Method and process system for innocuous treatment of high-salt and high-COD waste alkali liquid

A technology for harmless treatment and waste lye, applied in chemical instruments and methods, water/sewage treatment, water/sewage multi-stage treatment, etc. It can solve the problems of poor device operation and poor effluent quality, and achieve low-investment operation. cost, improve water quality, and increase the effect of efficient operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

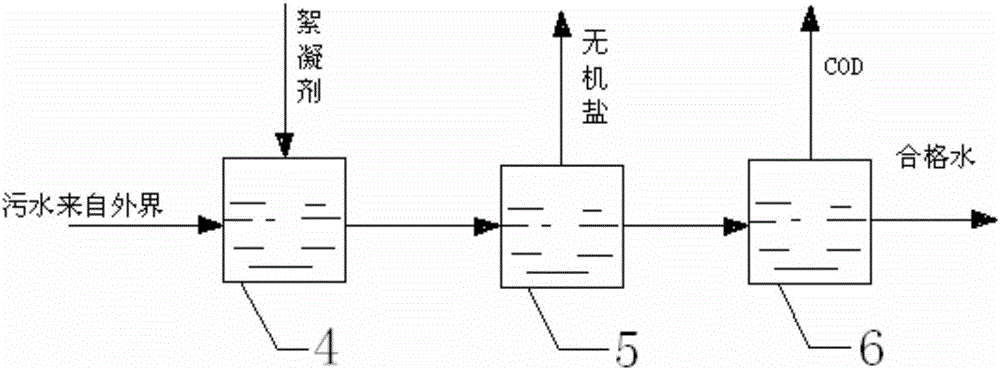

[0033] like figure 1 , as shown in 2, a high-salt and high-COD waste lye harmless treatment system includes a pretreatment pool 1, a COD removal unit 2 and a first desalination device 3, the pretreatment pool 1 and the COD removal unit 2 connected, the COD removal unit 2 is connected with the first desalination device 3;

[0034] The COD removal unit 2 includes an interconnected COD removal reactor 2-1 and a clarification tank 2-2, and the COD removal reactor 2-1 is provided with a modular catalyst 2-3 and an aeration pipe 2-4 ; The COD removal reactor 2-1 is connected to the pretreatment pool 1, and the clarification tank 2-2 is connected to the desalination device 3. The modular catalysts 2-3 are evenly distributed in the cubic grid module, and the catalytic reaction process is combined with aeration or stirring measures, which can increase the reaction rate and make the reaction points evenly distributed.

Embodiment 2

[0036] A method for harmless treatment of high-salt and high-COD waste lye, comprising using the system described in Example 1, the steps are as follows:

[0037] The waste lye raw water (COD content is 23000ppm, inorganic salt content is 5%) enters the pretreatment tank 1 and adds a neutralizer (31% hydrochloric acid) to adjust the pH of the waste lye to 2, and the pretreated waste liquid enters the COD for removal Unit 2, the modular catalyst 2-3 in COD removal unit 2 is activated carbon, and the amount of catalyst added is 2m 3 / (m 3 Waste lye), under aeration condition, 10~40 ℃, catalytic reaction 2h, remove most of COD waste liquid (COD content ≤ 70ppm) and send to the first desalination device 3. In the first desalination device 3, the waste liquid is evaporated by steam heating at 115°C. The COD of the wastewater flowing out from the desalination device 3 is reduced to 38ppm, and the content of inorganic salt is ≤200ppm.

Embodiment 3

[0039] A method for harmless treatment of high-salt and high-COD waste lye, comprising using the system described in Example 1, the steps are as follows:

[0040] Waste lye raw water (COD content is 11000ppm, inorganic salt content is 13%) enters pretreatment pool 1 and adds neutralizer (20wt% sulfuric acid) to adjust waste lye pH to 5, and waste liquid after pretreatment enters COD to remove Unit 2, the modular catalyst 2-3 in COD removal unit 2 is aluminum powder, and the amount of catalyst added is 1.5m 3 / (m 3 Waste lye), under aeration conditions, 10-40°C, catalytic reaction for 1.5h, and the waste liquid (COD content ≤ 60ppm) with most of the COD removed is sent to the first desalination device 3 . In the first desalination device 3, the waste liquid is evaporated by steam heating at 105°C. The COD of the wastewater flowing out from the first desalination device 3 is reduced to 30ppm, and the content of inorganic salt is ≤200ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com