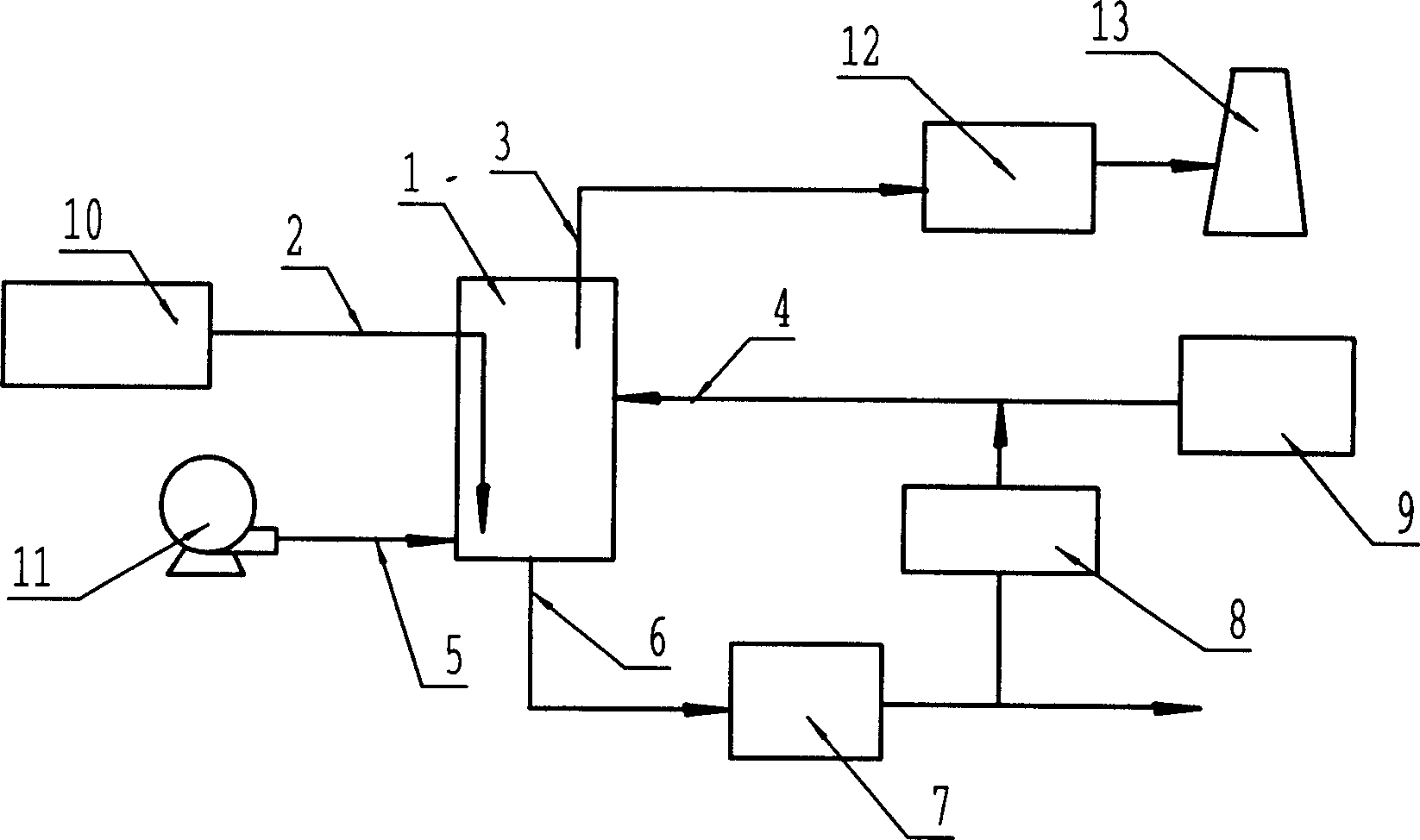

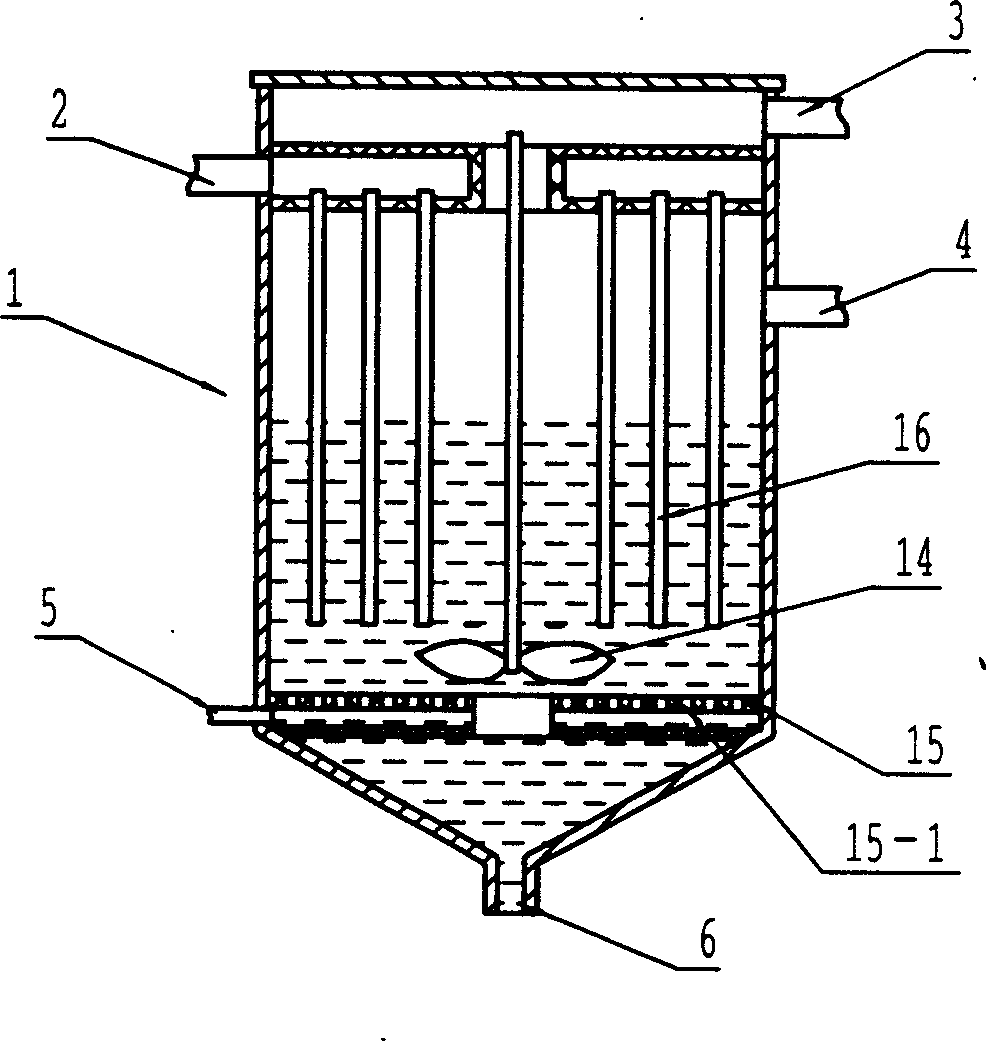

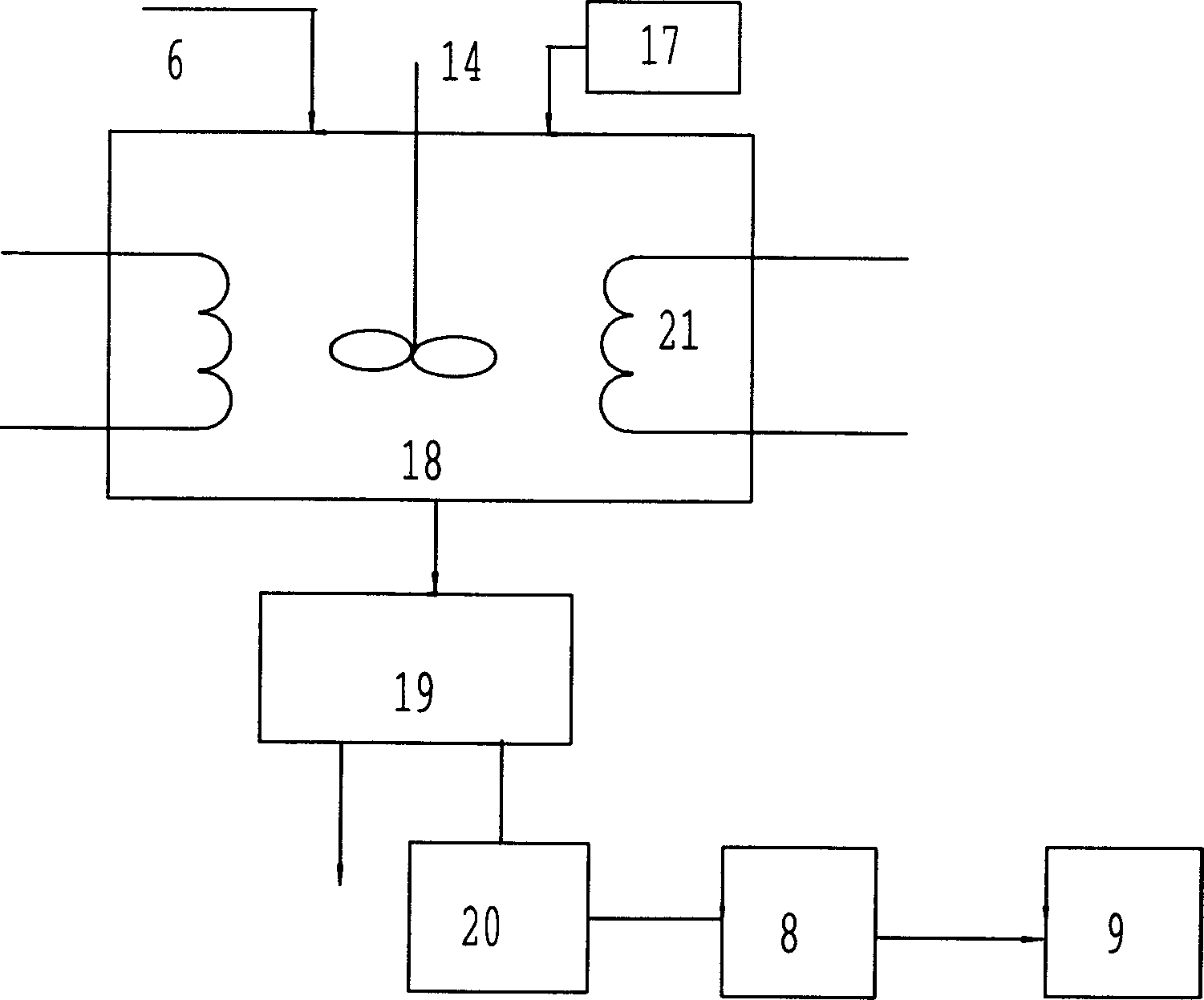

Liquid phase flue gas desulfurizing and denitrifying purification method and apparatus

A desulfurization, denitrification and purification device technology, applied in the field of flue gas purification, can solve the problems of resource waste, inability to recover nitrogen resources, consumption of large reducing agents, etc., achieving low investment and operating costs, high absorbent utilization rate, and easy popularization and application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Add the absorbent solution containing 0.001mol / L sodium chlorite and 0.001mol / L calcium chlorite into the preparation reactor, adjust the pH value to 3, and place it in the dark for activation at a temperature of 259°C. The absorption solution is obtained in minutes.

Embodiment 2

[0028] Example 2: Add the absorbent solution containing 0.002mol / L sodium chlorite and 0.001mol / L hydrogen peroxide into the preparation reactor, adjust the pH value to 4, activate at a temperature of 40°C for 60 minutes to obtain the absorbent solution.

Embodiment 3

[0029] Example 3: Add 0.005 mol / L sodium chlorite and 0.001 mol / L sodium bicarbonate into the preparation reactor, adjust the pH value to 5, activate at a temperature of 40° C. for 10 minutes to obtain the absorption solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com