Waste gas processing device and waste gas processing method

An exhaust gas treatment device and exhaust gas treatment technology, applied in the field of pollutants, can solve the problems of general adaptability and treatment effect of VOC exhaust gas, failure to eliminate ozone, air pollution, etc., and achieve low investment and operation costs, easy operation, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

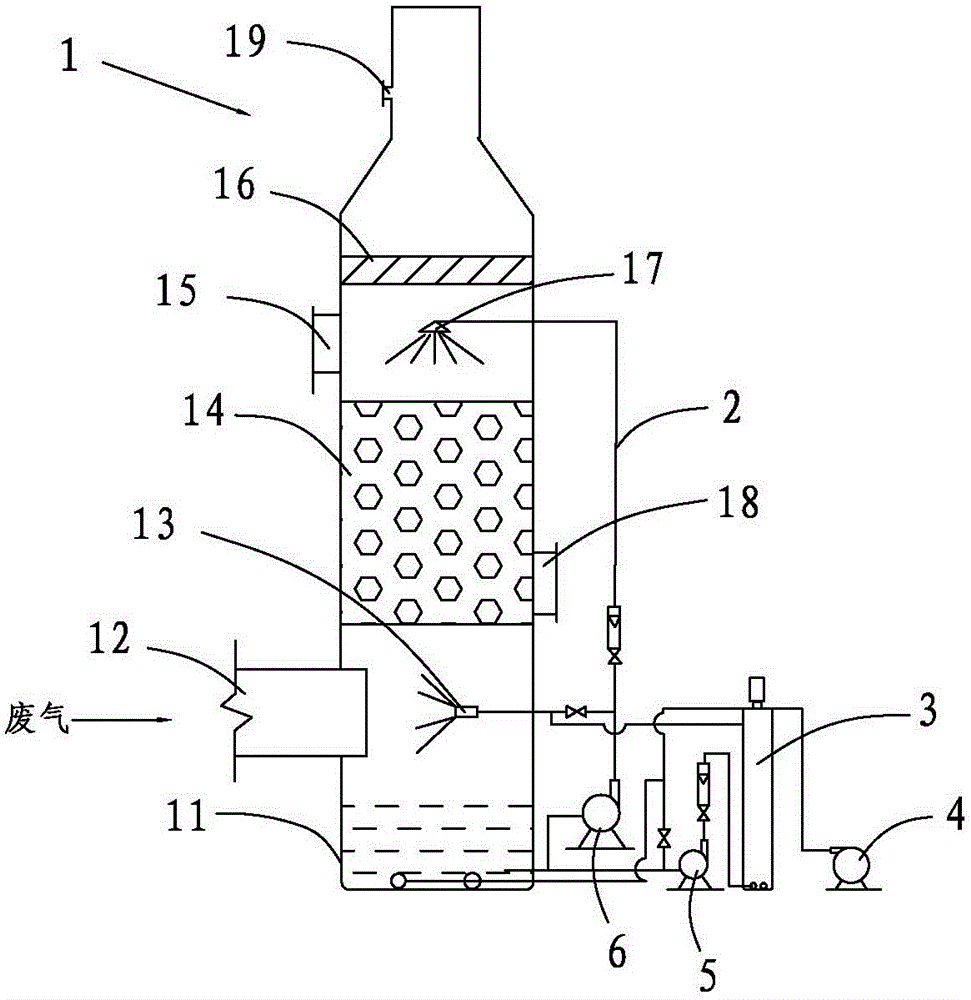

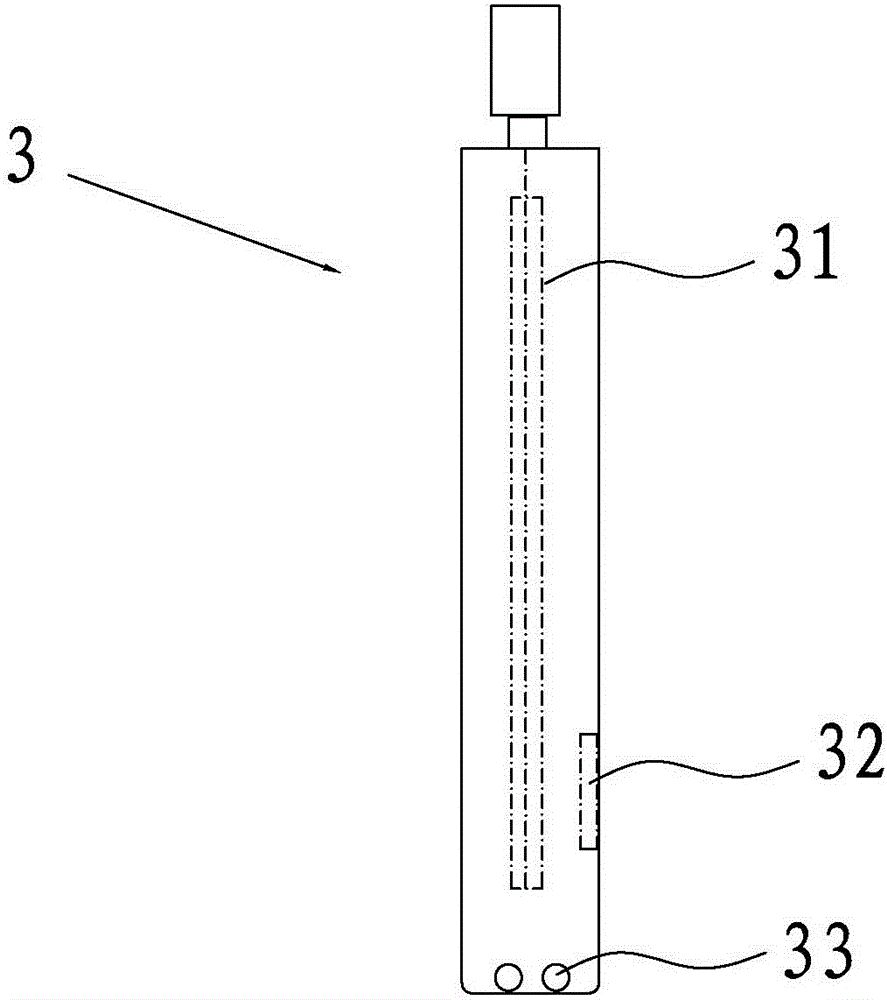

[0049] Such as figure 1 As shown, a waste gas treatment device includes an absorption tower 1, an ultraviolet oxidation device 3, a gas-liquid mixing device 5, a delivery device 6 and a release device 4 connected to the ultraviolet oxidation device 3, and the absorption tower 1 is sequentially arranged from bottom to top It is provided with a liquid setting part 11, an air inlet 12, an atomizing nozzle 13, a packing layer 14, a final nozzle 17 and a demister 16, and the atomizing nozzle 13 and the final nozzle 17 communicate with the liquid outlet of the delivery device 6, The liquid inlet of the gas-liquid mixing device 5 communicates with the liquid part 11, the liquid outlet of the gas-liquid mixing device 5 communicates with the ultraviolet oxidation device 3, and the gas outlet of the ultraviolet oxidation device 3 communicates with the liquid part 11. In communication, the ultraviolet oxidation device 3 is provided with an ultraviolet lamp group 31, and the packing layer...

Embodiment 2

[0074] Using the exhaust gas treatment device described in Example 1, the exhaust gas treatment method of the present embodiment is applied to the exhaust gas containing multi-component VOC in the spray paint manufacturing plant, including the following steps:

[0075] Step a), filling the liquid part 11 with absorbing liquid, starting the delivery device 6 and the final nozzle 17, and the final nozzle 17 sprays the oxidant;

[0076] Step b), after the final nozzle 17 sprays for 20 minutes, start the ultraviolet oxidation device 3 and the release device 4, the release device 4 transports air into the ultraviolet oxidation device 3, and the ultraviolet lamp group 31 in the ultraviolet oxidation device 3 radiates ultraviolet rays to convert the O in the air 2 Irradiation produces O 3 , and then release device 4 will generate O 3 Transport to the liquid part 11;

[0077]Step c), the air inlet 12 is opened, the waste gas is sent into the absorption tower 1 by the centrifugal fa...

Embodiment 3

[0090] Using the waste gas treatment device described in Example 1, the waste gas treatment method of this embodiment is applied to the treatment of multi-component VOC-containing paint spraying waste gas in plastic products factories, including the following steps:

[0091] Step a), filling the liquid part 11 with absorbing liquid, starting the delivery device 6 and the final nozzle 17, and the final nozzle 17 sprays the oxidant;

[0092] Step b), after the final nozzle 17 sprays for 17 minutes, start the ultraviolet oxidation device 3 and the release device 4, the release device 4 transports the air into the ultraviolet oxidation device 3, and the ultraviolet lamp group 31 radiates ultraviolet rays to remove the O in the air 2 Irradiation produces O 3 , and then release device 4 will generate O 3 Transport to the liquid part 11;

[0093] Step c), the air inlet 12 is opened, the waste gas is sent into the absorption tower 1 by the centrifugal fan after the pretreatment of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com