Long-acting dust sealing agent and preparation method thereof

A sealing agent and dust technology, which is applied in the field of long-acting dust sealing agent and its preparation, can solve the problems of affecting soil properties, dust sealing effect, and short dust sealing cycle, so as to achieve enhanced bonding effect, prolong the dust sealing cycle, and good dust sealing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

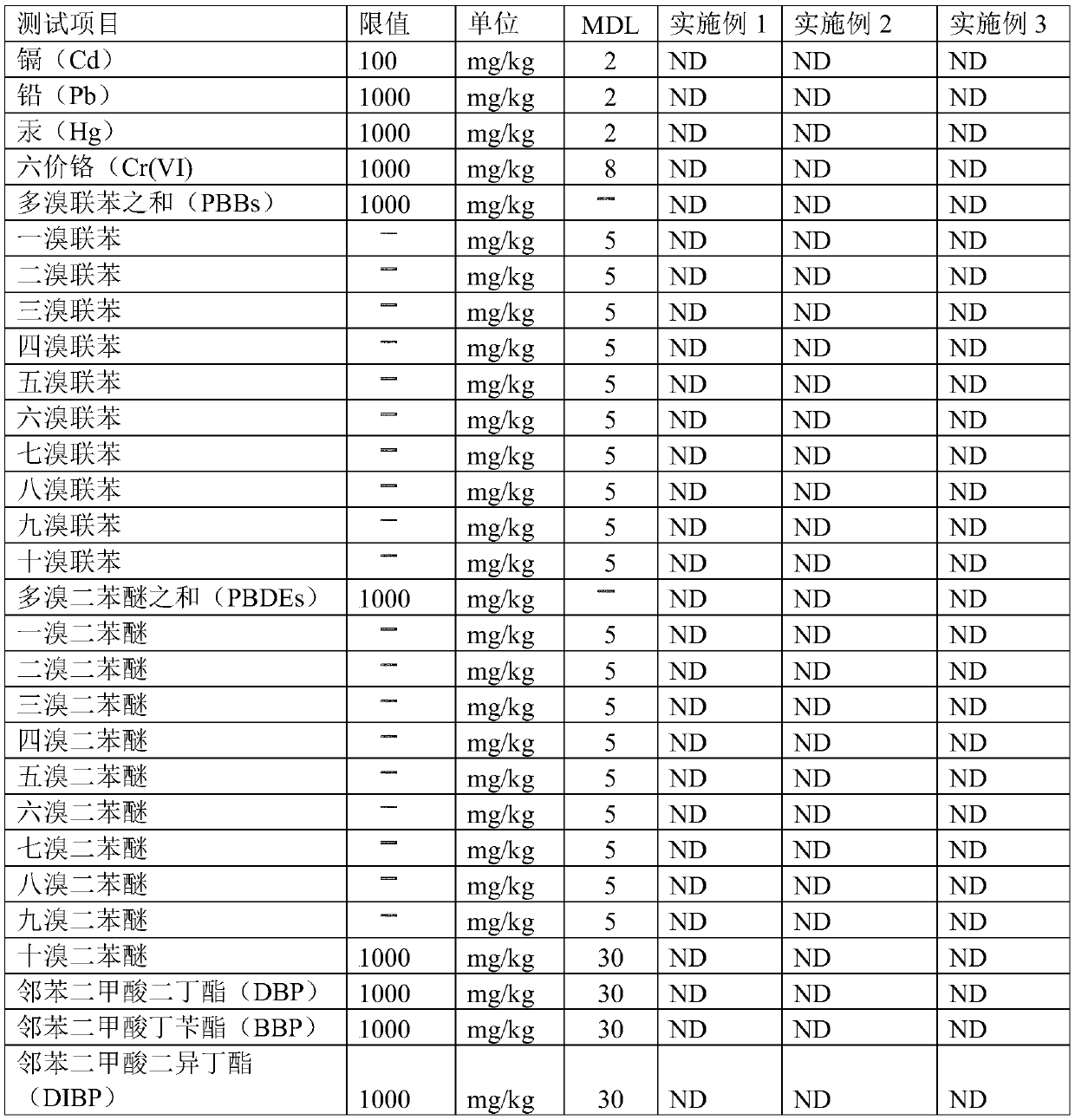

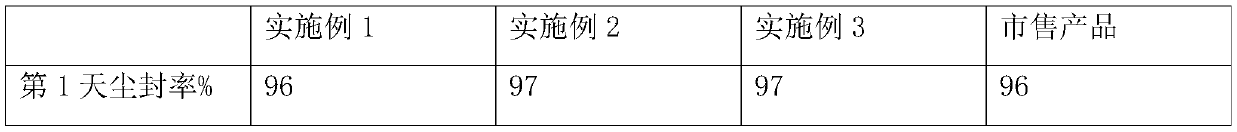

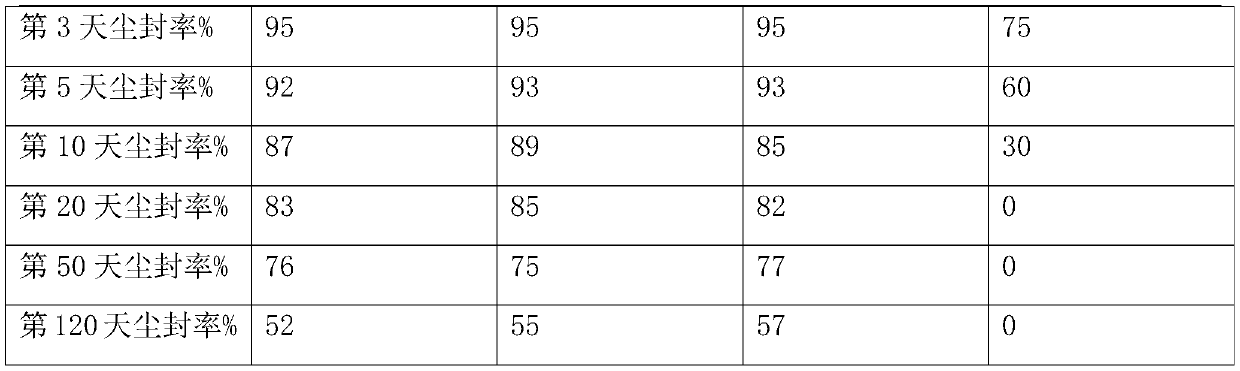

Embodiment 1

[0022] The long-acting dust sealant consists of the following raw materials in parts by weight: 30 parts of plant cellulose activated by dimethoxypropionic anhydride, 10 parts of polycaprolactone, 13 parts of sodium lignosulfonate, and a viscosity of 8000 mPa 10 parts of s alginate, 3 parts of polyfumaric acid with a molecular weight of 3800, 1 part of starch grafted acrylate, 2 parts of sodium carbonate, 5 parts of starch modified polyacrylamide, 1 part of carboxymethyl starch, 120 parts of ionized water.

[0023] The preparation method of described long-acting dust sealing agent, comprises the following steps:

[0024] (1) adding sodium lignosulfonate to deionized water and stirring evenly, then adjusting the pH value of the solution to 8;

[0025] (2) Add plant cellulose and polycaprolactone into the solution, stir and mix evenly, add alginate, stir and react for 3 hours, then add polyfumaric acid, starch grafted acrylate, sodium carbonate and starch-modified polyacrylamid...

Embodiment 2

[0029] The long-acting dust sealant consists of the following raw materials in parts by weight: 50 parts of plant cellulose activated by dimethoxypropionic anhydride, 30 parts of polycaprolactone, 18 parts of sodium lignosulfonate, and a viscosity of 10000mPa 15 parts of s alginate, 5 parts of polyfumaric acid with a molecular weight of 10000, 3 parts of starch grafted acrylate, 5 parts of sodium carbonate, 12 parts of starch modified polyacrylamide, 3 parts of carboxymethyl starch, 150 parts of ionized water.

[0030] The preparation method of described long-acting dust sealing agent, comprises the following steps:

[0031] (1) adding sodium lignosulfonate to deionized water and stirring evenly, then adjusting the pH value of the solution to 9;

[0032] (2) Add plant cellulose and polycaprolactone into the solution, stir and mix evenly, add alginate, stir and react for 4 hours, then add polyfumaric acid, starch grafted acrylate, sodium carbonate and starch-modified polyacryl...

Embodiment 3

[0036] The long-acting dust sealant consists of the following raw materials in parts by weight: 40 parts of plant cellulose activated by dimethoxypropionic anhydride, 20 parts of polycaprolactone, 15 parts of sodium lignosulfonate, and a viscosity of 9000 mPa 12 parts of s alginate, 4 parts of polyfumaric acid with a molecular weight of 5000, 2 parts of starch grafted acrylate, 3 parts of sodium carbonate, 8 parts of starch modified polyacrylamide, 2 parts of carboxymethyl starch, 140 parts of ionized water.

[0037] The preparation method of described long-acting dust sealing agent, comprises the following steps:

[0038] (1) adding sodium lignosulfonate to deionized water and stirring evenly, then adjusting the pH value of the solution to 8.5;

[0039] (2) Add plant cellulose and polycaprolactone into the solution, stir and mix evenly, add alginate, stir for 3.5 hours, then add polyfumaric acid, starch grafted acrylate, sodium carbonate and starch-modified polypropylene Am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com