Ultra-supercritical secondary re-heating steam turbine set

A steam turbine unit and secondary reheating technology, applied in steam engine installations, mechanical equipment, engine components, etc., can solve the problem of uncontrollable boiler pressure and flow distribution, high cost of power plant construction, increased energy consumption and environmental pollution, etc. problem, to achieve the effect of significant economic effect, compact structure and reduced construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

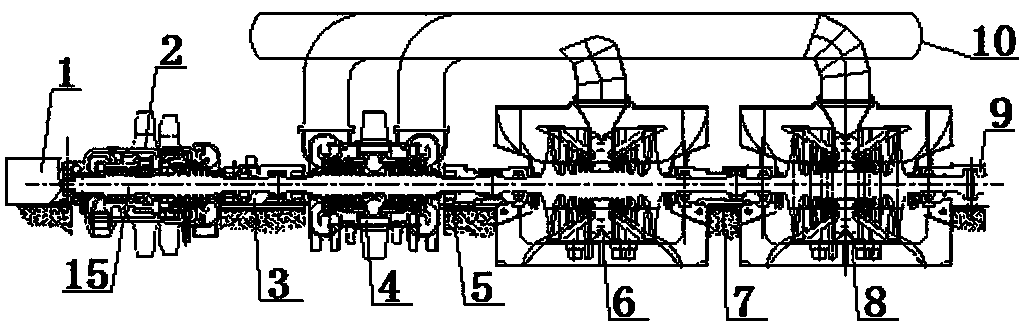

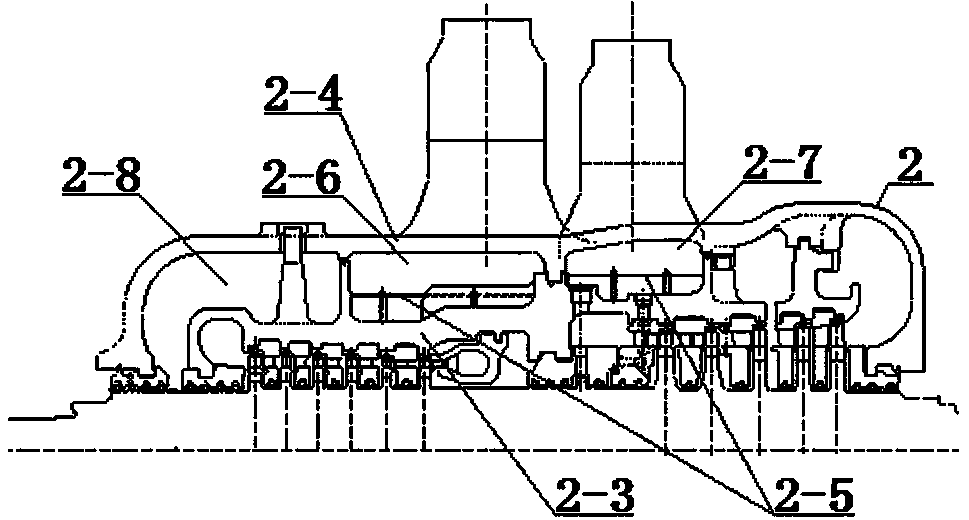

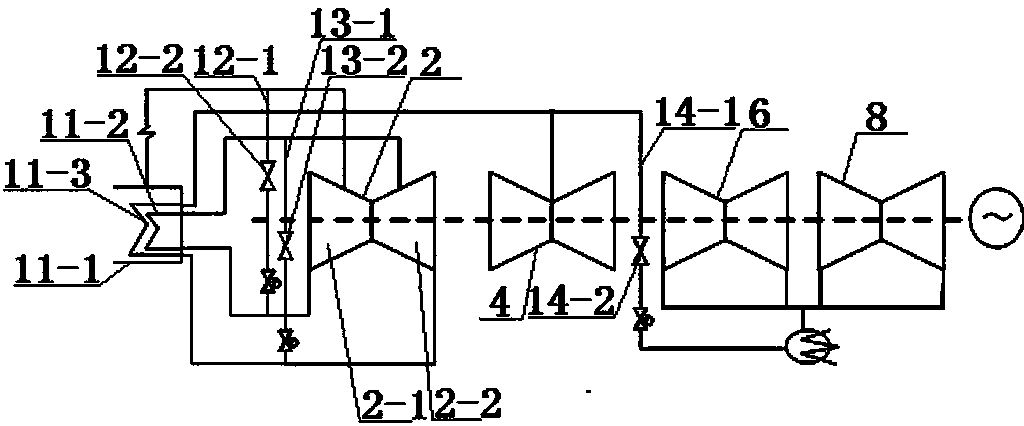

[0026] see figure 1 , figure 2 and image 3 : the present invention has 45 pressure stages, and its capacity is 1000~1300MW. The present invention includes a first bearing housing 1, an ultra-high pressure-high pressure cylinder 2, a second bearing housing 3, a medium pressure cylinder 4, a third bearing housing 5, a first low pressure cylinder 6, and a fourth bearing housing, which are sequentially assembled on the rotor 15 7. The second low-pressure cylinder 8 and the crankcase 9. The pressure level of the ultra-high pressure part 2-1 of the ultra-high pressure-high pressure cylinder 2 is 6, the pressure level of the high pressure part 2-2 of the ultra-high pressure-high pressure cylinder 2 is 5, and the pressure level of the medium pressure cylinder 4 is 2×7=14 , the pressure level of the first low-pressure cylinder 6 is 2×5=10, and the pressure level of the second low-pressure cylinder 8 is also 2×5=10.

[0027]Wherein, the ultra-high pressure-high pressure cylinder 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com