Use of cyclodextrins for odor control in papermaking sludges, and deodorized sludge and products

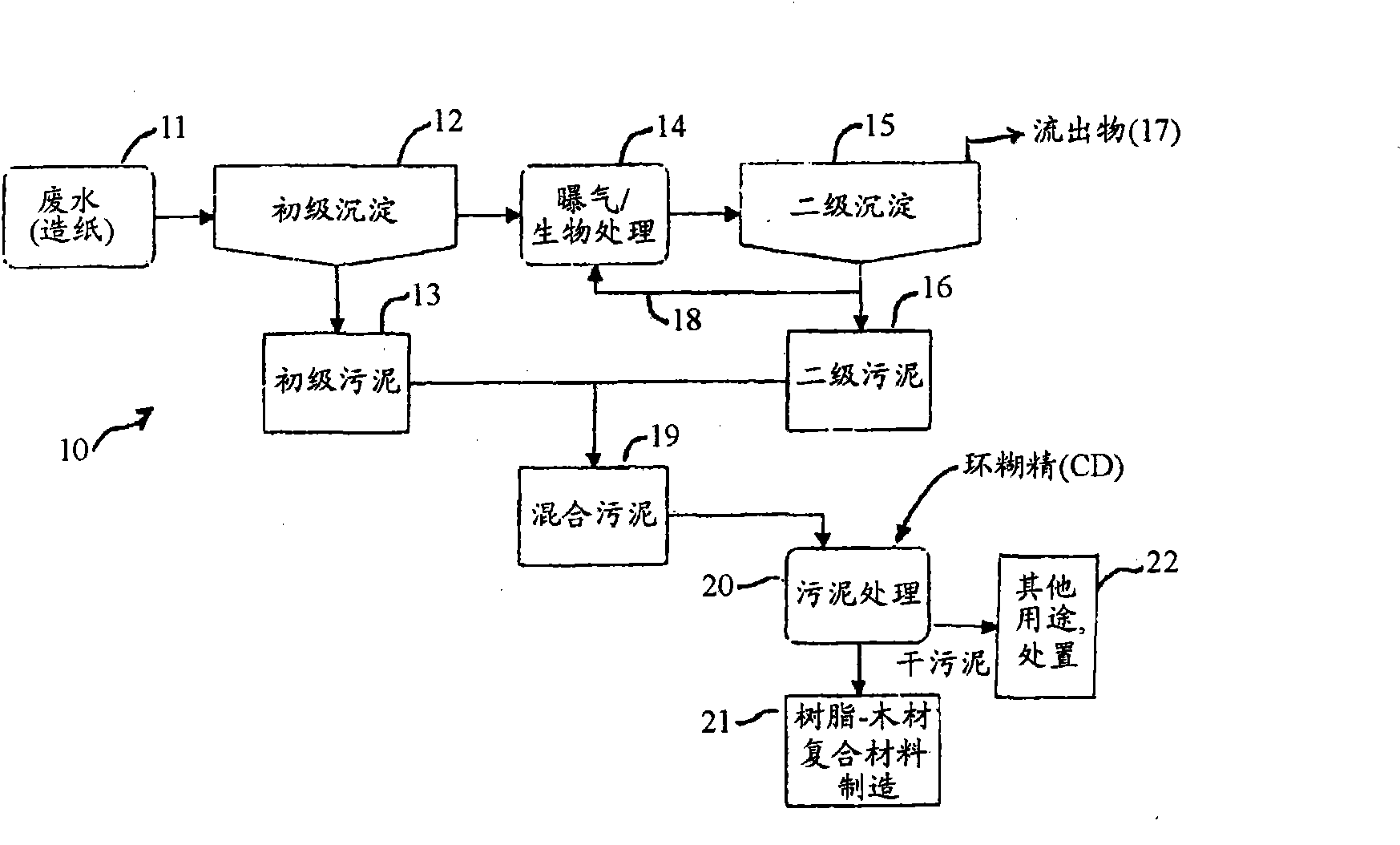

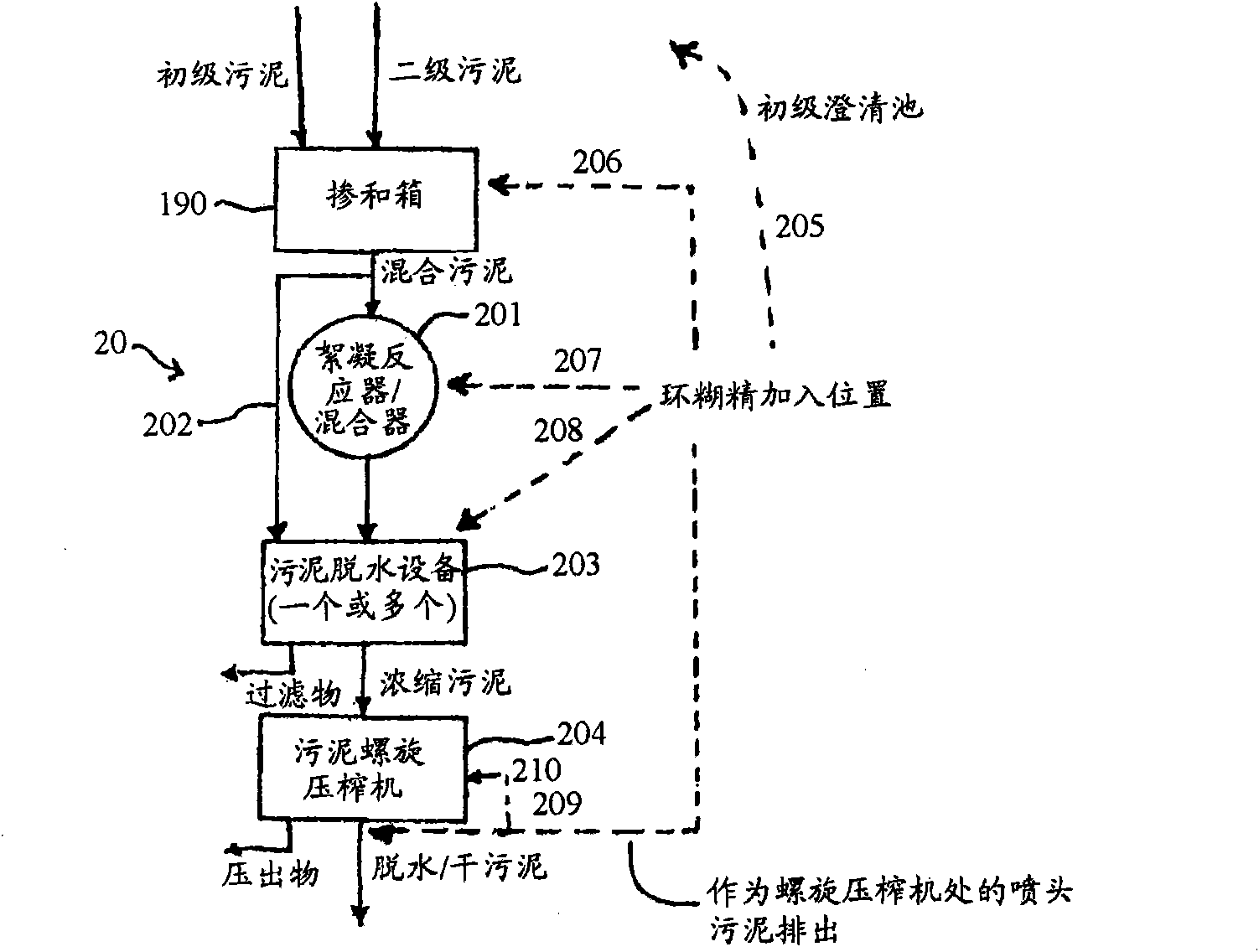

一种造纸污泥、环糊精的技术,应用在污泥脱毒、水/污泥/污水处理、造纸等方向,能够解决未涉及密集的厌氧生物活性体、应用成本高等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

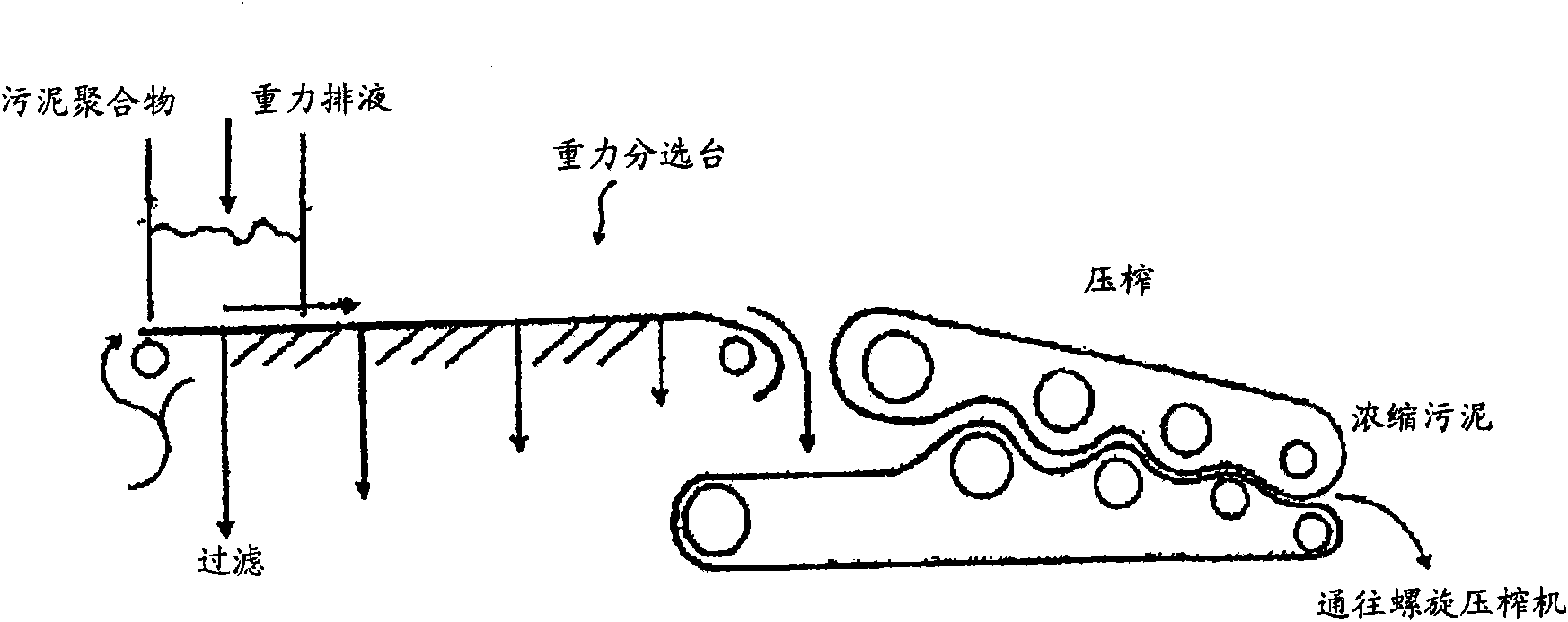

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1: research cyclodextrin can measure hydrogen sulfide ((H 2 S)) Influence

[0058] Test samples were prepared using 200 g of paper sludge obtained from a MeadWestvaco plant (Mahrt, AL.), which was added to 800 g of 50 mM phosphate buffer solution (pH 7.1). Phosphate buffer solution consists of 2.503g KH 2 PO 4 (anhydrous) / L and 5.47g K 2 HPO 4 (Anhydrous) / L mixed. Different forms of cyclodextrins, namely β-cyclodextrin and hydroxypropylated β-cyclodextrin, were detected in sludge samples at different dosage levels.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com