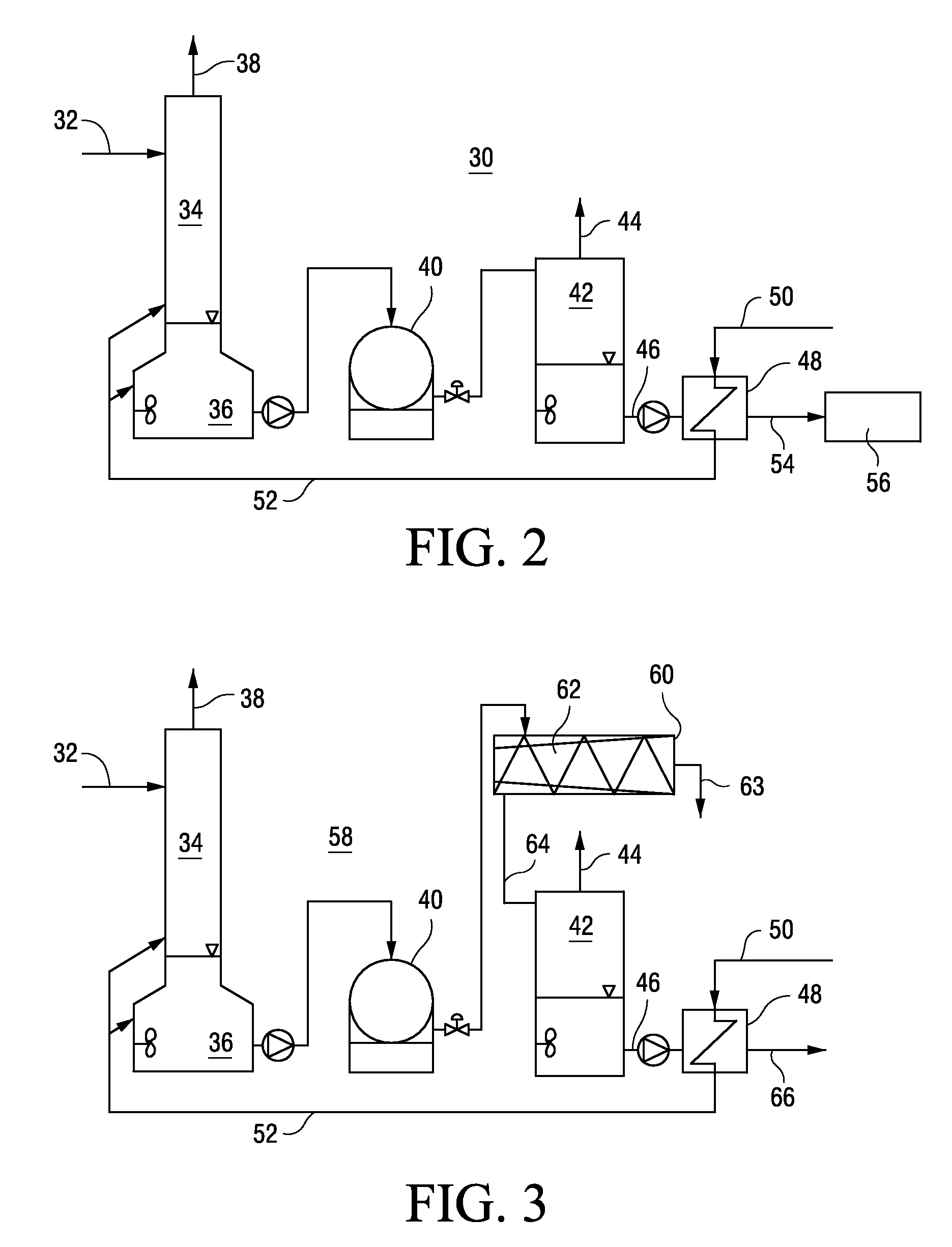

Methanol purification method and apparatus

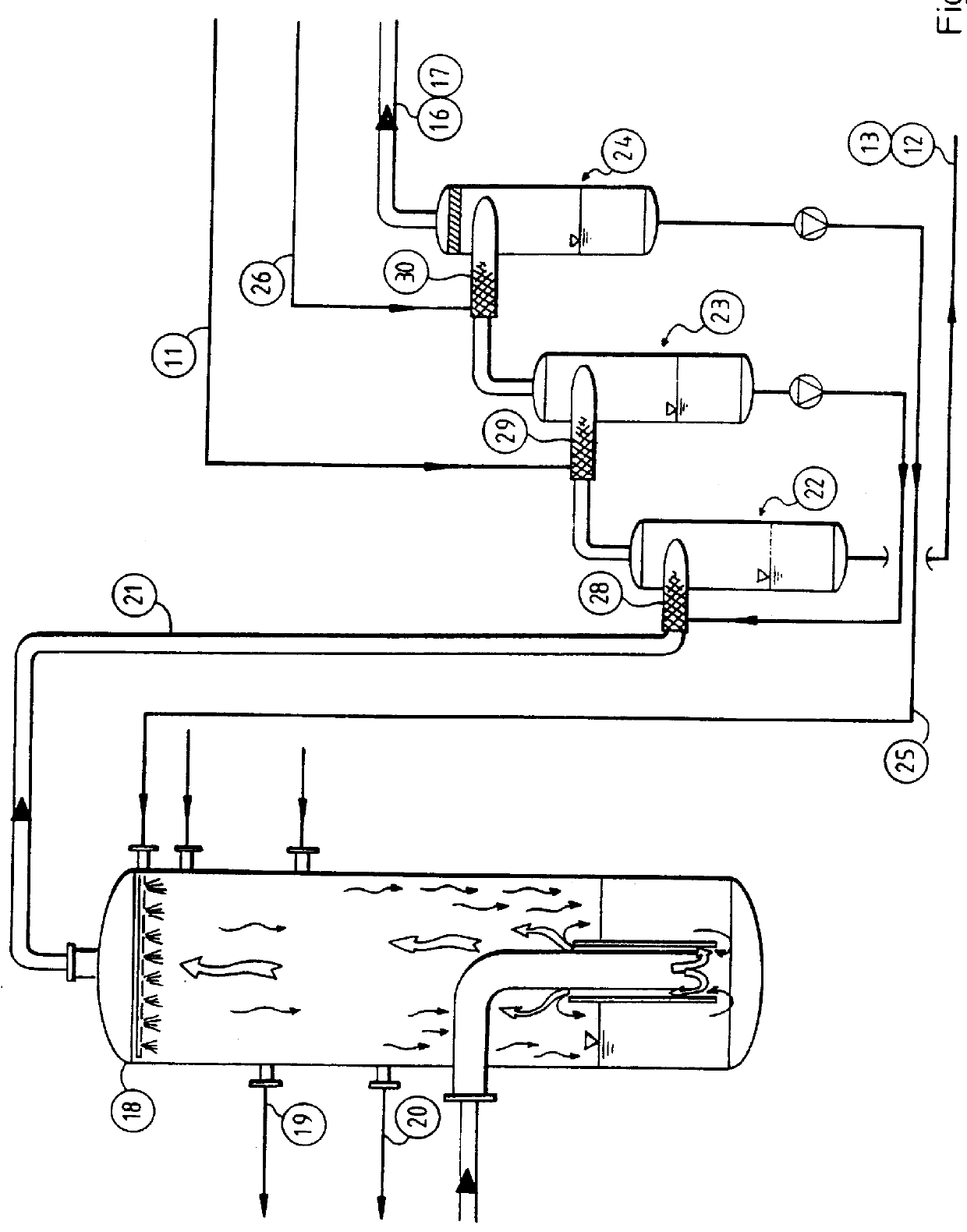

The invention relates to a method and apparatus to recover and purify methanol from gases produced in the digester during the kraft pulping process. The gas is typically recovered as a foul gas (called stripper off gas or SOG) comprising methanol, water and various other contaminants. The gas is then treated with successive decanting and distillation steps to remove impurities, thereby producing highly purified methanol.

Owner:A H LUNDBERG SYST

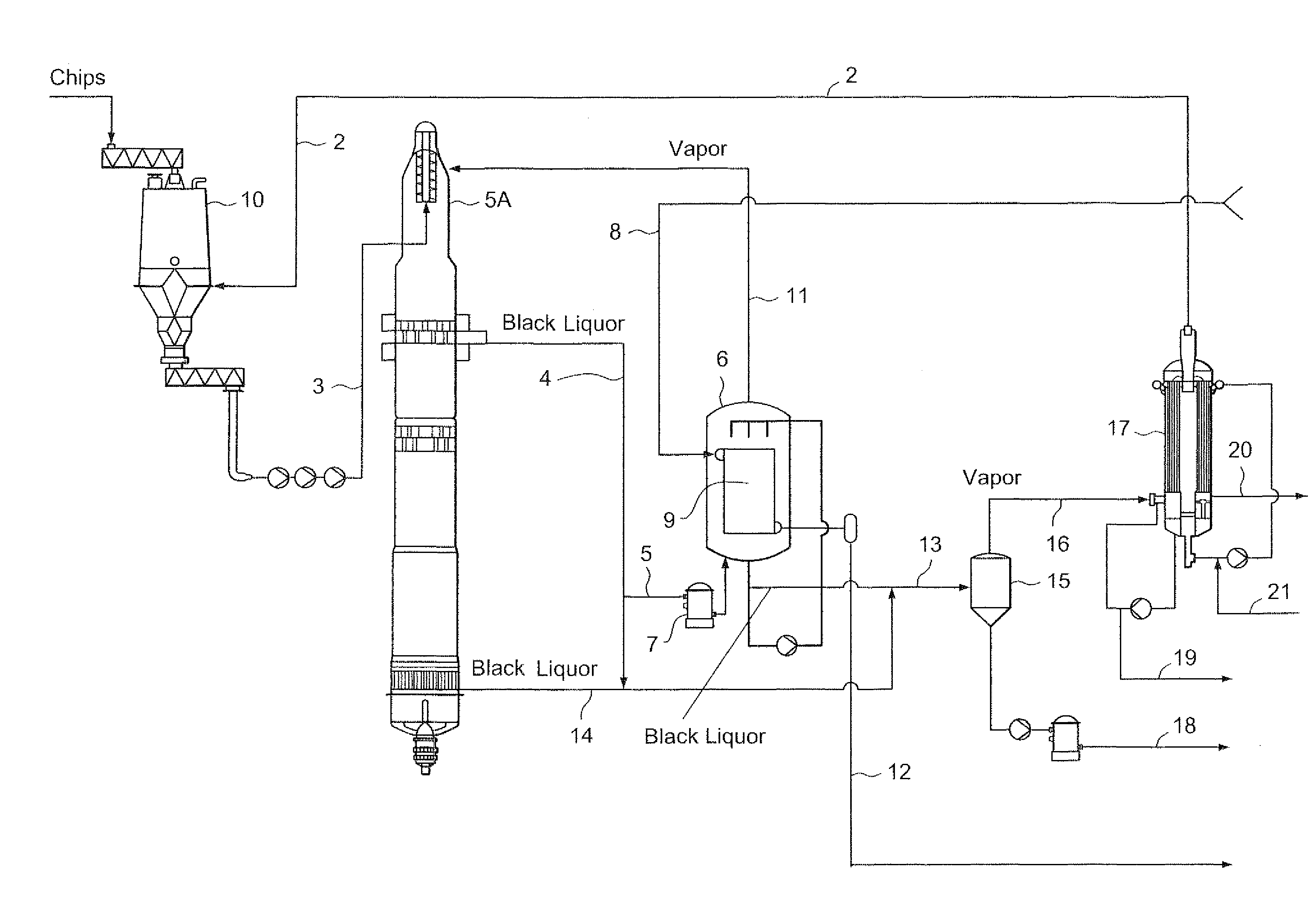

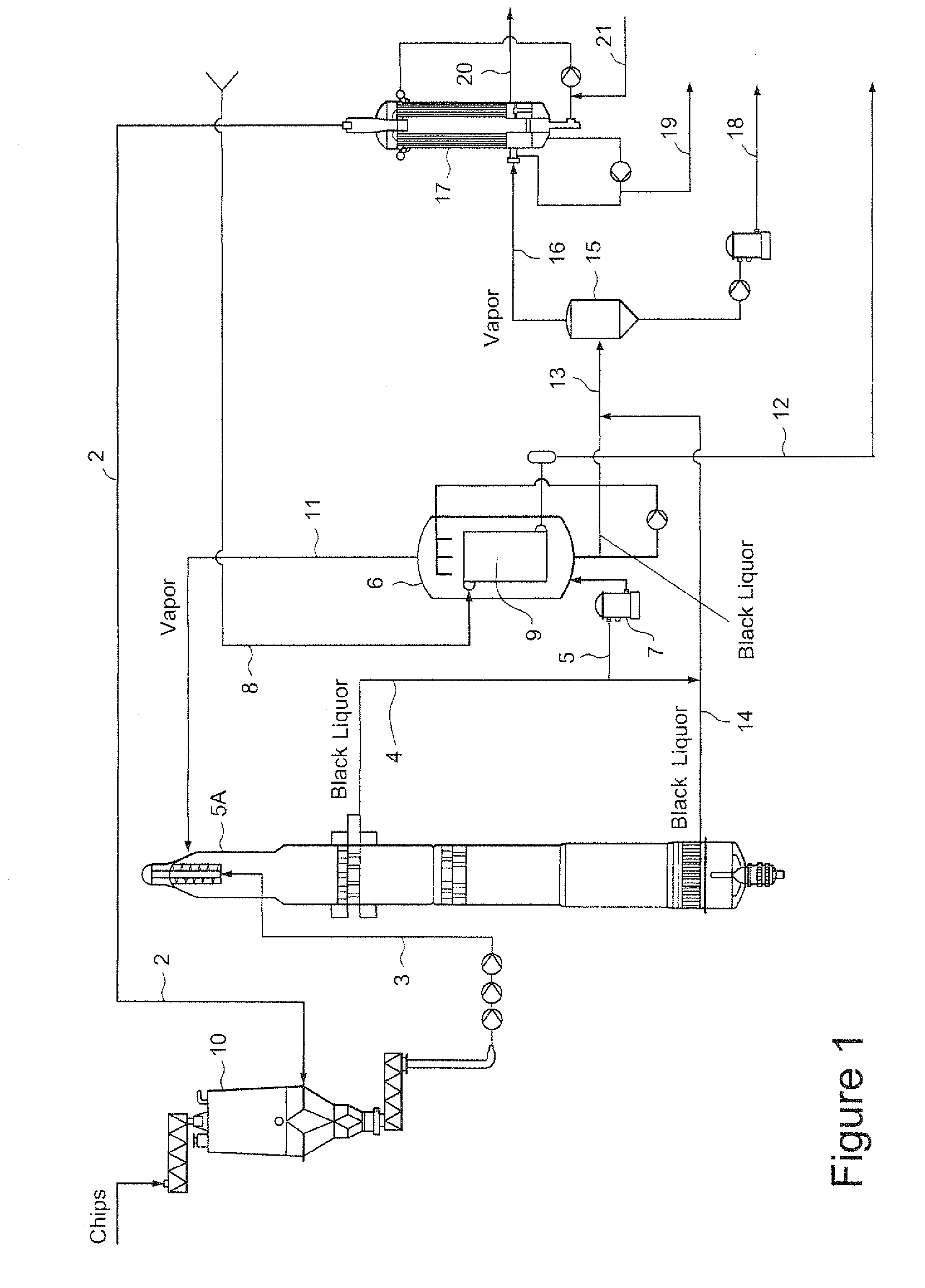

Method and system to generate steam in a digester plant of a chemical pulp mill

ActiveUS20100236733A1Improve energy economyMaintain good propertiesPretreatment with water/steamDigestersCelluloseFiber

A method for generating steam in a digester plant of a chemical pulp mill including: producing black liquor in the digester plant, extracting a first stream of black liquor from the digester; generating vapor by evaporating the first stream of black liquor by heating the first stream with fresh steam; heating fibrous material in the digester with the generated vapor from the evaporated first stream of black liquor; extracting a second stream of black liquor from the digester; flashing the second stream of black liquor to generate flashed black liquor and flashed black liquor vapor; introducing the flashed black liquor vapor to at least one heat exchanger to indirectly heat a clean evaporable liquid to produce clean steam from the clean evaporable liquid; and steaming, with the clean steam produced in the at least one heat ex-changer, cellulosic feed material before feeding the cellulosic feed material to the digester plant.

Owner:ANDRITZ INC

Biomass treatment for hydrothermal hydrocatalytic conversion

InactiveUS20150167238A1Reduced effectivenessMinimize amount of waterPretreatment with water/steamPretreatment with alkaline reacting compoundsCatalytic transformationHydrodeoxygenation

A selective removal of metal and its anion species that are detrimental to subsequent hydrothermal hydrocatalytic conversion from the biomass feed prior to carrying out catalytic hydrogenation / hydrogenolysis / hydrodeoxygenation of the biomass in a manner that does not reduce the effectiveness of the hydrothermal hydrocatalytic treatment while minimizing the amount of water used in the process is provided.

Owner:SHELL OIL CO

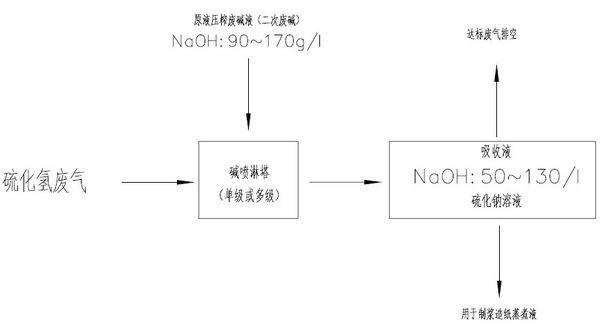

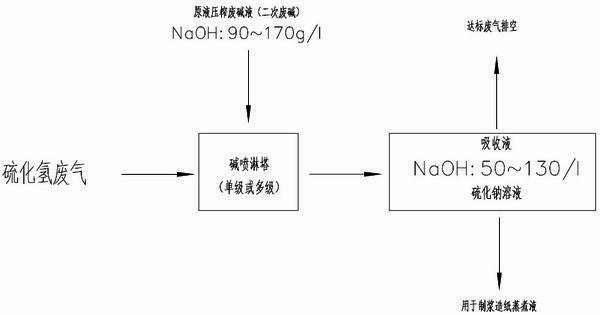

Method for recycling hydrogen sulfide waste gas

InactiveCN102512937ASolve pollutionFix security issuesDispersed particle separationPulp gases treatmentFiberFiltration

The invention relates to the field of waste gas recovery in viscose fiber industry, in particular to a method for recycling hydrogen sulfide waste gas. The method mainly includes the steps: A, squeezing alkali fibers to generate waste alkali liquor, and subjecting the waste alkali liquor to membrane filtration to obtain secondary waste alkali liquor; B, utilizing the secondary waste alkali liquor as alkali absorption liquor, and jointly delivering the secondary waste alkali liquor and the hydrogen sulfide waste gas generated during viscose fiber production to an alkali spray tower; and C, utilizing drained alkali spray absorption liquor as digestion liquor for sulfate pulping, and delivering Na2S (sodium sulfide) obtained by reaction and the rest of NaOH (sodium hydroxide) liquor to a pulping process. The method has the advantages that the method is high in hydrogen sulfide waste gas absorption efficiency and large in treatment quantity in unit time, the problems of environmental pollution and potential production safety hazards due to hydrogen sulfide waste gas emission are solved, and the purposes of treating waste with waste and turning the waste into wealth are realized by the aid of the waste alkali liquor generated by squeezing the alkali fibers.

Owner:YIBIN HIEST FIBER +2

Method of producing process steam from a black liquor

Method of producing a process steam from a first black liquor derived in connection with the production of paper pulp, wherein the first black liquor is treated to give a second black liquor of a higher concentration than the first black liquor as well as a liquid of low concentration, whereafter said process steam is produced from the low concentration liquid.

Owner:METABO PAPER SWEDEN

Use of cyclodextrins for odor control in papermaking sludges, and deodorized sludge and products

InactiveCN101784722ASludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeOdor control

Owner:BUCKMAN LAB INT INC

Vapor relief strainer with cleaner

ActiveUS20180207557A1Reduce the impactMitigating filter screen fatigueDispersed particle filtrationWashing/displacing pulp-treating liquorsProduct gasTurbine

A vapor relief strainer cleaning assembly comprising a turbine and dislodger assembly, wherein the turbine is configured to move a dislodger assembly disposed within a vapor screen relief vessel. Exemplary dislodger assemblies are configured to be powered by vapor or gas and to use excess vapor or gas optionally to dislodge non-condensable contaminants from the filter screen or to facilitate contaminant dislodgement from the inner wall of the filter screen.

Owner:ANDRITZ INC

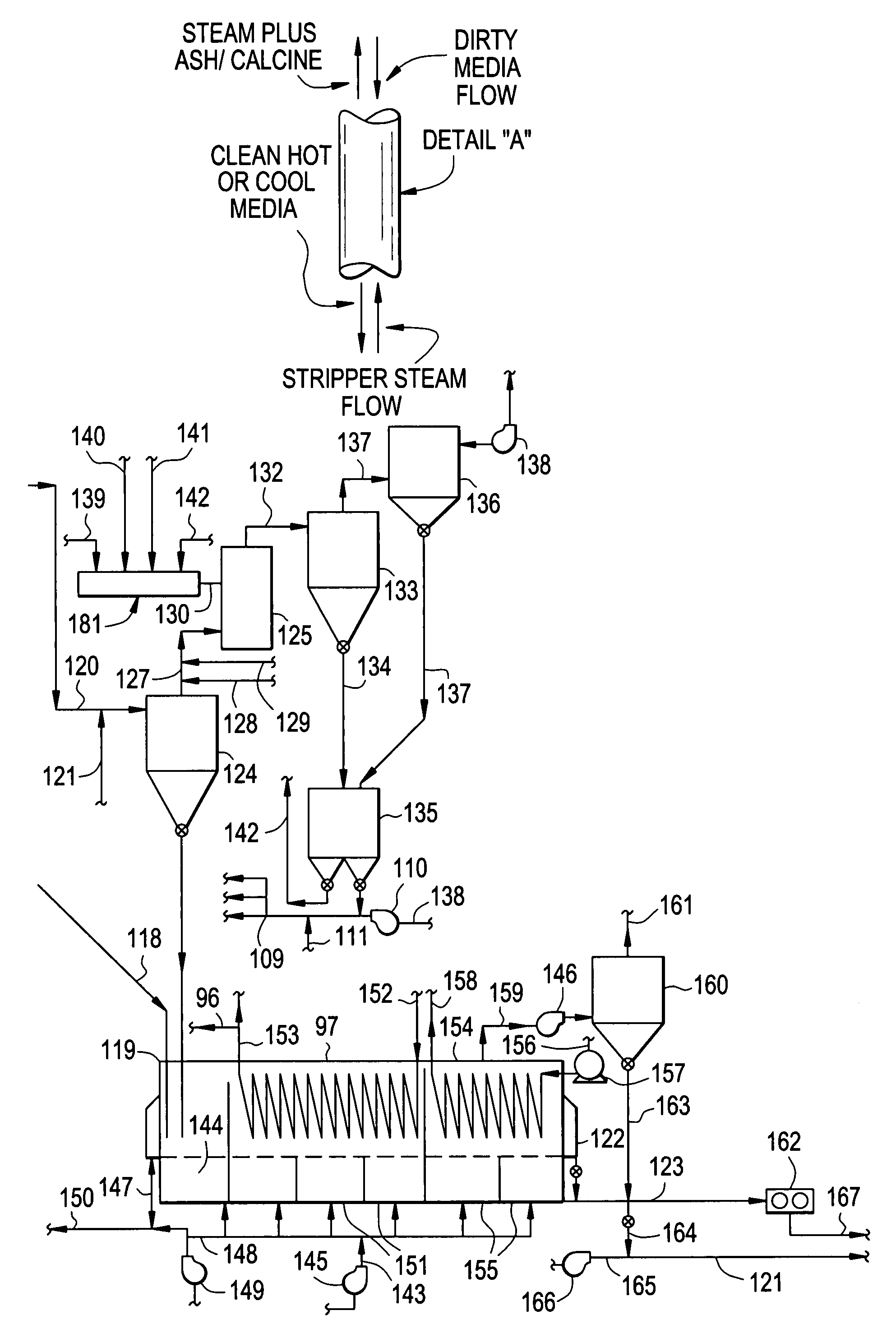

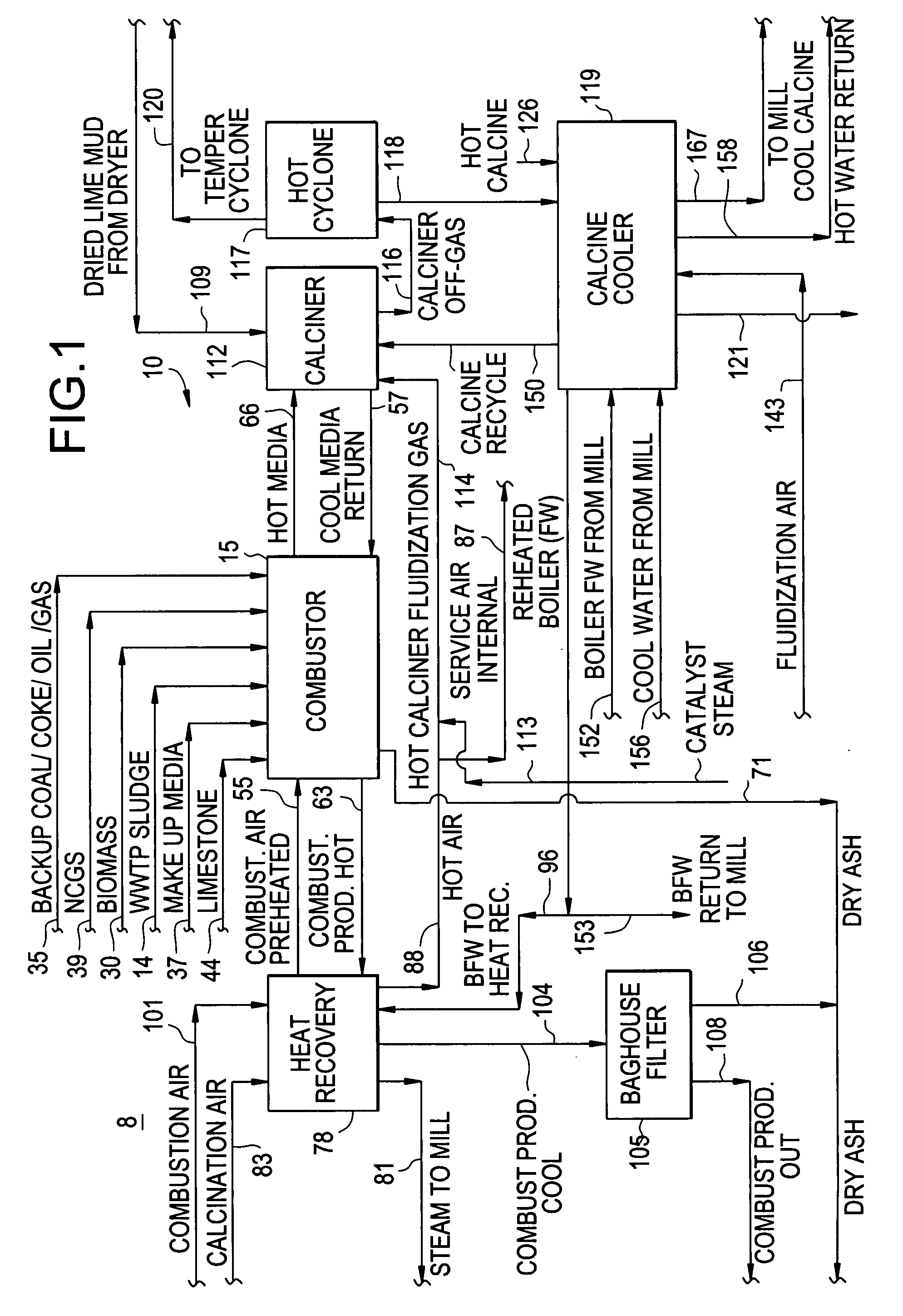

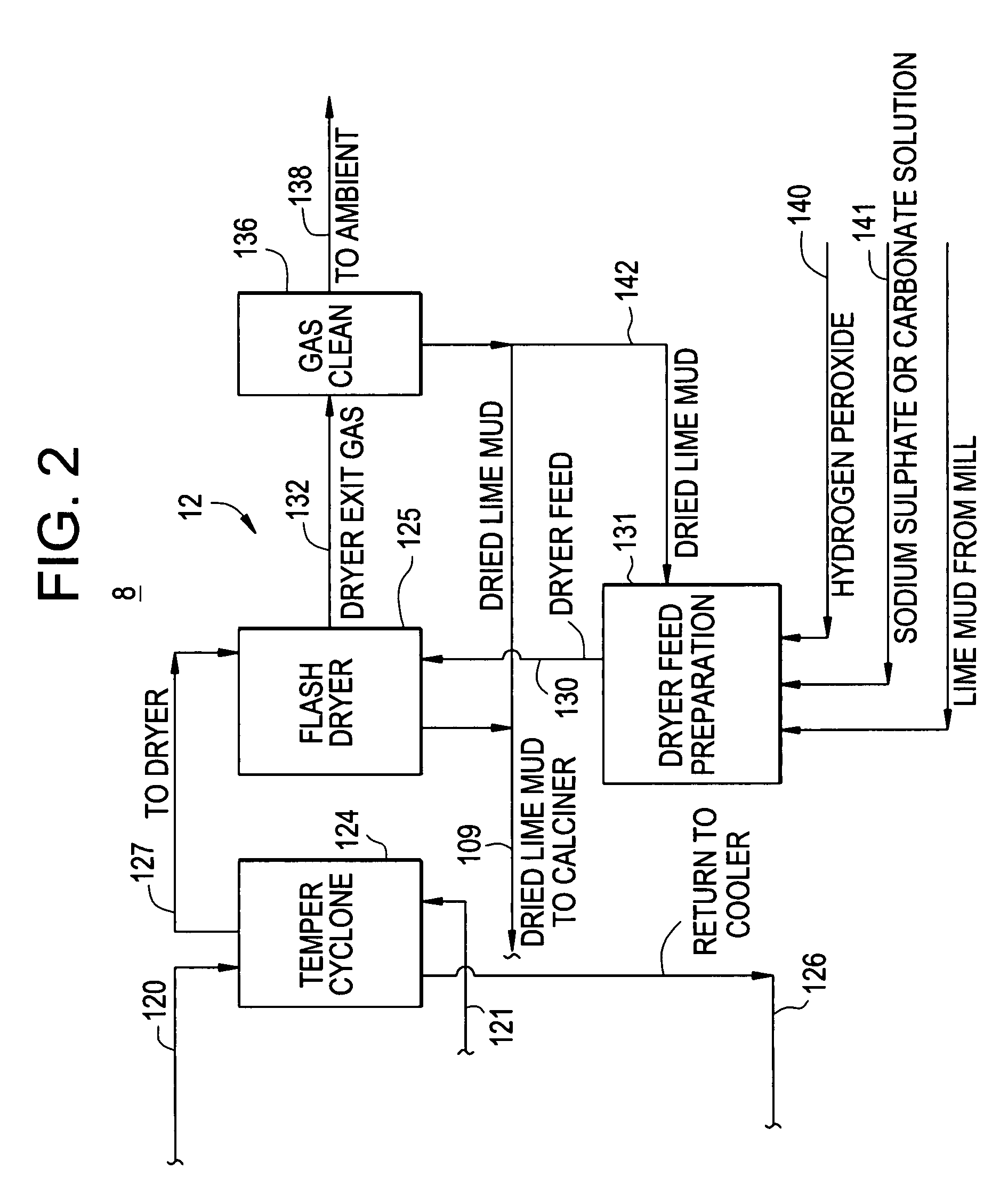

Process and system for calcination of high solids kraft paper pulp mill lime mud

InactiveUS20090114352A1High melting pointMitigate calciner scaling and fouling and unwanted gaseous emissionsCarbon compoundsDryer sectionSludgeSolid particle

The invention features methods and systems for calcining wet calcium carbonate lime mud produced in a re-causticizing manufacturing operation, for instance, Kraft pulp mill lime mud (“lime mud”) and converting it to re-burned lime by (a) feeding wet lime mud obtained from a re-causticizing manufacturing process into a flash dryer and then feeding the dried lime mud into a bubbling fluid bed calciner thermally linked by moving media heat transfer (MMHT) utilizing solid particulate media to a circulating fluid bed combustor wherein the MMHT provides heat input for calcination and drying; (b) recycling the media being from said calciner to said combustor wherein said combustor receives mill WWTP sludge, or precipitated lignins, or biomass, or NCGs as fuels to re-heat the solid particulate media; and (c) recovering calcined “soft-burned” lime mud from the fluid bed calciner. Steam and heated boiler feed-water are also generated and exported to the mill's steam distribution and generation system as well as hot process water for use in the mill's boiler house and manufacturing operation. The system for calcining calcium carbonate lime mud produced from a re-causticizing manufacturing operation and converting it to re-burned lime comprises a calciner and a combustor linked by a moving media heat transfer MMHT system or apparatus. The MMHT system or apparatus thermally links separate fluid bed combustion (exothermic) and calcination (endothermic) stages. The system further comprises a flash dryer or spray dryer that utilizes exhausted heat from the calcination stage.

Owner:ROSSI ROBERT A

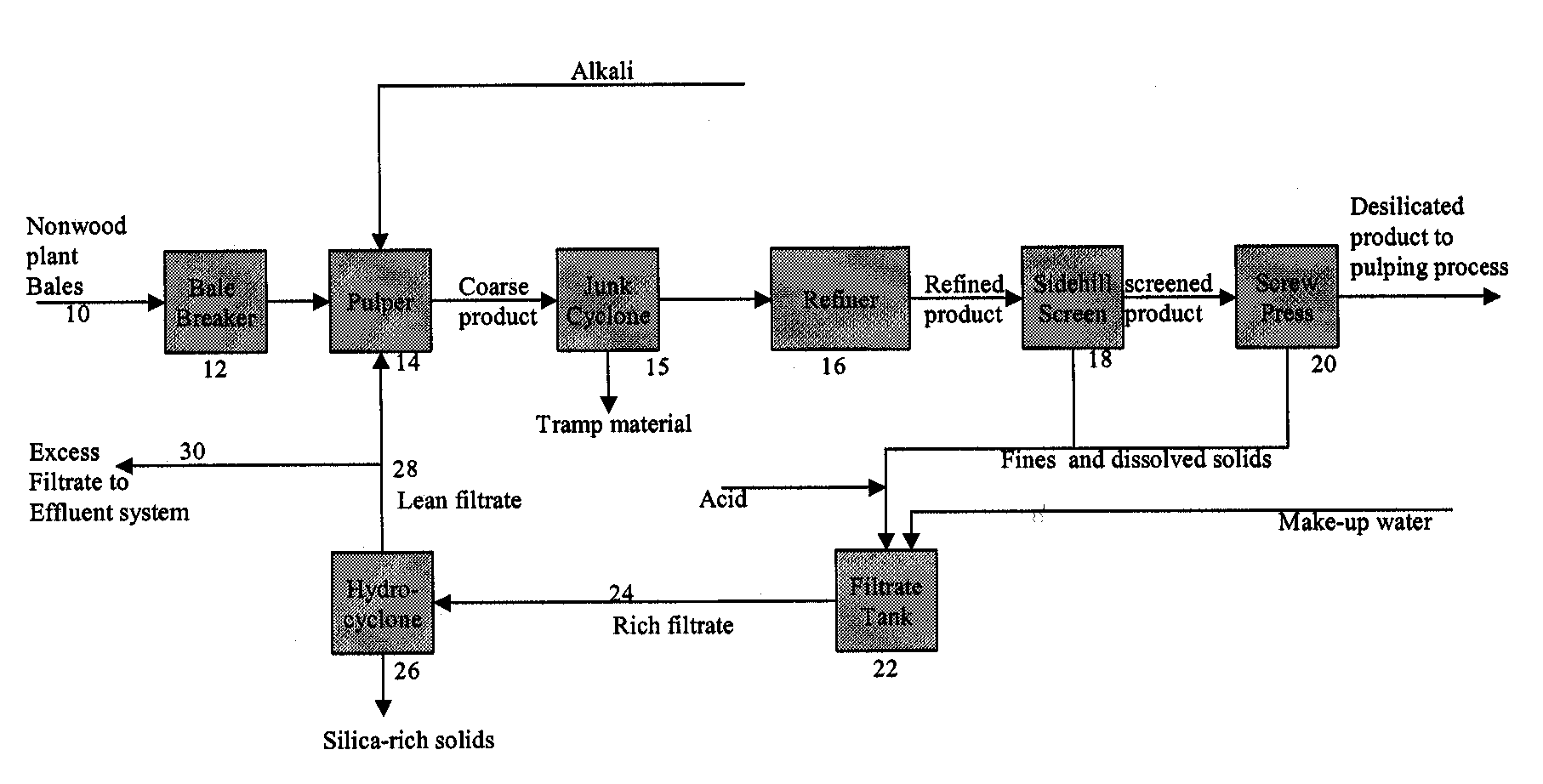

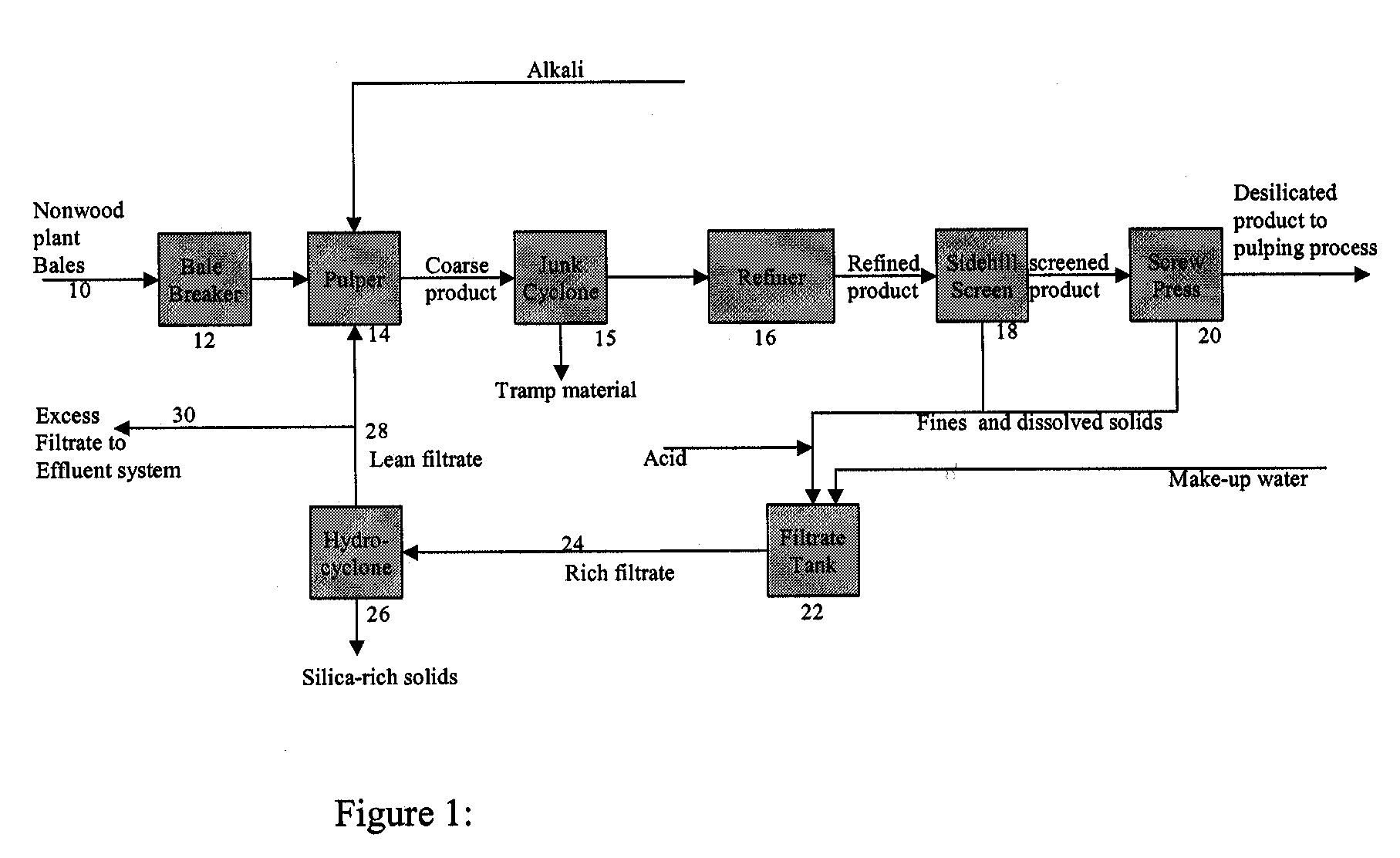

Chemimechanical desilication of nonwood plant materials

A process for removing silica from nonwood plant materials involving both chemical and mechanical action is described. The silica-rich epidermal cells are liberated mechanically by a pre-pulping and low-consistency refining step and subsequently removed from the pulp via the filtrate of a thickening step. Amorphous silica is liberated chemically by using an alkaline dilution source in the pulper, then removed from the pulp via the filtrate of a thickening step and a dewatering step. The silica is then removed from the filtrate by adjusting the pH, followed by a separation step. The desilicated fibrous material may then be chemically or mechanically pulped and bleached using known processes. The silica removed from the nonwood plant material may then be used as a feedstock for other applications.

Owner:INNOTECH ALBERTA INC

Method for continuous cooking of chemical pulp to improve heat economy

ActiveUS7112256B2Reduces and eliminates requirementImprove thermal economyDigestersPulp bleachingCelluloseBlack liquor

A method for the continuous cooking of chemical pulp with the aim of achieving improved heat economy in a digester system having a vessel (1) for impregnation and a vessel (2) for cooking the impregnated cellulose chips. A part of the black liquor (14) withdrawn from the digester (2) is added at the beginning of a transfer system (4) to increase the temperature of the chips mixture in the transfer system (4). A fraction of the transport fluid (10) from the transfer system (4) that is continuously withdrawn from the impregnated chips fed into the top of the digester is returned to the impregnation vessel (1) at essentially the maintained transfer temperature.

Owner:METABO PAPER SWEDEN

Waste water treatment

The present invention relates to wastewater treatment in general and to methods of controlling odors and degrading compounds contained in wastewater in particular.

Owner:NOVOZYMES BIOLOGICALS

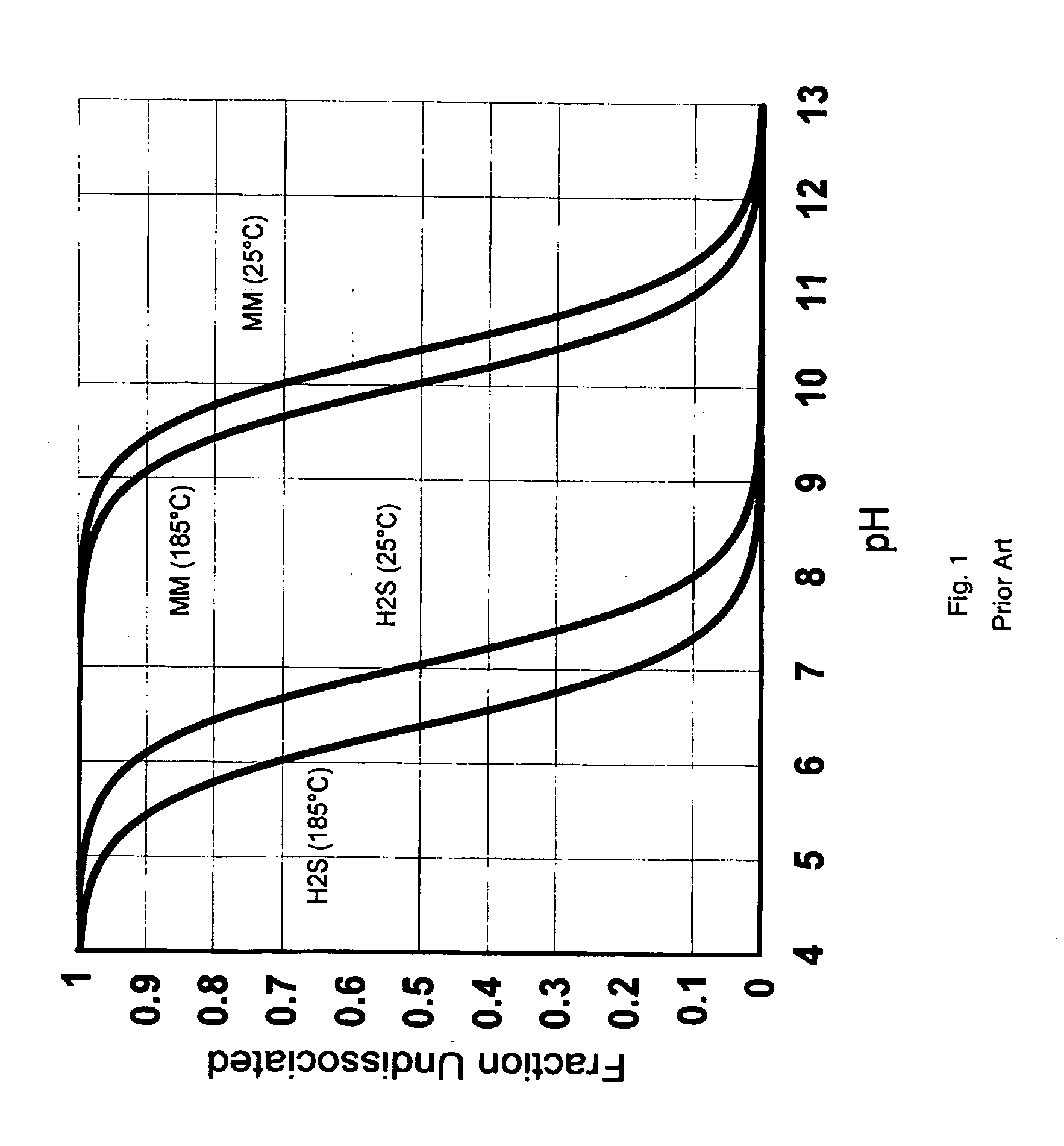

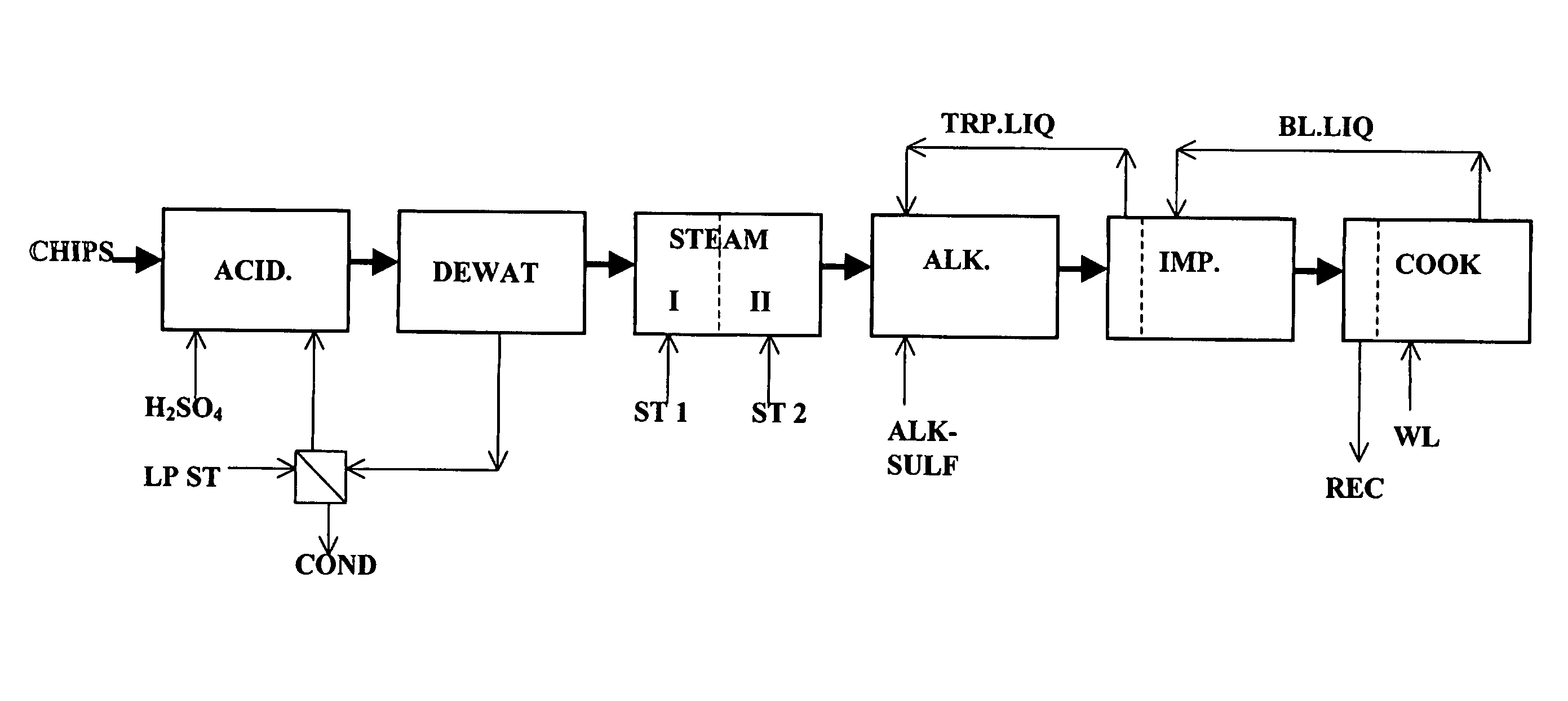

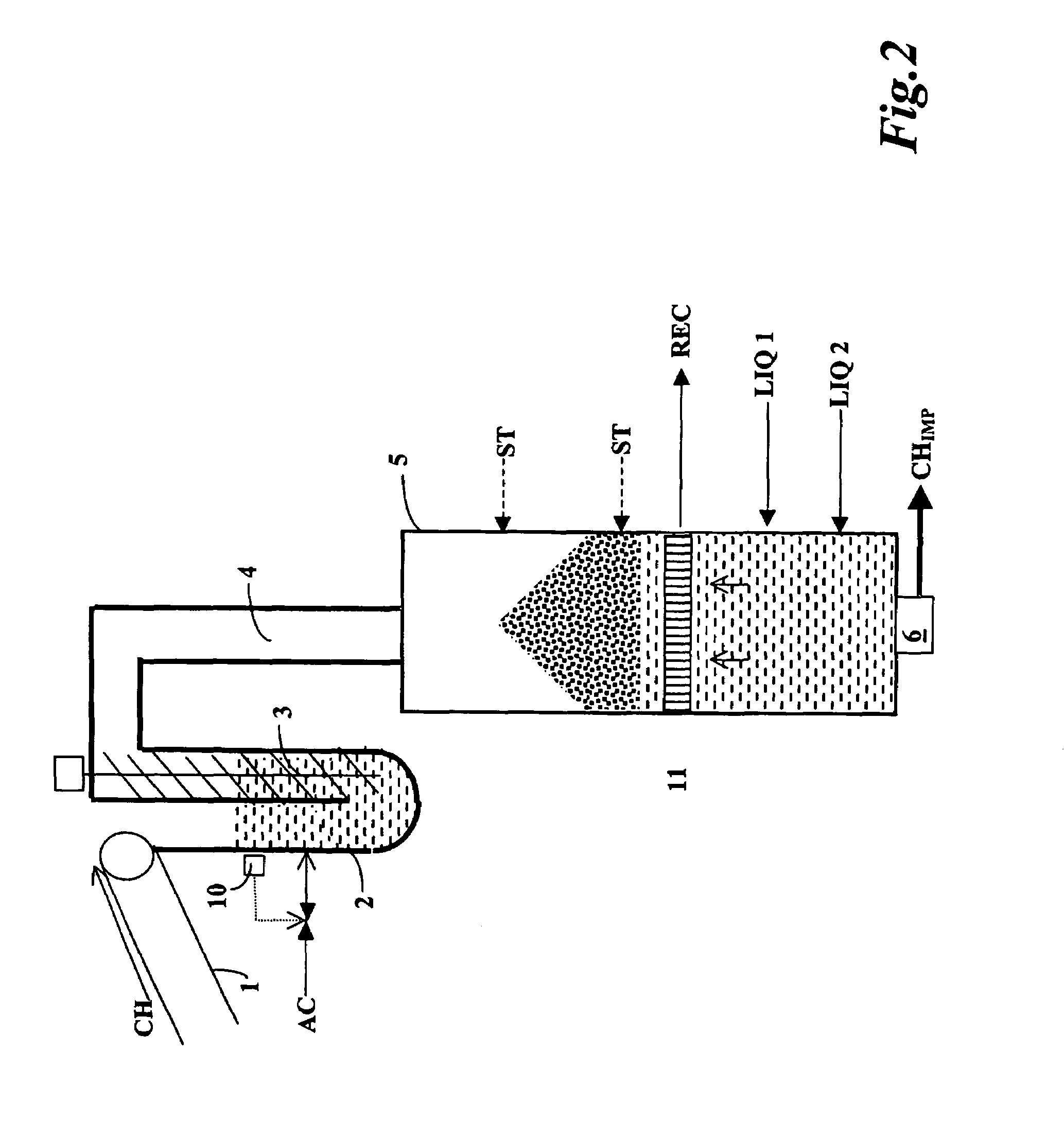

Impregnation of chips with an acid liquid prior to a sulphate pulping process

InactiveUS7445691B2Cellulosic pulp after-treatmentPretreatment with acid reacting compoundsHigh concentrationHydrogen

The method is for pre-treatment of chips that are fed to a sulphate cooking process. Through acidification of the chips in an acidic treatment fluid with a subsequent draining of free treatment fluid before subsequent steaming or wet-steaming, a high concentration of free hydrogen ions is established within the chip pieces. When the chips are subsequently formed into slurry with preferably a sulphide-rich alkali cooking fluid, H2S is formed locally in the chip pieces which gives a yield-increasing effect in the subsequent cooking step of 1-3%.

Owner:METABO PAPER SWEDEN

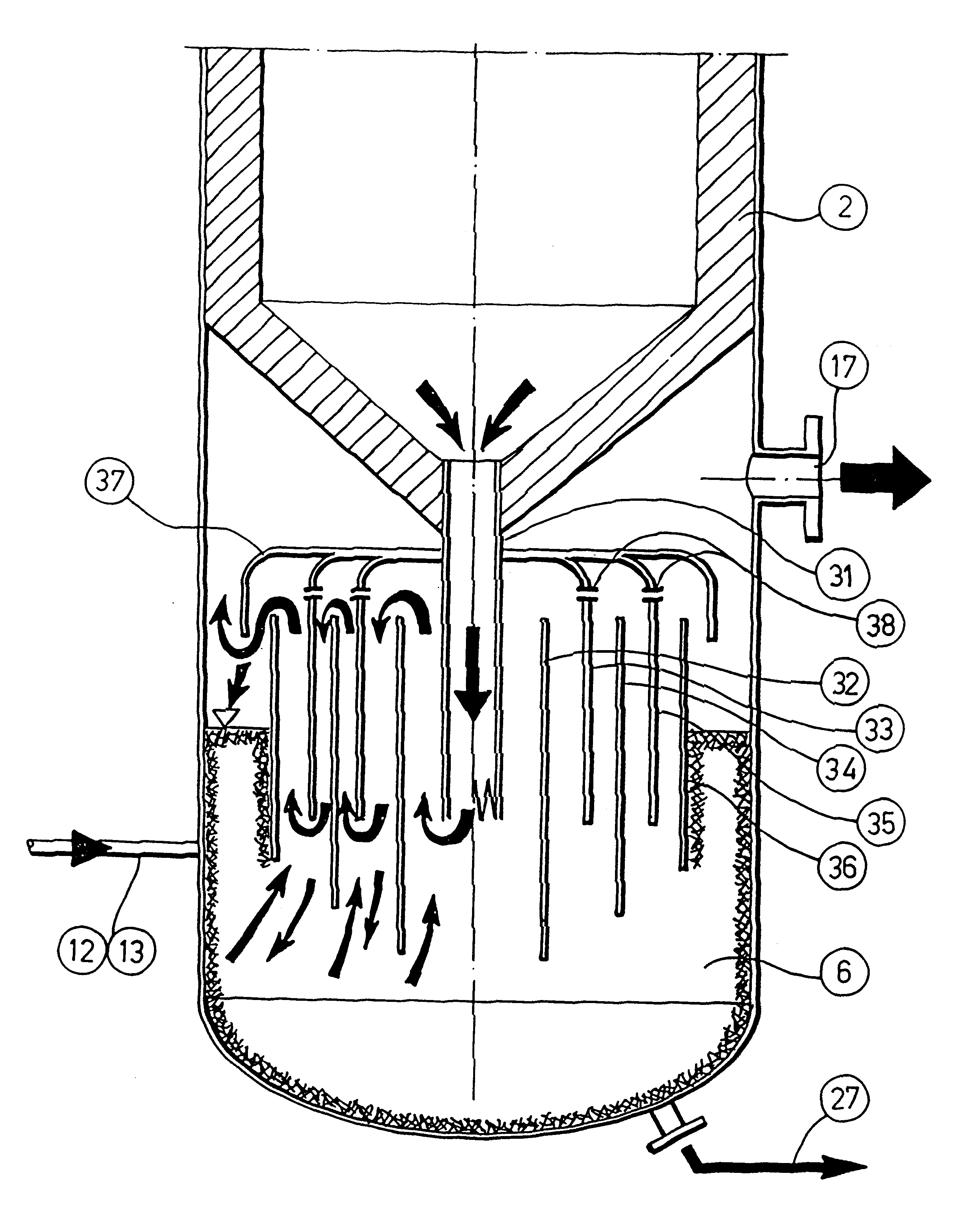

Quench vessel

InactiveUS6238468B1Easy to adjustEasy to customizePulp liquors combustionUsing liquid separation agentCombustionEngineering

Owner:CHEMREC AB

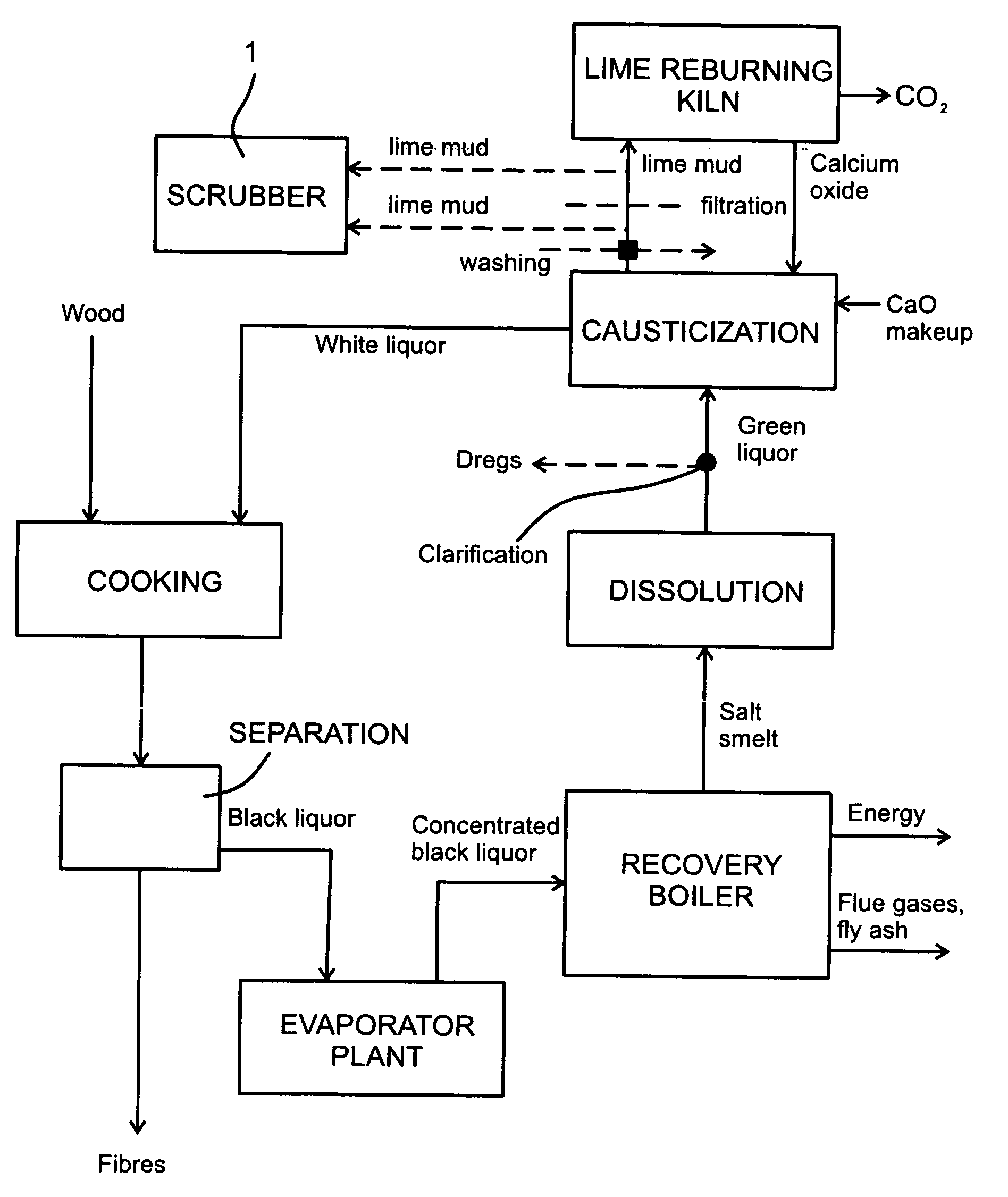

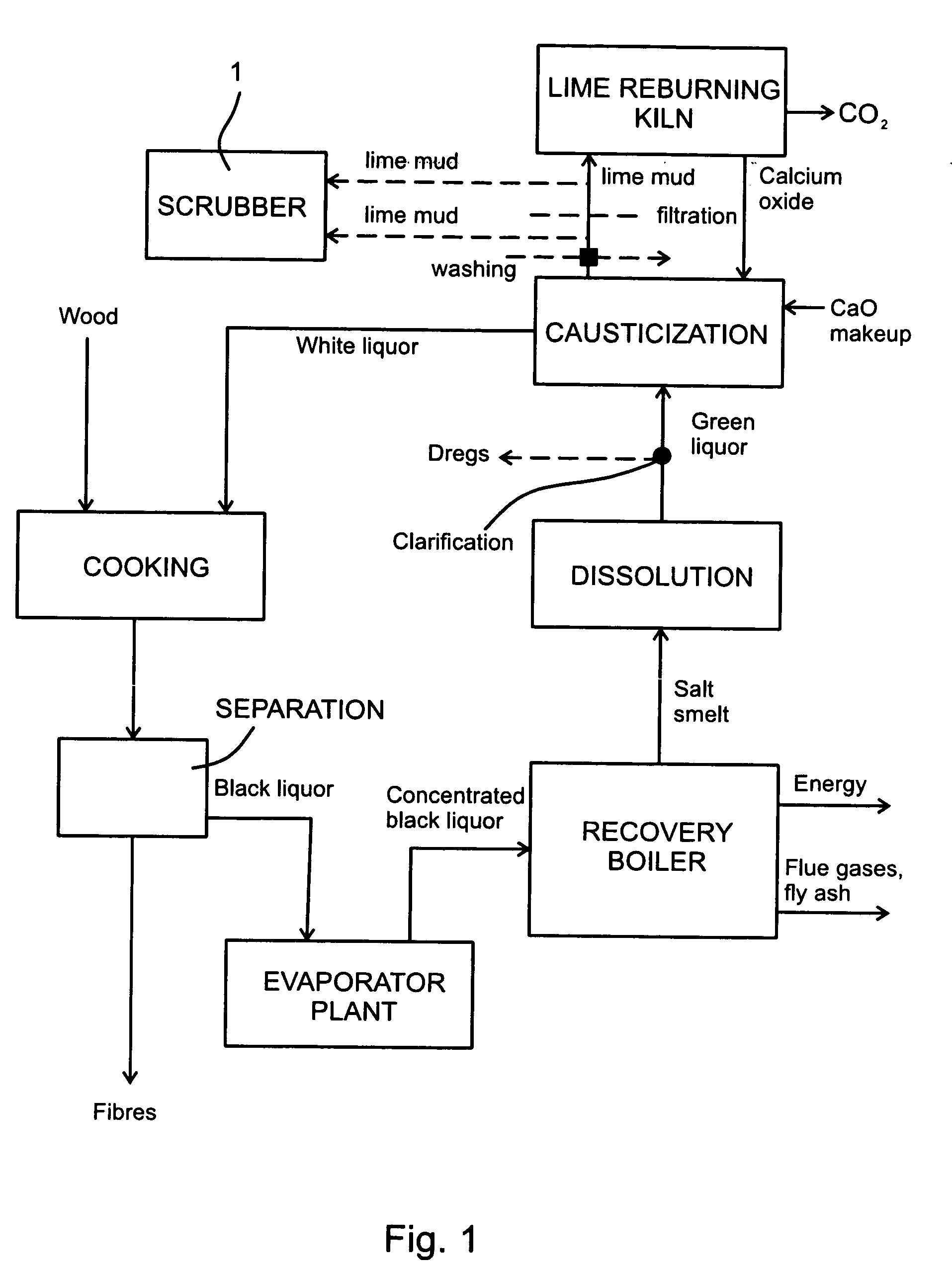

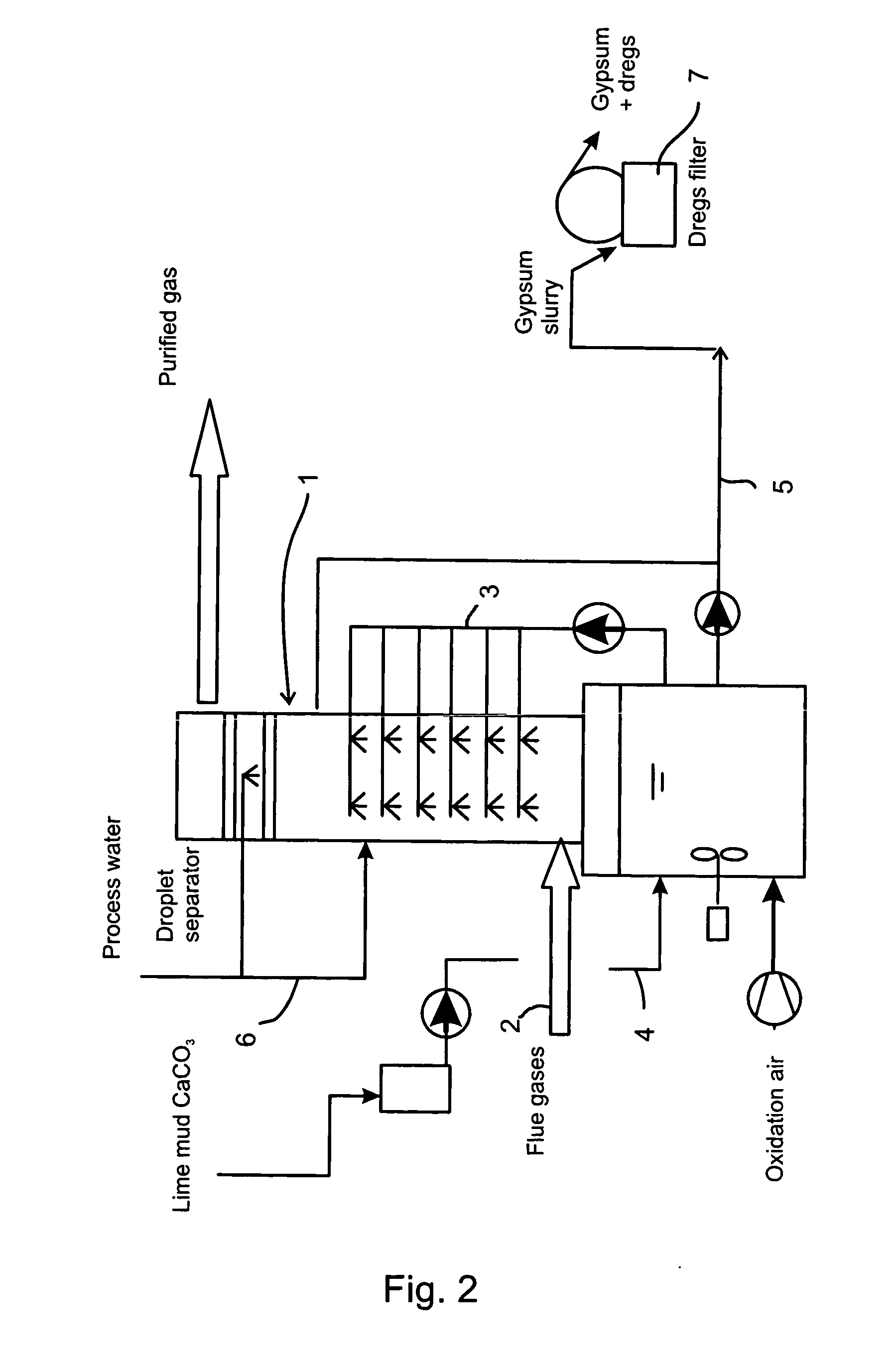

Method for processing flue gases

ActiveUS20070092422A1Low investment costReduce caustic makeupDispersed particle separationAlkali metal sulfides/polysulfidesFlue gasSulfate

In a method for processing flue gases, flue gases from an incineration plant for non-condensable gases of a kraft pulp mill are scrubbed by means of a calcium compound. The calcium compound is lime mud taken from the chemical recirculation of the kraft pulp mill after causticization and before a lime reburning kiln, and it is used in the scrubbing of gas as a substance reacting with sulphur dioxide.

Owner:METSO POWER OY

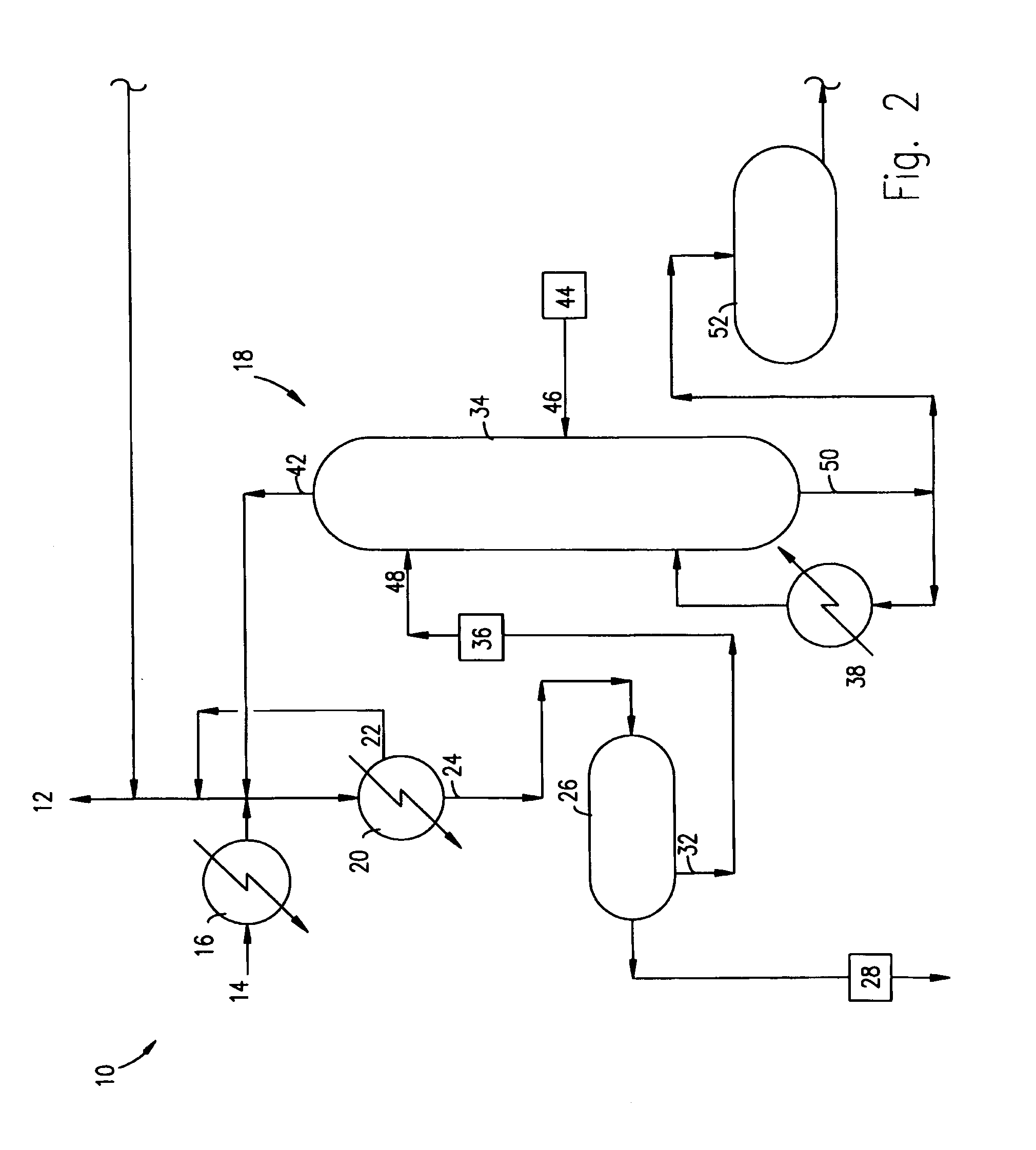

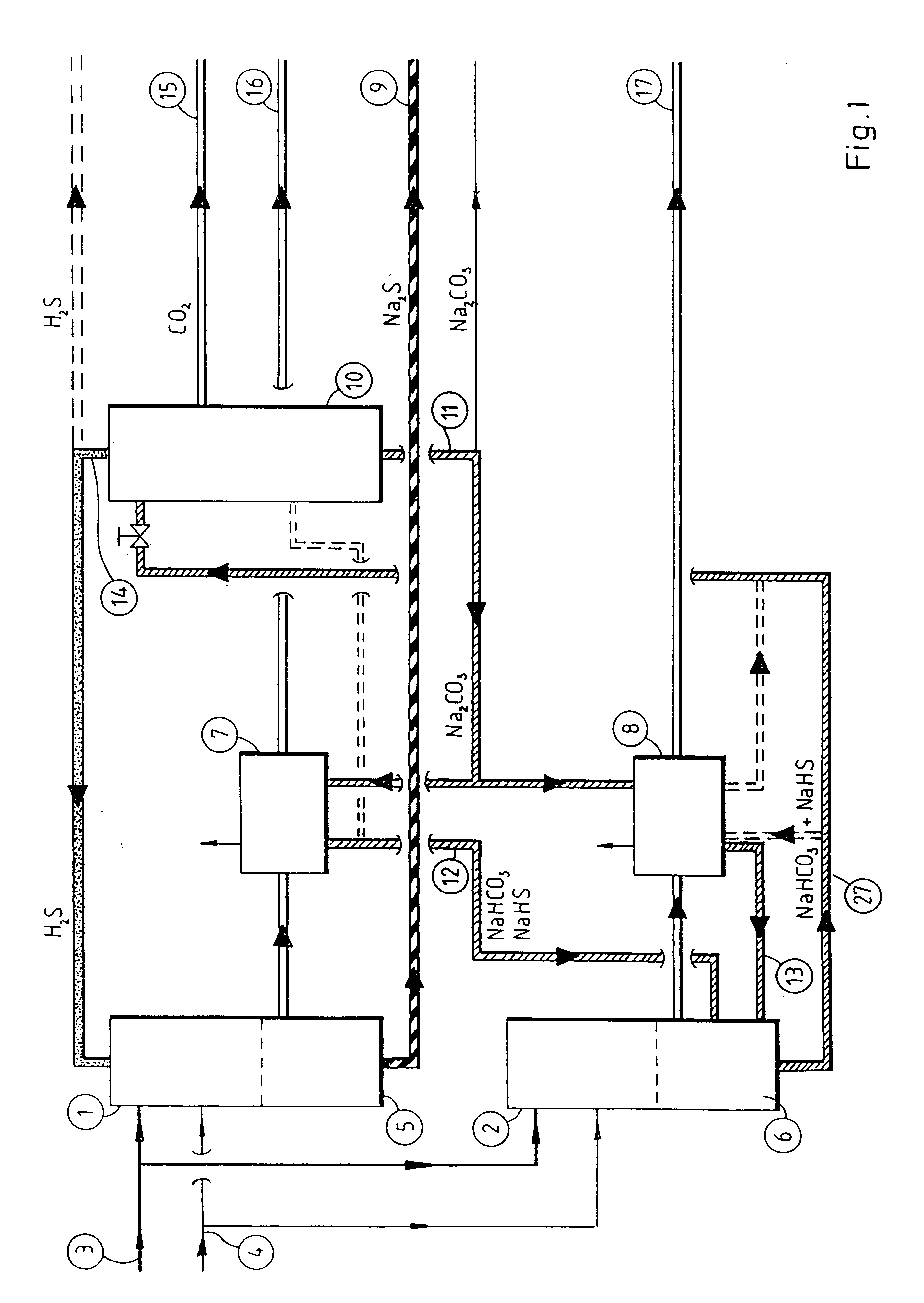

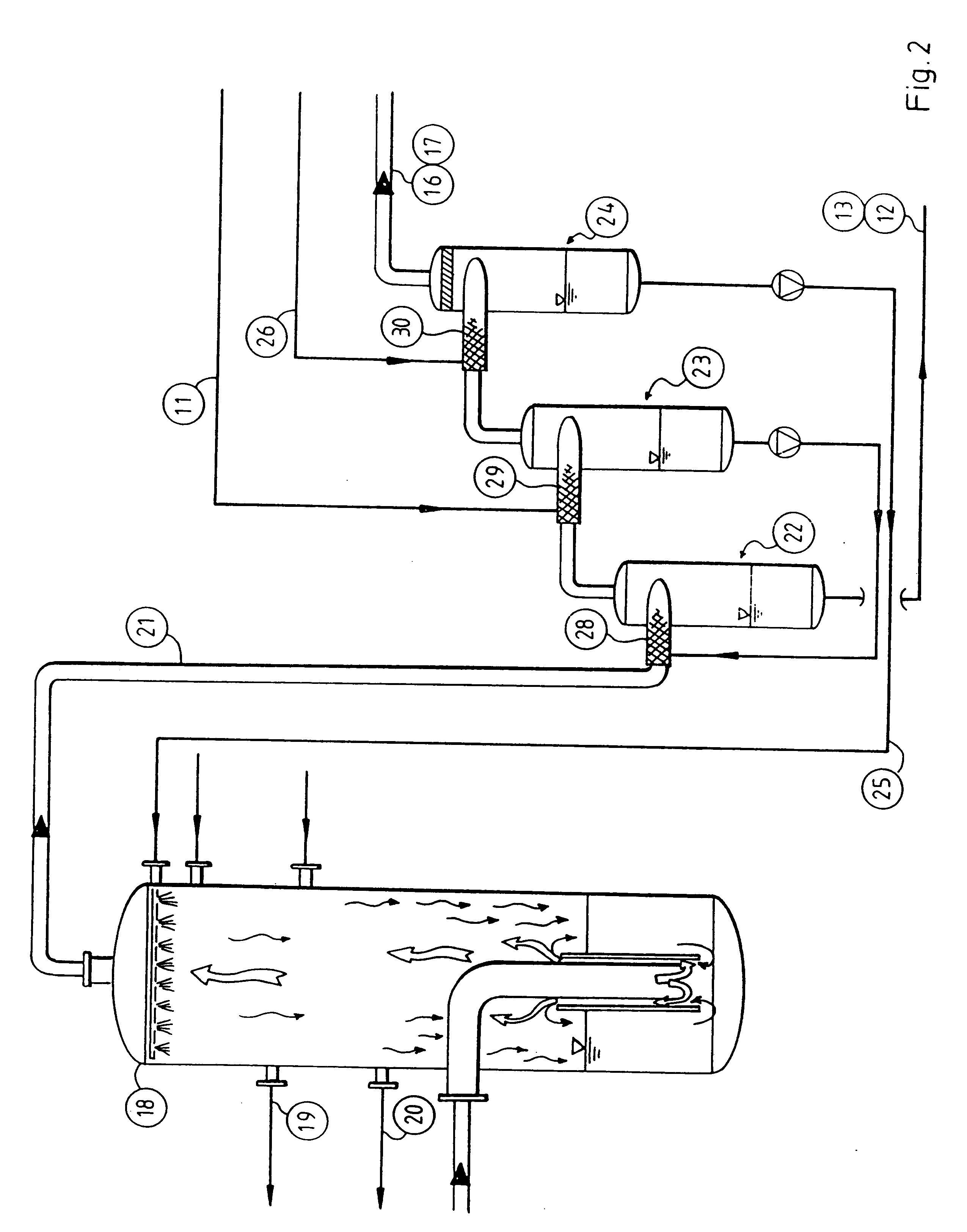

Process for recovering chemicals and energy from cellulose spent liquor using multiple gasifiers

InactiveUS6030493APulp liquors combustionChemical/physical/physico-chemical stationary reactorsFiberCellulose

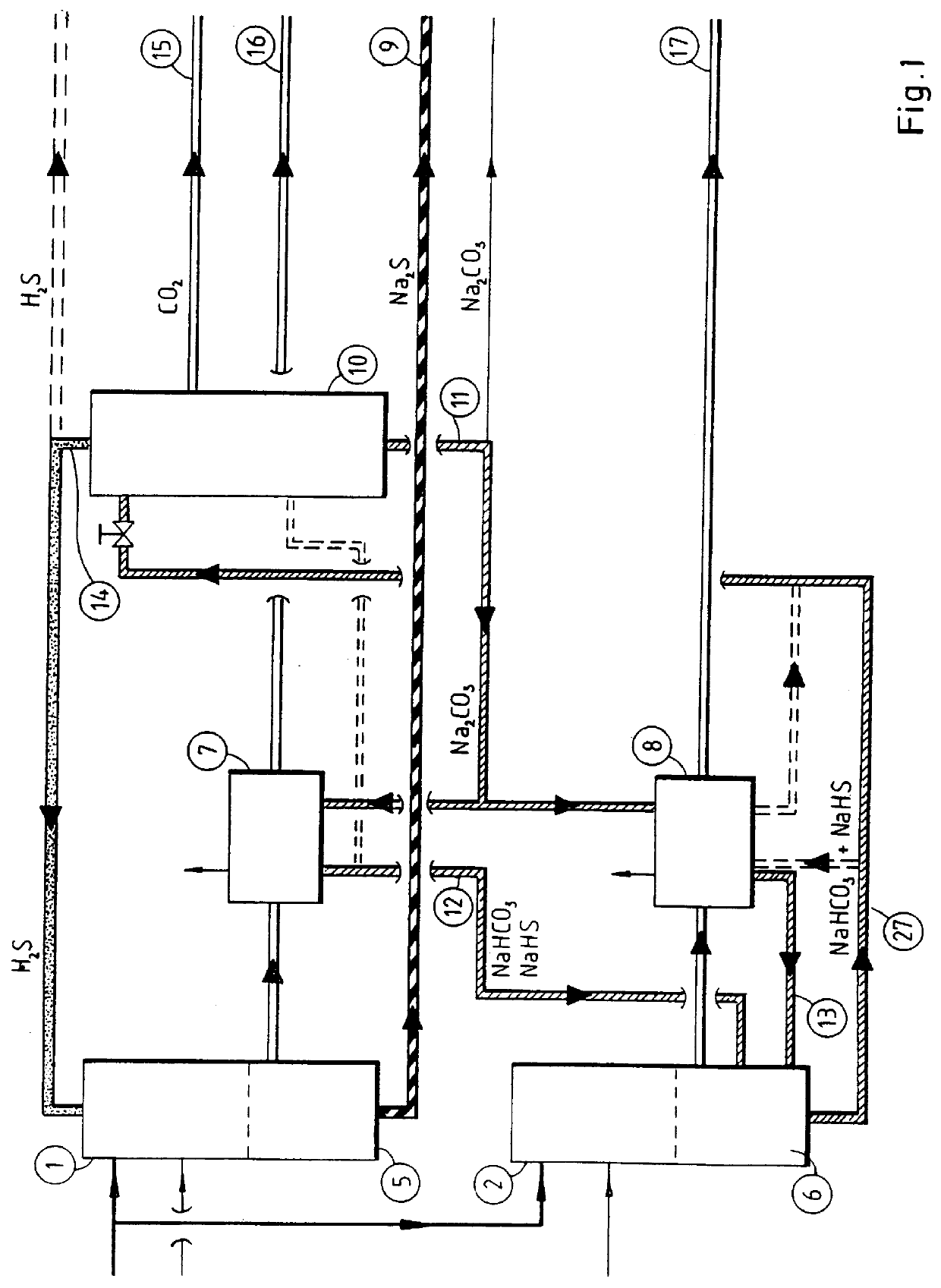

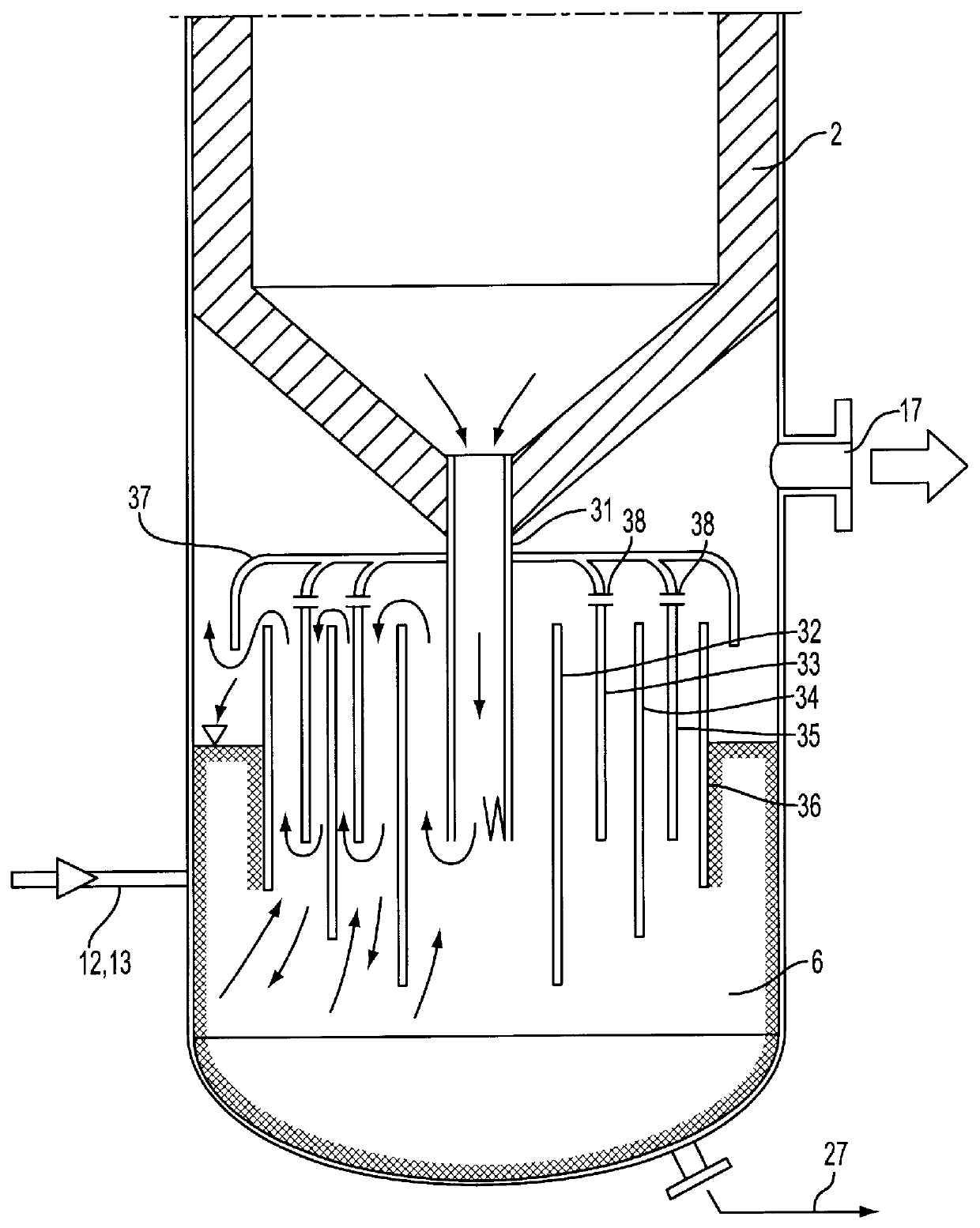

Provided is a process for recovering chemicals and energy from spent liquor obtained when producing paper pulp by chemical delignificatation of fibrous raw material. The spent liquor is gasified in at least two reactors, a first and a second stream of solid and / or smelt material and of combustible gaseous material being formed. The formed material is treated in one or more devices (5, 6, 7, 8), whereby a first (9) and a second liquor (27) are formed. The pressure and / or temperature in the first reactor differ(s) from the pressure and / or temperature in the second reactor. In addition, one or more process chemicals are recovered selectively from the formed liquor and / or gas, and are thereafter returned in whole or in part to one or more of the reactors (1, 2) and / or to one or more of the devices (5, 6, 7, 8) for treatment of the formed material.

Owner:CHEMREC AB

Method for extracting ammonium salt and methanol from a liquid obtained from foul condensates in a cellulose pulp mill

InactiveUS20100316553A1Avoid NOx emissionIncrease the number ofAmmonium nitratesNitrogen compoundsCellulose pulpAmmonia

Desirable chemicals are recovered from a raw material that is formed in substantial amounts during the production of cellulose pulp from renewable lingo-cellulose material. An ammonia / ammonium-containing methanol / water mixture is acidified with an acid that has the ability of forming ammonium salt with the ammonium. The mixture is circulated and passed through an apparatus that has an indirect heat exchanger combined with an storage volume fitted with a gas collection device.

Owner:METSO POWER AB +1

Apparatus and method for producing energy at a pulp mill

A spent liquor recovery boiler in the pulp and paper industry including a water / steam circulation system having superheaters, the circulation system connected to a steam turbine comprising a high-pressure part, and a furnace for burning spent liquor to produce flue gases, and including an upper portion through which the flue gases flow, wherein the steam / water circulation system of the recovery boiler is provided with a reheater for reheating steam from the high-pressure part of the turbine.

Owner:ANDRITZ AG

Treating methanol containing waste gas streams

InactiveUS6198005B1Facilitate partial oxidationReduce compoundingOrganic compound preparationSulfur compoundsSufficient timeWaste stream

A method wherein a methanol-containing waste gas stream, such as a pulp mill waste stream which contains methanol and other waste products, including methyl mercaptans, is passed in contact with a catalyst comprising a supported or unsupported bulk metal oxide catalyst in the presence of an oxidizing agent; preferably the gas stream is contacted with the catalyst, in the presence of the oxidizing agent, for a time sufficient to convert at least a portion of the methanol to formaldehyde (CH2O).

Owner:LEHIGH UNIVERSITY

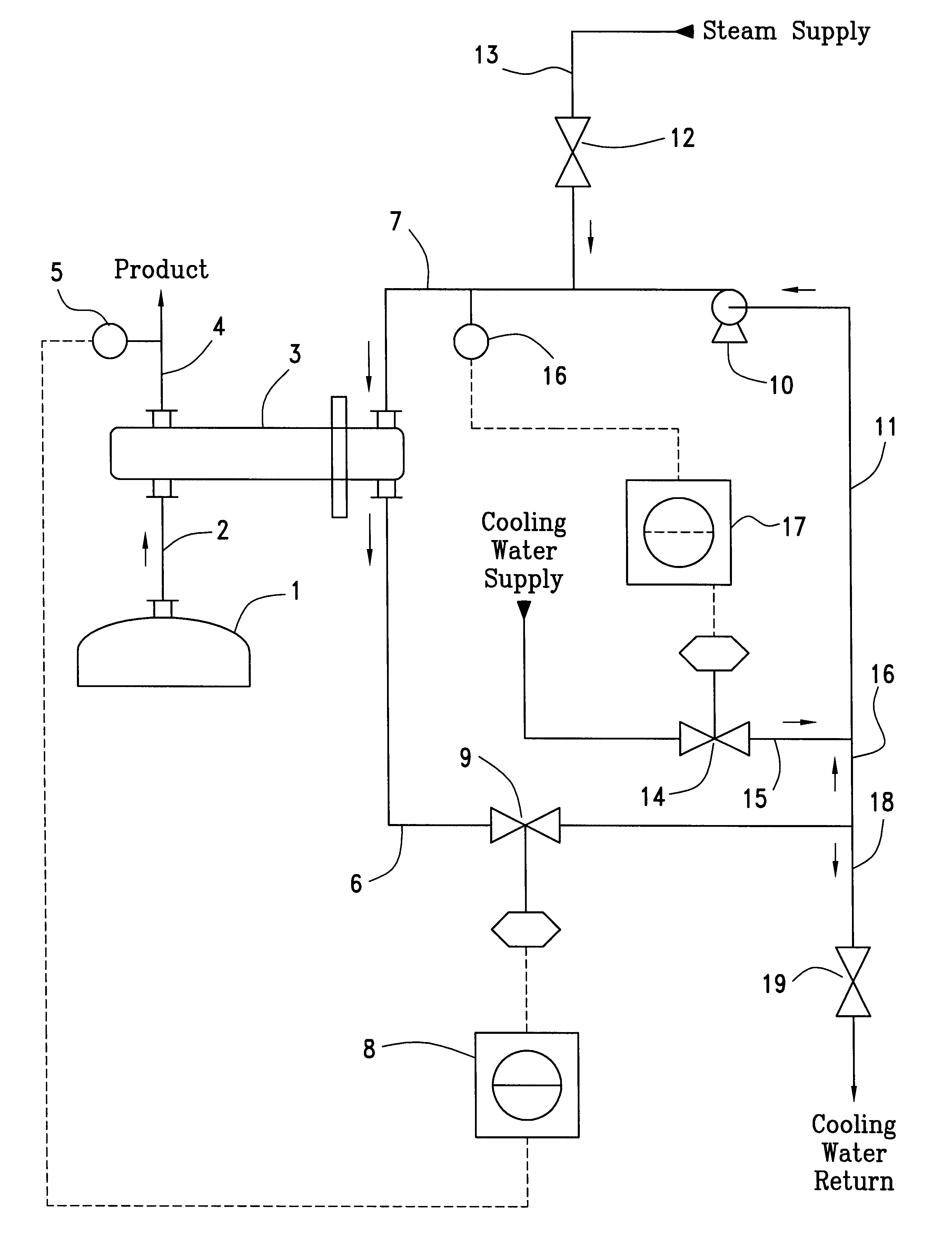

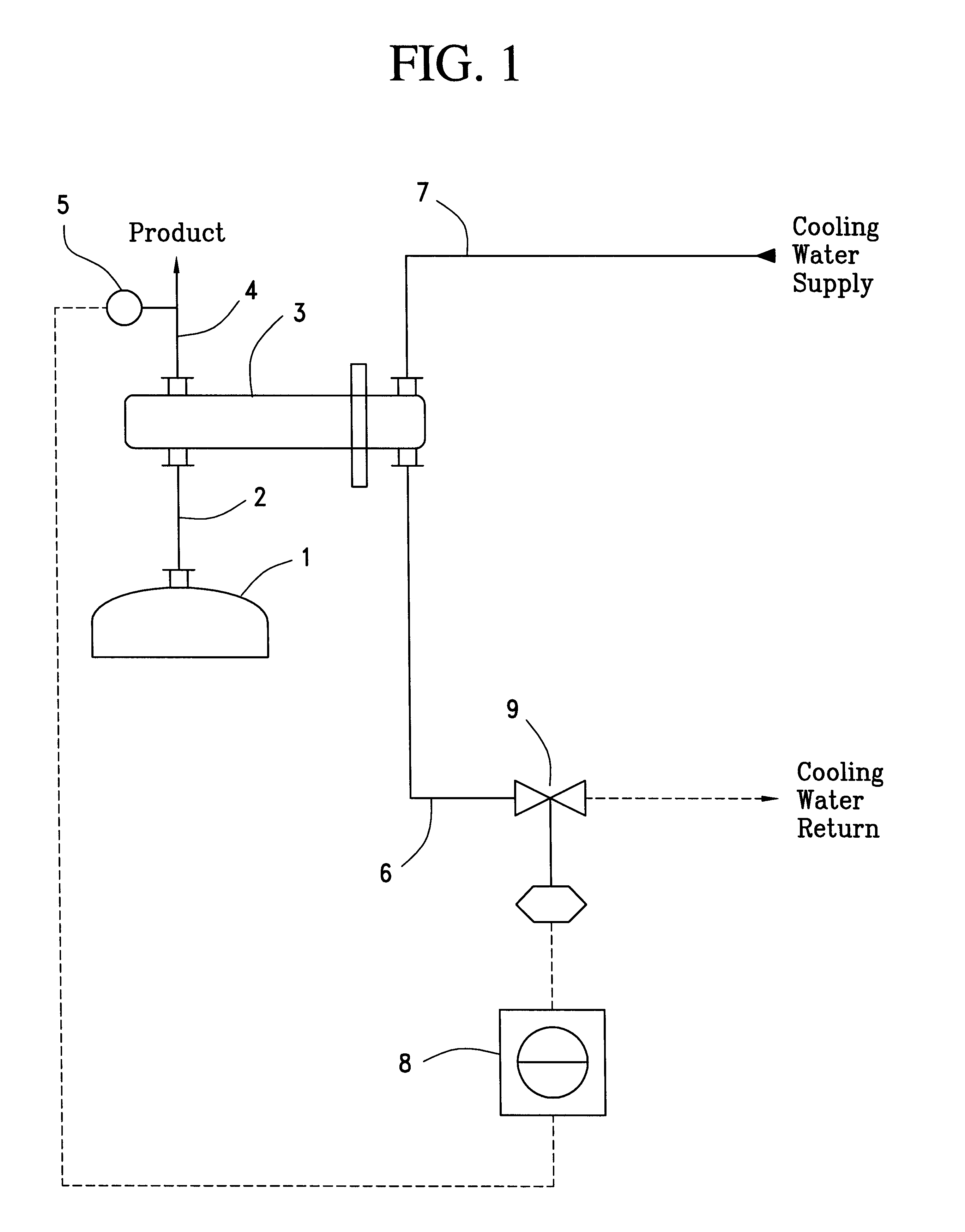

Tall oil refining improvement

InactiveUS6409882B1Avoiding anthraquinone condensationIncrease pressure dropDistillation regulation/controlDigestersCooling towerWarm water

In a tall oil refining operating plant, a warm water loop is disclosed for cooling the tall oil heads fraction extracted from the crude tall oil, rather than the conventional use of cold water. This avoids condensation and the subsequent solidification of athraquinone pulping aid remaining in the crude tall oil; thus, avoiding fouling of the cooling towers. The temperature of the warm-water is controlled automatically by tempering the cold water entering the warm water "cooling" loop, while removing excessively warm water from said loop to the cooling tower system, as needed.

Owner:MEADWESTVACO CORP

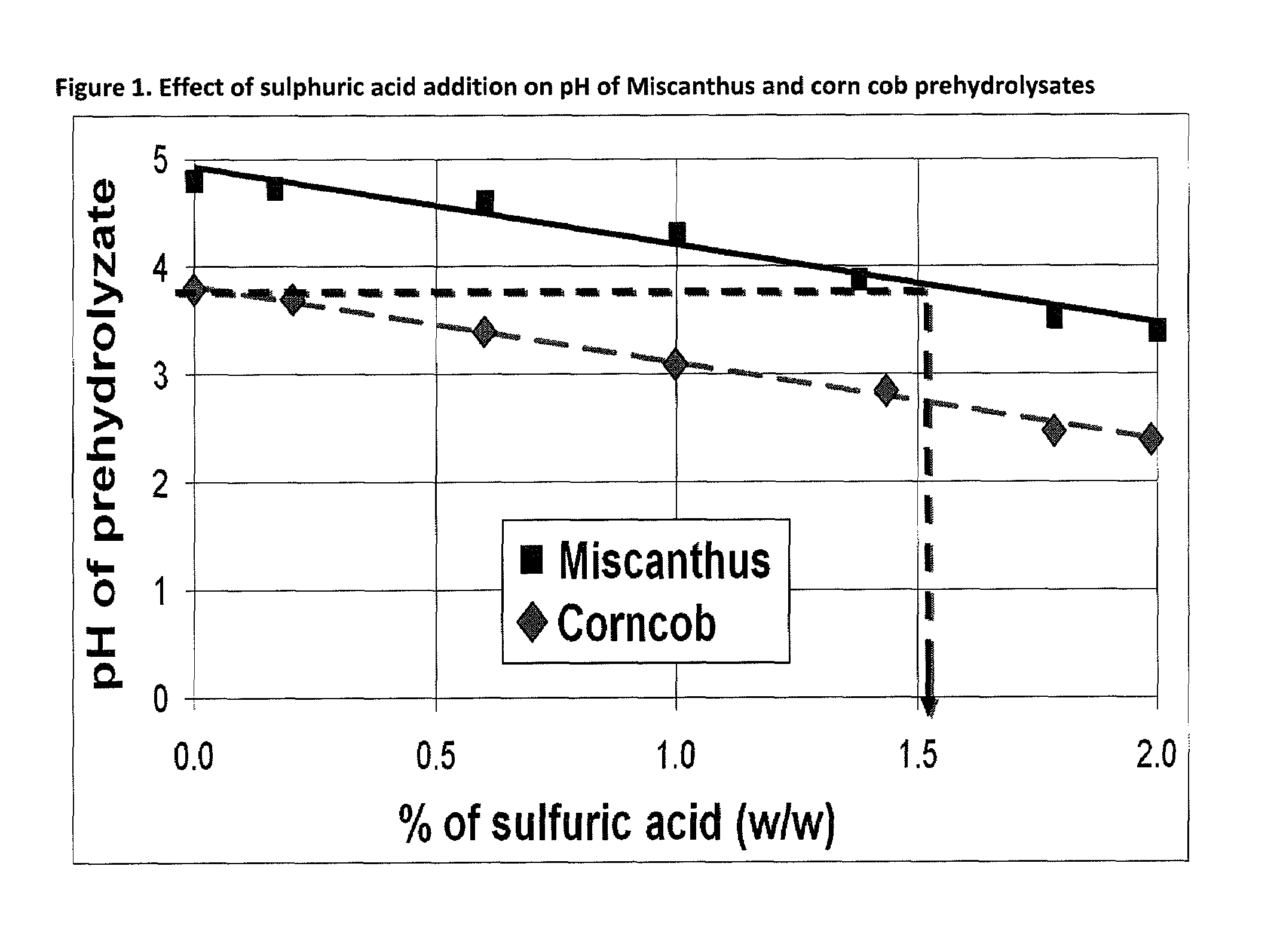

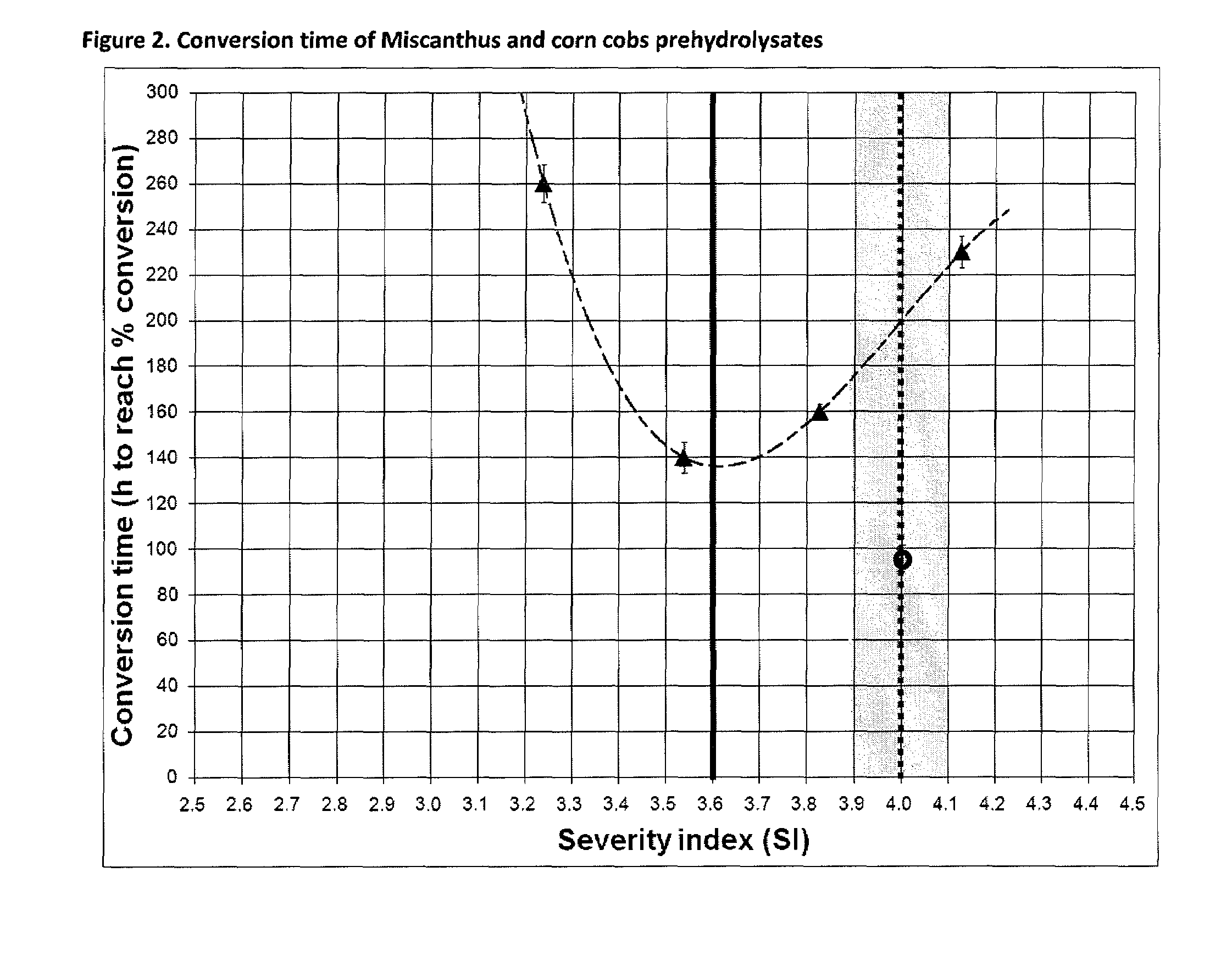

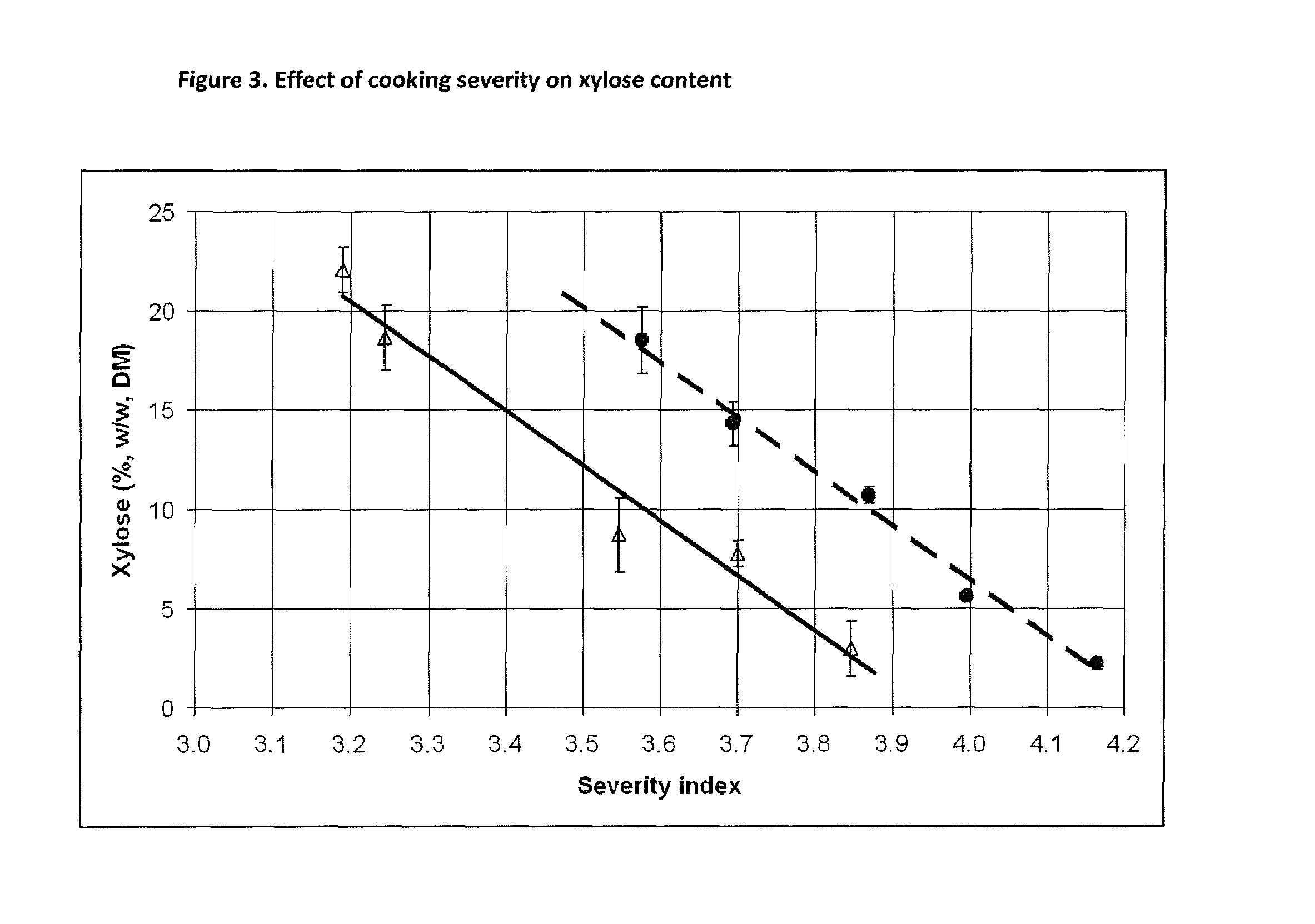

Cellulose pretreatment process

InactiveUS8287651B2Reduce the amount requiredReduce usageBiofuelsLiquid hydrocarbon mixture productionCelluloseDecomposition

A process for the production of ethanol from biomass is disclosed. The process relates to the pretreatment of corncob biomass and includes the steps of exposing corncob to steam in a reaction vessel at an elevated temperature and reaction pressure for a preselected exposure time. Volatile compounds are continuously vented during pretreatment. The reaction pressure is released for explosive decomposition of the corncob biomass into fibrous solids and condensate. The exposure is preferably carried out at a temperature of 190-210° C. and a pressure of 190 psig to 275 psig and an exposure time of 3 to 10 minutes.

Owner:GREENFIELD SPECIALTY ALCOHOLS

Method and system for energy savings in TMP by high temperature LC/MC refining of pulp

InactiveUS7540938B2Significant energy savingImprove flowPulp properties modificationFibrous raw materialsFiberPulp and paper industry

A method for recovering heat from a pulp refining process comprising: discharging pressurized pulp from a high pressure refiner, wherein the pressurized pulp comprises a pressurized slurry of fibers and liquid; introducing at least the liquid from the pressurized pulp slurry to a pressurized flash tank; exchanging heat from the pressurized flash tank with water, such that the water is heated, and using the heated water in the pulp refining process.

Owner:ANDRITZ AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com