Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

186results about How to "Low investment and operating costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid phase flue gas desulfurizing and denitrifying purification method and apparatus

InactiveCN1843574AImprove removal efficiencyLow investment and operating costsDispersed particle separationAir quality improvementCalcium hypochloriteCalcium hydroxide

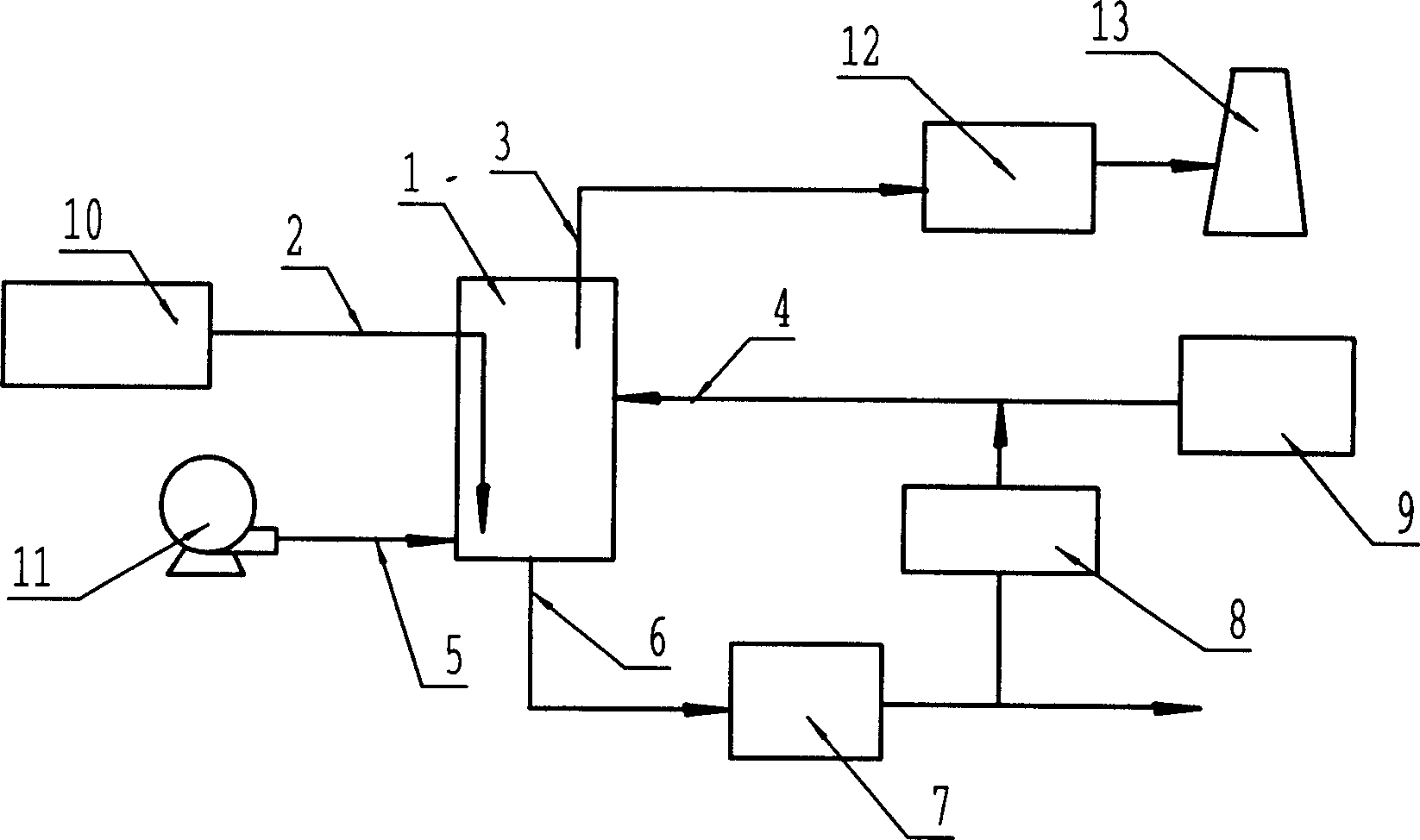

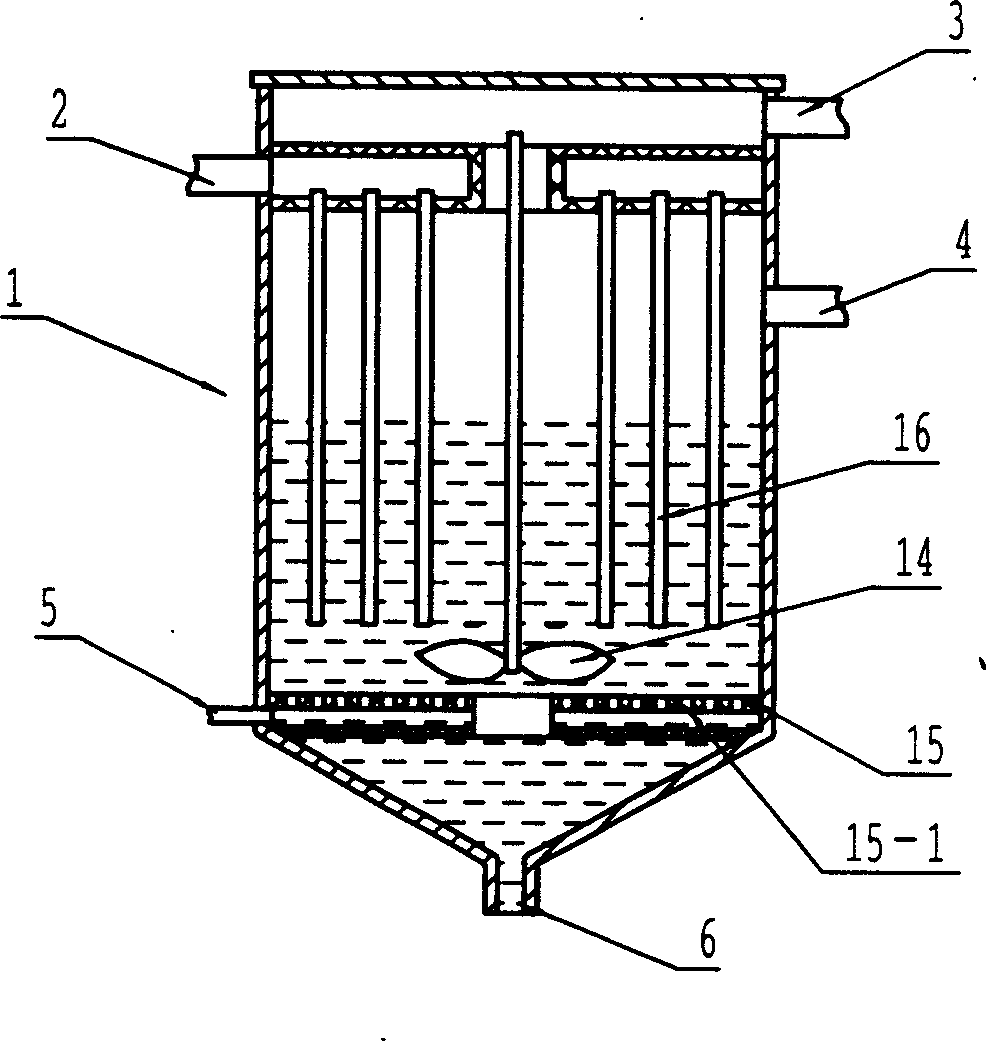

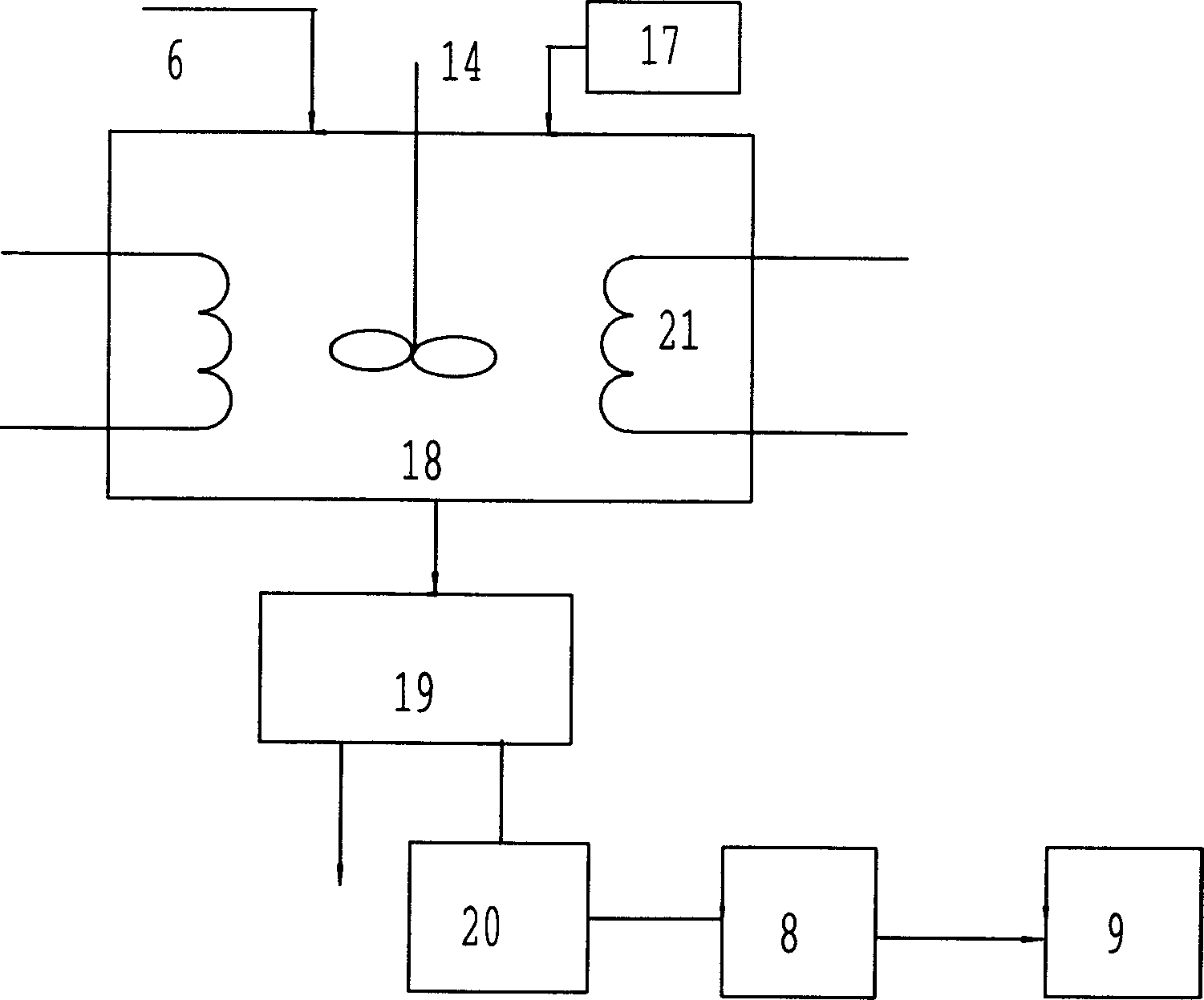

The invention relates to a liquid-phase smoke desulfuration denitration purifying method and relative device, belonging to the smoke purifying technique. It can effectively remove sulfur dioxide and nitrogen oxide of smoke. It utilizes ejection bubbling method to adsorb the sulfur dioxide and nitrogen oxide of smoke, while the adsorption solution is the sodium chlorite solution in 0.001MOL / L-0.100MOL / or the additive in 0.001MOL / L-0.005MOL / L, and the pH valve of adsorption solution is 3-11; the additive is one or the combination of calcium hypochlorite, baking soda, hydrogen dioxide solution, acid sodium phosphate, or calcium hydrate. The removing efficiency of sulfur dioxide in said invention is above 99%; the removing efficiency of nitrogen oxide is above 90%; and the utilization of adsorption solution is above 97%. Therefore, said invention has the advantages that high removing efficiency, lower cost, simple device, high utilization of adsorption solution and wider application for large, middle, and small boiler, etc.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

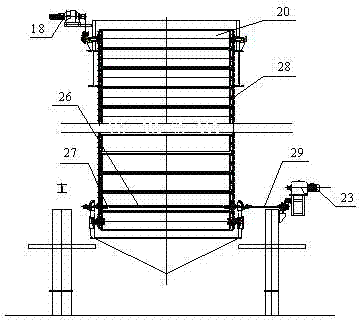

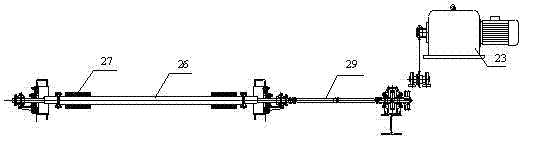

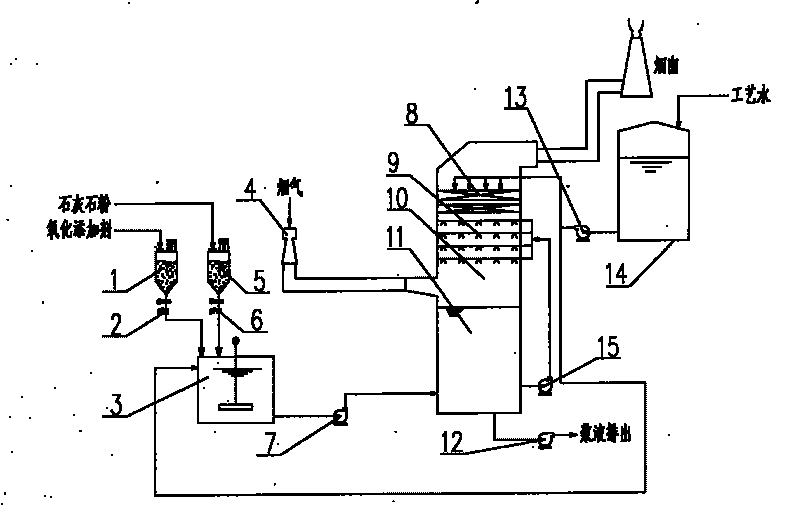

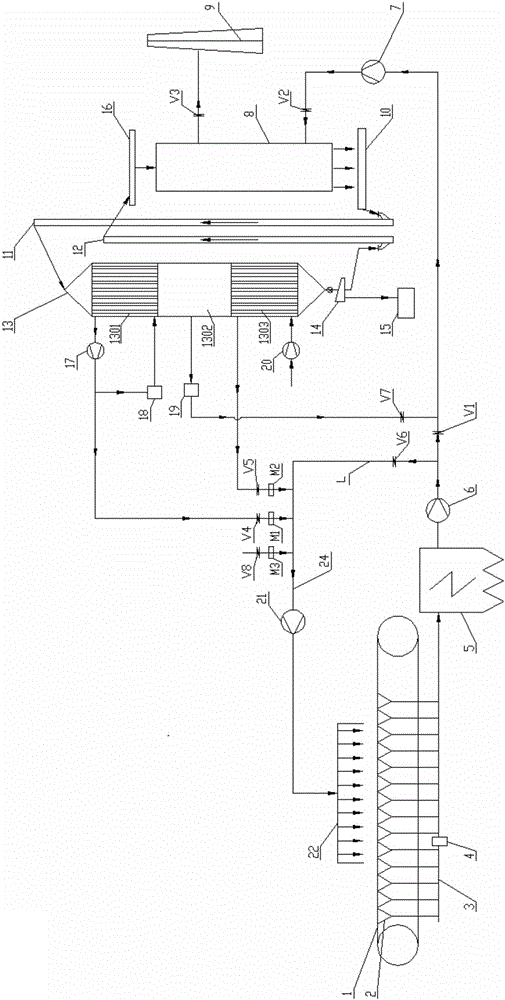

Method for cooperatively promoting agglomeration growth of PM (particulate matter) 2.5 and treating desulfuration wastewater in evaporation manner and device of method

InactiveCN102380278ALow running costConvenient sourceCombination devicesWater/sewage treatmentAir preheaterFlue gas

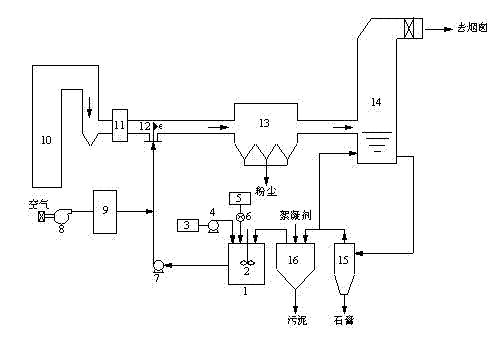

The invention discloses a method for cooperatively promoting agglomeration growth of PM (particulate matter) 2.5 and treating desulfuration wastewater in an evaporation manner and a device of the method. The method particularly includes steps that agglomeration liquor prepared by desulfuration wastewater, high polymer adhesive and wetting agent is sprayed into an inlet flue of an electric precipitator and is evaporated by the aid of heat of flue gas, in an evaporation process, the wetting agent promotes dust to enter drops of the agglomeration liquor, the high polymer adhesive is connected with PM2.5 via a polymer chain with polar groups, the grain diameter of the PM2.5 is prompted to be enlarged, so that the PM2.5 can be gathered by the follow-up electric precipitator, the desulfuration wastewater is evaporated completely, suspended matters and dissolvable pollutants in the wastewater are converted into solid to be dissolved out, and the suspended matters and the dissolvable pollutants in the wastewater, together with dust in the flue gas, are gathered by the electric precipitator. The device consists of a boiler, an air preheater, the electric precipitator, a desulfurizing tower, a hydraulic cyclone, a desulfuration wastewater clarification tank and an agglomeration liquor preparation tank, and a double-fluid atomizing nozzle is arranged in the flue between the air preheater and the electric precipitator.

Owner:SOUTHEAST UNIV

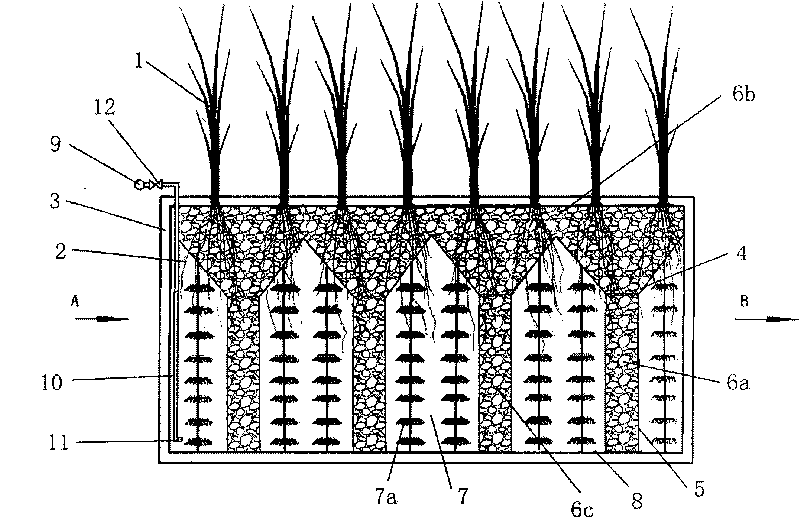

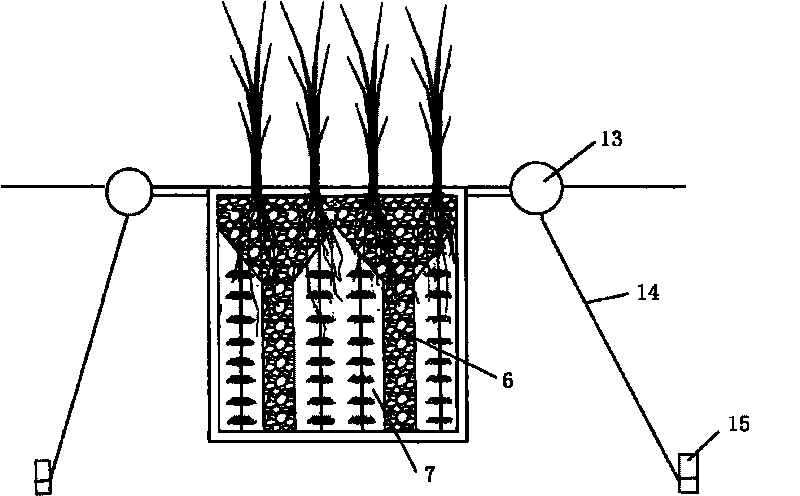

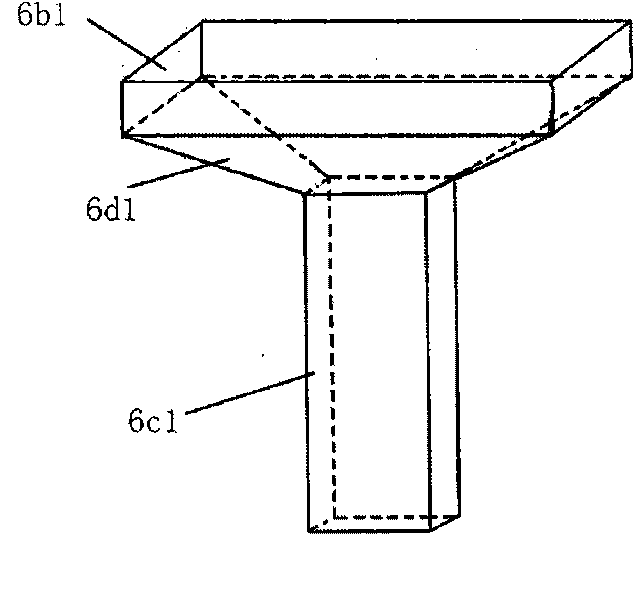

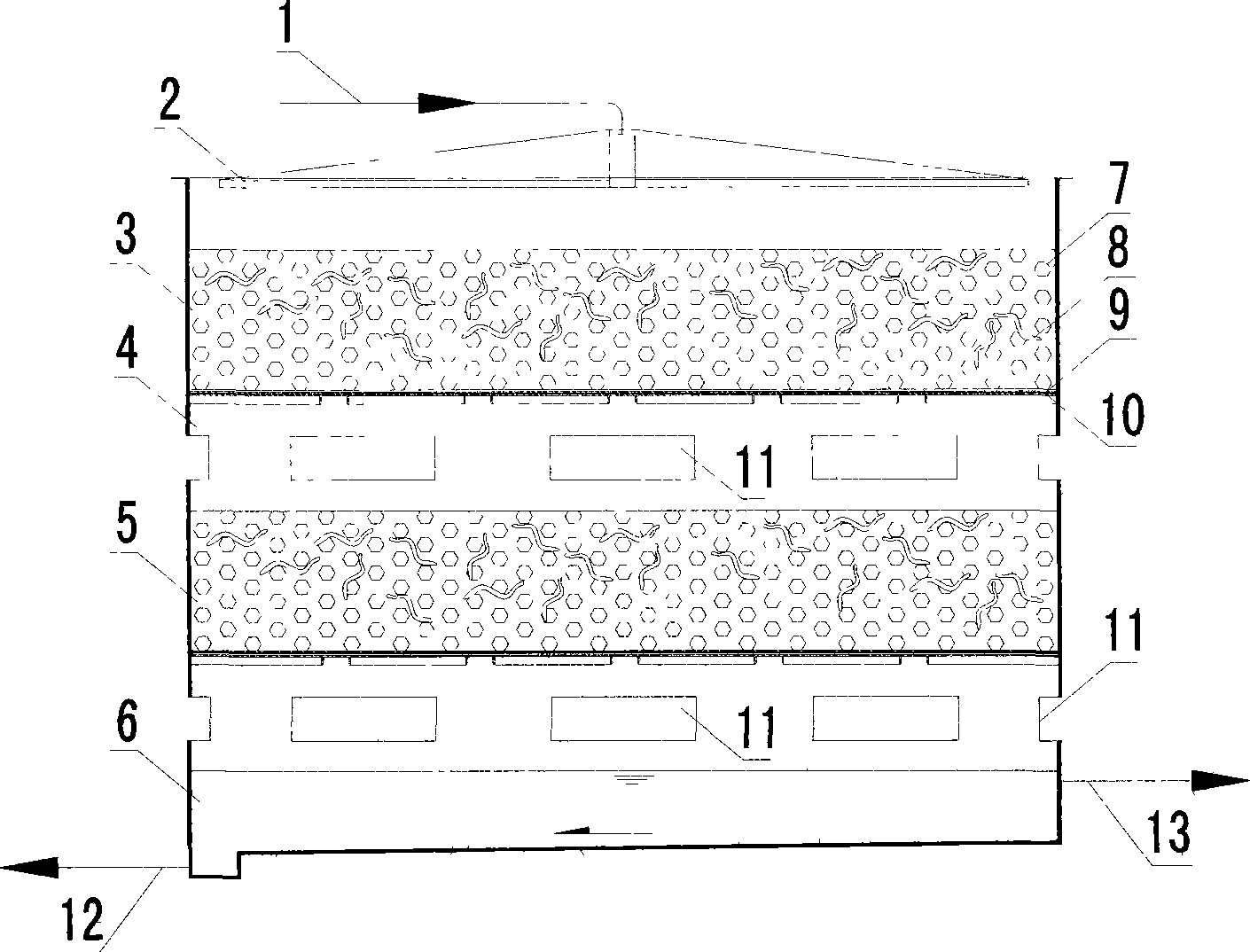

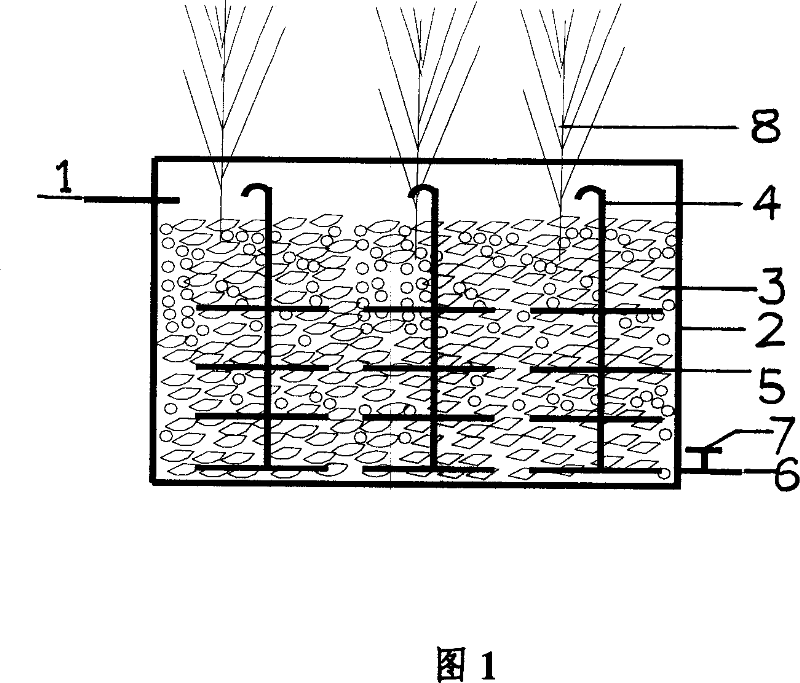

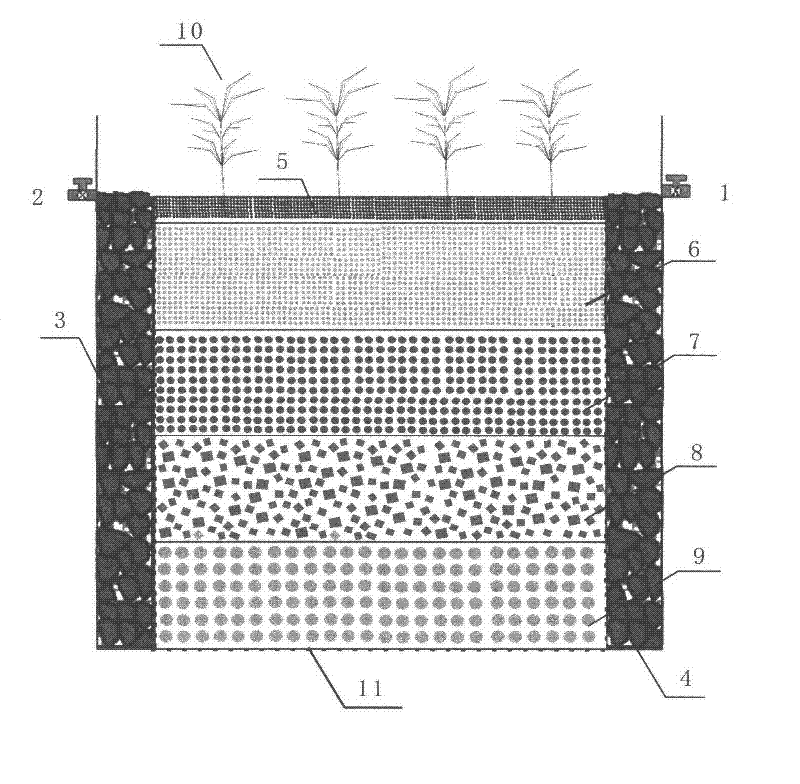

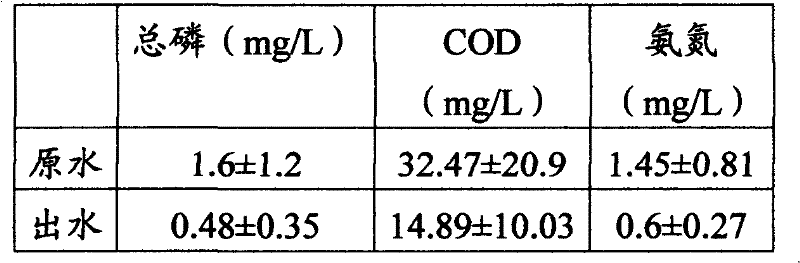

Method and device for purifying combined-flow artificial floating island water body

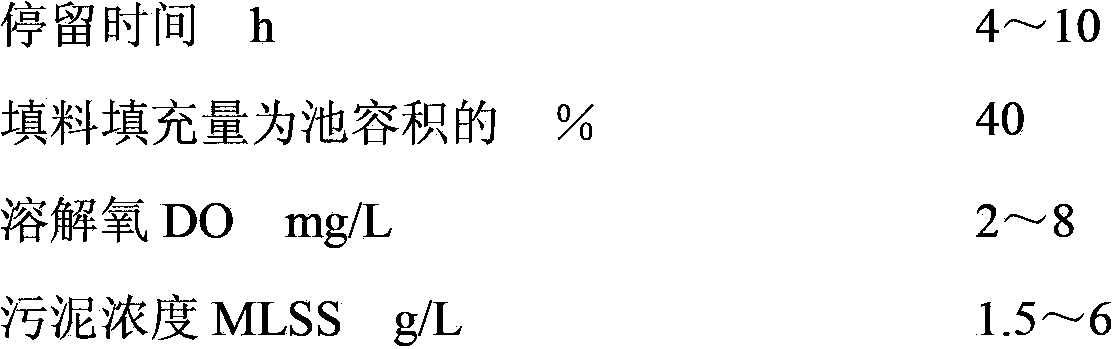

ActiveCN101734783AConstituent flow rate is highLarge specific surface areaSustainable biological treatmentBiological water/sewage treatmentEutrophicationPorous medium

The invention relates to a method and a device for purifying combined-flow artificial floating island water bodies. The device is provided with an artificial floating island frame; particle filling areas (6) are arranged in the artificial floating island frame; tightly accumulated particle fillers (6a) are filled in the particle filling areas; the particle filling areas are distributed at the lower part of the artificial floating island frame in a dispersed manner; sparse fillers (7a) with good overflowing property are arranged between the dispersed particle filling areas (6c) to form a sparse filling area (7) in which the flow is obviously higher than the osmosis flow in the particle filling areas; the particle filling areas are distributed at the upper part of the artificial floating island frame in a whole area or in sub-area to form an upper layer particle filling area on which humidogene emergent aquatic plants can be planted. In the invention, different filling areas are arranged to form combined flow of coexistence of porous media seepage and space continuity flow, thus fully purifying water bodies under the actions of physics, chemistry, plants and microorganisms and the like, and achieving the high effects of nitrogen and phosphorus removal by adopting the invention to process eutrophic surface water bodies, such as rivers and lakes and the like.

Owner:GRADUATE SCHOOL OF THE CHINESE ACAD OF SCI GSCAS +1

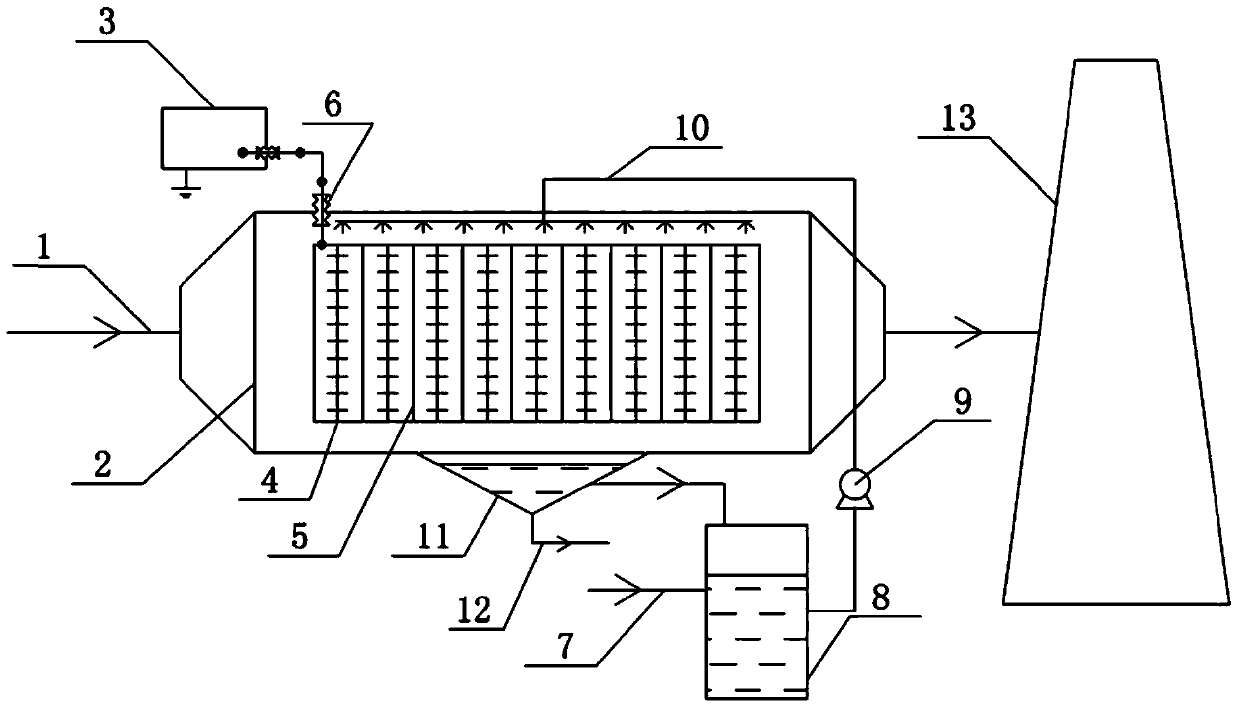

Dust removal method and device based on chemical agglomeration and split linked anode electric dust removal

InactiveCN102416363ASolve the technical bottleneck that is difficult to remove fine dustWide variety of sourcesElectrodes cleaningElectricityCompound (substance)

The invention discloses a dust removal method and a dust removal device based on chemical agglomeration and split linked anode electric dust removal. An agglomerating agent solution is sprayed into an inlet flue of an electric dust remover through a double-fluid atomizing nozzle, compressed air is also sprayed into the inlet flue, and a polymer binder is connected with fine dust through a polymer long chain with a polar group, so that the particle size of the fine dust is increased, and the fine dust enters an electric dust removal unit to be removed. By the method and the device, dust removal performance can be obviously improved.

Owner:JIANGSU RUIFAN ENVIRONMENTAL PROTECTION EQUIPCO

Comprehensive treatment method of high-sulphur high-COD (Chemical Oxygen Demand) caustic sludge waste liquid

ActiveCN103045288AReduce CODMild operating conditionsOrganic chemistryOrganic compound preparationLiquid wasteHigh concentration

The invention relates to a comprehensive treatment method of high-sulphur high-COD (Chemical Oxygen Demand) caustic sludge waste liquid. The comprehensive treatment method comprises the steps of: 1, acidizing high-sulphur high-COD caustic sludge waste liquid by using an N2 / SO2 mixed gas, when the pH value of the waste liquid reaches 2-6, stopping acidizing; 2, sending tail gas discharged in the acidizing process in the step 1 to a sulphur production device for preparing sulphur; 3, settling the waste liquid generated in acidizing treatment in the step 1and recovering an oil phase; 4, further reducing the COD of the waste liquid by adopting an extraction method when the COD of the waste liquid after the oil phase is separated in the step 3 is always high; and 5, regenerating the waste liquid extracted in the step 4 by using lime. The comprehensive treatment method is low in investment, is mild in operation conditions, is capable of recycling the caustic sludge waste liquid, avoiding the impact of the high-concentration wastewater on a wastewater treatment field, is also capable of recovering sulfide and crude carbolic acid from the caustic sludge waste liquid, and has a certain economic benefit.

Owner:CHINA PETROLEUM & CHEM CORP +1

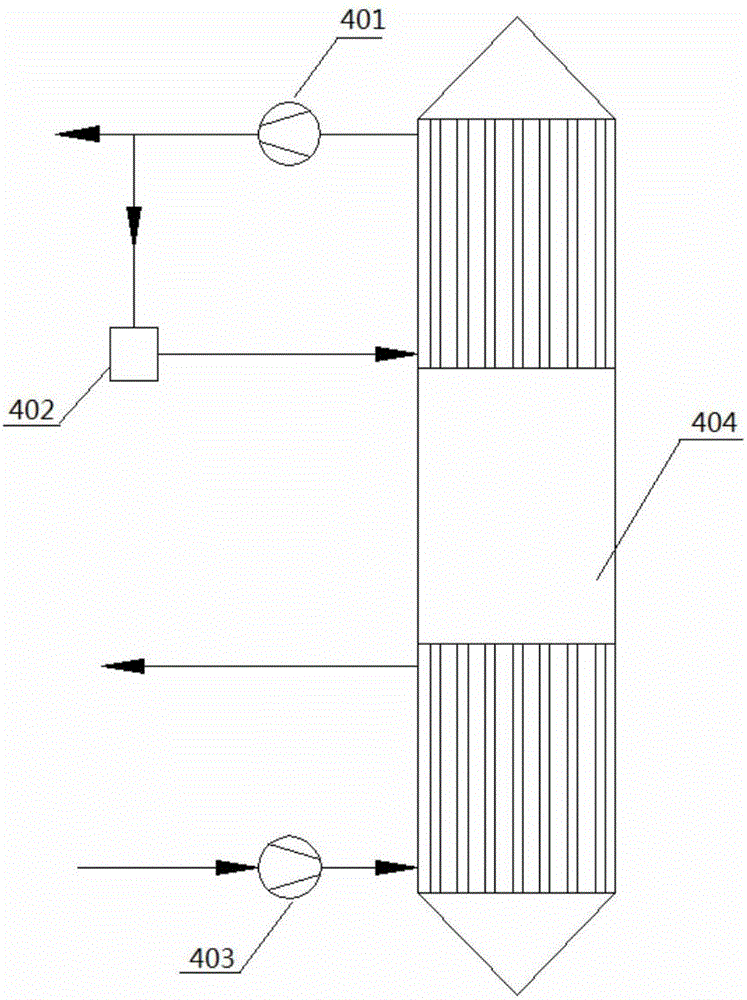

Biological trickling filter bed for treating odorant pollutant in air

ActiveCN1772352ALow operating costLow investment and operating costsDispersed particle separationAir quality improvementPollutantTrickling filter

The biological trickling filter bed for treating odorant pollutant in air is one stuffing tower with spraying head in the top, air inlet in the bottom, air outlet in the top, and height / diameter ratio of 4-10. The biological trickling filter bed adopts new type stuffing of different grain sizes and has decreased stuffing size distribution from the bottom to the top. Stuffing of two different sizes, including large grain stuffing in the bottom and small grain stuffing in the top, are adopted. The present invention has high treating load, homogeneous load distribution and low pressure drop.

Owner:江苏三强环境工程有限公司

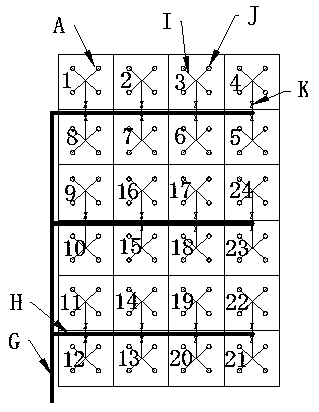

Sub-grid adjustable anaerobic-anoxic-aerobic biochemical reactor

InactiveCN103408143AReasonable designCompact structureTreatment with aerobic and anaerobic processesBiochemical engineeringWater quality

The invention discloses a sub-grid adjustable anaerobic-anoxic-aerobic biochemical reactor which is in the form of a covered way and comprises 24 sub-grid tanks (A), wherein the 24 sub-grid tanks (A) are divided into an anaerobic segment, an anoxic segment and an aerobic segment; a trough (B) is formed between every two sub-grid tanks from the first sub-grid tank (A) to the twelfth sub-grid tank (A); division plates (C) are inserted into the troughs (B) to realize the segmentation of the anaerobic segment, the anoxic segment and the aerobic segment; a water passing orifice is formed in the lower part of each trough (B); and an aerator is arranged at the lower part of each sub-grid tank (A) of the reactor. The biochemical reactor is reasonable in design and compact in structure, the relative residence time of the anaerobic segment, the anoxic segment and the aerobic segment can be flexibly adjusted according to the water quality condition of waste water to be treated, and when different waste water is treated or the water quality of the waste water to be treated is changed, the anaerobic segment, the anoxic segment and the aerobic segment can perform efficient biochemical treatment, so that the reactor can obtain an overall stable and efficient treatment effect and has good environmental and economic benefits.

Owner:YANCHENG INST OF TECH

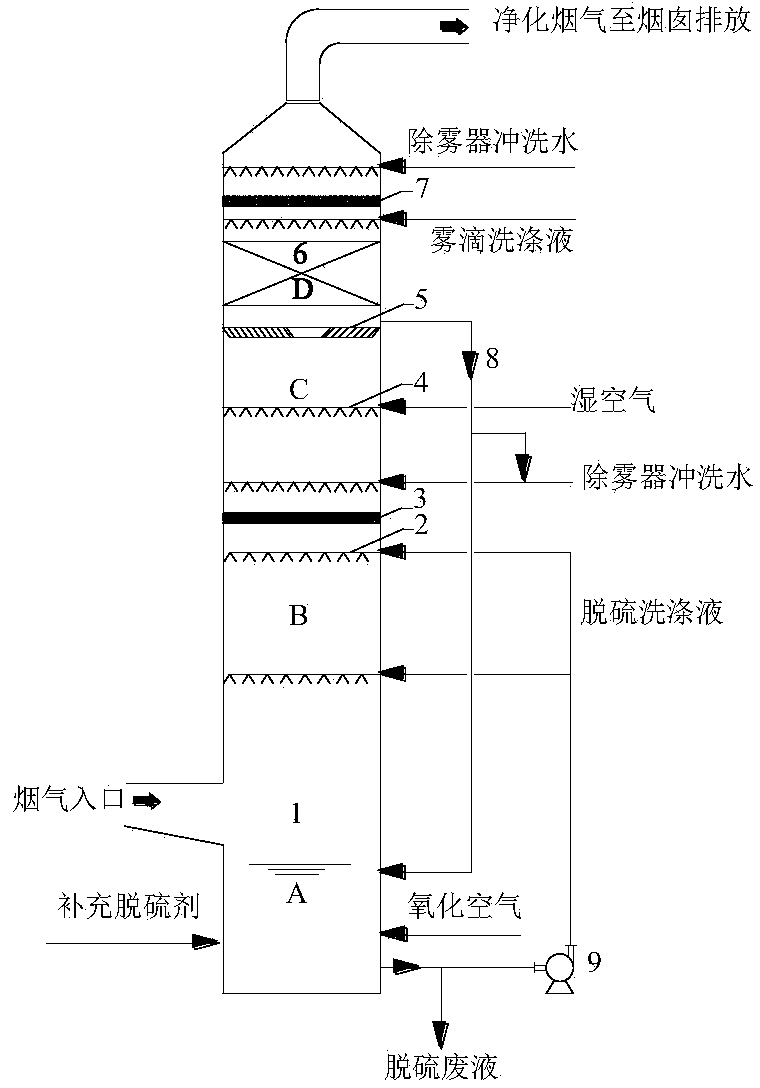

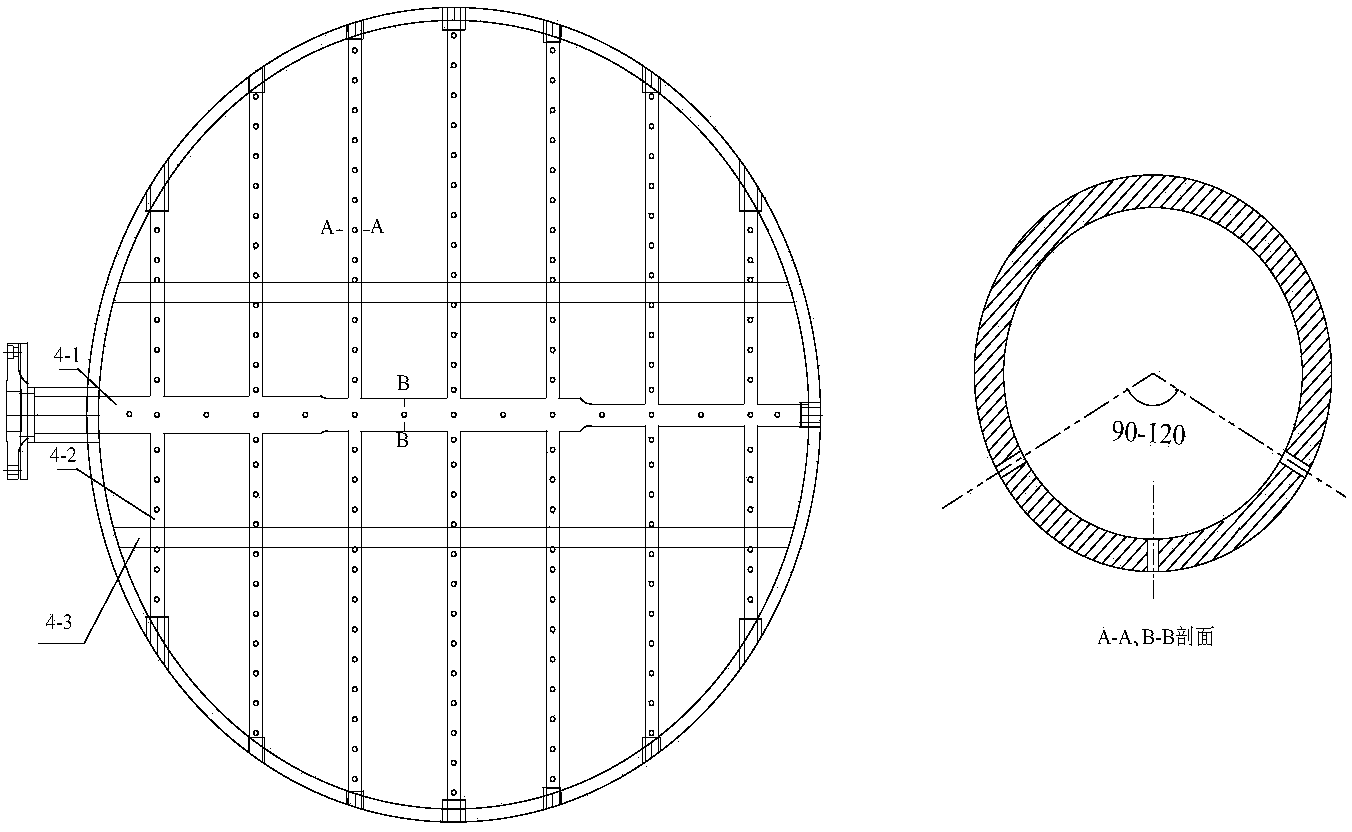

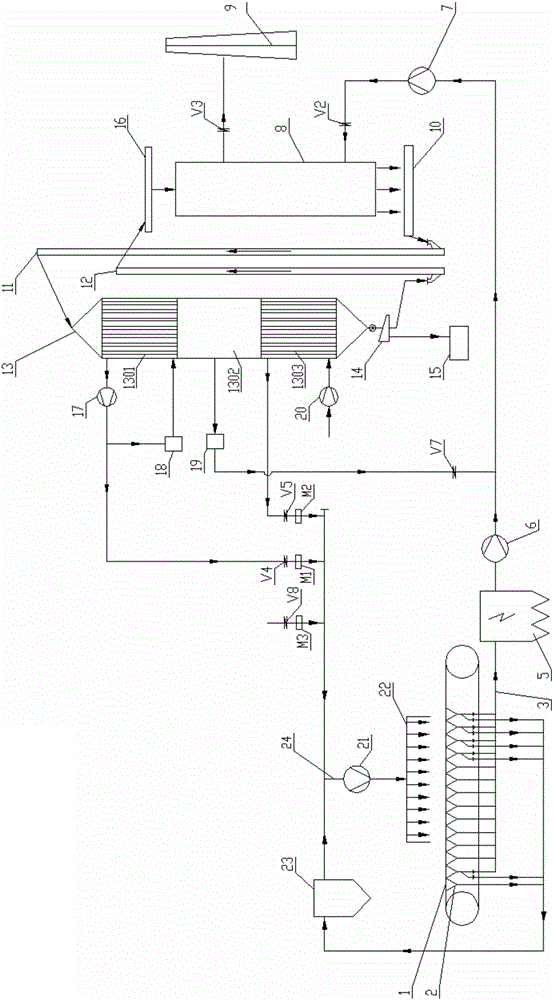

Desulfurization device and desulfurization method for promoting removal of PM2.5 in clean flue gas after wet desulphurization

ActiveCN103721548AReduce energy consumptionSolve the defect of easy cloggingCombination devicesWater vaporFlue gas

The invention discloses a desulphurization device and a desulphurization method for promoting removal of PM2.5 in clean flue gas after wet desulphurization. The desulphurization device comprises a flue gas desulphurization washing device and a fog drop collecting device which are connected in series, wherein the flue gas desulphurization washing device comprises a desulphurization liquid oxidation region, a desulphurization washing region and a water vapor phase change region which are arranged in sequence from bottom to top; the fog drop collecting device forms an integral or split structure together with the flue gas desulphurization washing device and is arranged on the flue gas desulphurization washing device or at an outlet. According to the method, flue gas enters the water vapor phase change region after SO2 is removed through the desulphurization washing region; wet air is filled through a wet air distributor, so that the clean flue gas after the wet desulphurization reaches an oversaturated state; oversaturated water vapor is nucleated and condensed on the PM2.5 surface, so that the PM2.5 is turned into dust fog drops with liquid films on the surfaces and the particle sizes are increased; the condensed expanded dust fog drops enter the fog drop collecting device and are collected through fog drop washing liquid and a defroster of the fog drop collecting device. According to the desulphurization device, the energy consumption for building an oversaturated water vapor environment can be effectively reduced and the PM2.5 emission problem of a wet flue gas desulphurization system is solved.

Owner:SOUTHEAST UNIV

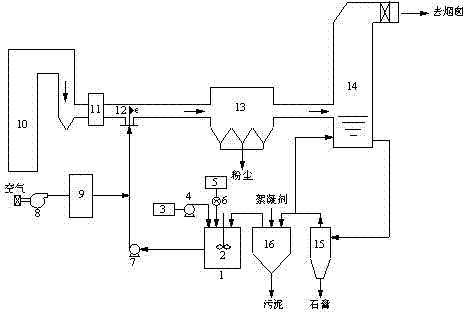

Device and method for removing various pollutants simultaneously by lime stone-gypsum wet process

ActiveCN101708421ASimplify tail gas treatment processLow investment and operating costsLighting and heating apparatusDispersed particle separationGypsumSpray tower

The invention discloses a device and a method for removing various pollutants simultaneously by lime stone-gypsum wet process. The device comprises an absorption liquid seriflux pot, a booster fan, a spray tower and the like, strong oxidizing agent and efficient absorbent are mixed to prepare absorption liquid desulfurated by wet process, fume with motive power supplemented by the booster fan enters into the spray tower, the upper middle part of the spray tower is provided with 2-4 layers of spray layers for spraying the absorption liquid into the spray tower so that the absorption liquid and the fume contact well, and the absorption liquid in the liquid storing tank can be used circularly under the action of an absorption liquid circulation pump. The upper part of the spray layers is provided with a demister for removing the water vapor in the fume, and the fume demisted by the demister is exhausted from the top of the spray tower to be out of the chimney. The invention has the following advantages: 1) simultaneous removal of various pollutants can be realized by only one lime stone-gypsum process technology; 2) selectable oxidizing agent varieties are plentiful; and 3) the removal efficiency of the pollutants is high.

Owner:ZHEJIANG UNIV

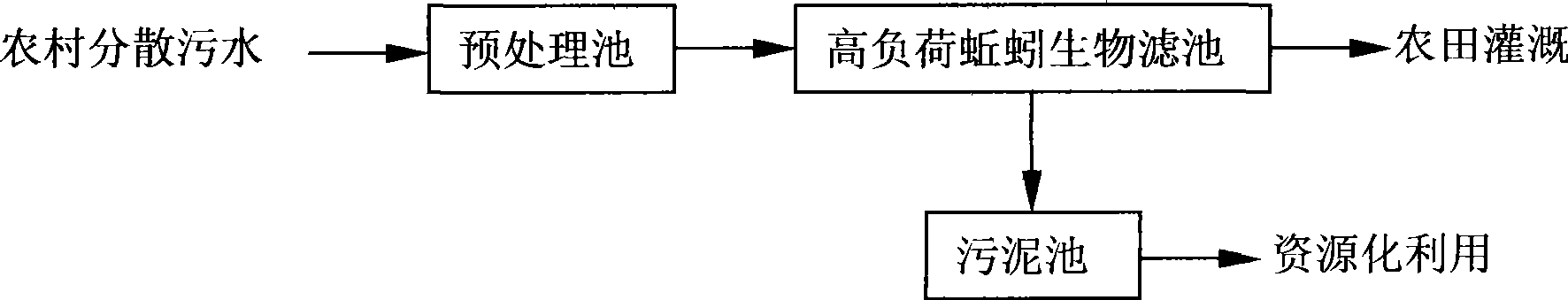

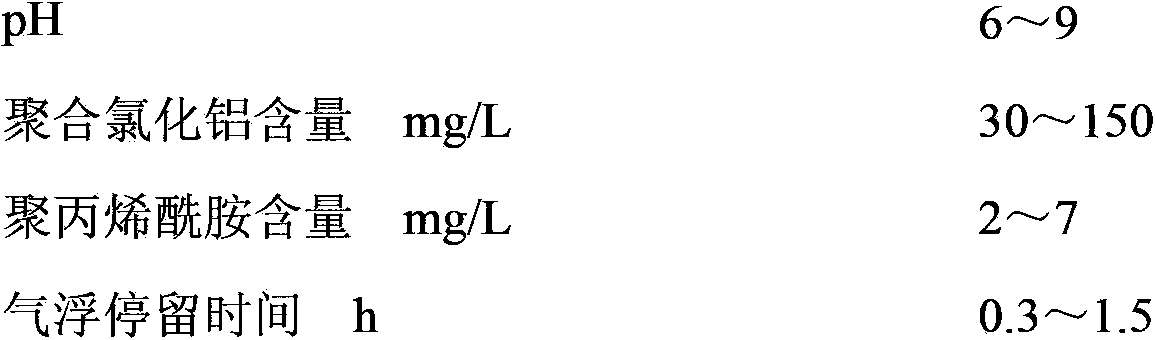

Method for treating rural disperse sewage by using high load vermibiofilter

InactiveCN101391855AChemically stableLow priceBio-organic fraction processingMultistage water/sewage treatmentFertilizerSewage

The invention discloses a method for utilizing high-load earthworm biological filter to treat decentralized sewage in countries, and relates to a sewage treatment method. The treatment method comprises the following steps: the decentralized sewage in the countries is firstly collected; suspended matter and floating matter are removed by a pretreatment tank; BOD5 is led to be 110 to 160mg / L, COD is 120 to 150mg / L and SS is 90 to 130mg / L; then the obtained mixture is pumped into the high-load earthworm biological filter according to hydraulic loading of 4 to 6m<3>(m<2> question mark d); after passing through a first earthworm biological filtering layer and a second earthworm biological filtering layer which are filled with light shale spherical porcelain granules (7) filtering media with the diameter of 3 to 7mm and 15000 to 28000 eisenia foetidas (8) are added on the surface of the filtering media per square meter, the water which is discharged from a settling tank (6) and has BOD5 of less than 15mg / L, COD of less than 60mg / L and SS of less than 15mg / L reaches the national water quality standard for field irrigation; little amount of residue sludge which is collected by the settling tank (6) and contains wormcast is used for improving the soil or is used as fertilizers. The method has large hydraulic loading, small occupy area, is hard to be blocked, has simple process and operation, good water outlet quality and low construction cost and operating cost and can be widely used for treatment of the waste water in rural areas.

Owner:TONGJI UNIV

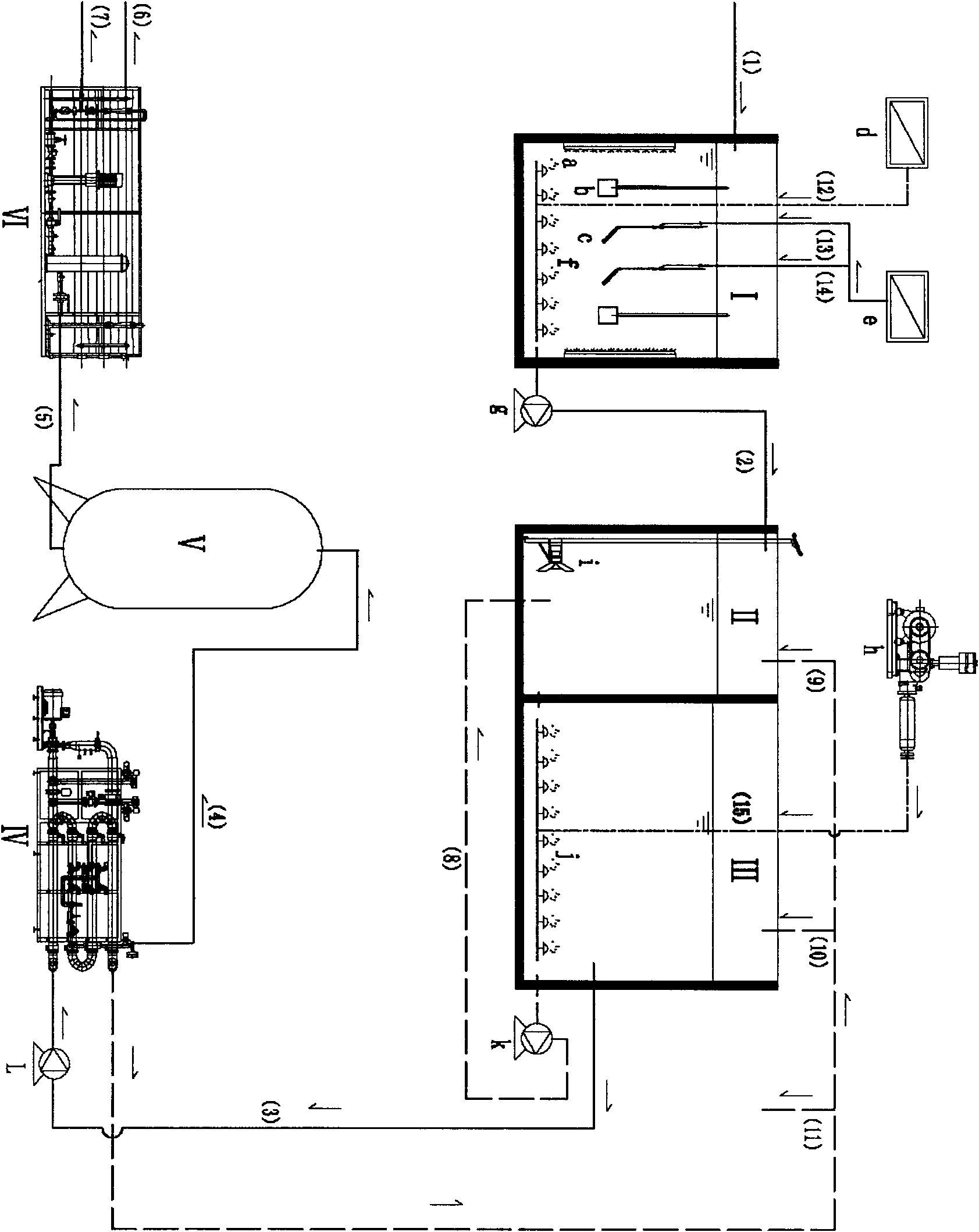

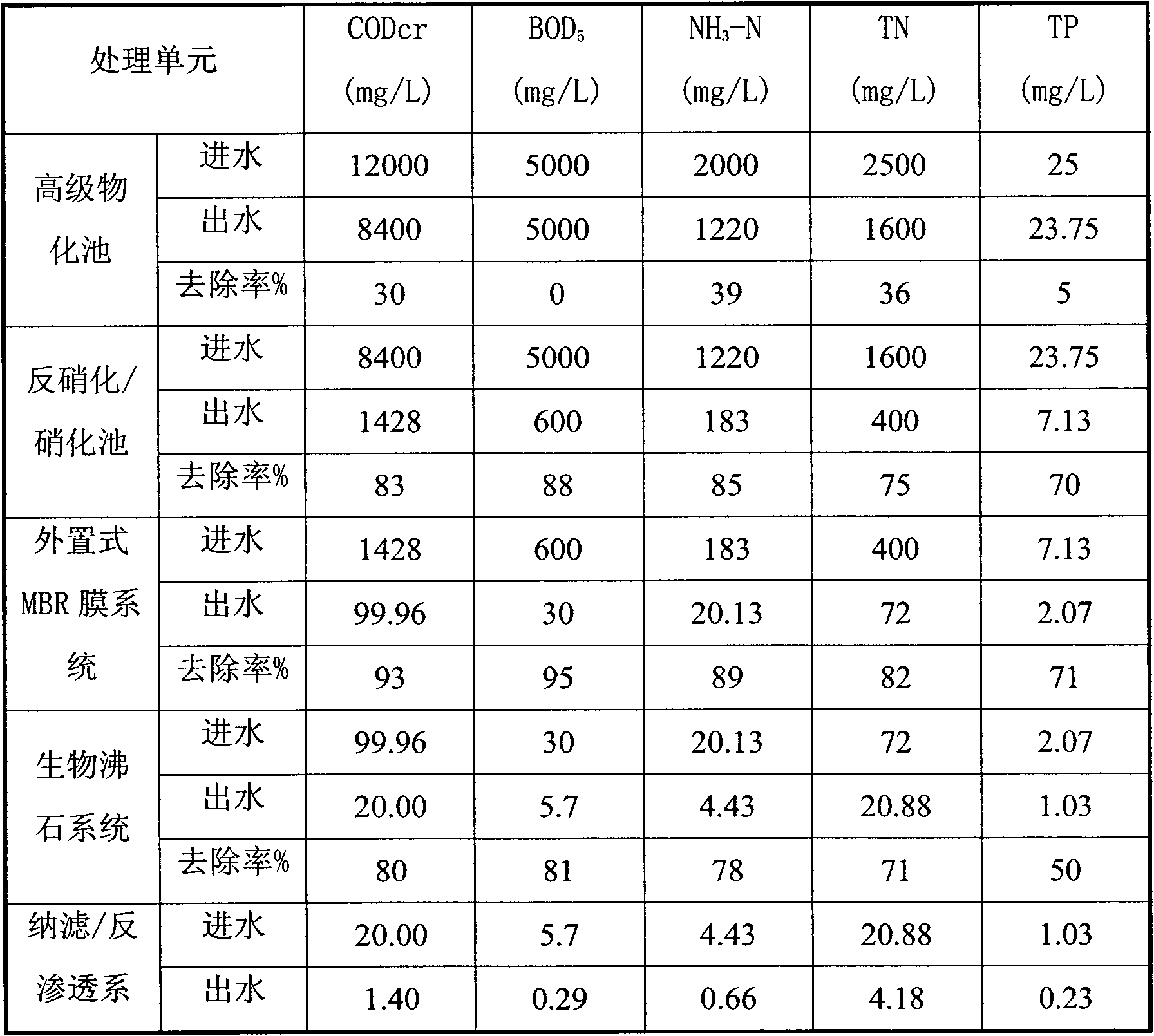

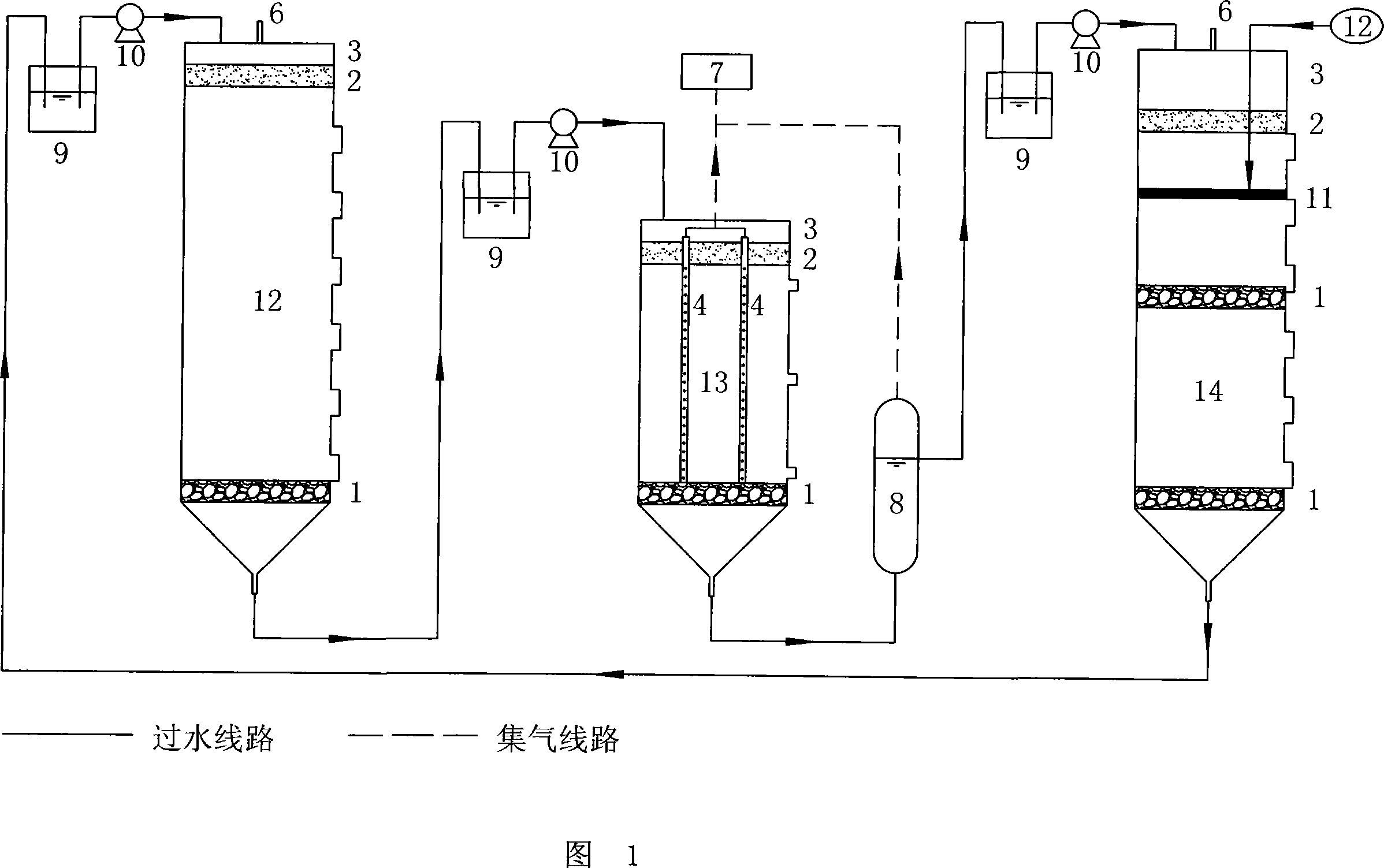

Integral treatment process for rural garbage seeping liquid

ActiveCN102139996AReduced sludge productionLow investment and operating costsTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentNanofiltrationDomestic waste

The invention discloses an integral treatment process for rural garbage seeping liquid; aiming at the characteristics of rural garbage seeping liquid and based on the long-term engineering practice, the following treatment process is provided: the process comprises a high-level physical-chemical technology, a denitrification / nitration technology, an external MBR (meane biological reactor) membrane technology, biozeolite and a nanofiltration / reverse osmosis system, has higher impact resistance load and can adapt to characteristics of rural garbage infiltration of different areas and different landfill ages. The integral treatment process has stable treatment effect; treated water can reach the standard of emission limits specified in Standard for Pollution Control on the Landfill Site of Municipal Solid Waste (GB16889-2008). The integral treatment process reduces the usage of chemical agents, has low investment and operating cost and high treatment efficiency and is easily popularized and used in rural areas.

Owner:北京沁润泽环保科技有限公司

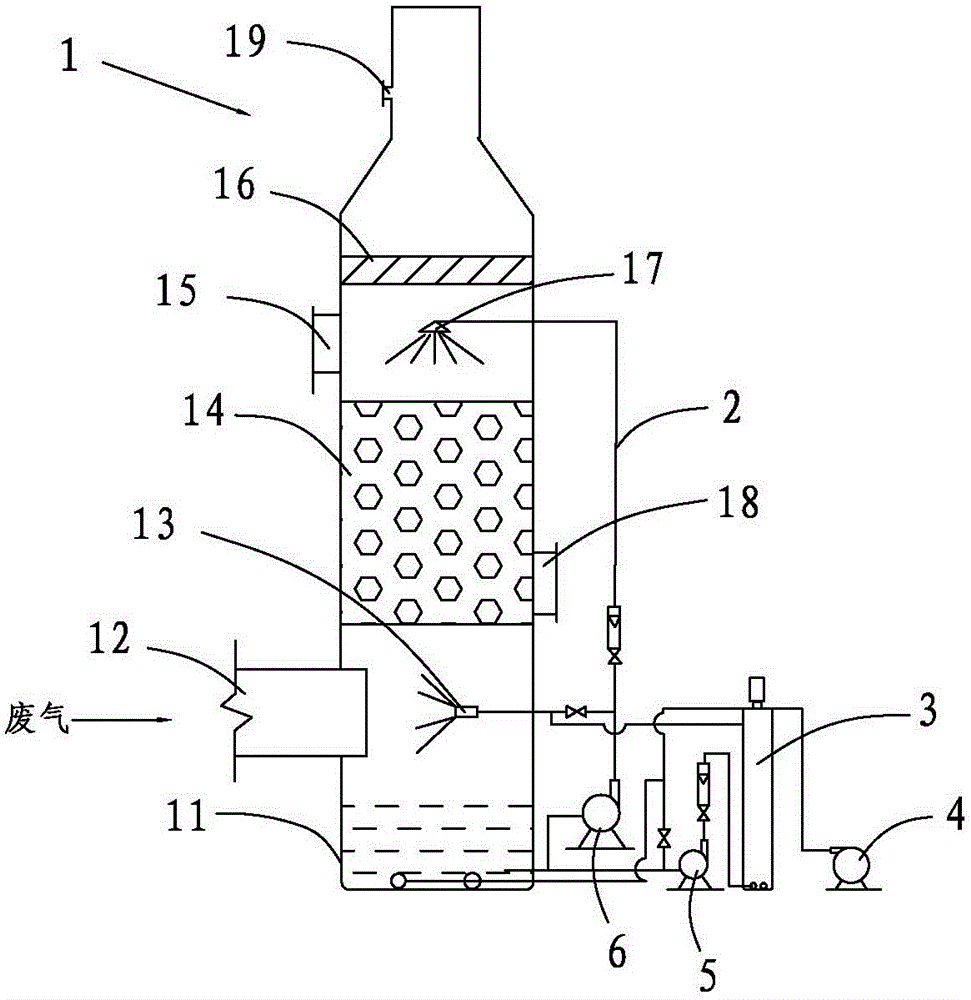

Waste gas processing device and waste gas processing method

ActiveCN105126534AExtended service lifeAvoid frequent replacementDispersed particle separationDemisterProcess engineering

The invention relates to the technical field of waste gas processing, and specifically relates to a waste gas processing device and a waste gas processing method. The waste gas processing device comprises an absorbing tower, a gas-liquid mixing device, a delivering device, a UV oxidizing device, and a releasing device which is connected to the UV oxidizing device. The absorbing tower is provided with a liquid containing part, a gas inlet, a filling material layer, a final nozzle, and a demister from bottom to top in sequence. The final nozzle is communicated with the liquid outlet of the delivering device, the liquid inlet of the gas-liquid mixing device is communicated with the liquid containing part, the liquid outlet of the gas-liquid mixing device is communicated with the UV oxidizing device, and the gas outlet of the UV oxidizing device is communicated with the liquid containing part. The waste gas processing method utilizes the provided waste gas processing device. According to the processing method, the adsorption, catalytic oxidation, and spraying are effectively integrated together to strengthen the waste gas processing effect, moreover, different absorbing liquids that can effectively absorb the waste gas is provided according to the waste gas generated by different types of factories; the waste processing method is flexible and has a wide application range, furthermore, the purification efficiency is improved, the operation is simple and convenient, and the investment cost and operation cost are low.

Owner:邓杰帆

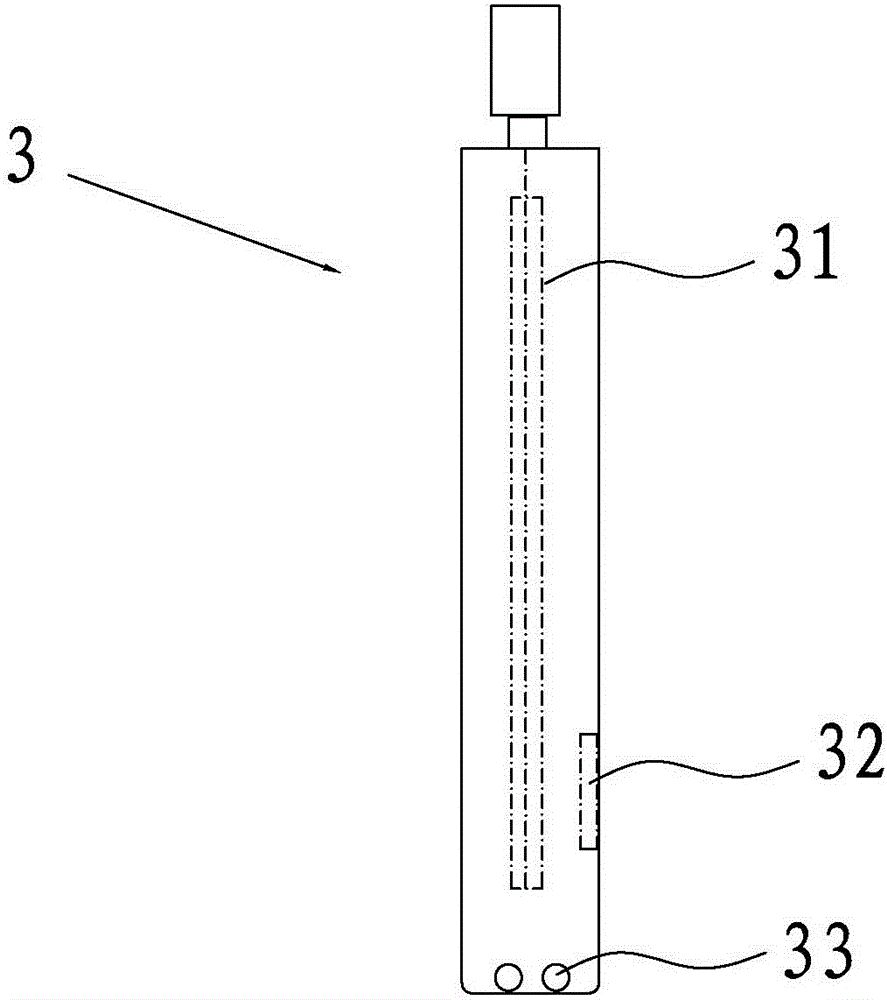

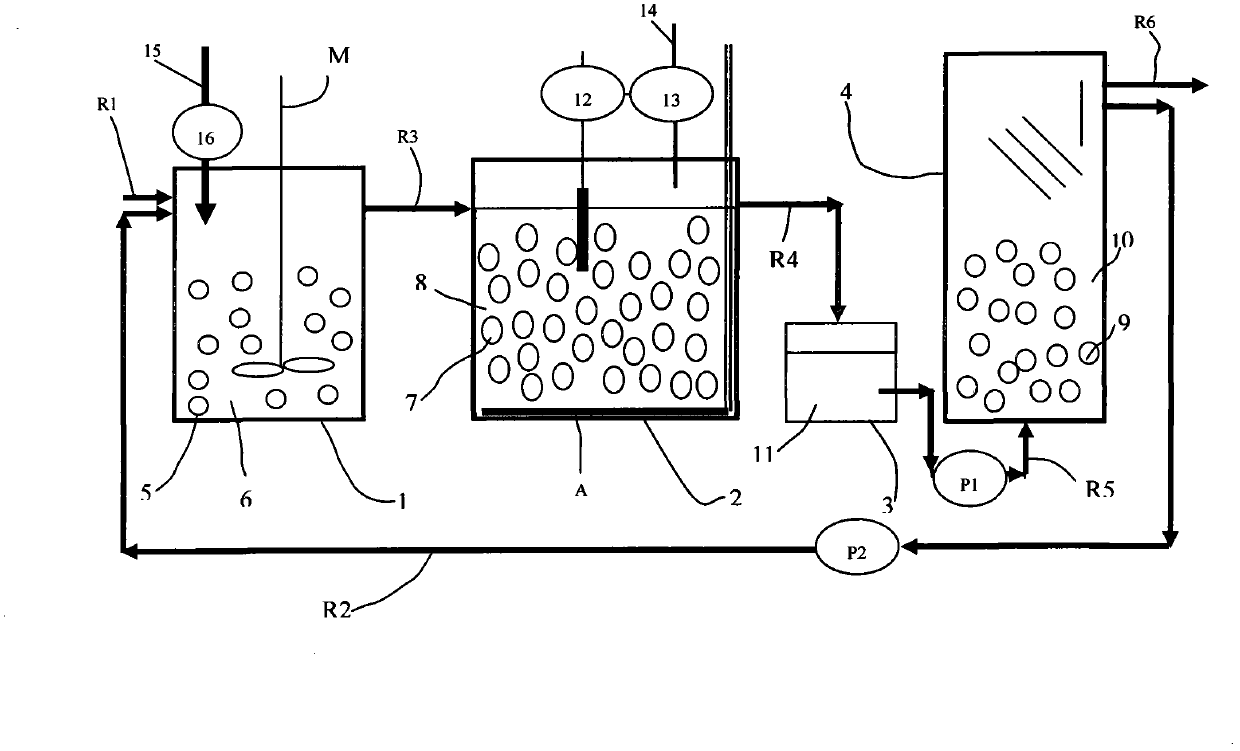

Integrated A/O bacteria filter device for treating dispersed wastewater

ActiveCN101723560ARealize integrationCompact structureTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentSludgeWastewater

The invention relates to an integrated A / O bacteria filter device for treating dispersed wastewater, which has a cylindrical structure in shape. The center of the integrated A / O bacteria filter device is provided with a cylindrical erect flow primary settling tank, a baffle wall is arranged between an inner cylinder body and an outer cylinder body, and a space is divided into an adjusting tank, a hypoxia bacteria filter, an aerobe filter, a clear water tank and a mud storage tank. The aerobe filter and the clear water tank are in a concentric circle arc structure. Wastewater in the adjusting tank is lifted into the primary settling tank through an air lifter, the settled wastewater and recycled nitrification liquor are together distributed into the hypoxia bacteria filter for denitrification, the bottom and the middle part of the hypoxia bacteria filter are provided with backwashing pipelines which can realize subsection washing; the hypoxia bacteria filter is communicated with the bottom of the aerobe filter, the denitrified wastewater overflows from the surface into the clear water tank for outputting after organic matters are removed and nitrification is carried out in the aerobe filter. The backwashing wastewater of the device flows into the adjusting tank per se, and mud in the primary settling tank is lifted into the mud storage tank through the air lifter. The invention has the advantages of less investment, little operation cost, longer mud discharge period and convenient management, thereby being suitable for treating the dispersed wastewater in countryside.

Owner:TONGJI UNIV

Intermission type artificial marsh sewage treating method and sewage treating system

InactiveCN101037264AImprove blockagePromote oxidative decompositionTreatment using aerobic processesSustainable biological treatmentDecompositionSewerage

The present invention relates to a batch type constructed wetland sewerage treatment method and a system thereof, wherein the system comprises a cell body, a filling, a water intake pipe, a water output pipe and a ventilating pipe. The cell body is filled with matrix filling and is provided with a ventilating pipe, wherein plants are planted in the filling. Each performance period of the system comprises four steps of feeding water, reaction, discharging water and emptying, and the system runs in a manner of an ordinal batch type and a repetitive cycle period. The water intake pipe is switched in from the upper part, and the reaeration of the system bottom at reaction stage is intensified by the ventilating pipe, which improve the nitration efficiency. After the reaction finishes, discharging is carried out by the bottom water output pipe, and then the constructed wetland is at an emptying and idlesse step, wherein the reaeration of the constructed wetland system is completed, so as to improve the nitration efficiency of the system, the oxidative decomposition of sludge and the jam of the system. The present invention has the advantages of high efficiency, excellent denitrogenation effete, small occupation of land, little energy consumption, low cost, and is not easy to be jammed.

Owner:CHONGQING UNIV

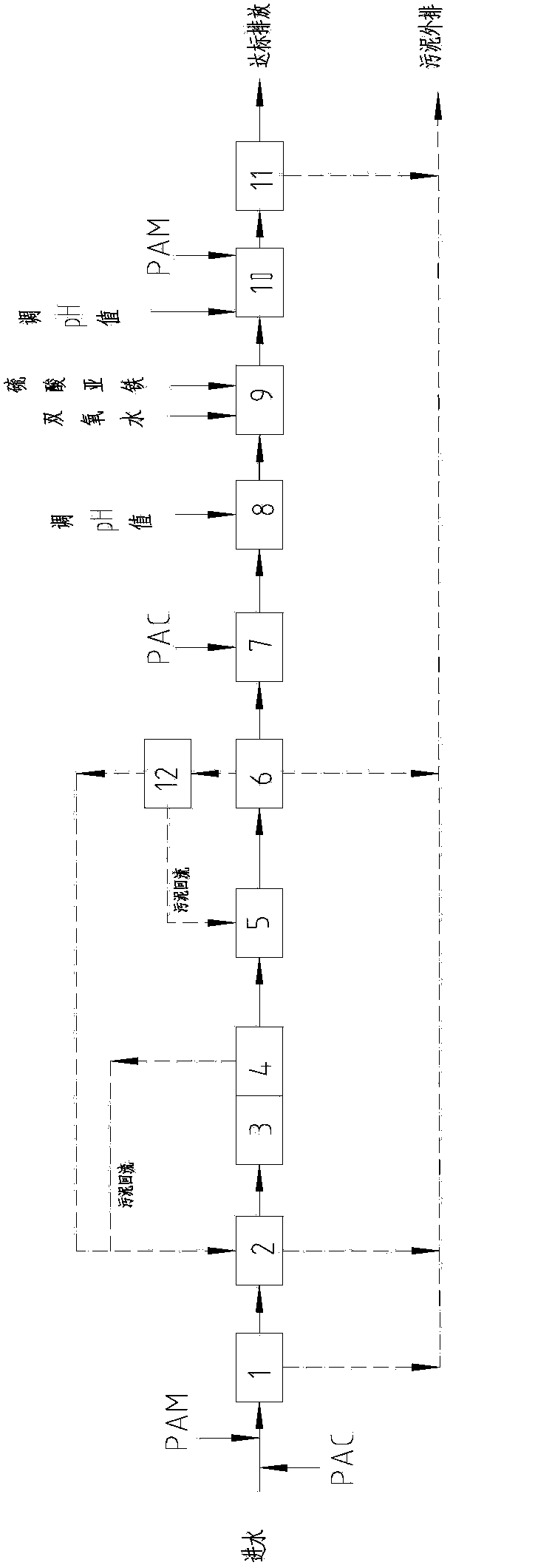

Method for deep treatment on industrial wastewater discharged by styrene-butadiene rubber production device

ActiveCN103723878AEasy maintenance and operationLow running costMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationTreatment effectFiltration

The invention relates to a method for deep treatment on industrial wastewater discharged by a styrene-butadiene rubber production device and belongs to the field of wastewater multilevel treatment. Water treatment devices such as a pre-treatment unit, a sludge adsorption unit, an aerobic biochemical treatment unit, a flocculation and filtration unit and a high-grade oxidation treatment unit are orderly connected and combined; and discharged wastewater treated by the above water treatment devices has COD less than or equal to 40mg / L and NH3-N less than or equal to 5mg / L. The method solves the problem that the prior art has a high treatment cost and poor treatment effects, is a deep treatment method having the advantages of stable, safe and reliable operation, high pollutant removal rate and low operation cost, and realizes stable and standard discharge of industrial wastewater produced by a styrene-butadiene rubber production device. Compared with the prior art, the method reduces a high-grade oxidation phase Fenton's reagent use amount by about 30%, improves treatment depth by 15% and has an industrial application value.

Owner:CHINA PETROLEUM & CHEM CORP

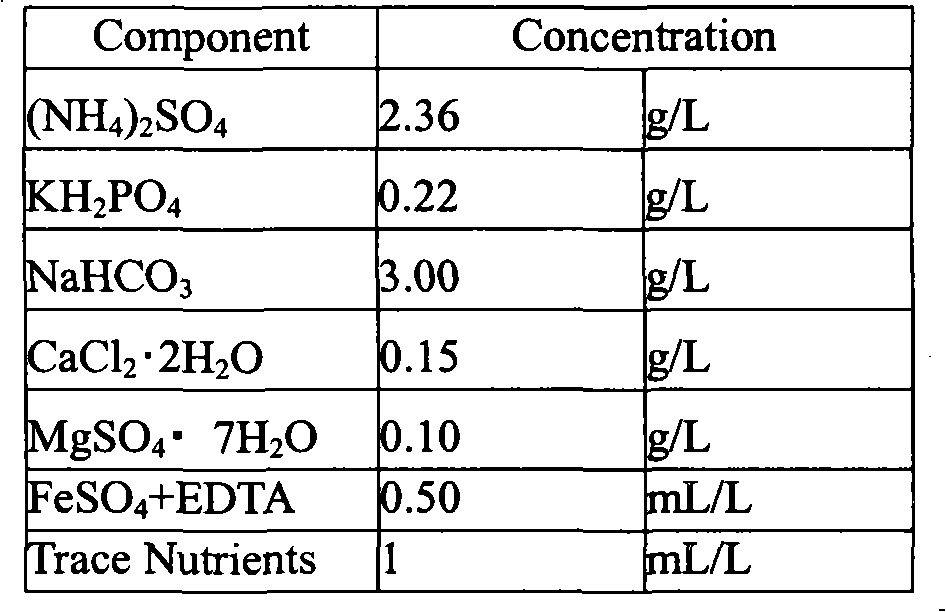

Nitrogen-containing waster water purification method

InactiveCN102167475AEasy to handleEfficient denitrification effectMultistage water/sewage treatmentPurification methodsNitrogen gas

The invention discloses a nitrogen-containing waster water purification method. A denitrification pool, a partial nitrosation pool, an intermediate pool, an anaerobic ammonium oxidation pool and a water outlet reflux system are sequentially arranged; sewage and the outlet water of the anaerobic ammonium oxidation pool enters the denitrification pool respectively through a water inlet end and a reflux pump, and NOx in the outlet water of the anaerobic ammonium oxidation pool is reduced into nitrogen gas by utilizing organic matter in the sewage or additional organic matter as a carbon source under the action of denitrification bacteria; the outlet water with high pH value of the denitrification pool enters the partial nitrosation pool, and ammonia nitrogen in the outlet water of the denitrification pool is oxidized into nitrite nitrogen under the action of nitrobacterium; then, the outlet water of the denitrification pool enters the intermediate pool for adjustment; and finally, the supernatant separated out by the intermediate pool is pumped into the anaerobic ammonium oxidation pool by the pump, is subjected to denitrification reaction under the action of anaerobic ammonium oxidation bacteria, and for the outlet water of the anaerobic ammonium oxidation pool, one part flows back to the denitrification pool, and the other part is directly discharged. The nitrogen-containing waster water purification method has the advantages of stability in running, low investment and running cost, convenience in management, high efficiency for removing pollutant and the like.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Method for advanced treatment and reuse of printing and dyeing wastewater pre-processed by macroporous resin

InactiveCN104098206ALow investment and operating costsImprove water qualityMultistage water/sewage treatmentWaste water treatment from textile industryUltrafiltrationChemistry

The invention discloses a method for advanced treatment and reuse of printing and dyeing wastewater pre-processed by macroporous resin. The method comprises the following steps: taking the printing and dyeing wastewater for the secondary treatment; performing conducting Fenton reaction precipitation, ultra-filtrate membrane filtration, macroporous resin absorption and reverse osmosis membrane separation on discharged wastewater subjected to the treatment, wherein the output water of the reverse osmosis membrane is adopted as the high-quality water for recycling for enterprises, and the concentrated water of the reverse osmosis membrane is emitted on standard, or is emitted to a sewage plant through nano tubes for centralized processing. The method has the advantages that (1) the regular pre-processing technology and multi-media filtration procedure before the macroporous resin is eliminated, and the investment and operation cost is reduced; (2) the ultra-filtrate membrane filtration is adopted as the pre-processing of the macroporous resin, the input water quality is improved, pollutants, such as suspended solids, in water are greatly reduced, the service life and the regeneration period are prolonged, and the operation cost is lowered; (3) the macroporous resin absorption is added as the pre-processing of the reverse osmosis membrane on the basis of the ultra-filtration, the input water quality of the reverse osmosis membrane is improved, pollution is relieved, the service life and the cleaning period are prolonged, and the water output of the reverse osmosis membrane is improved.

Owner:NINGBO QINGSHUIYUAN WATER TECH

Sintering flue gas purification system and method achieving energy conservation and emission reduction

ActiveCN105698550ALow investment and operating costsReduce consumptionNitrous oxide captureGas treatmentFlueExhaust gas

The invention belongs to the technical field of sintering flue gas purification technologies, and provides a sintering flue gas purification system and method achieving energy conservation and emission reduction in order to solve the problems existing in the prior sintering flue gas purification technology. The system comprises a sintering machine, a flue gas distributor, a sintering machine bottom bellows, a sintering machine large gas duct, an electric dust remover, a sintering main exhaust fan, a first fan, a second fan, an adsorption tower, a chimney, a material conveyor and a regeneration tower. Besides, a heat exchanger is arranged in the sintering machine large gas duct of the system, or the system is further provided with a dust remover, and all the devices are connected sequentially through pipelines. The method includes the steps of utilization of flue gas heat of the sintering machine, adsorption of the adsorption tower and regeneration of active coke. According to the system and method, on the basis of effectively controlling the temperature of flue gas, fully utilizing heat-contained exhaust gas, reducing the scale of an active coke flue gas purification device, avoiding secondary pollution and realizing recycling of resources, the investment and operation expenses are lowered.

Owner:中冶北方(大连)工程技术有限公司

Combined filtrating system and method for advanced treatment of dyeing wastewater

InactiveCN101250011AEfficient removalSmall footprintWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentFiberWater storage tank

The invention relates to a combined filtration system for advanced treatment of printing and dyeing wastewater and a method, the system comprises a micro-flocculate deep-bed filtration subsystem and an ultrafiltration membrane filtration subsystem, and the method comprises pumping the printing and dyeing wastewater inside a raw water tank (2) into a pipeline mixer (15) to be sufficiently mixed with flocculating agent and oxidant, discharging mixed water into a water storage tank (25) after being filtered and purified via a fiber ball filter (10), then filtering by a pressure pump (41) via an ultrafiltration membrane component (47) and finally discharging water into a clear water tank (55). The process of the invention is simple in flow, small in accommodation area and low in investment and operation cost, and not only can effectively removing contaminants as chroma, turbidity, TOC, ammonia nitrogen and the like from the wastewater, but also takes the micro-flocculate deep-bed filtration subsystem as a pretreatment process of ultrafiltration, thereby largely reducing load of the ultrafiltration membrane and reducing chances of membrane fouling. Therefore, the combined filtration system for advanced treatment of printing and dyeing wastewater and the method have wide application prospect in advanced treatment field of the printing and dyeing wastewater.

Owner:DONGHUA UNIV

Method and device for purifying nitric oxide and fog particles in wet desulphurization aerial fog by low-temperature plasma

ActiveCN103990359ALow investment and operating costsIncrease contactCombination devicesAir quality improvementChemistryNitric oxide

The invention discloses a method and device for purifying nitric oxide and fog particles in wet desulphurization aerial fog by low-temperature plasma. The method comprises the steps of introducing the wet flue gas desulphurization aerial fog into a purification device, and oxidizing nitric oxide in the aerial fog into nitrogen dioxide with strong hydrophilia by the low-temperature plasma generated by high voltage discharge; furthermore, catching the fog particles in the aerial fog, which are charged and directionally move onto an electrode liquid film under high voltage discharge; and prompting the airflow to move towards an electrode by the inductive effect of moving particles in the electric field, and contacting nitrogen dioxide with the electrode liquid film so that nitrogen dioxide is absorbed and removed. Due to the oxidation of the low-temperature plasma and the directional movement of the airflow and the charged particles under the action of electric field force, gaseous mercury, sulfur trioxide sol, smoke and the like in the aerial fog can be removed. The method and the device realize the purpose that multiple pollutants in the wet desulphurization aerial fog are removed at the same time, namely, the multiple pollutants can be removed in a reactor, so that the investment and the operating cost of flue gas treatment can be greatly reduced.

Owner:BEIHANG UNIV

Domestic garbage stuffing and processing technique with in-situ denitrogenation function and bioreactor

ActiveCN101164926ARealize the function of biological in situ denitrificationLow investment and operating costsSolid waste disposalSludge processingElectron donorNitration

This invention discloses a technique for garbage buried treatment with denitrification in site. In a nitration reactor, there are: an upper layer-aeration zone having aerator, a medium layer-facultative zone and the bottom layer-anaerobic zone. In the aeration zone, ammonia is oxidized into NO3-by the autotrophic nitrifier; in the facultative zone, NO3-is reduced into N2 by denitrifying bacteria by using organic substances as electron donor, and the N2 is released into the air to achieve the transformation from NH4 to N2 and its removal. In the anaerobic zone, the organic matter is degraded into methane. This invention provides a biological reactor by using above-mentioned technique. In this invention, the three (buried main body, produced gas and liquid) is considered into an integral one, so having advantages of: low cost, high efficiency.

Owner:ZHEJIANG UNIV

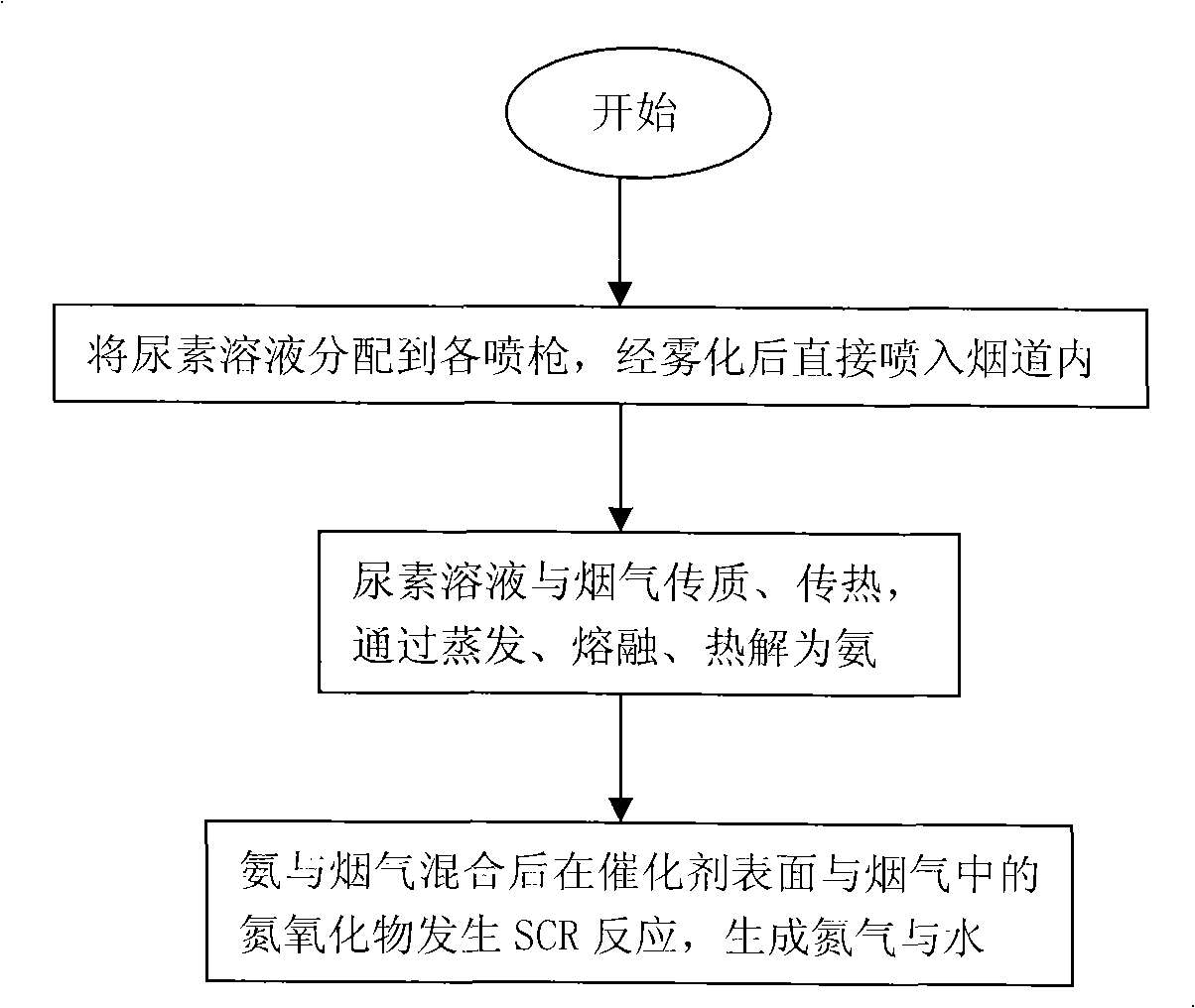

Selective catalytic reduction device by directly spraying urea solution and method thereof

InactiveCN102210974ALow investment and operating costsSave equipment spaceDispersed particle separationAmmonia preparation/separationFlueChemistry

The invention discloses a selective catalytic reduction device by directly spraying a urea solution and a method thereof, and relates to the technical field of environmental protection. The device comprises a plurality of groups of spray guns for spraying the urea solution, which are arranged at an inlet flue before a selective catalytic reduction (SCR) reactor, and a mixer and a catalyst which are arranged along the flowing direction of flue gas in turn, wherein each spray gun is connected with a urea solution tank through a metering distributor. Compared with the prior art, the invention has the advantages that: the urea solution is directly sprayed into the flue to thermally decompose the supplied ammonia, the operating cost and equipment investment are reduced, the space is saved, and the device is safe and reliable to use.

Owner:TONGFANG ENVIRONMENT

Dry desulfurization and urea solution direct injection denitrification device for flue gas of sintering machine

InactiveCN106139846AReduce emission concentrationReduce dosageHuman health protectionDispersed particle filtrationInlet valveRotary feeder

A dry desulfurization and urea solution direct injection denitrification device for flue gas of a sintering machine comprises the sintering machine, an air bellow, an online flue gas monitoring control device, an electric air inlet valve, a reaction tower, a bag-type dust collector, a fan and a chimney. The device is characterized in that the sintering machine is sequentially connected with the air bellow, the online flue gas monitoring control device, the electric air inlet valve, the reaction tower, the bag-type dust collector, the fan and the chimney, an electric flow regulating valve is connected between the air bellow and the online flue gas monitoring control device, the online flue gas monitoring control device is connected with a PLC (programmable logic controller) control box connected with a variable-frequency rotary feeder, the upper side of the variable-frequency rotary feeder is connected with an electronic screw scale connected with a discharger, the discharger is connected with a urea granule bin, and the lower side of the variable-frequency rotary feeder is connected with the upper side of a jet flow mixer. With the adoption of the device, harmful pollutants such as SO2, NOx, dioxin, heavy metals and the like in the flue gas of the sintering machine can be removed, up-to-standard emission of the flue gas is realized, and environmental pollution is avoided.

Owner:WUXI LUSHENG MACHINERY EQUIP

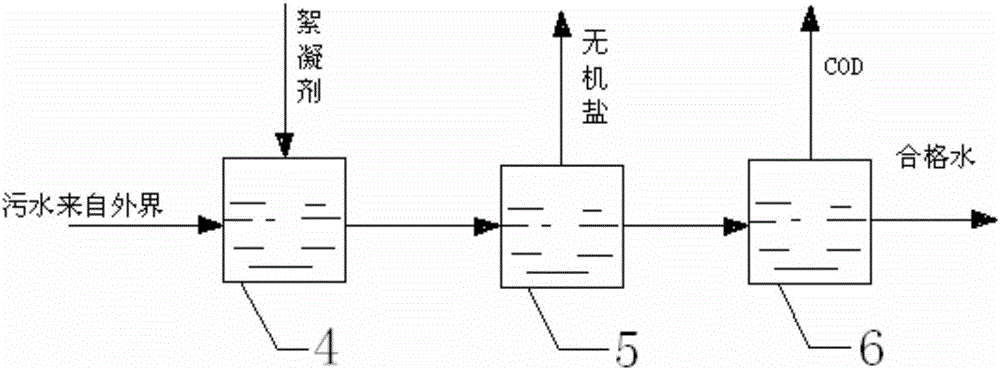

Method and process system for innocuous treatment of high-salt and high-COD waste alkali liquid

InactiveCN106587470ALower quality requirementsEasy to handleMultistage water/sewage treatmentWater/sewage treatment by neutralisationInorganic saltsProcess systems

The invention discloses a method and a process system for innocuous treatment of high-salt and high-COD waste alkali liquid. The method includes the steps of: adding a neutralizer to pre-treat the high-salt and high-COD waste alkali liquid, wherein the pH of the treated waste alkali liquid is 2-8; adding a catalyst to perform a catalytic reaction under an aeration or a stirring condition to remove COD in the waste alkali liquid; and performing evaporating desalination to the waste alkali liquid to complete the treatment. The method has lower requirement on the quality of the waste alkali liquid and can be used for treating the waste alkali liquid well even inorganic salt content reaches 20% and COD content reaches 10%. The method has more environment-friendly treatment process and is free of addition of microorganisms. The treated liquid is not more than 45 ppm in COD content and is not more than 200 ppm in inorganic salt content.

Owner:SHANDONG DONGYUE FLUO SILICON MATERIALS CO LTD

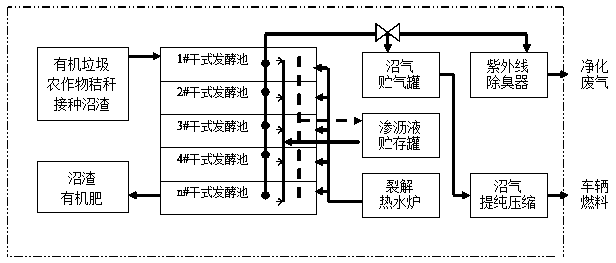

Biological dry type fermentation treatment device for household garbage and crop straws

ActiveCN103865781AAvoid occupyingAvoid pollutionGas production bioreactorsWaste based fuelSlurryFermentation

The invention relates to a biological dry type fermentation treatment device for household garbage and crop straws. The device comprises fermentation tanks, a spray pipe, a reflux sewage electric pump, a spray sewage electric pump, a leachate storage tank and a heating coil, wherein a cone-shaped door hole is formed in one end of each fermentation tank while an emptying valve is arranged at the other end of the fermentation tank; a plurality of biogas collecting pipes are communicated with a biogas storage cabinet; the fermentation tank is a dry type fermentation tank, no water is used for fermentation, and no biogas slurry is discharged; the fermentation tank has an arched top to collect biogas conveniently; the dry type fermentation tank is modular and multiple tanks are circularly used to realize continuity of treatment and gas generation of garbage and crop straws; 25-30 days of dry type fermentation is a cycle; through intermediate temperature fermentation at 35-38 DEG C, the hot water coil is used to heat in winter or seasons at low temperatures. Acidified gases are discharged before the gas generation cycle, the hydrogen sulfide content of the biogas generated by dry type fermentation is lower than that of biogas generated in a wet process, and the purity of biogas is high. CH4 is greater than or equal to 65%, and H2S is less than or equal to 12ppm. 120-150 of biogas is generated by mixed raw materials of garbage and straws per ton.

Owner:山东恒仁工贸有限公司

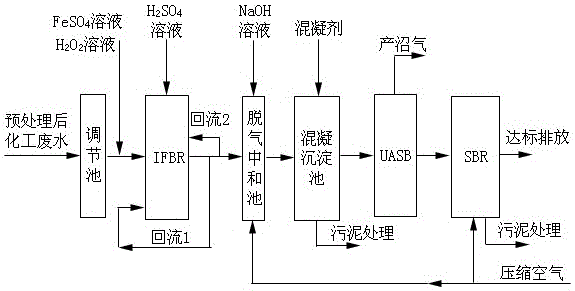

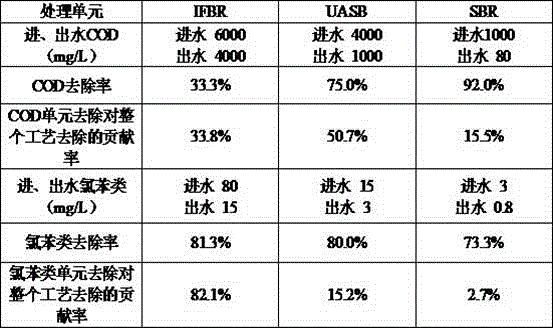

Novel combined process for treating chemical wastewater

InactiveCN105884154AMeet environmental requirementsSimple processWater treatment parameter controlWater treatment compoundsSequencing batch reactorFluidized bed

The invention provides a novel combined process for treating chemical wastewater. The process adopts a regulating tank, an improved Fenton fluidized bed, a degassing neutralizing tank, a coagulative precipitation tank, an up-flow anaerobic sludge bed and an SBR (sequencing batch reactor), wherein the units are connected by a water pipe in sequence to treat the chemical wastewater. The novel combined process has the beneficial effects that the process is optimized and is clear and concise in route; the overall COD (chemical oxygen demand) removal rate is not less than 95%; the removal rate of characteristic organic pollutants is not less than 95%; and the process is convenient to operate and manage, is stable and is low in investment and operating costs.

Owner:YANCHENG INST OF TECH

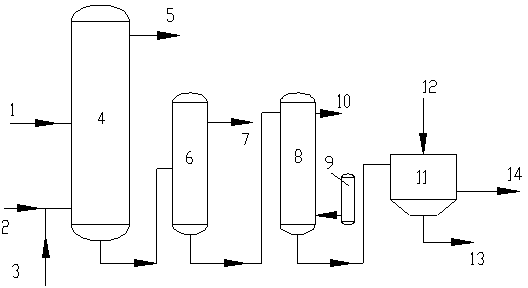

Flue gas desulfurization and denitration method

ActiveCN102371110AEasy to recycleLow investment and operating costsUsing liquid separation agentAir quality improvementAtmospheric airFlue gas

The present invention discloses a flue gas desulfurization and denitration method. The method comprises the following steps that: ozone is introduced to a flue gas pipeline with a temperature of 50-200 DEG C, wherein a molar ratio of the ozone to the NOx is 1-3:1; the flue gas mixture after the reaction enters a water washing tower, and is subjected to counter current contact with water to carry out quenching, wherein a volume ratio of the water to the flue gas is 0.002-0.003:1; the water-washed flue gas enters a SO2 absorption tower, and contacts with an absorption agent, wherein the temperature of the SO2 absorption tower is 40-65 DEG C, the volume ratio of the absorption agent to the flue gas is 0.25-0.5:1000; the absorption agent absorbing the SO2 enters a regeneration tower to carry out regeneration; the regenerated absorption agent is recycled, and the purified flue gas is discharged to atmosphere by a chimney.

Owner:CHINA PETROLEUM & CHEM CORP +1

Water purifying method of uniform flow constructed wetland

ActiveCN102381767AAvoid formingFull play of physicsSustainable biological treatmentBiological water/sewage treatmentConstructed wetlandWater flow

The invention discloses a water purifying method of a uniform flow constructed wetland. A constructed wetland is established; a water inlet end is arranged on one wall of the wetland pool, and a water outlet end is arranged on the other wall of the wetland pool; the water inlet end and the water outlet end are respectively provided with a water distributing zone and a water gathering ground, which are filled with cobblestones with a particle size of 30-50mm; a main body filling material zone comprises, from top to bottom: a first layer filter pack filled with a quartz sand filling material with a particle size of 0.1-1 mm, a second layer filter pack filled with a quartz sand filling material with a particle size of 0.1-3mm; a third layer filter pack filled with a quartz sand filling material with a particle size of 1-3 mm; a fourth layer filter pack filled with a quartz sand filling material with a particle size of 1-5 mm; a fifth layer filter pack filled with a quartz sand filling material with a particle size of 3-7 mm; and humidogene emergent aquatic plant plants are planted on top of the first layer filter pack. The invention can be used in treatment of household sewage in cities and towns and industrial wastewater of food processing industry and slaughter industry, etc., so as to avoid current short flow and formation of a dead zone and remove pollutants efficiently.

Owner:恒晟水环境治理股份有限公司

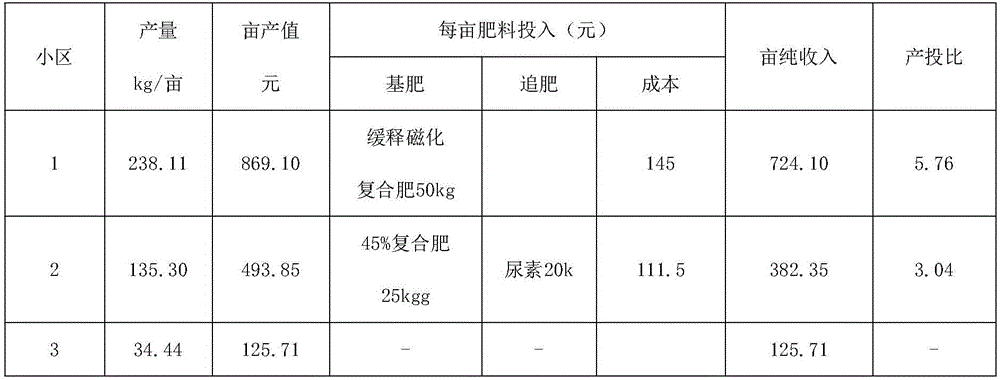

Slow-release magnetized composite fertilizer for planting rapeseed and its preparation method

InactiveCN106187587AIncrease or decrease usageEarly administrationCalcareous fertilisersMagnesium fertilisersPhosphateRapeseed

The invention relates to slow-release magnetized composite fertilizer for planting rapeseed and its preparation method. The slow-release magnetized compound fertilizer for planting rape includes the following raw materials in parts by weight: 24-28 parts of urea, 18-22 parts of potassium dihydrogen phosphate, 3 to 5 parts of calcium powder, 10 to 16 parts of potassium chloride, 2 to 2.5 parts of humic fertilizer, 0.2 to 0.5 part of selenium-rich fertilizer, 0.5 to 1 part of magnesium sulfate heptahydrate, 1 to 2 parts of starch ether, 4 to 8 parts of fertilizer additives, and 34 to 40 parts of magnetic carrier. The slow-release magnetized composite fertilizer for planting rapeseed is characterized in that the iron mineralized tailing sand compound fertilizer is magnetized, the soil environment is improved, the fertilization period of the fertilizer is enhanced, the nutrition absorption of the crop is enhanced, the lodging resistance and disease resistance of the rape are enhanced, yield and earnings are increased, and the environment is protected.

Owner:ANHUI JINLU COMPOSITE MAGNETIC FERTILIZER

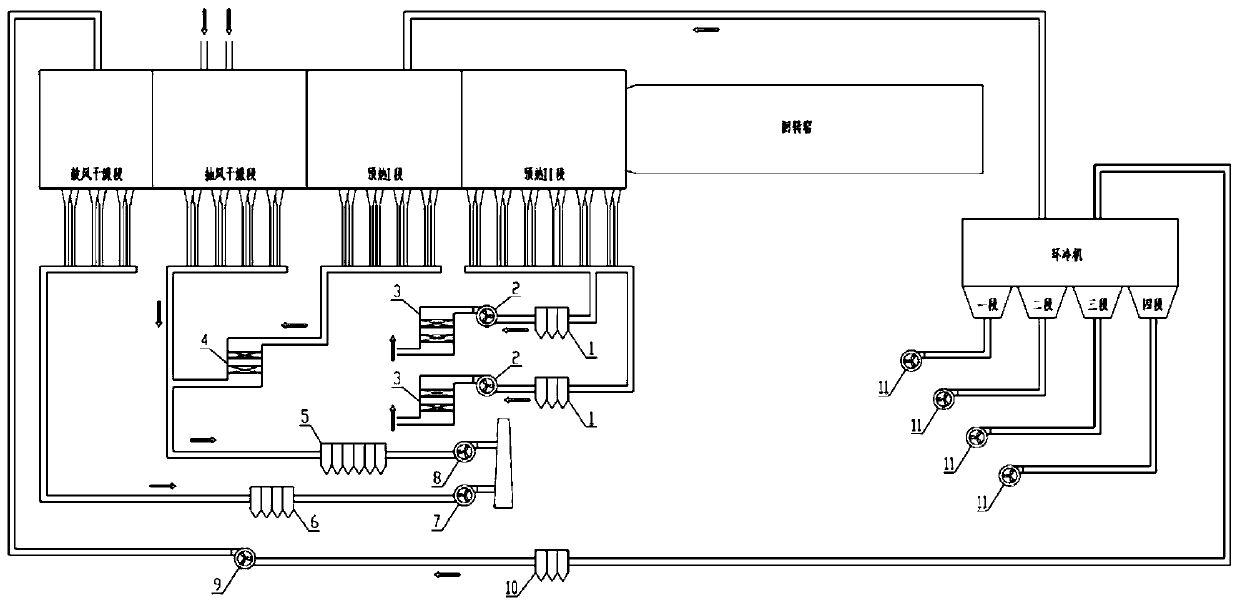

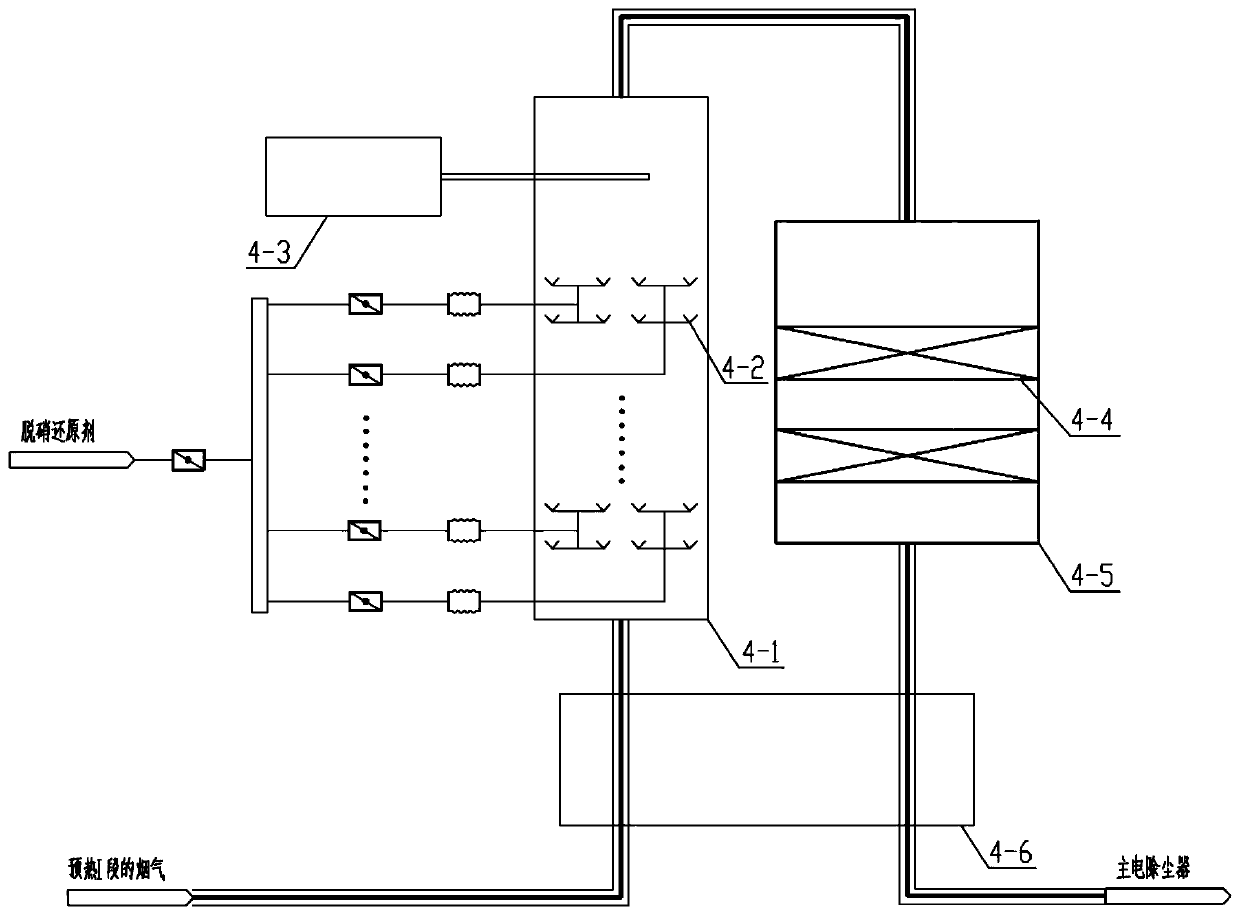

Denitrification system for grate-rotary kiln pellet equipment

PendingCN110420558AHigh activityLow investment and operating costsGas treatmentDispersed particle separationFlue gasEngineering

The invention discloses a denitration system for grate-rotary kiln pelletizing equipment. The grate-rotary kiln pelletizing equipment comprises a grate, a rotary kiln and an annular cooler which are sequentially connected, wherein the denitration system comprises a first SCR denitration unit arranged at a flue gas outlet of a grate preheating section II and a second SCR denitration unit arranged at a flue gas outlet of a grate preheating section I, wherein the second SCR denitration unit further comprises a flue gas heating subunit. According to the invention, the first SCR denitration unit isarranged at the outlet of the preheating section II, so that flue gas temperature is high, flue gas does not need to be heated, the catalyst activity is good, the investment operation cost is low, the system is simple and high in reliability, the catalyst consumption can be reduced, and the ultra-low emission standard can be met; by arranging the second SCR denitration unit and a flue gas heatingdevice at the flue gas outlet of the preheating section I, the total fuel gas consumption and the investment cost are reduced.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com