Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

156results about How to "Improve thermal economy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

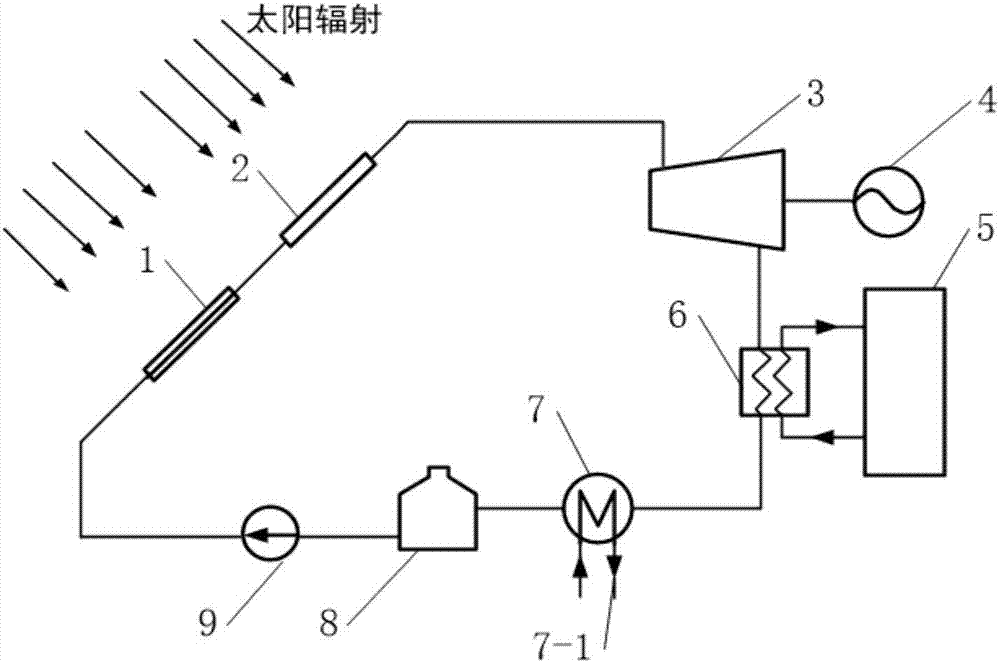

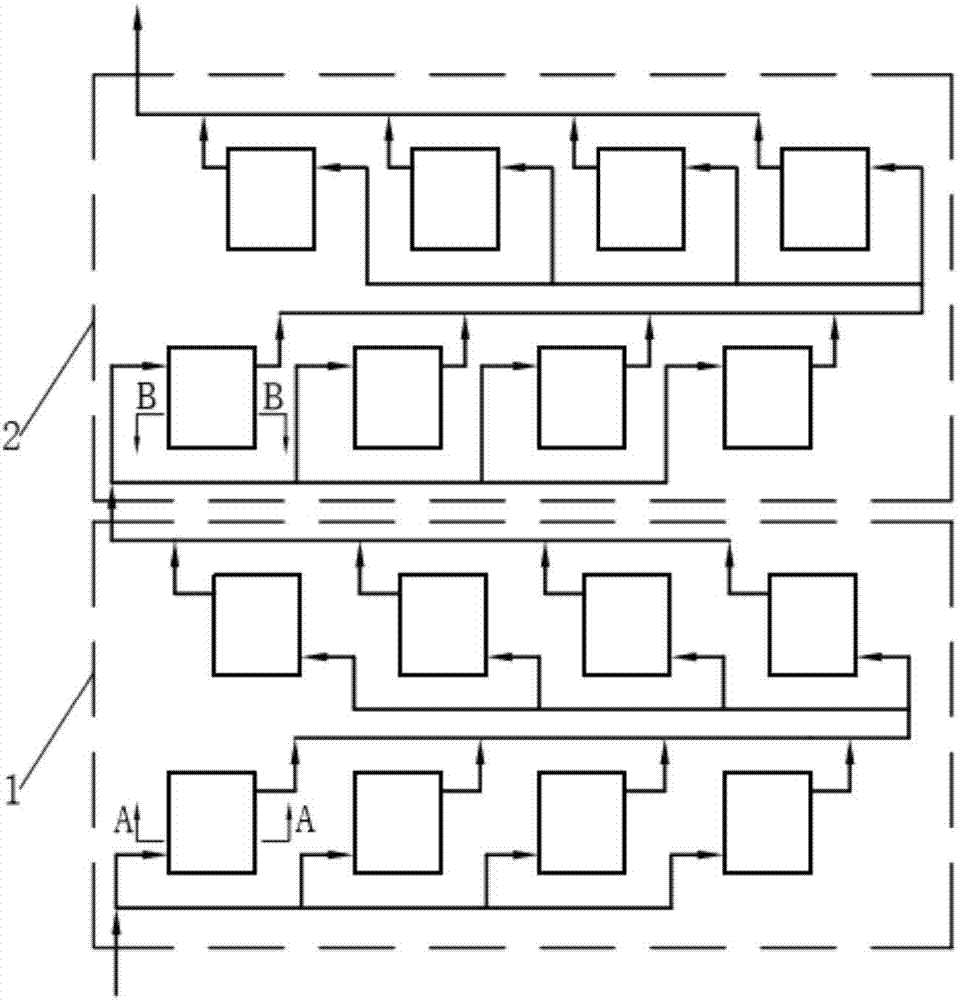

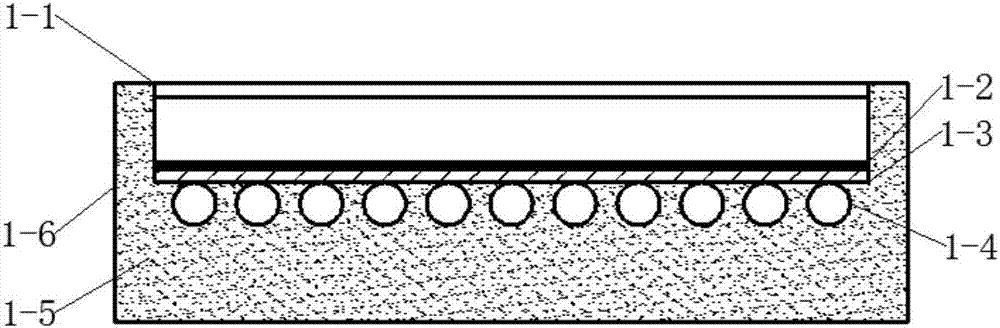

Paraboloid trough type solar heat-collector auxiliary coal-burning boiler mixing heat power generation system

InactiveCN101260815AHigh thermal efficiencyLess coal consumptionSteam engine plantsDeaeratorEngineering

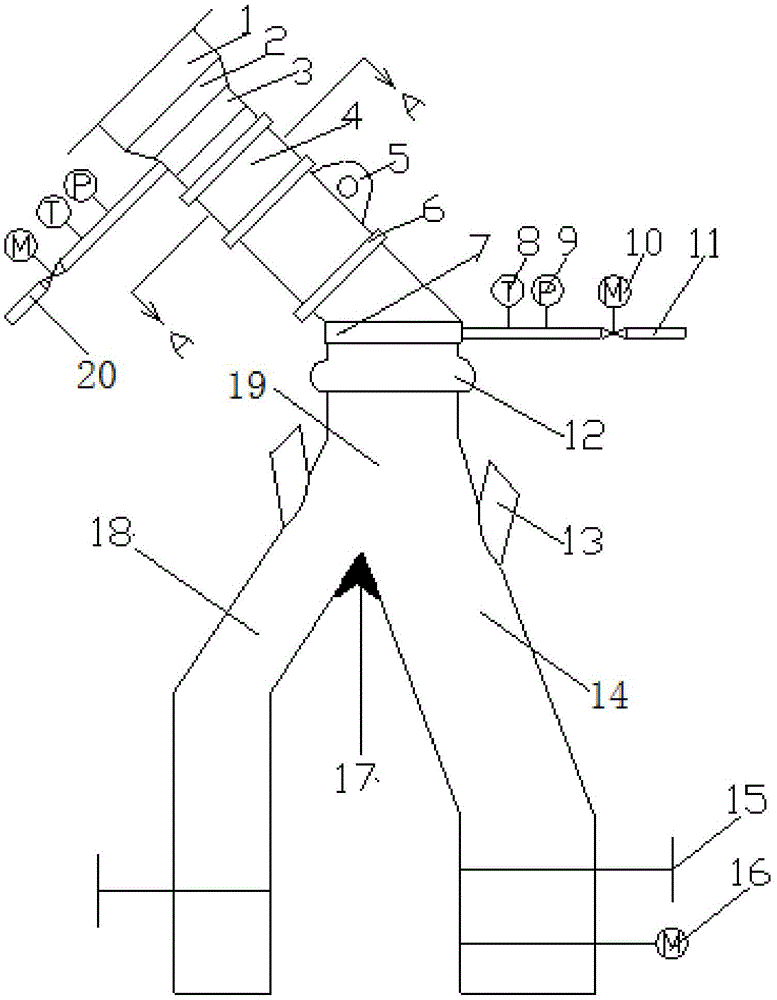

The invention belongs to the generating equipment scope and in particular relates to a mixed heat power generating system with a paraboloid groove type solar heat collector to assist a coal burning boiler. A solar heat collector field is connected with a feed pump and a second or a third high-pressure heater; a condenser, an extraction pump, a low-pressure heater, a deaerator, the feed pump, the high-pressure heater, the coal burning boiler and a steam turbine are connected in series in turn; and the steam turbine drives a dynamo and discharges steam to the condenser. Condensed water flows out from the condenser and is heated up and pressurized up by a the low-pressure heater, deoxidized by the deaerator, fed with water by a leading-out part of the feed pump and enters the solar heat collector field for heat absorption; after reaching a stream drawing parameter of a certain stage high-pressure heater, the condensed water returns and joins the drawing gas of the corresponding stage heater; the other part of feeding water enters the coal burning boiler through the high-pressure heater and becomes steam with high temperature and high pressure; and the steam enters the stream turbine, applies work and flows into the condenser to complete a thermodynamic cycle. The mixed heat power generating system with the paraboloid groove type solar heat collector to assist the coal burning boiler reduces coal consumption of a coal burning unit, improves thermal efficiency of the solar heat power generation and reduces the investment on the simple paraboloid groove type solar heat power generation.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Device for removing CO2 of flue gas by highly active potassium-base absorbing agent dry method and method thereof

InactiveCN101298023AImprove removal efficiencyReduce energy consumptionDispersed particle separationBy chemical separationCoalProcess engineering

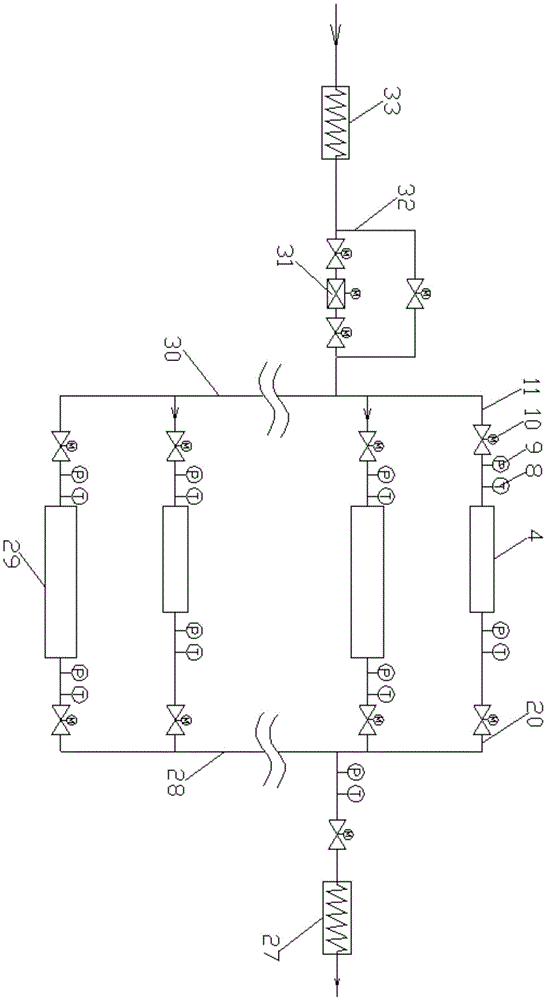

The invention discloses a device and a method for removing CO2 in flue gas by dry process and using a highly active potassium based absorbent. The device essentially consists of two circulating fluidized bed reactors, two sets of buried pipe type heat exchangers, two sets of materiel cycle devices and a gas generating, mixing and delivery device. After desulfurization, flue gas and steam generated by the exhausted spare heat of a steam turbine are mixed and sent into a first circulating fluidized bed reactor and react with the highly active potassium based absorbent in the reactor to remove CO2 in the flue gas; after reaction, the absorbent is sent to the other circulating fluidized bed reactor and regenerated in the reactor through the buried pipe by using the heat of hot flue gas generated in a station boiler. Mixed gas generated is dehydrated by a condenser and high purity of CO2 is obtained. Part of CO2 is taken as a fluidizing medium for a regeneration reactor and the rest is collected and disposed. The device is organically integrated with a coal power generation system and utilizes coal flue gas to provide heat needed by the device, which is a prioritization scheme with low energy consumption and investment.

Owner:SOUTHEAST UNIV

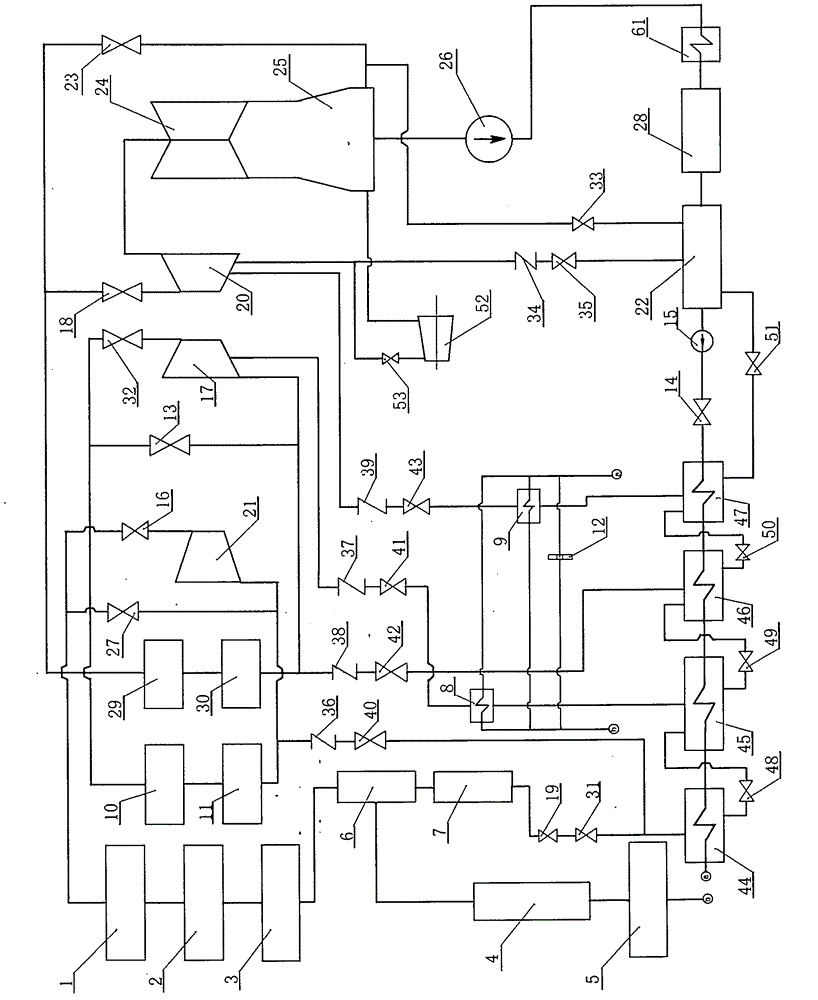

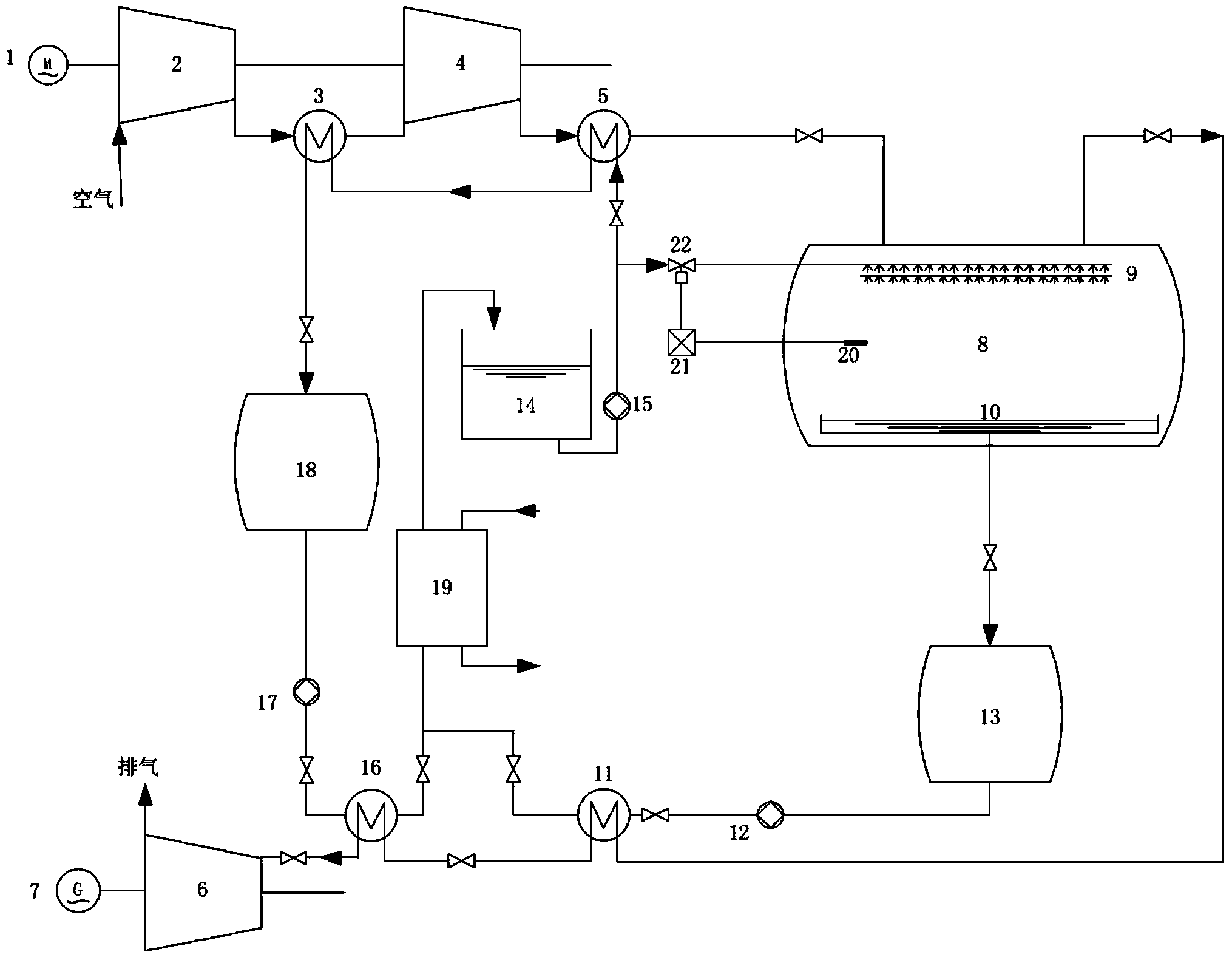

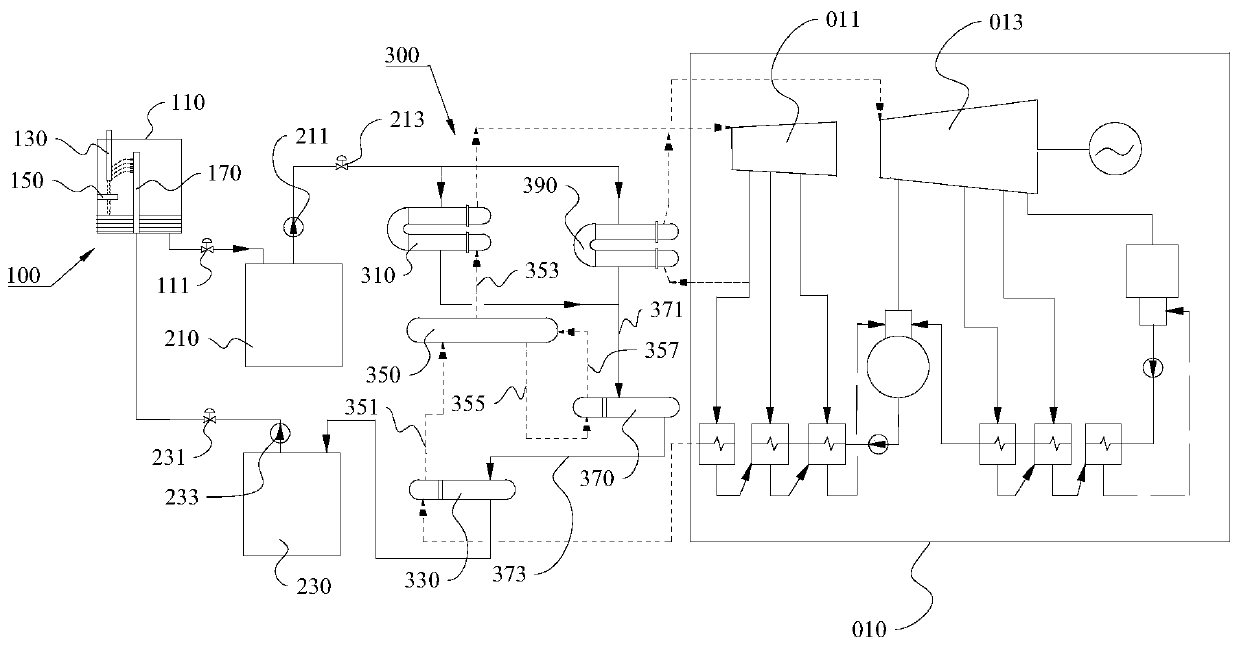

Integrated power generation system for compressed air energy storage and combined cycle

ActiveCN103233820AImprove thermal economyAchieve optimal utilizationGas turbine plantsSteam engine plantsThermal energyThermal energy storage

The invention discloses an integrated power generation system for compressed air energy storage and combined cycle. The integrated power generation system comprises a compressed air energy storage system, an air turbine power generation system, a gas turbine power generation system, a steam turbine power generation system and a heat storage device and a cold storage device, wherein the compressed air energy storage system is formed by sequentially connecting a motor, an air compressor and a large air storage chamber; the large air storage chamber supplies compressed air to the air turbine power generation system and the gas turbine power generation system; the heat storage device is used for absorbing the exhausted air sensible heat of the air compressor, and heating water supplied by the steam turbine power generation system through a water supply heat exchanger; and the cold storage device is used for acquiring cooling quantity from the low-temperature exhausted air of an air turbine, and performing heat exchange with a condenser of the steam turbine power generation system. The compressed air energy storage system is organically combined with a gas-steam combined cycle power generation system, heat energy in air compression and expansion links is optimally utilized, and the heat economy of the power generation system and the peak shaving performance of a power grid are improved.

Owner:甘肃西拓能源有限公司

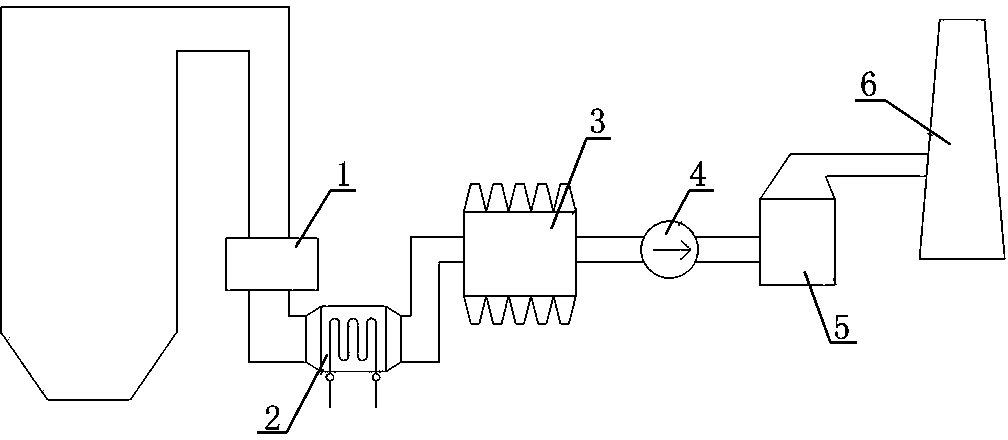

Low temperature electric precipitation system in fuel electric plant

InactiveCN103363536AImprove the dust collection rateMeet the requirements of emission standardsLighting and heating apparatusAir preheaterEnvironmental resistance

A low temperature electric precipitation system in a fuel electric plant comprises at least one air preheater, at least one electric precipitator and connecting pipes for connecting the air preheater and the electric precipitator together, a flue-gas heat exchanger for lowering the flue-gas temperature entering the electric precipitator to enable the flue-gas temperature to reach or be lower than flue-gas dew point at the temperature of 90 DEG C is arranged between the air preheater outlet and the electric precipitator inlet; the electric precipitator is communicated with a desulfuration absorption tower through an induced-draft fan; a chimney is connected with the rear part of the desulfuration absorption tower. The flue-gas heat exchanger adopts a backward flow heat exchange type; a vertical pipe heat exchange flow passage or a horizontal pipe heat exchange flow passage is arranged at the inner part of the flue-gas heat exchanger; the system has the characteristics that the project equipment investment is reduced; the auxiliary power ratio is lowered; the energy is saved; the consumption is reduced; the heat economy of the unit can be improved; the latest environment-friendly emission standard can be satisfied.

Owner:ZHEJIANG ELECTRIC POWER DESIGN INST +1

Multi-effect membrane distillation-multistage flash evaporation seawater desalination system

InactiveCN103387308ARecovery of latent heat of vaporizationHigh thermal efficiencySeawater treatmentMultistage water/sewage treatmentDistillationConcentration ratio

The invention discloses a multi-effect membrane distillation-multistage flash evaporation seawater desalination system. The multi-effect membrane distillation-multistage flash evaporation seawater desalination system comprises a steam jetting pump (9), a concentrated water discharge pump (1), a material liquid circulating pump (2), a vacuum pump (3), a product water pump (4), N membrane assemblies, N freshwater flash evaporation tanks, N+1 heat exchange assemblies and N-1 concentrated water flash evaporation tanks, wherein the plurality of membrane assemblies and heat exchange assemblies are connected in series to form 'multi-effect' distillation in the term of the traditional distillation; the plurality of freshwater flash evaporation tanks and the plurality of concentrated water flash evaporation tanks are connected in series to form 'multistage' flash evaporation in the term of traditional distillation; the multi-effect membrane distillation process and the multistage flash evaporation process are coupled, secondary steam generated by membrane distillation is used for heating material liquid seawater, high-temperature concentrated seawater and product water which are discharged by membrane distillation are subjected to flash evaporation stage by stage, and the flash-off steam is used for heating material liquid seawater, so gradient utilization of energy and double concentration of the material liquid are realized, vaporized latent heat is effectively recovered, and heat efficiency, water making ratio and concentration ratio of a system are increased.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

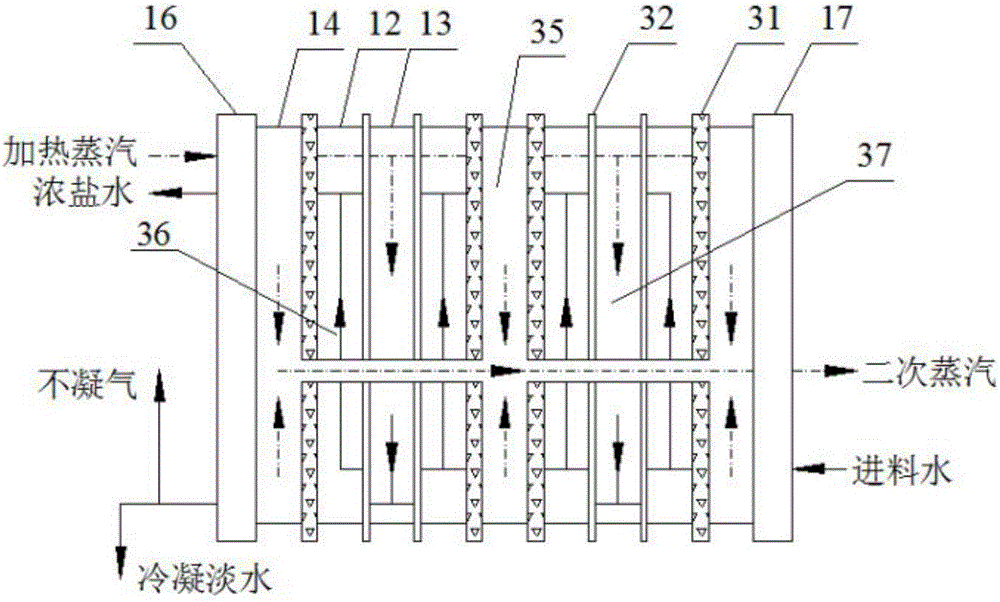

Segment water-water preheating multiple-effect distillation sea water desalination technical process

InactiveCN101264947AIncrease water production ratioImprove thermal economyGeneral water supply conservationSeawater treatmentChemistrySeawater

The invention relates to a sectional multiple-effect distillation seawater desalination process by supplementing preheated seawater via a water-water heat exchanger, and belongs to the technology field of multiple-effect distillation seawater desalination. The process comprises the steps of dividing an evaporator into a plurality of sections, leading out the final-effect condensed products fresh water and concentrated seawater in a high-temperature section, and supplementing preheated seawater via a water-water heat exchanger to reduce the degree of supercooling of the supplemented water entering into the high-temperature section of the evaporator, so as to solve the key restriction factor troubling the MED system design, and effectively improve the heat economical efficiency of the system. The final-effect secondary steam from the high-temperature section of the evaporator is introduced into an adjacent low temperature section of the evaporator as a heating steam, so as to recycle the latent heat of the steam. Therefore, the inventive process can adopt more effects, larger operating temperature range, and higher water generation ratio.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

A new geothermal and photothermal combined power generation system

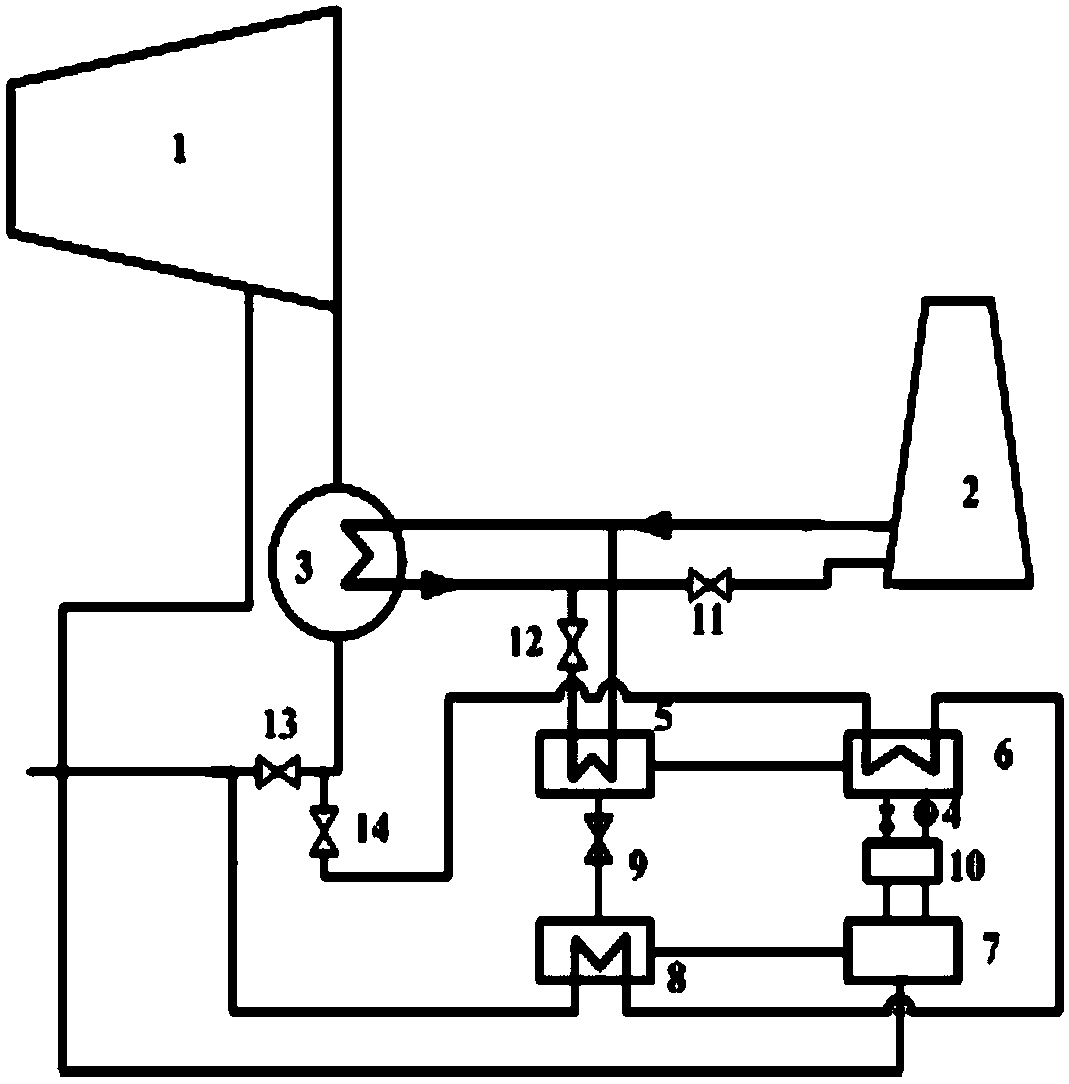

InactiveCN102287344AImprove the initial parametersImprove working abilityFrom solar energyGeothermal energy generationLiquid storage tankCompression device

The invention relates to a novel geothermal and optothermal cogeneration system, which is characterized by comprising a geothermal evaporator, a solar overheater, a prime motor, a prime motor exhaust port, a working medium compression device, an air-cooling radiator, a liquid storage tank and a working medium booster pump. The solar overheater, the prime motor, the prime motor exhaust port, the working medium compression device, the air-cooling radiator, the liquid storage tank and the working medium booster pump are sequentially communicated with the geothermal evaporator; and the prime motor is respectively communicated with the working medium compression device and the air-cooling radiator through a three-way reversing valve. The invention has the advantages that a substance with a lowboiling point is used as a working medium for power and refrigeration circulation, the medium-temperature and low-temperature geothermal heat can be used as a heat source for evaporation of the working medium, solar energy is adopted as an overheating source for the working medium, and the geothermal evaporator is arranged in a downhole. The circulating working medium is delivered into the evaporator at the bottom of a geothermal well for evaporation to absorb heat of geothermal fluid, geothermal hot water needs not to be pumped to the surface, the evaporation temperature of the working medium can be increased, well backfilling can be eliminated, corrosion and scaling can be reduced, and the service life of the system can be prolonged. Moreover, the system has a simple and reasonable structure and good economical performance in heat for power generation.

Owner:杨善让

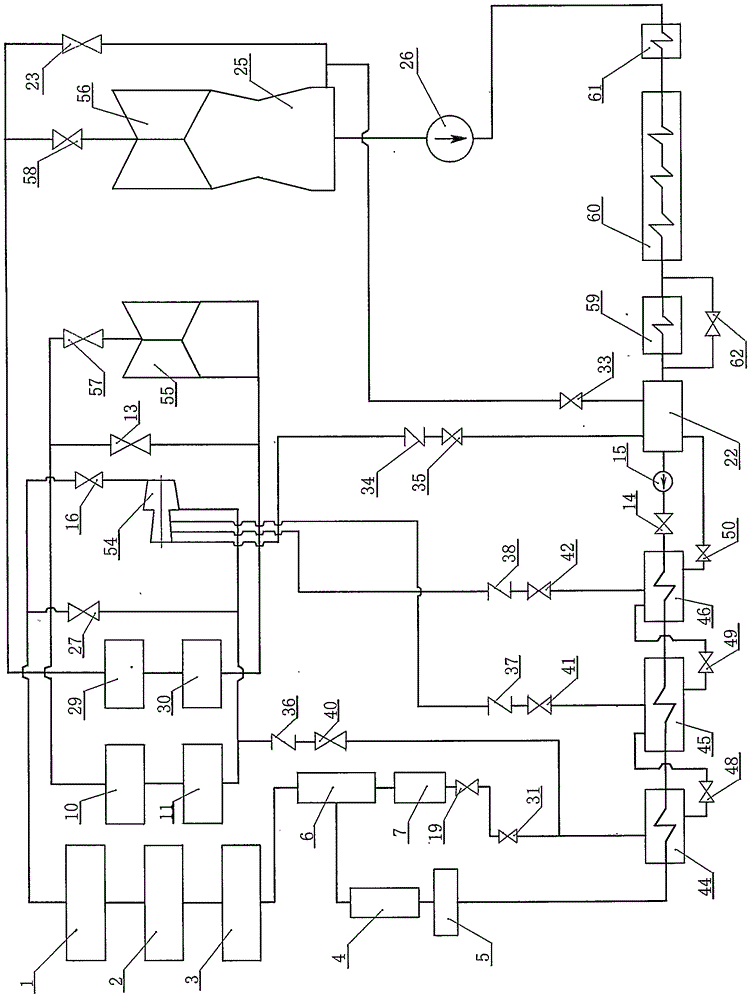

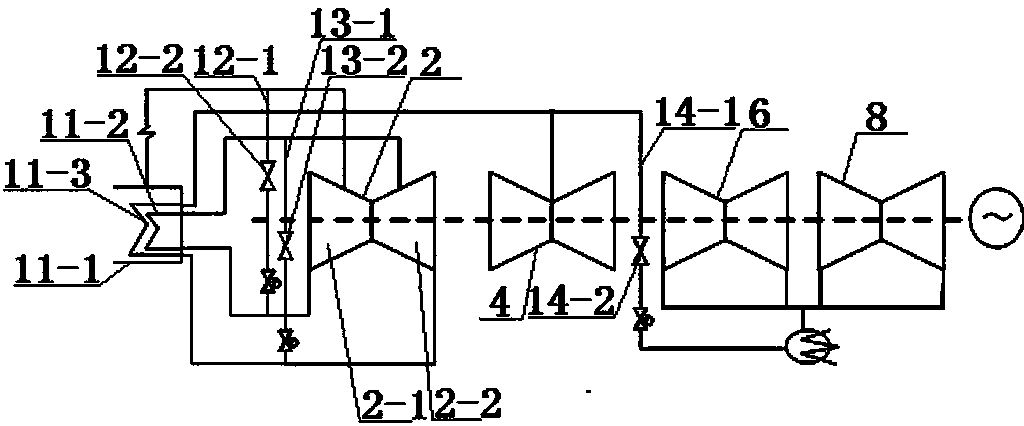

Industrial steam residual pressure gradient utilization system applied to machine halt and boiler-stop-free manner of coal-fired steam supply unit

PendingCN111237018AImprove thermal economyImprove safety and reliabilitySuperheating controlLiquid degasificationProcess engineeringDeaerator

The invention belongs to the technical field of energy saving in the field of heat supply reliability of a coal-fired industrial steam supply unit, and particularly relates to an industrial steam residual pressure gradient utilization system applied to a machine halt and boiler-stop-free manner of the coal-fired steam supply unit. A bypass combined heat supply system and a direct temperature and pressure reduction direct supply system are additionally arranged on the basis of an original system, when a steam turbine or a power generator needs to be overhauled in a failure state, the steam turbine and the power generator stop, main steam of a boiler enters the reheater side of the boiler after being subjected to temperature and pressure reduction of a high-pressure bypass temperature and pressure reduction valve set, then enters a boiler reheater to be subjected to heat absorption and then enters a heat supply steam back pressure steam turbine generator unit to do work and drive power generation, a station service system is connected, and the heat economical efficiency of an emergency heat supply system is improved. If the heat supply steam back pressure steam turbine generator unitfails, the direct temperature and pressure reduction direct supply system can be switched to, steam of an outlet of the boiler reheater is directly subjected to temperature and pressure reduction toenter a whole-plant industrial steam supply mother pipe, temperature reduction water is taken from outflow water of a deaerator, the safety and the reliability are high, and it is guaranteed that heatsupply of the system is stable.

Owner:HUANENG POWER INT CO LTD DEZHOU POWER PLANT

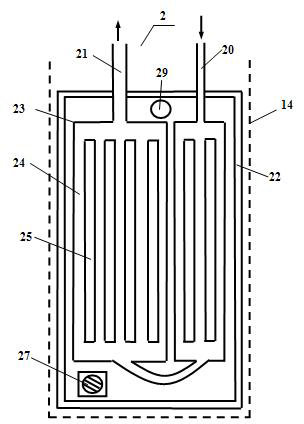

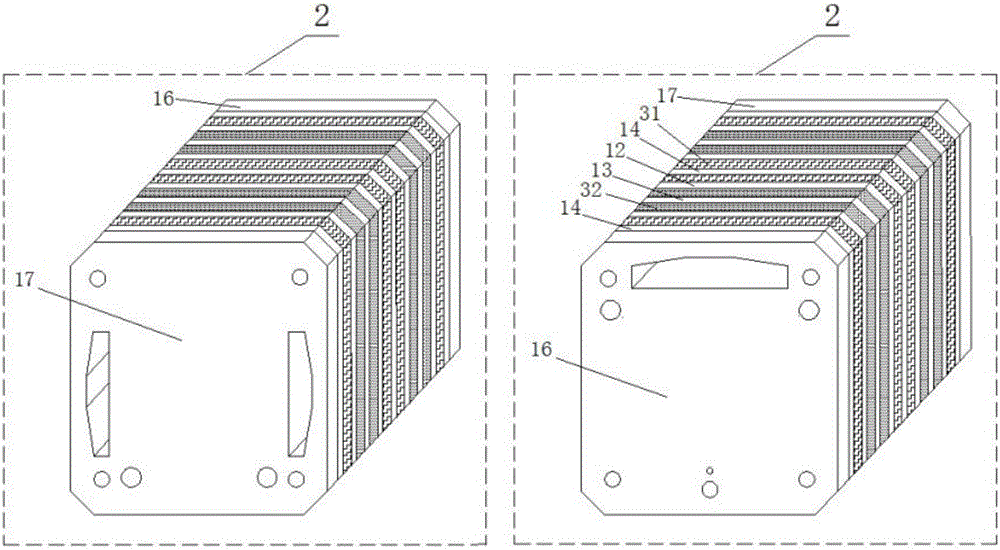

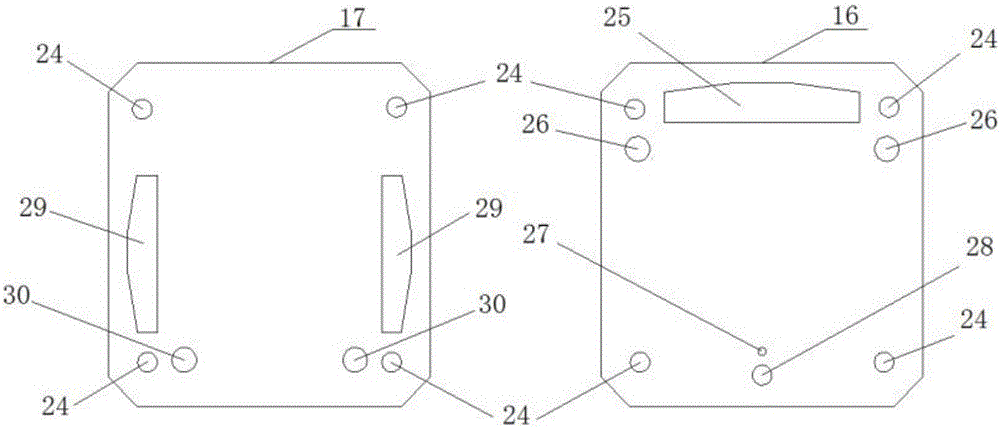

Plate-type vacuum membrane distillation evaporator and application thereof

ActiveCN106731852AStable temperatureReduce trafficGeneral water supply conservationSeawater treatmentWater desalinationComputer module

The invention relates to a plate-type vacuum membrane distillation evaporator and application thereof. The evaporator comprises a steam inlet side end plate on the left side and a steam outlet side end plate on the right side, wherein modules composed of a secondary steam channel sealing ring, a plate-type membrane frame, a feed liquid channel sealing ring, a heat exchange plate frame, a heater steam channel sealing ring, a heat exchange plate frame, a feed liquid channel sealing ring and a plate-type membrane frame are sequentially arranged and mounted between the steam inlet side end plate and the steam outlet side end plate from the left to right; and the multiple modules are sequentially connected to form a membrane stack by the secondary steam channel sealing ring. According to the application, multiple evaporators are combined into a high-efficiency and compact multiple-effect plate-type membrane distillation sea water desalination system. According to the plate-type vacuum membrane distillation evaporator and application thereof disclosed by the invention, gradient utilization ratio and thermal efficiency of membrane distillation vaporization latent heat are greatly improved, and the device has the advantages of compactness, high efficiency, high thermal efficiency, great water producing ratio and the like.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

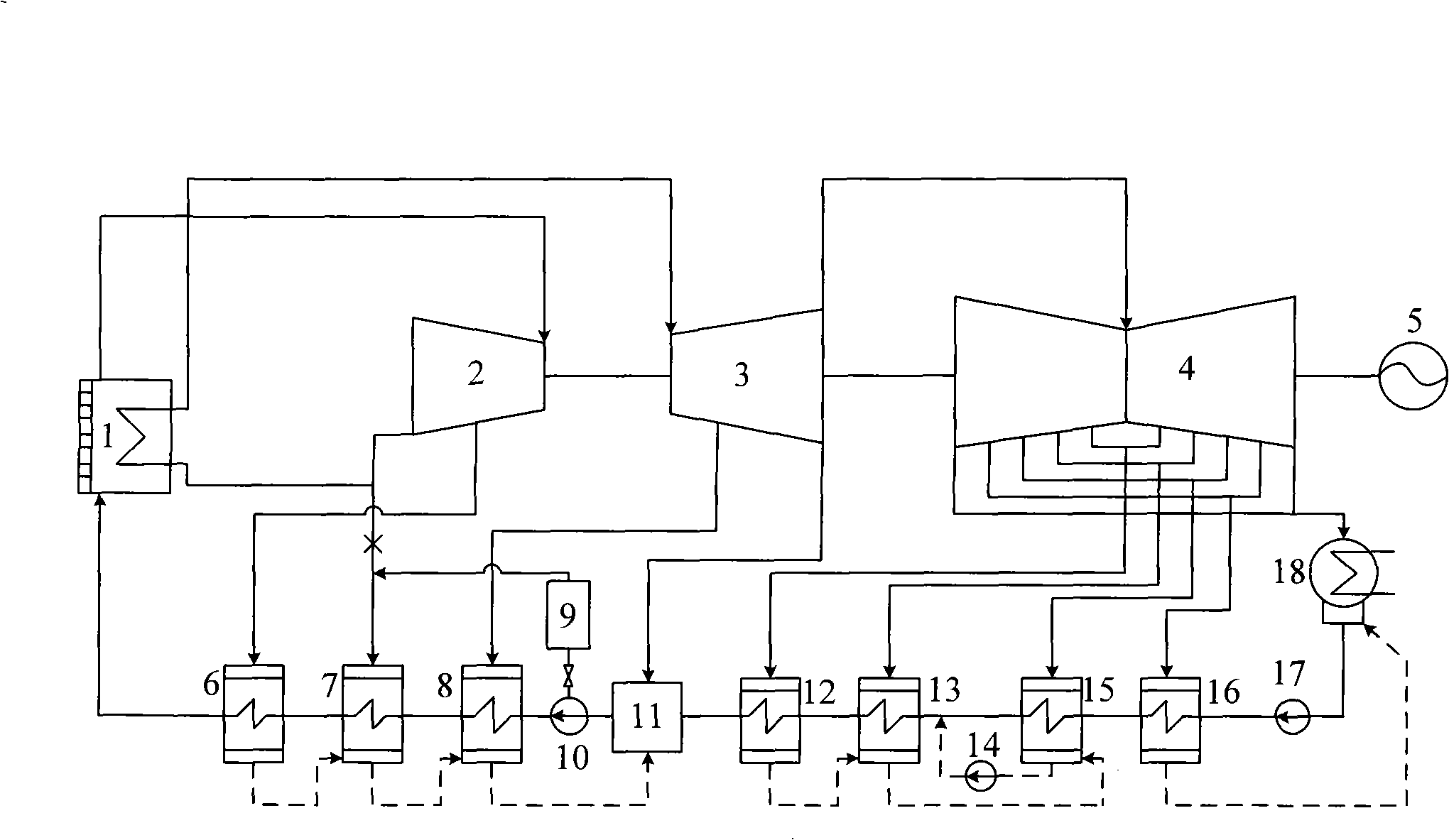

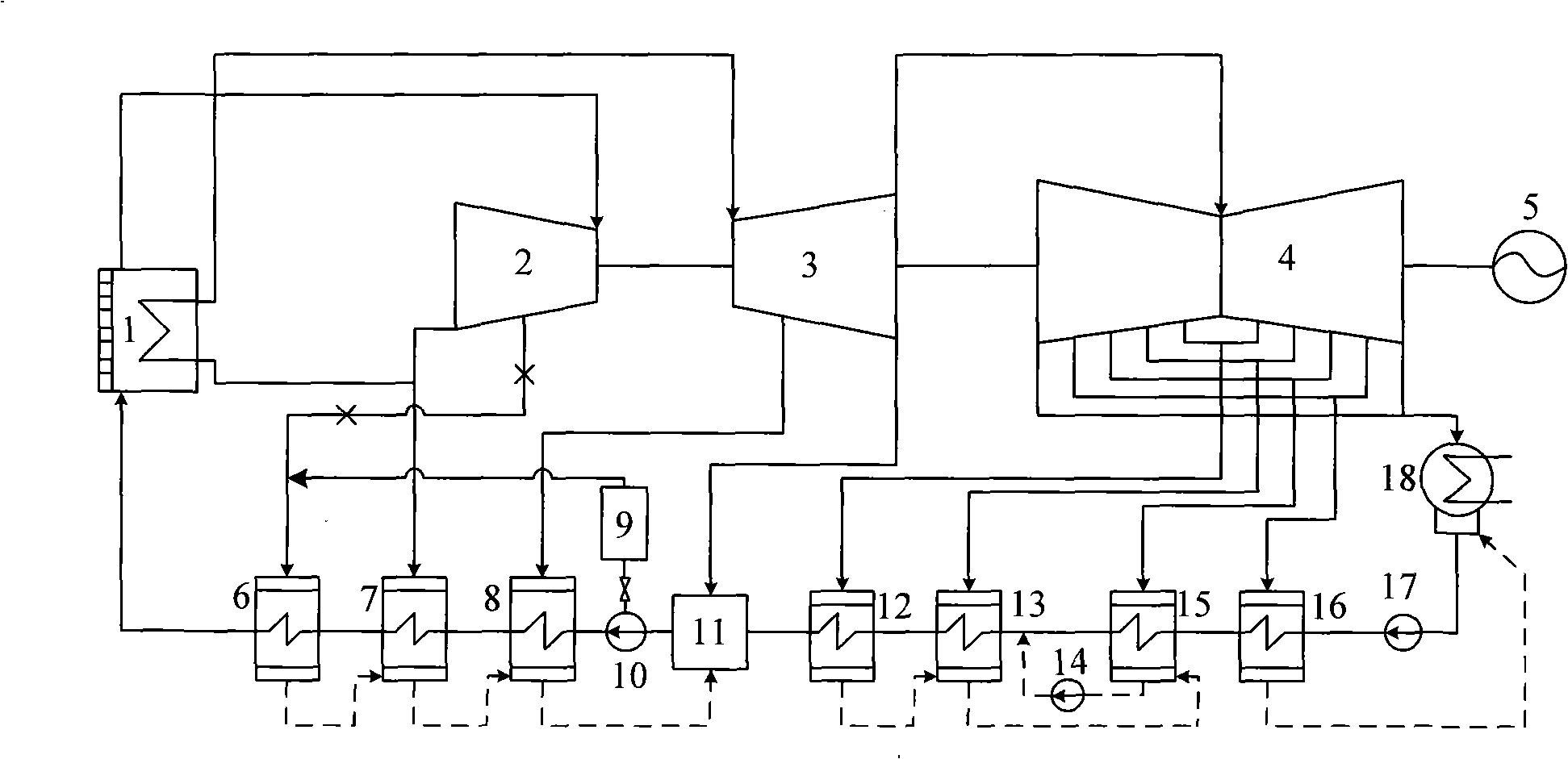

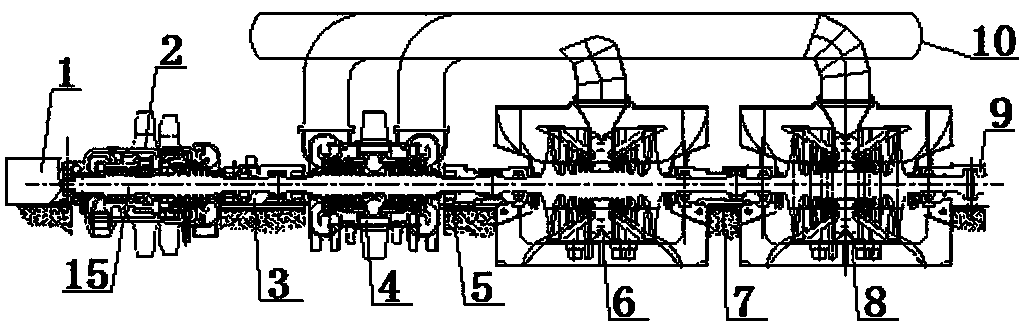

Optimum scheme of ultra-supercritical secondary reheating unit

ActiveCN104806308AIncrease output powerReduce heat consumptionSteam engine plantsUltra high pressureEngineering

The invention discloses an optimum scheme of an ultra-supercritical secondary reheating unit, and refers to a secondary reheating unit of a coal-fired power plant after optimization of a back heating system, parameter optimization of main steam, primary reheating steam, and secondary reheating steam, and structural optimization of a turbine body. The optimum scheme of the ultra-supercritical secondary reheating unit can obviously reduce the heat loss of the secondary reheating unit, and significantly decrease greenhouse gas emission and decreases cost of the ultra-supercritical secondary reheating unit obviously. By taking a 1200 MW grade unit as an example, four mono-axial cylinders are used for gas exhausting, the ultra-supercritical secondary reheating unit is composed of a single-flow ultra-high pressure cylinder capable of completely supplying water, back-heating and pumping gas, a dual-flow high and medium pressure cylinder, and two dual-flow middle and low pressure cylinders; there is no middle pressure cylinder and a middle low pressure linking pipe; no gas pumping opening is arranged on the high middle pressure cylinder and the middle low pressure cylinder; the water supply and back heating are provided by a first pump, a new second pump, a new third pump, and a new fourth pump; a ultra-low temperature coal economizer, and a heat primary wind condensing water heater replace a seventh pump, an eighth pump, a ninth pump, and a tenth pump to heat the condensed water; all low-pressure heaters are canceled.

Owner:章礼道

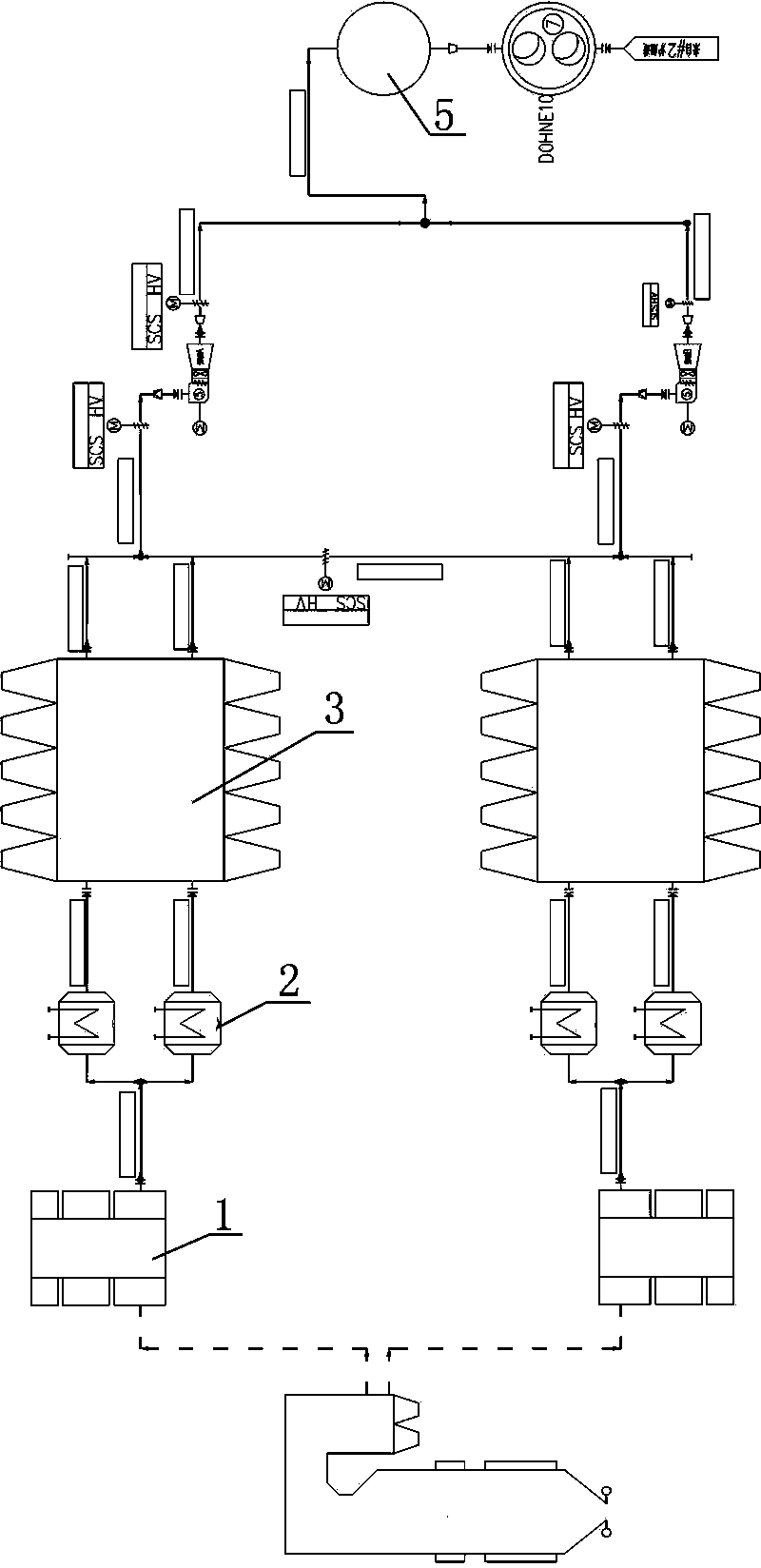

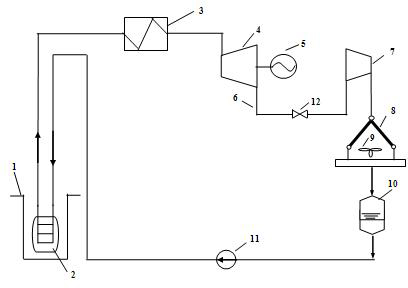

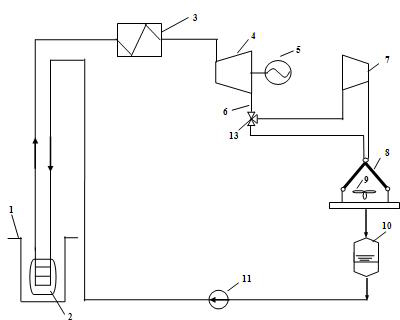

Method for continuous cooking of chemical pulp to improve heat economy

ActiveUS7112256B2Reduces and eliminates requirementImprove thermal economyDigestersPulp bleachingCelluloseBlack liquor

A method for the continuous cooking of chemical pulp with the aim of achieving improved heat economy in a digester system having a vessel (1) for impregnation and a vessel (2) for cooking the impregnated cellulose chips. A part of the black liquor (14) withdrawn from the digester (2) is added at the beginning of a transfer system (4) to increase the temperature of the chips mixture in the transfer system (4). A fraction of the transport fluid (10) from the transfer system (4) that is continuously withdrawn from the impregnated chips fed into the top of the digester is returned to the impregnation vessel (1) at essentially the maintained transfer temperature.

Owner:METABO PAPER SWEDEN

Heat engine plant A335P92 steel welding technique

ActiveCN101357413AImprove thermal efficiencyImprove thermal economyArc welding apparatusShielded metal arc weldingEngineering

The invention discloses a technology for welding A335P92 steel in a heat-engine plant, wherein, welding material adopted is Thyssen welding material or Oerlikon welding material, and welding method is manual arc welding or submerged arc automatic welding. The welding technology adopted is that: when the manual arc welding is adopted, Phi 3.2 welding rods are used for welding with the total of 15 layers and 76 passes and the average thickness of each welding deposit is 2.0mm; when the submerged arc automatic welding is adopted, Phi 3.0 welding rods are adopted for welding with the total of 10 layers and 16 passes and the average thickness of each welding deposit is 3.0mm; the tempering parameter value of heat treatment on welding positions ranges from 21.3 to 21.6.

Owner:HUADIAN HEAVY IND CO LTD

Compressed air energy storage system

InactiveCN103727011AEnsure safety and stabilityPrevent alternating hot and coldPump installationsPositive-displacement liquid enginesAir compressionThermal energy storage

The invention discloses a compressed air energy storage system which comprises a motor, an air compression unit connected with the motor, an air storage chamber storing compressed air and a temperature controller controlling the temperature inside the air storage chamber. A water atomizing and spraying mechanism used for keeping the temperature inside the air storage chamber stable and a temperature sensor used for measuring the temperature inside the air storage chamber. The air compression unit is used for sucking in air, and after the air is compressed, the air compression unit delivers the compressed air to the air storage chamber through an air channel to be stored. The temperature controller is connected with the temperature sensor so as to receive signals of the temperature sensor. The temperature controller is arranged in a pipeline connected with the water atomizing and spraying mechanism so as to control the work state of the water atomizing and spraying mechanism according to the signals, guarantee that the temperature of the air inside the air storage chamber is kept in a relatively stable temperature interval all the time, prevent frequent alternation of heat and cold of the inner wall of the air storage chamber and guarantee that the air storage chamber is safe and stable.

Owner:TSINGHUA UNIV +1

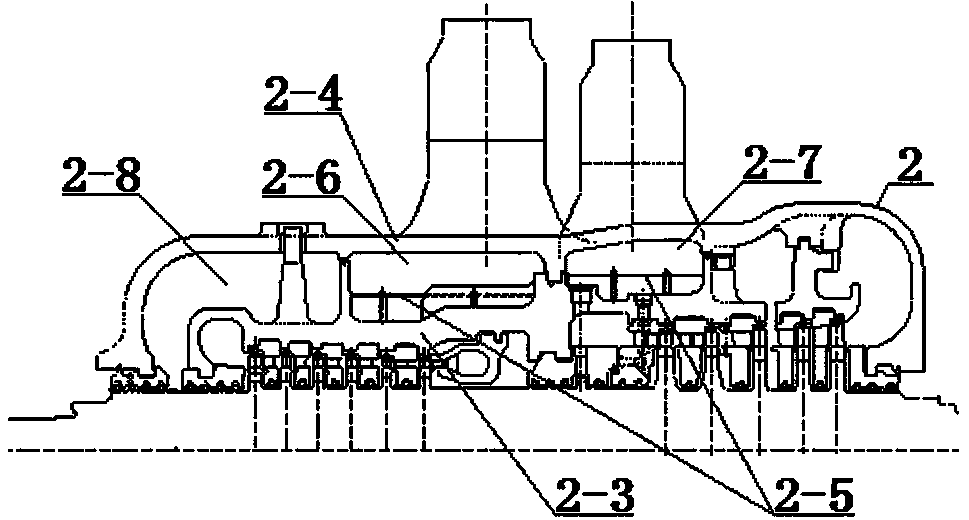

Ultra-supercritical secondary re-heating steam turbine set

InactiveCN103670550ADoes not affect safety and reliabilityDoes not affect runnabilityEngine componentsSteam engine plantsUltra high pressureEngineering

The invention discloses an ultra-supercritical secondary re-heating steam turbine set. The ultra-supercritical secondary re-heating steam turbine set comprises a first bearing box, an ultra high pressure-high pressure cylinder, a second bearing box, a medium-pressure cylinder, a third bearing box, a first low-pressure cylinder, a fourth bearing box, a second low-pressure cylinder and a turning gear box which are assembled on a rotor in sequence. The capacity of the steam turbine set is 1000-1300MW, the ultra high pressure-high pressure cylinder is of a cylinder combined structure, the pressure of a steam inlet of an ultra high pressure part is 30-35MPa, the temperature is 600 DEG C, the pressure of a primary re-heating steam inlet of a high pressure part is 10MPa, the temperature is 610-630 DEG C, the medium-pressure cylinder, the first low-pressure cylinder and the second low-pressure cylinder are respectively of a double-flow-division structure, the medium-pressure cylinder provides steam for the first low-pressure cylinder and the second low-pressure cylinder respectively through communication pipes, the pressure of a secondary re-heating steam inlet of the medium-pressure cylinder is 2.8MPa, and the temperature is 610-630 DEG C. The ultra-supercritical secondary re-heating steam turbine set has the advantages of being large in capacity, high in parameter, small in occupied space, low in investment cost, stable and reliable in operation and obvious in economical benefit, saving energy, reducing consumption and the like.

Owner:DONGFANG TURBINE CO LTD

Heat supply system of high-back-pressure double-rotor electric heating unit

PendingCN107202355AMeet the output requirementsImprove thermal economyLighting and heating apparatusSteam useSteam pressureEngineering

The invention relates to a heat supply system of a high-back-pressure double-rotor electric heating unit. In the heating period in winter, a turbine unit operates at a high back pressure, a condenser is used as a basic heating network heater of the heat supply system, latent heat of vaporization of exhaust steam of a low-pressure cylinder of the unit heats heating network circulating water once, and the temperature of a heating network circulating water outlet of an outlet of the condenser reaches the difference between a saturated steam temperature corresponding to the exhaust steam pressure of the low-pressure cylinder under the working condition and the terminal temperature difference of the condenser; a turbine unit heating network heater is used as a peak load heater to conduct secondary heating on the heating network circulating water existing after dead steam conducts primary heating, and the temperature of the heating network circulating water is raised to a heat supply temperature value designed by the heat supply system.

Owner:DATANG DONGBEI ELECTRIC POWER TESTING & RES INST

Matching method of supercritical secondary reheating unit reheater and thermal system

The invention belongs to the field of large supercritical secondary reheating thermal power generating units, and relates to a method capable making a heat exchange area needed by secondary reheating and a thermal system matched, in particular to a matching method of a supercritical secondary reheating unit reheater and the thermal system. According to the scheme, the heated face needed by the reheater is reduced, reasonable match between the reheater and the thermal system is achieved, exhausted steam of a water pump turbine is absorbed through a hybrid heater, the heat exchange area is reduced, and initial investment of a power plant is reduced. Heat for pumping steam of the water pump turbine can be finally recycled to the thermal system, and economical performance of the power plant is improved. Therefore, according to the scheme, the method is favorable for reducing the initial investment of the power plant and improving operating benefits of the power plant.

Owner:GUODIAN SCI & TECH RES INST +1

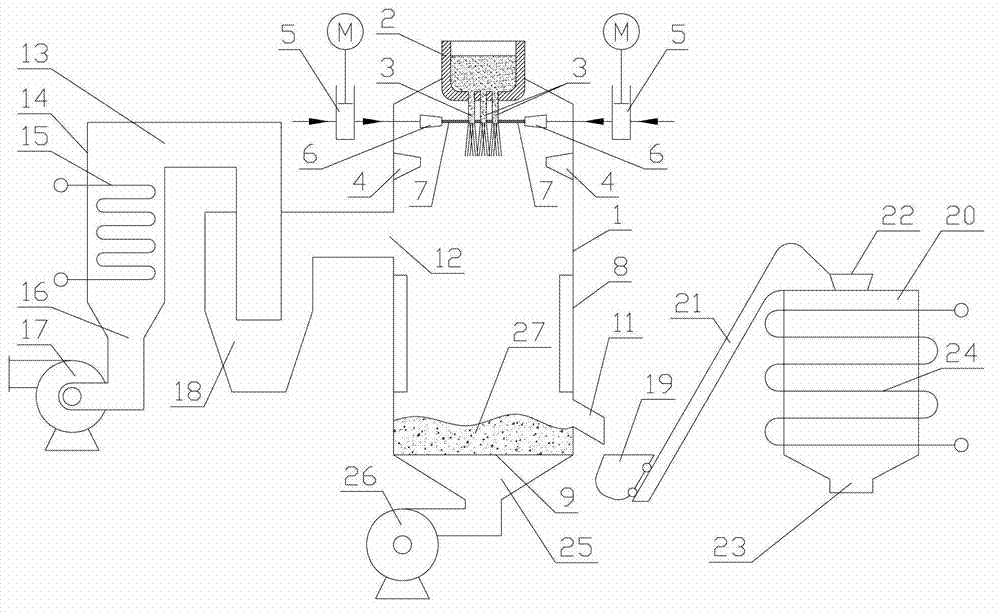

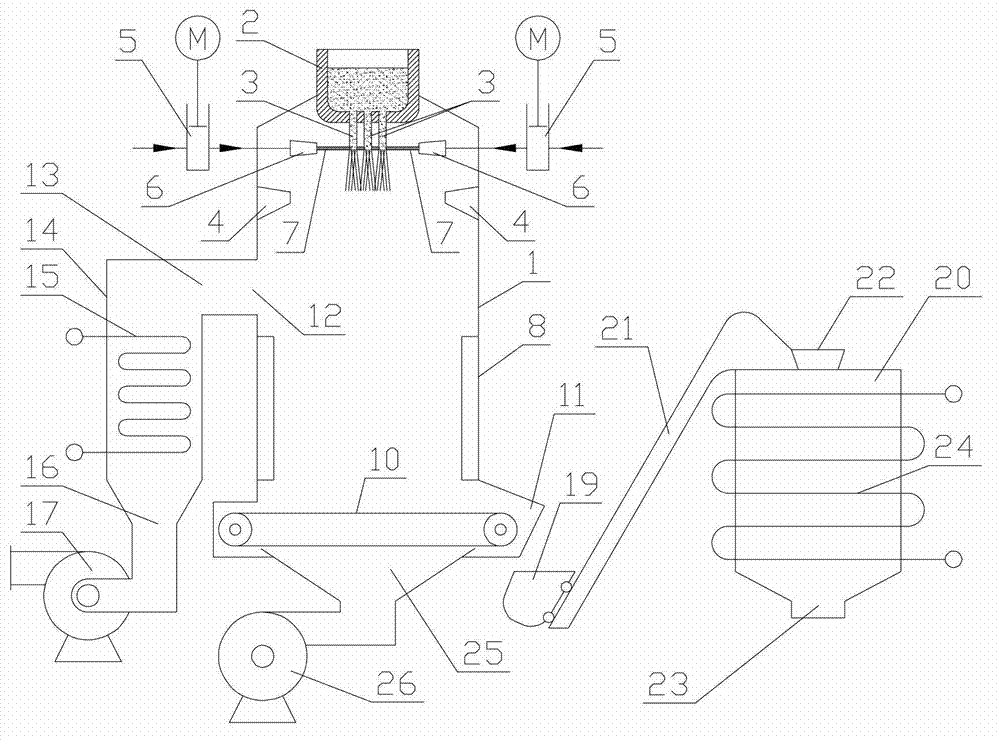

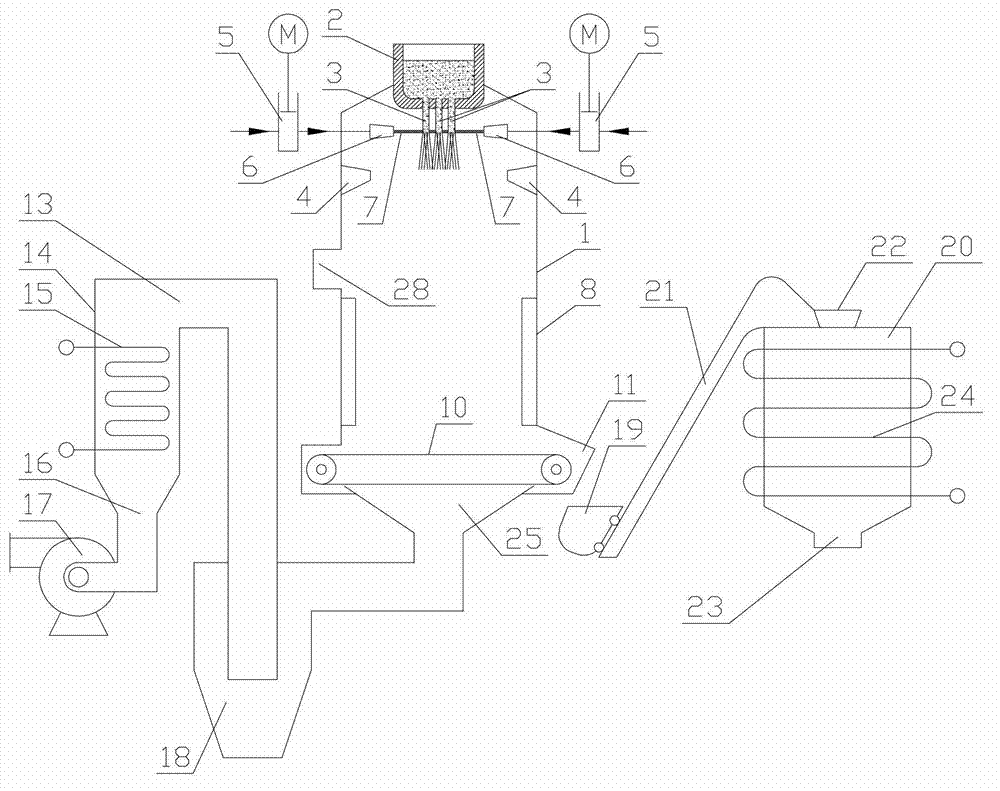

Method and system for molten slag granulation and sensible heat recovery

ActiveCN102864254AStrong impactGood penetrationProcess efficiency improvementIndustrial wasteWater jet

The invention discloses a method and a system for molten slag granulation and sensible heat recovery, and belongs to the technical field of industrial waste residue treatment and utilization. The method comprises the following steps of: pressurizing water, and injecting water from a nozzle to form a columnar high-speed water jet flow; impacting multiple strands of columnar molten slag flows on the same row in sequence; breaking the molten slag; in the falling process, cooing the broken molten slag by a water cooling wall; recovering parts of sensible heat; then, falling into the bed layer of a fluidized bed or a travelling grate to be cooled by air entering from outside, completely solidifying the molten slag to finish granulation and obtain hot air; sending hot air obtained on the fluidized bed or the travelling grate into a waste heat boiler to recover heat; and sending solidified molten slag particles output out of the fluidized bed or the travelling grate into a moving bed for further recovering the sensible heat. The molten slag can be broken by the high-speed water flow, the breaking and flying effect of the method is good, a slag wool generation amount is small, slag wool is easy to process because the slag wool contains water, the operation energy consumption and the water consumption of the slag wool are low, and therefore the sensible heat recovery of the molten slag can be favorably carried out.

Owner:TSINGHUA UNIV

Process for capturing carbon dioxide in flue gas based on wet reclamation technology

The invention discloses a process for capturing carbon dioxide in flue gas based on the wet reclamation technology. The process comprises pretreatment, adsorption treatment, washing displacement treatment, water spraying desorption treatment, product air purging treatment, displacement air purging treatment and drying reclamation treatment. A method for efficient and low-cost adsorption separation of high-purity carbon dioxide based on the wet reclamation technology by adopting a functional ion exchange resin membrane material through organic integration with a thermodynamic system of a power plant is provided by the invention.

Owner:ZHEJIANG UNIV

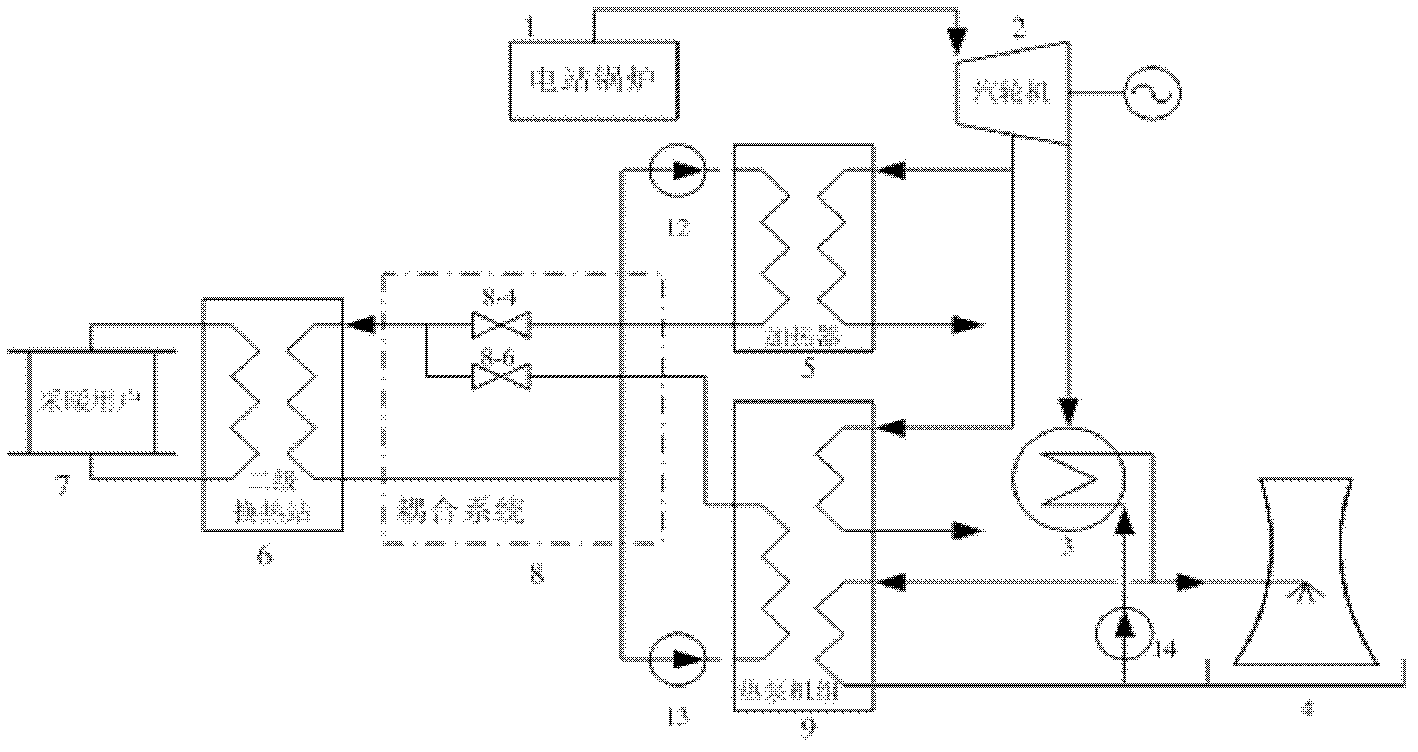

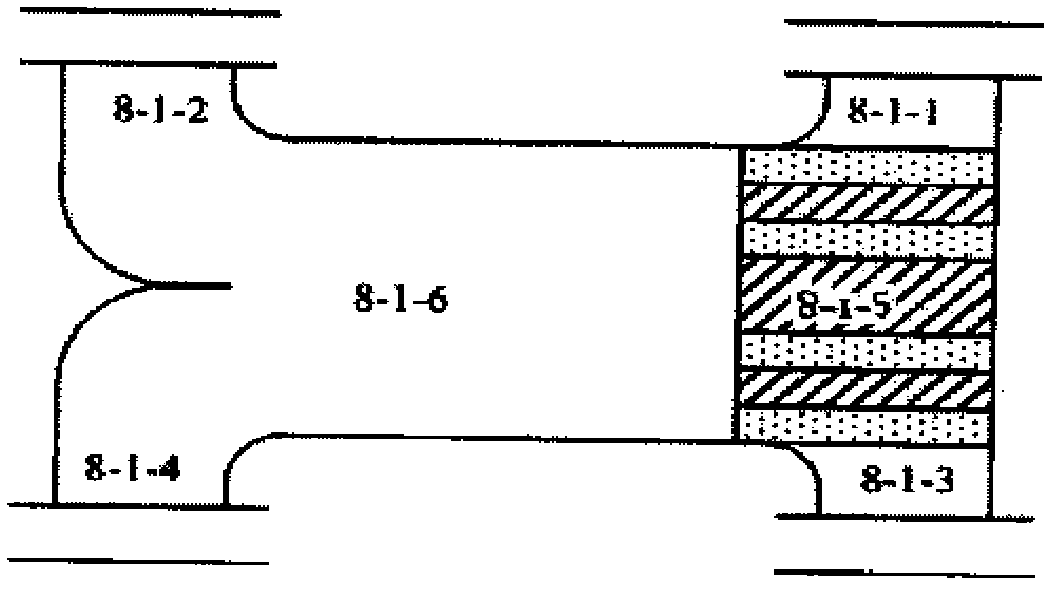

Molten salt electrode boiler heat storage and power generation system

InactiveCN111288428AAchieve large-scale storageImplement schedulingHeat storage plantsEnergy storageElectric powerBoiler (power generation)

The invention provides a molten salt electrode boiler heat storage and power generation system, and belongs to the field of energy storage. The system involves a heating part, a high-temperature molten salt storage tank and a heat utilization part; the heating part comprises a boiler body, a high-voltage electrode, a neutral electrode and a low-temperature molten salt supply head, wherein the high-voltage electrode, the neutral electrode and the low-temperature molten salt supply head are arranged in the boiler body, the high-voltage electrode is used for being connected with a power generation system, and the low-temperature molten salt supply head is used for filling the boiler body with low-temperature molten salt; one end of the high-temperature molten salt storage tank is connected with the bottom of the boiler body, and the other end of the high-temperature molten salt storage tank is connected with the heat utilization part; and the heat utilization part is used for carrying outheat exchange on the molten salt sent out by the high-temperature molten salt storage tank and a water working medium for pushing the steam turbine to act, and sending the cooled molten salt back tothe boiler body. Wind power photovoltaic curtailed electricity is used for heating the molten salt and storing heat in the off-peak period of electricity utilization, and high-temperature molten saltis used for heating feed water to generate high-temperature and high-pressure steam in the peak period of electricity utilization, so that the steam turbine is pushed to act, he stored heat is converted into electric energy to be output, and the curtailed wind and light can be effectively consumed to realize large-scale storage and scheduling of non-water renewable energy power.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

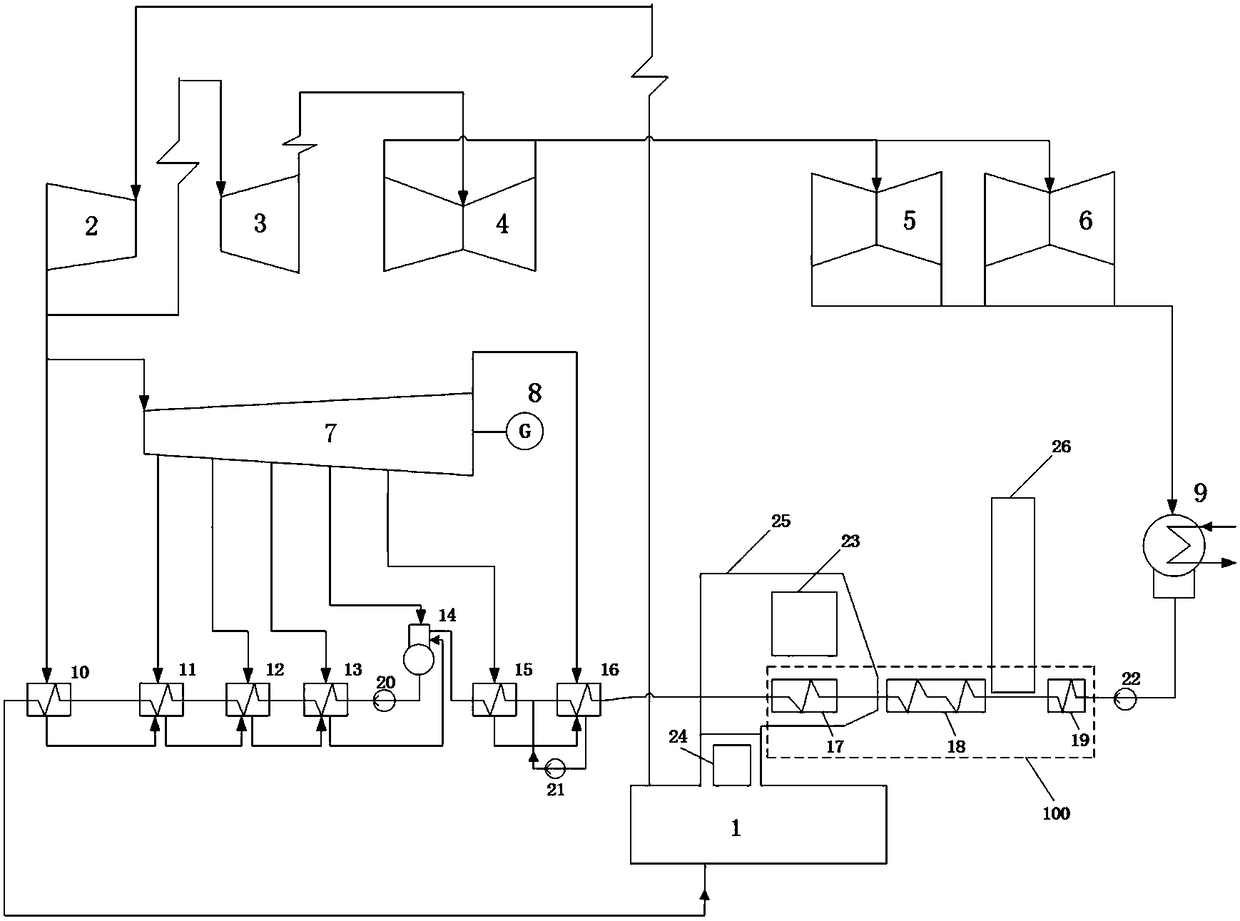

Secondary reheating system and method achieving efficient regeneration and steam exhaust optimization

The invention discloses a secondary reheating system and method achieving efficient regeneration and steam exhaust optimization, and relates to the field of thermal power generation. The system mainlycomprises a boiler, a regeneration steam turbine and a waste heat recovery system, wherein the waste heat recovery system replacing a traditional low-pressure heater is arranged between a condensatewater pump and feedwater of a seventh-stage low-pressure heater, condensate water is preliminarily heated by the waste heat recovery system through flue gas of the boiler and pipeline leaking steam ofthe regeneration steam turbine, and the waste heat recovery system is composed of a flue gas cooler, a low-temperature coal economizer and a sealing heater. The flue gas cooler, the low-temperature coal economizer and the sealing heater replace the traditional low-pressure heater to heat the feedwater, and steam exhaust energy losses of the steam turbine are reduced while heat of the boiler is recovered. The arrangement of a unit is optimized as a whole, efficient regeneration is further enhanced, and the complexity of the system is lowered. The coal consumption can be reduced by 2 g / kW.h to3 g / kW.h while the power supply efficiency of a traditional 1,000 MW secondary reheating unit is improved by 0.2% to 0.3%.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Part control phase change air preheating system and air preheating method

InactiveCN103115377AImprove securityImprove adaptabilityCombustion processIndirect carbon-dioxide mitigationAir preheaterEngineering

The invention relates to a part control phase change air preheating system and an air preheating method. The part control phase change air preheating system and the air preheating method well solve the coupling problem of traditional air preheater low temperature corrosion and heat efficiency, an operating method of the air preheating system can be timely adjusted according to actual operation parameters, adjusting capability is greatly increased, and not only is economy and high efficiency of a thermal circulation system guaranteed, but also security and adaptability of the air preheating system can be improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Deslagging waste heat utilization device for circulating fluidized bed boiler

PendingCN105588107AObvious cooling effectSolve thermal deformationFluidized bed combustionApparatus for fluidised bed combustionSlagCirculating fluidized bed boiler

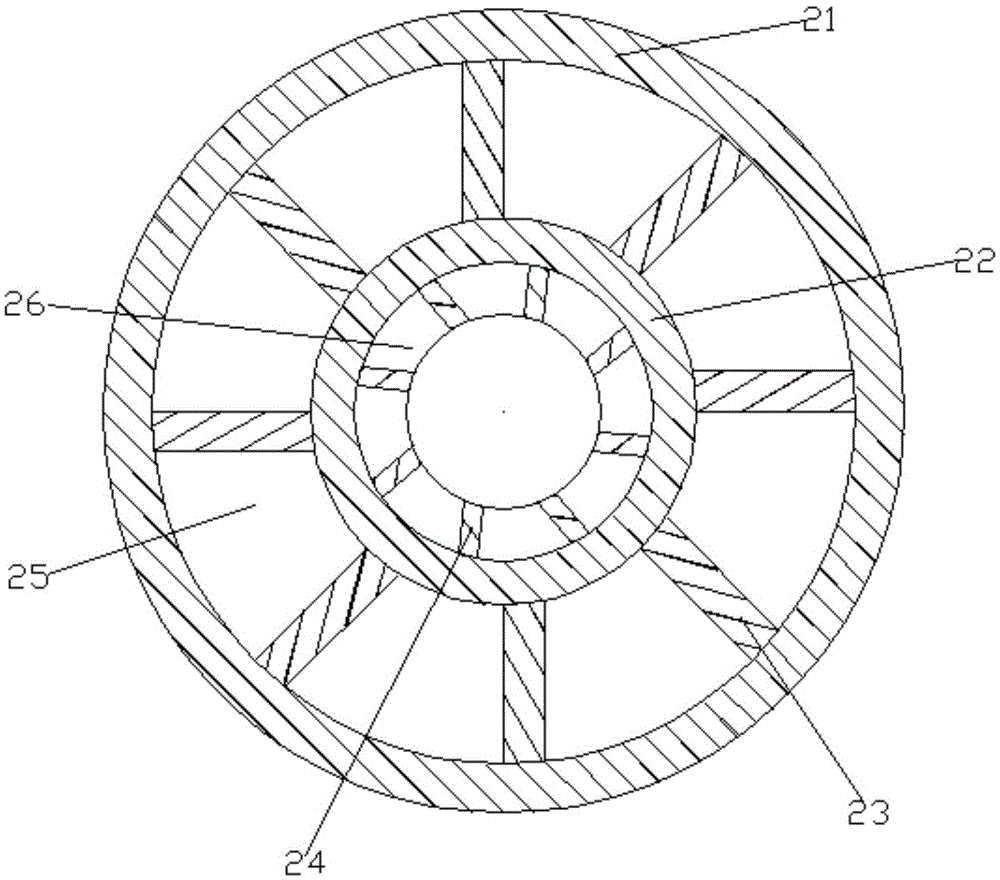

The invention discloses a deslagging waste heat utilization device for a circulating fluidized bed boiler. By the adoption of the deslagging waste heat utilization device for the circulating fluidized bed boiler, the situations that heat deformation of a deslagging pipe is caused, and leakage is also caused due to the fact that an inner pipe is abraded by bottom slag are prevented. The deslagging waste heat utilization device for the circulating fluidized bed boiler comprises a deslagging hole, a deslagging connector, a collection header, a deslagging heat exchange pipe, a plurality of reinforcing ribbed plates, a distribution header, a cooling water inlet pipe, a cooling water outlet pipe, a three-dimensional expansion joint, a cooling air inlet, the deslagging pipe, a manual gate valve, an electric gate valve, an accident deslagging pipe, an underpant-shaped tee joint, an outer pipe, the inner pipe, a plurality of guide plates, pins and guide cavities. The deslagging connector is in a cone shape. The upper end opening of the deslagging connector is connected with the boiler deslagging hole, and the lower end opening of the deslagging connector is connected with the upper end of the collection header. An annular cavity is formed by the deslagging heat exchange pipe by concentrically sleeving the small-diameter inner pipe with the large-diameter outer pipe. The guide plates with the same width are welded between the wall of the inner pipe and the wall of the outer pipe, and the annular cavity is equally divided into the guide cavities not communicating with one another in the circumferential direction by the guide plates. The annular reinforcing ribbed plates which can prevent the deslagging heat exchange pipe against heating expansion and deformation are arranged on the outer wall surface of the outer pipe of the deslagging heat exchange pipe.

Owner:SHANXI GUOFENG COAL POWER CO LTD +1

Method and Apparatus for Reducing the Amount of Sludge Produced in a Pulp and/or Paper Mill

InactiveUS20070221346A1Reduce the amount requiredReduce processing loadSludge treatment by de-watering/drying/thickeningPulp liquors combustionSolid fuelPulp and paper industry

The amount of sludges produced in a pulp and / or paper mill is reduced. The sludge produced in a pulp and / or paper mill as a result of waste water treatment is conveyed to solid fuel and the produced fuel-sludge mixture is burned in a power boiler. The solid fuel is heated before sludge is mixed therein.

Owner:VALMET TECH INC

System and method of waste heat utilization of indirect cooling tower circulating water in integrated absorption heat pump

InactiveCN108981222AReduce high back pressureFlexible operationHeat recovery systemsClimate change adaptationAridCooling tower

The invention discloses a system and a method of waste heat utilization of an indirect cooling tower circulating water in an integrated absorption heat pump. The system and the method are mainly applied to an indirect air-cooling coal-fired unit in an arid and water-deficient area of China; the system comprises an turbine, an absorption heat pump and an indirect cooling tower, wherein a main turbine extracts steam to drive the absorption heat pump, an evaporator of the absorption heat pump takes away part of circulating water heat, so as to achieve the effect of reducing the backpressure of the indirect air-cooling coal-fired unit especially in summer high-temperature strong wind weather; condensed water enters an absorber and a condenser of the absorption heat pump to absorb heat, and heat recovery is achieved. By adopting the system, the circulating water temperature can be effectively reduced, and the purpose of reducing the back pressure of the indirect air-cooling coal-fired unitis achieved; and a calculation result shows that the coal consumption of a 660 MW unit can be reduced by 8 g / kWh or above by adopting the system and the method, and relatively high energy-saving and social benefits are achieved.

Owner:XI AN JIAOTONG UNIV

Photovoltaic and photo-thermal coupled thermoelectric generation system and method

InactiveCN107061201AReduce heat collecting areaImprove thermal efficiencySolar heating energyFrom solar energyOrganic Rankine cycleCogeneration

The invention belongs to the field of solar energy utilization, and particularly relates to a photovoltaic and photo-thermal coupled thermoelectric generation system and method. The system consists of a heat collection subsystem, a power generation subsystem and a heat supply subsystem which are connected in series, wherein the heat collection subsystem comprises a photovoltaic and photoelectric integrated assembly and a compound parabolic heat collector; the power generation subsystem consists of an expansion machine, a power generator, a heat exchanger, a condenser, a liquid storage tank and a working medium pump which are connected in series; and the heat supply subsystem consists of a heat exchanger and a heat consumer. According to the photovoltaic and photo-thermal coupled thermoelectric generation system disclosed by the invention, photovoltaic power generation and low temperature photo-thermal organic Rankine cycle power generation are combined, and a working medium is preheated through heat generated by photovoltaic power generation, so that the unit electrical work heat collection area is reduced, and power generation and heat supply are realized simultaneously. Therefore, photovoltaic and photo-thermal coupled thermoelectric generation system can fully make use of solar resources and realize 'parallel temperature and gradient utilization', and the heat efficiency and the economy of the whole system are improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

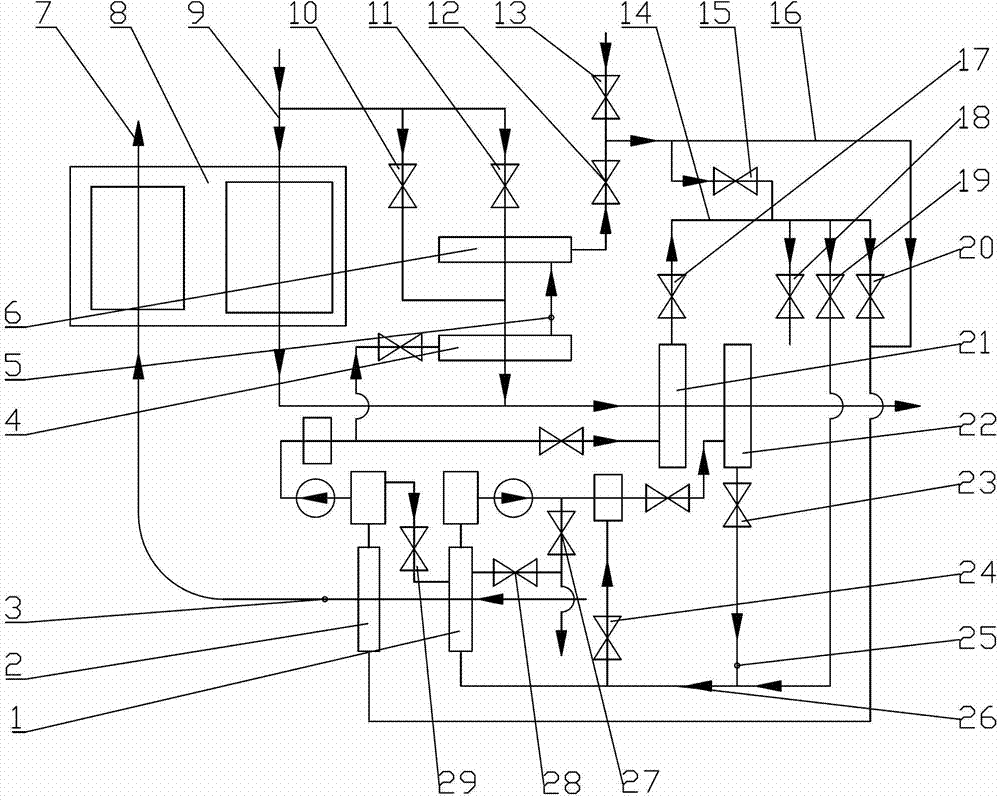

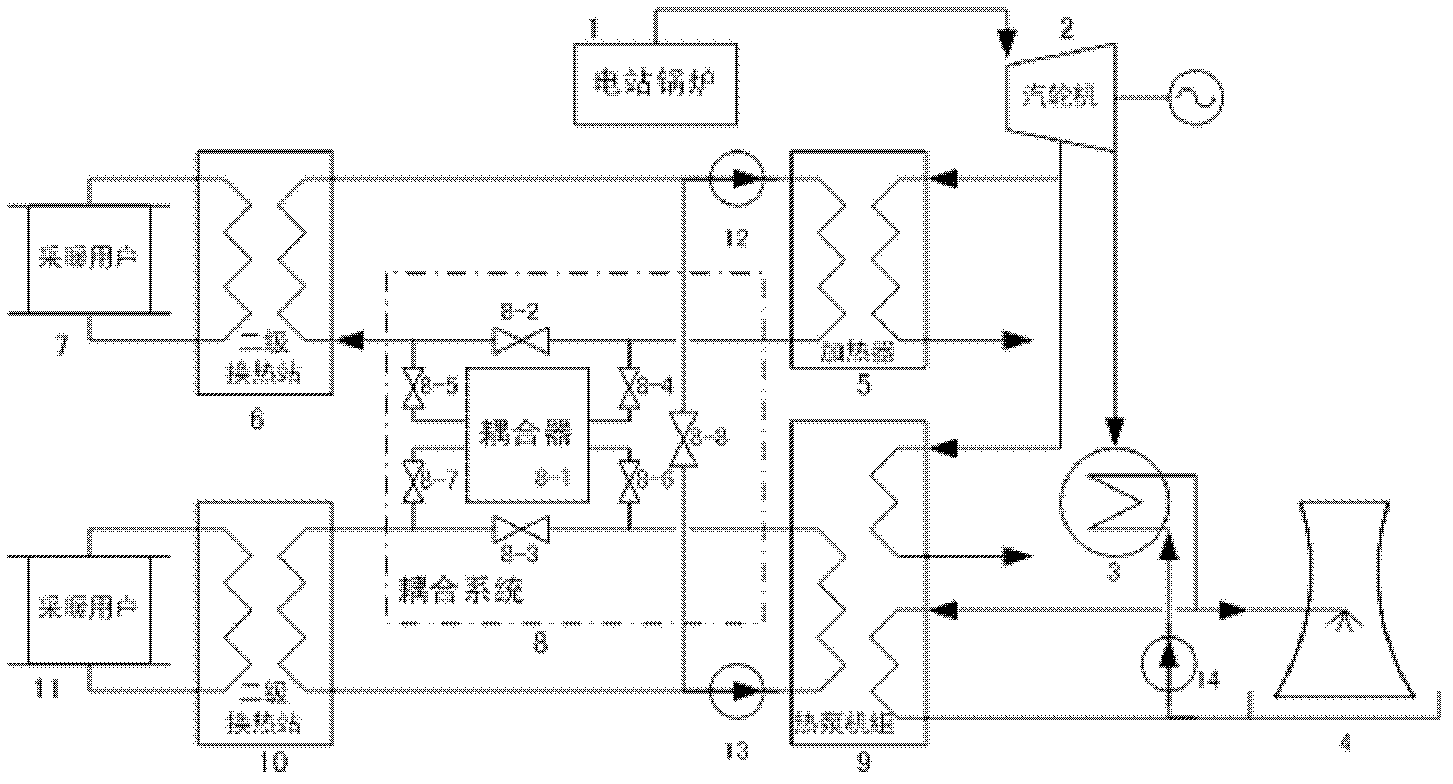

Energy-saving heat pump and co-generation coupled heating system and coupled heating method

InactiveCN102589035AMeet regulatory requirementsImprove thermal economyLighting and heating apparatusSpace heating and ventilation detailsCogenerationEngineering

The invention discloses an energy-saving heat pump and a co-generation coupled heating system and a coupled heating method, belonging to the field of energy sources. The system is composed of a steam turbine, a steam-turbine condensing plant, steam-turbine circulation cooling equipment, a steam-absorption heat pump, a heat network heater, a coupler, a heat-exchange station, corresponding pipelines and accessory equipment. The system utilizes the heat pump and the co-generation heat network heater to heat circulating water of a heat network, the heat pump uses circulating cooling water of a generating plant as a low-temperature heat source, the extracted steam of the steam turbine is utilized as a driving heat source, and the heat of the circulating cooling water is extracted to heat the circulating water of the heat network. The water yield and temperature of water from the heat pump and water from the heat network heater are distributed and adjusted through the coupler, and the heating temperature and the rate of flow in a full heating season are qualified. According to the method, a peak heater is cancelled, so the occupied area and the investment are reduced. The heat pump can have basic heat load, the residual heat is extracted to the maximum extent, the heating capacity is increased, the economical efficiency of the heat pump is maximized, and the purposes of energy saving and emission reduction are achieved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Reheat steam temperature control system and method and thermal power generating unit device

InactiveCN105020697AGuaranteed safe operationImprove thermal economySuperheating controlTesting/monitoring control systemsControl systemComputer module

The invention discloses a reheat steam temperature control system and method and a thermal power generating unit device. The reheat steam temperature control system comprises a first function module, a first addition module, an addition and subtraction module, a first adjusting module, a third addition module, a minus selection module and a first operation module. The input end of the first addition module is connected with the output end of a first fixed value module. The input end of the third addition module is connected with the output end of a second function module. The output end of the addition and subtraction module is sequentially connected with a second addition module, a second adjusting module, a fourth addition module and a second operation module. The input end of the second addition module is connected with the output end of a second fixed value module. The input end of the fourth addition module is connected with the output end of a fourth function module. A single-loop PI adjustment mode is adopted, the burner port pendulum angle adjustment serves as the main part, the attemperation water spraying serves as the auxiliary part, and accordingly the reheat steam temperature can be adjusted by changing the inclination angle of a burner port; and safety running of a unit is guaranteed, and the heat economy of the unit is improved.

Owner:ELECTRIC POWER RES INST STATE GRID SHANXI ELECTRIC POWER

Air temperature adjusting system

InactiveCN103233821AGreat effortEnsure the amount of smokeTurbine/propulsion engine coolingCombined combustion mitigationAtmospheric airEngineering

The invention discloses an air temperature adjusting system which comprises an air heat exchanger (1). A hot side air inlet pipe of the air heat exchanger (1) is communicated with air, a hot side air outlet pipe of the air heat exchanger (1) is connected with an air compressor (8), and a cold side water inlet and a cold side water outlet of the air heat exchanger (1) are communicated with a cold water inlet and a backwater opening of a steam absorption refrigerator (2) by pipelines respectively. A hot source steam inlet of the steam absorption refrigerator (2) is connected with a waste heat boiler low-pressure steam collecting box (5). A hot source condensation water outlet of the steam absorption refrigerator (2) is connected with a waste heat boiler condensation water inlet (d) of a waste heat boiler (7). The system disclosed by the invention has the advantages of simplicity, low investment and low operation and maintenance cost and can be widely applied to a gas-steam combined cycle power generation technique.

Owner:CISDI ENG CO LTD

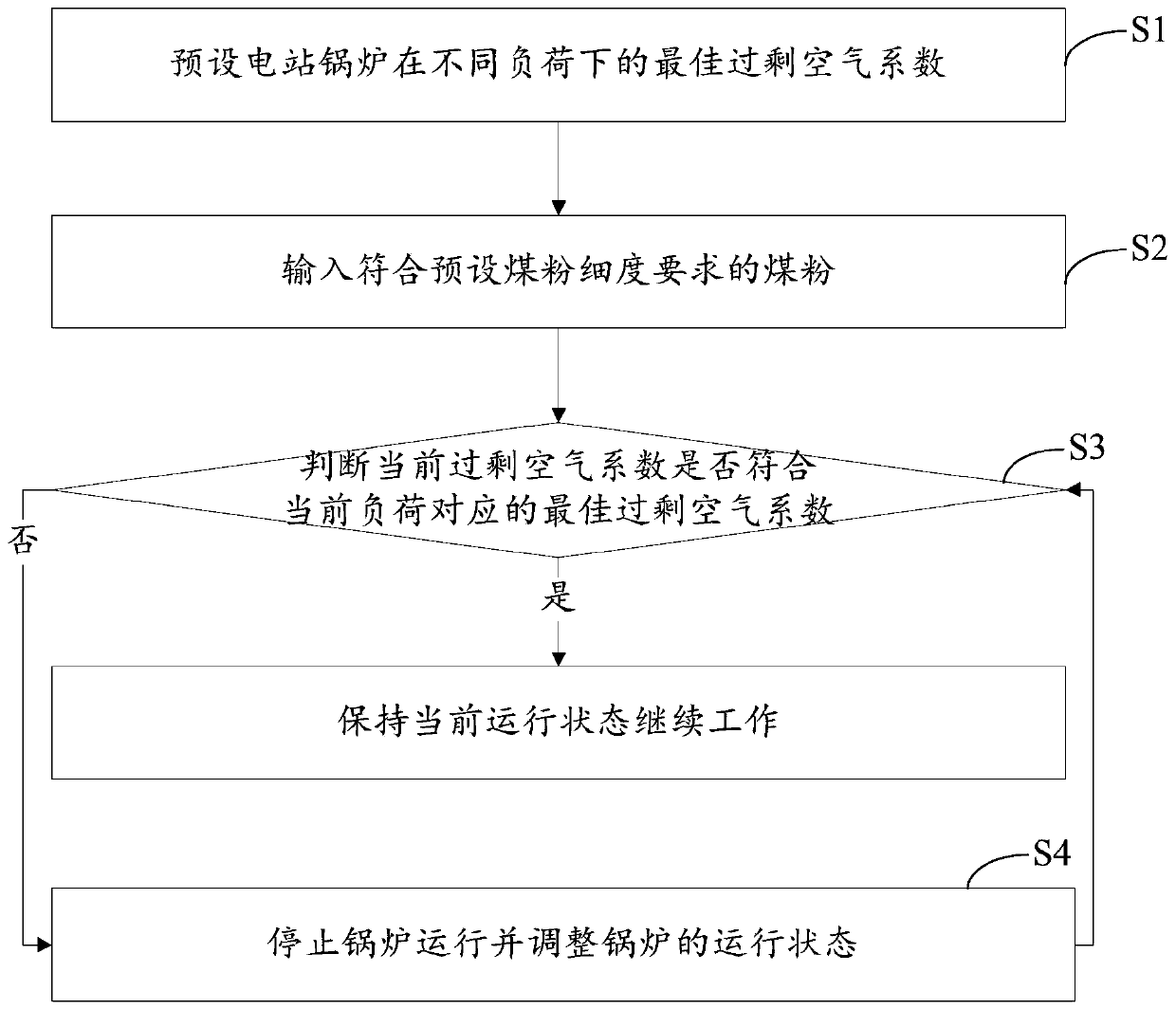

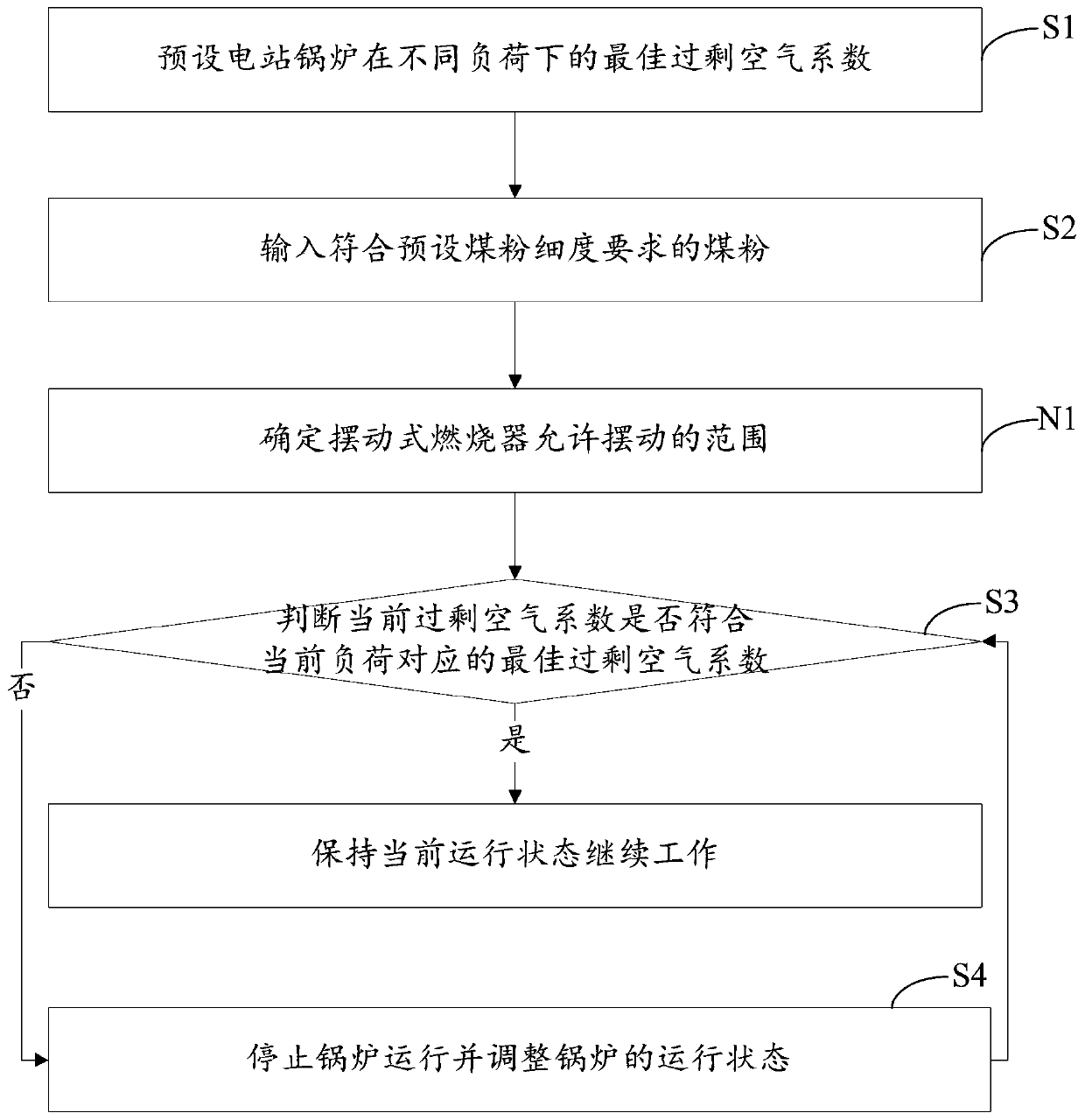

Method and device capable of preventing power station boiler slagging

ActiveCN109855113AAvoid cokingIncrease coal consumptionCombustion regulationLump/pulverulent fuel preparationCurrent loadLoop control

The invention discloses a method and device capable of preventing power station boiler slagging. The method capable of preventing power station boiler slagging comprises the steps of S1, presetting optimal excess air coefficients of a power station boiler under different loads; S2, inputting pulverized coal l meeting the preset pulverized coal fineness need; S3, judging whether the current excessair coefficient meets the optimal excess air coefficient corresponding to the current load in the power station boiler running process, if yes, continuing work with the current running state, and if not, the S4 is executed; S4, stopping boiler running, and adjusting the running state of the boiler, starting the power station boiler and executing the S3. Generation of boiler coking can be prevented, heat transfer resistance of the boiler heating face is reduced, coal consumption is reduced, the boiler heat economy is improved, meanwhile, through online analysis of the change tendency of the outlet pulverized coal finenesses of a coal grinding machine, the pulverized coal fineness is subjected to closed-loop control within the preset range, and pulverized coal fineness and uniformity stableoutput is achieved.

Owner:XINAO SHUNENG TECH CO LTD

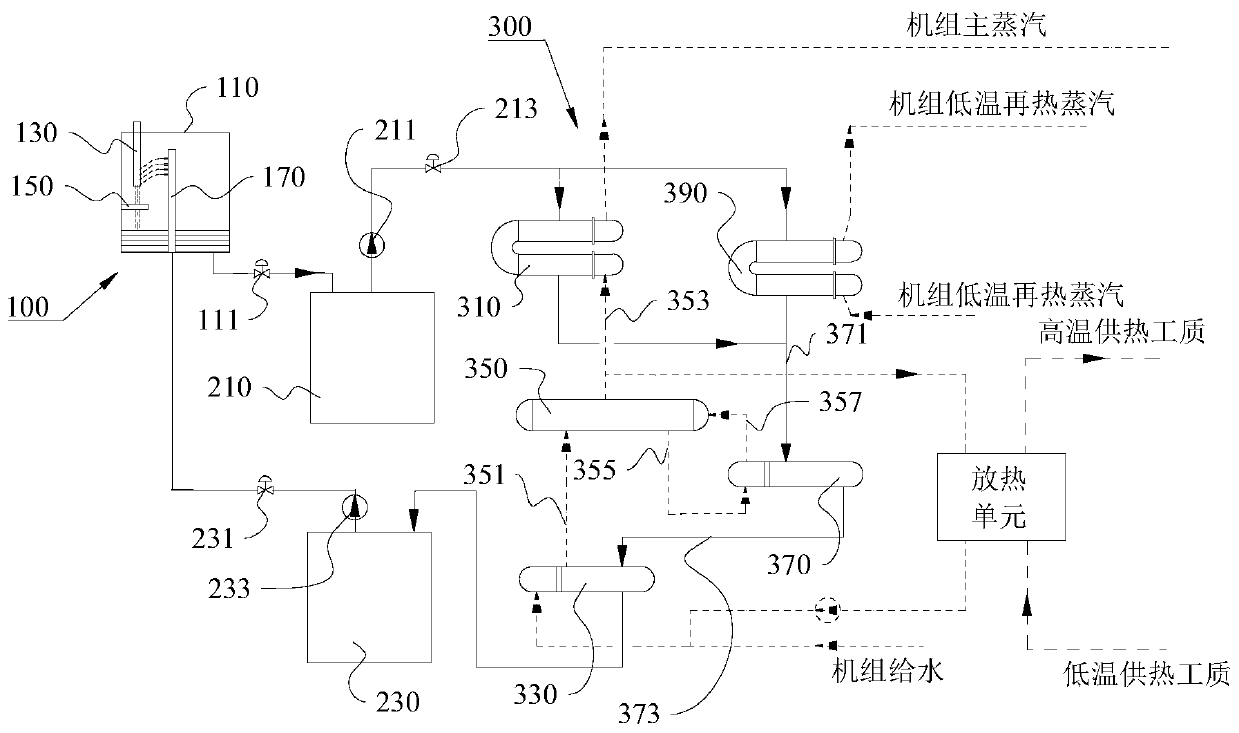

Heat supply steam residual pressure gradient utilization system applied to coal-fired heat supply unit

InactiveCN110953571AImprove thermal economyImprove safety and reliabilityBoiler controlSteam generation plantsProcess engineeringHeat recirculation

The invention discloses a heat supply steam residual pressure gradient utilization system applied to a coal-fired heat supply unit, and specifically relates to the technical field heat supply reliability and energy saving of the coal-fired heat supply unit. The heat supply steam residual pressure gradient utilization system comprises a boiler, a high-pressure cylinder, a medium-pressure cylinder,a low-pressure cylinder and a generator, and is characterized in that a first pipeline is arranged between a steam outlet of the boiler and the high-pressure cylinder, and a second pipeline is arranged between the high-pressure cylinder and a reheater of the boiler. When a steam turbine or a generator needs to be overhauled in a fault state, the steam turbine and the generator stop working, main steam of the boiler enters the reheater of the boiler through a high-pressure bypass temperature and pressure reducing valve set, then enters a heat supply steam back pressure steam turbine generator unit to do work to drive power generation after absorbing heat through the reheater of the boiler, and is connected with a station service power system, and the heat economy of an emergency heat supplysystem is improved. If the heat supply steam back pressure steam turbine generator unit breaks down, steam at an outlet of the reheater of the boiler can directly enter a heating network heater to heat urban heat supply circulating water through temperature and pressure reduction.

Owner:天津华能杨柳青热电有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com