System and method for co-processing organic waste by cement kiln

A technology of organic waste and co-processing, applied in cement production, combustion method, combustion type, etc., can solve the problems affecting the stable operation of cement sintering system and clinker quality stability, and achieve the effect of reducing negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

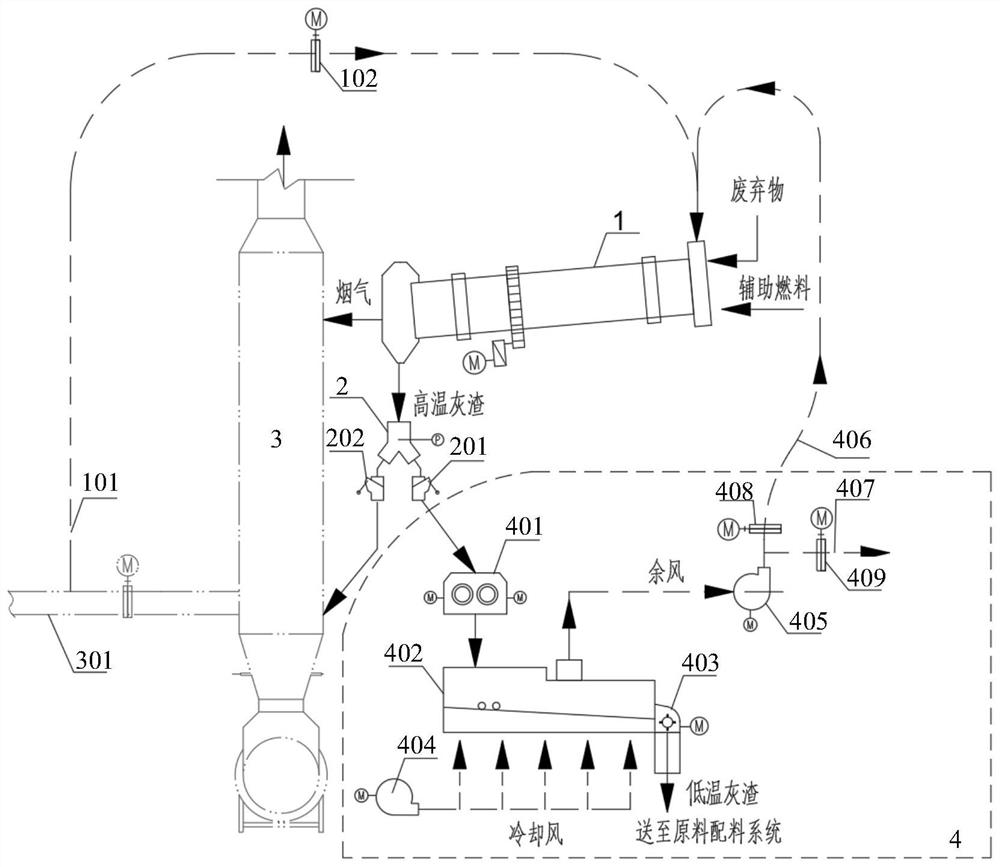

[0023] Example 1: as figure 1 As shown, the system for co-processing organic wastes in a cement kiln of the present invention includes a multiphase pre-combustion furnace 1 and a material distribution device 2 connected to the solid outlet of the multiphase pre-combustion furnace 1, and the outlets of the material distribution device 2 are respectively connected with the decomposition furnace. 3 is connected with the ash and slag cooling system 4 , a first valve 201 is arranged between the material distribution device 2 and the ash and slag cooling system 4 , and a second valve 202 is arranged between the material distribution device 2 and the decomposition furnace 3 .

[0024] The front end of the multi-phase pre-combustion furnace 1 of the present invention is provided with an inlet and an auxiliary burner for feeding wastes in various phases (solid, semi-solid, liquid). In the example, the main body of the multiphase pre-combustion furnace 1 adopts a rotary kiln structure w...

Embodiment 2

[0030] Embodiment 2: a method for processing organic wastes by utilizing the system for co-processing organic wastes in a cement kiln of Embodiment 1, comprising the following steps:

[0031](S1) The waste is sent into the multi-phase pre-combustion furnace 1, and the air volume sent into the multi-phase pre-combustion furnace 1 is adjusted through the air volume control valve of the tertiary air branch pipe 101 and the first residual air branch pipe 406, and at the same time according to the tertiary air branch pipe 101 and the air volume ratio of the first residual air branch pipe 406 and the injection amount of auxiliary fuel to control the operating temperature of the multiphase waste pre-combustion furnace;

[0032] (S2) the ash and slag processed by the multiphase pre-combustion furnace 1 is sent into the decomposition furnace 3 for processing through the material distribution device 2 or into the ash and slag cooling system 4;

[0033] (S3) The ash sent into the ash coo...

Embodiment 3

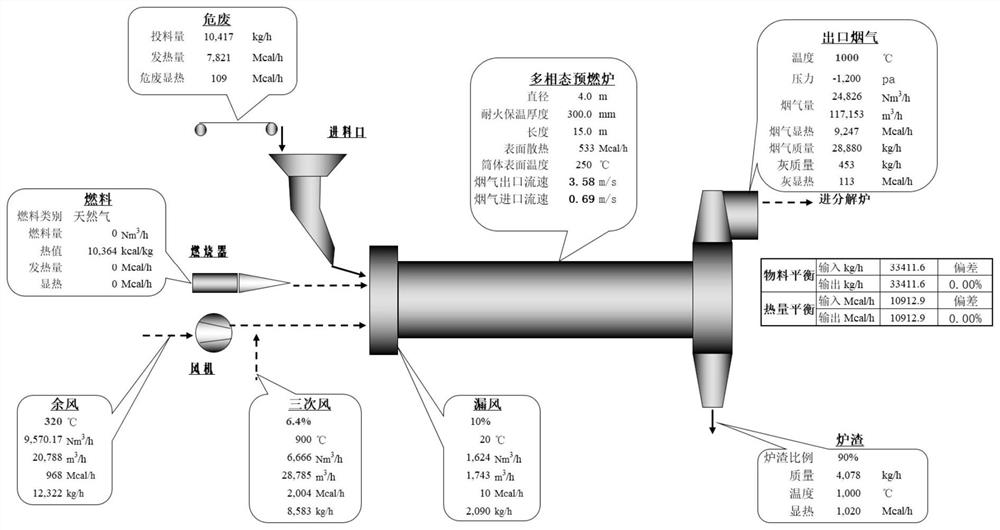

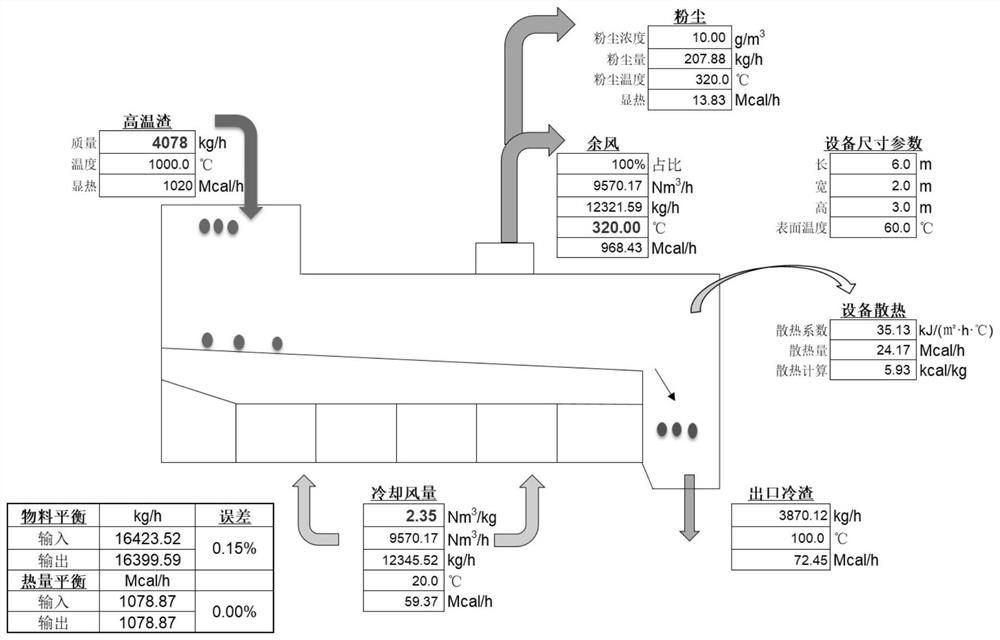

[0035] Embodiment 3: the material of the present invention and heat balance are calculated as follows:

[0036] (1) Calculation of material and heat balance of multiphase pre-combustion furnace

[0037] The calculation uses the tertiary air of the cement production line and all the residual air of the ash cooling system as the combustion air source and heat source, and adjusts the proportion of the tertiary air supply to ensure that the rotary kiln does not need supplementary combustion. The organic waste with low calorific value (1000kcal / kg) was selected as the research object, and its composition is shown in Table 1.

[0038] Table 1 Elemental composition of low calorific value (1000kcal / kg) organic waste materials co-processing in cement kilns

[0039] type C H O N S Cl Water ASH F total waste 10.00% 2.20% 4.30% 0.00% 0.00% 0.00% 40.00% 43.50% 0.00% 100%

[0040] The design parameters are selected as follows:

[0041] ①The outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com