Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Good penetration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pharmaceutical spray compositions comprising a bioactive agent, at least one volatile silicone and a non-volatile oily phase

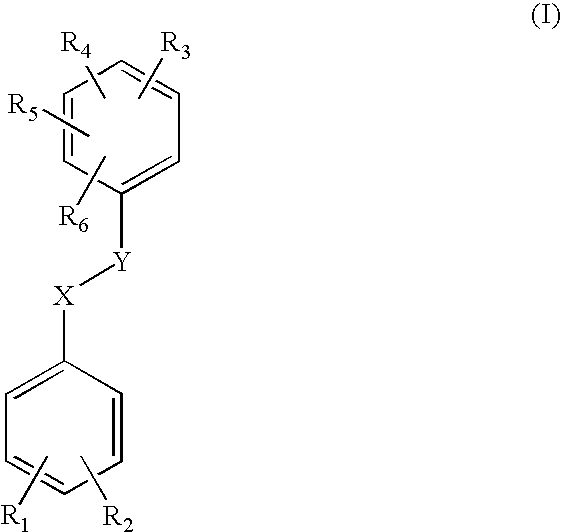

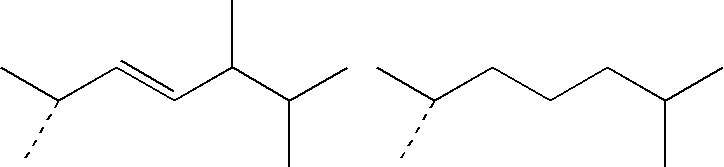

InactiveUS20070041910A1Good penetrationImprove permeabilityBiocideMetabolism disorderActive agentOil phase

Sprayable pharmaceutical compositions suited for improved transdermal penetration contain a) at least one bioactive agent, notably at least one derivative of vitamin D, (b) at least one volatile silicone and c) a non-volatile oily phase, formulated into d) a pharmaceutically acceptable vehicle therefor.

Owner:GALDERMA RES & DEV SNC

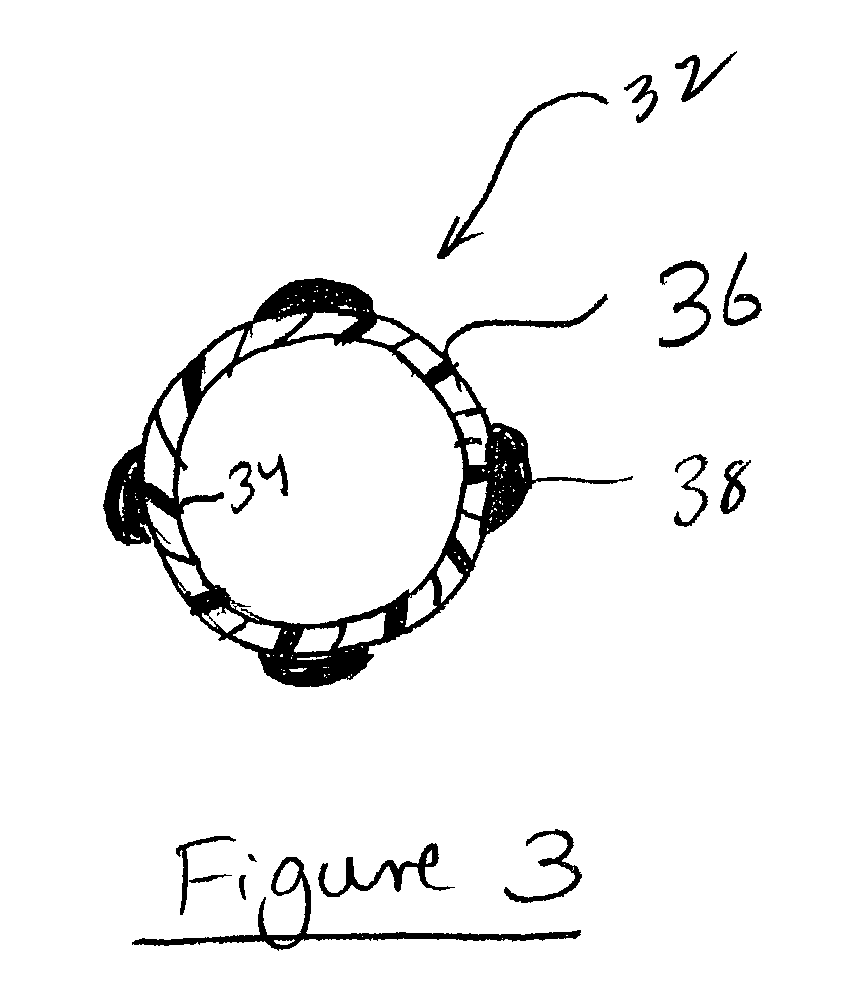

ePTFE crimped graft

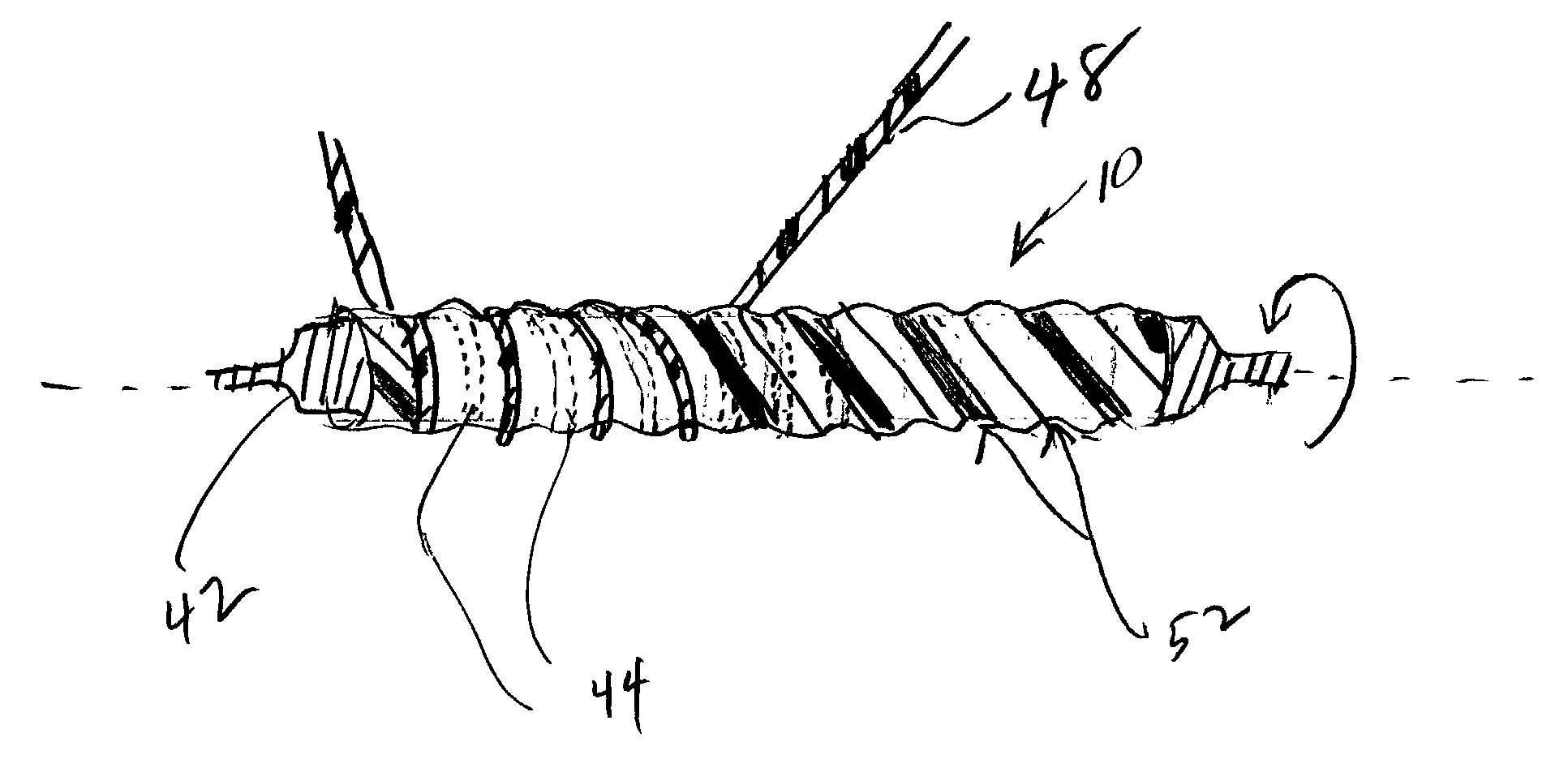

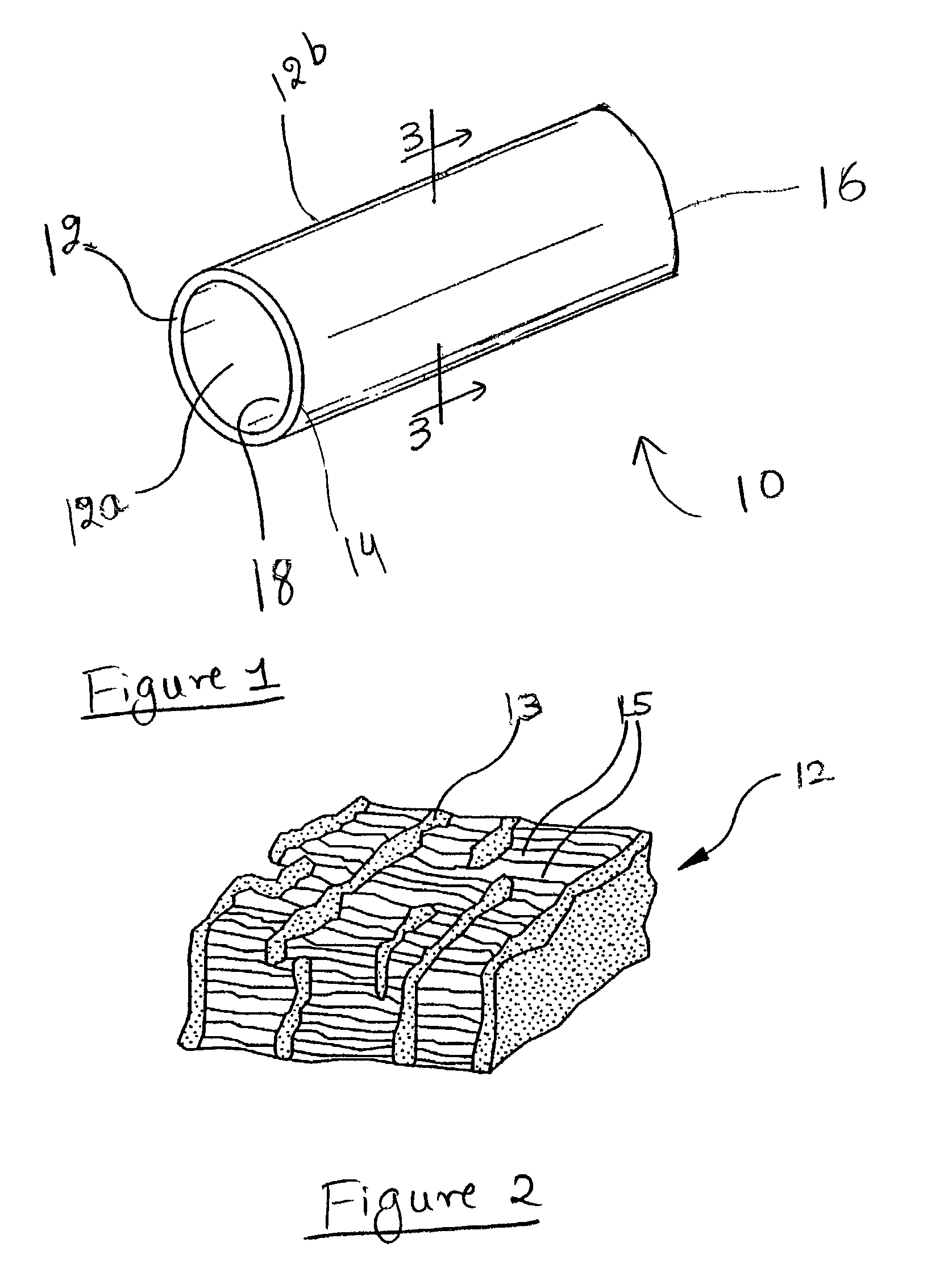

InactiveUS7879085B2AdjustabilityGood penetrationStentsLigamentsPtfe graftExpanded polytetrafluoroethylene

The present invention provides an expanded tubular graft formed of expanded polytetrafluoroethylene (ePTFE). The graft has first and second open ends and a surface longitudinally extending between the ends. The graft also includes an inner and outer cylindrical walls, where the walls have crimps or corrugations located along the surface of the graft. Additionally, the graft is coated with biocompatible elastomer covering portions of the outer cylindrical walls of the PTFE graft. The resulting ePTFE crimped graft exhibits various enhanced properties, such as adjustable graft length, high kink resistance, improved suture retention and high crush resistance as compared to the same graft without the crimps.

Owner:LIFESHIELD SCI

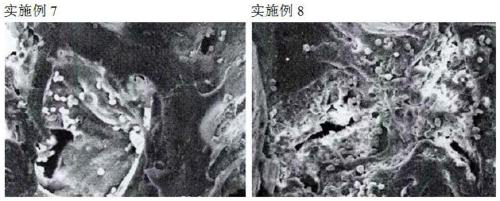

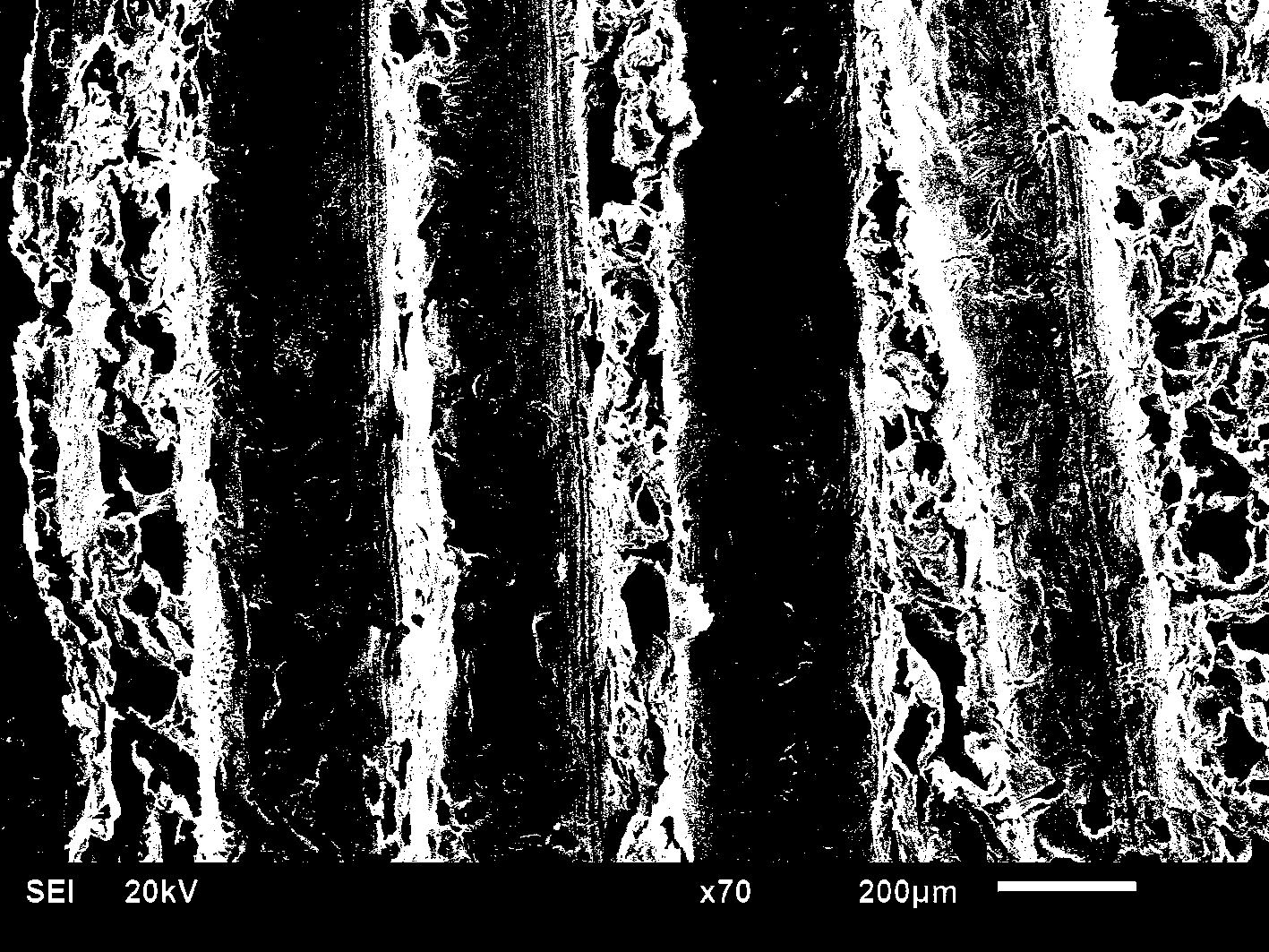

Method for preparing ethylene-trifluorochlor oethylene copolymer porous membrane

The invention discloses a method for preparing an ethylene-trifluorochlor oethylene copolymer porous membrane, and belongs to the fields of high polymer material science and technology. In the method, a proper solvent, namely diethyl phthalate is provided, and the ethylene-trifluorochlor oethylene copolymer porous membrane is prepared by initiating phase separation by reducing the temperature of an ethylene-trifluorochlor oethylene copolymer / diethyl phthalate system. When the polymer concentration is lower than 60 weight percent, the section of the ethylene-trifluorochlor oethylene copolymer porous membrane has a uniform spongeous structure. By controlling the conditions such as the concentration of the ethylene-trifluorochlor oethylene copolymer, cooling rate and the like, the microstructure of the membrane can be controlled.

Owner:TSINGHUA UNIV

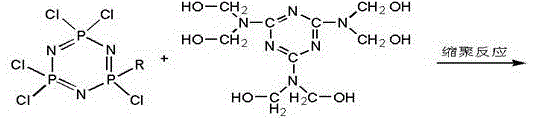

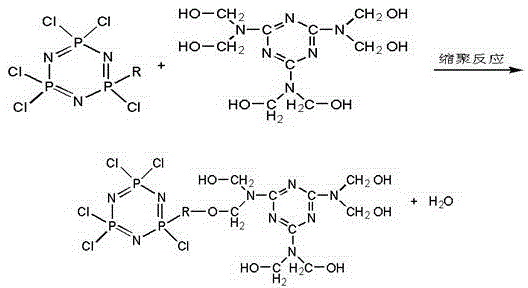

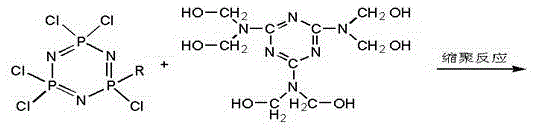

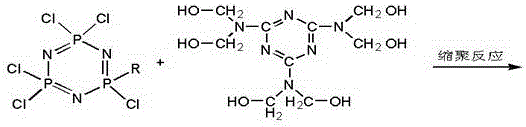

Flame-retardant oriented strand board

ActiveCN105619565ASolving Diversity Matching ProblemsWell-Matched SynergiesWood treatment detailsWood veneer joiningChlorideEngineering

The invention relates to boards, in particular to a flame-retardant oriented strand board. The flame-retardant oriented strand board comprises a core layer oriented four-layer laying flame-retardant strand layer and facing layers which are pressed and glued to the upper surface and the lower surface of the core layer oriented four-layer laying flame-retardant strand layer correspondingly. A fire retardant in the flame-retardant strand layer is a magnesium-aluminum nano layered double metal hydroxide fire retardant. The fire retardant comprises, by molar mass, 1-5 parts of magnesium chloride, 0.5-1.2 parts of aluminum chloride, 0.5-1 part of sodium hydroxide and 0.6-1.3 parts of sodium carbonate. The facing layers are made of anyone of decorative paper, veneer or engineered veneer. When the facing layers are made of the decorative paper, balancing layers are further pressed and glued between the core layer oriented four-layer laying flame-retardant strand layer and the facing layers. The engineered veneer with the required thickness is formed by slicing functional engineered wood. The flame-retardant strand layer is vivid in decoration effect, low in cost and good in formaldehyde purifying effect.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

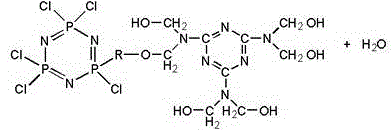

Construction technology for waterproof system

InactiveCN107288225AGood penetrationSimple construction processRoof covering using flexible materialsBuilding insulationsSizingEngineering

The invention discloses a construction technology for a waterproof system. The construction technology for the waterproof system comprises the following steps of (a) treating of a base layer; (b) coating of a rubber asphalt waterproof coating layer on the base layer; (c) paving of a first reinforcing layer on the rubber asphalt waterproof coating layer; (d) coating of a first asphalt sizing layer on the first reinforcing layer; (e) paving of a second reinforcing layer on the first asphalt sizing layer; and (f) coating of a second asphalt sizing layer on the second reinforcing layer. According to the construction technology for the waterproof system, all the rubber asphalt waterproof coating layer, the first asphalt sizing layer and the second asphalt sizing layer are asphalt base coatings and can be integrated into a whole due to good compatibility, the rubber asphalt waterproof coating layer can be firmly bonded with the base layer, a seamless coating film can be formed by the first asphalt sizing layer and the second asphalt sizing layer, and the problem of poor integrality caused by overlapped joint in tradition waterproof coiled materials is solved.

Owner:SHENZHEN ZHUOBAO TECH

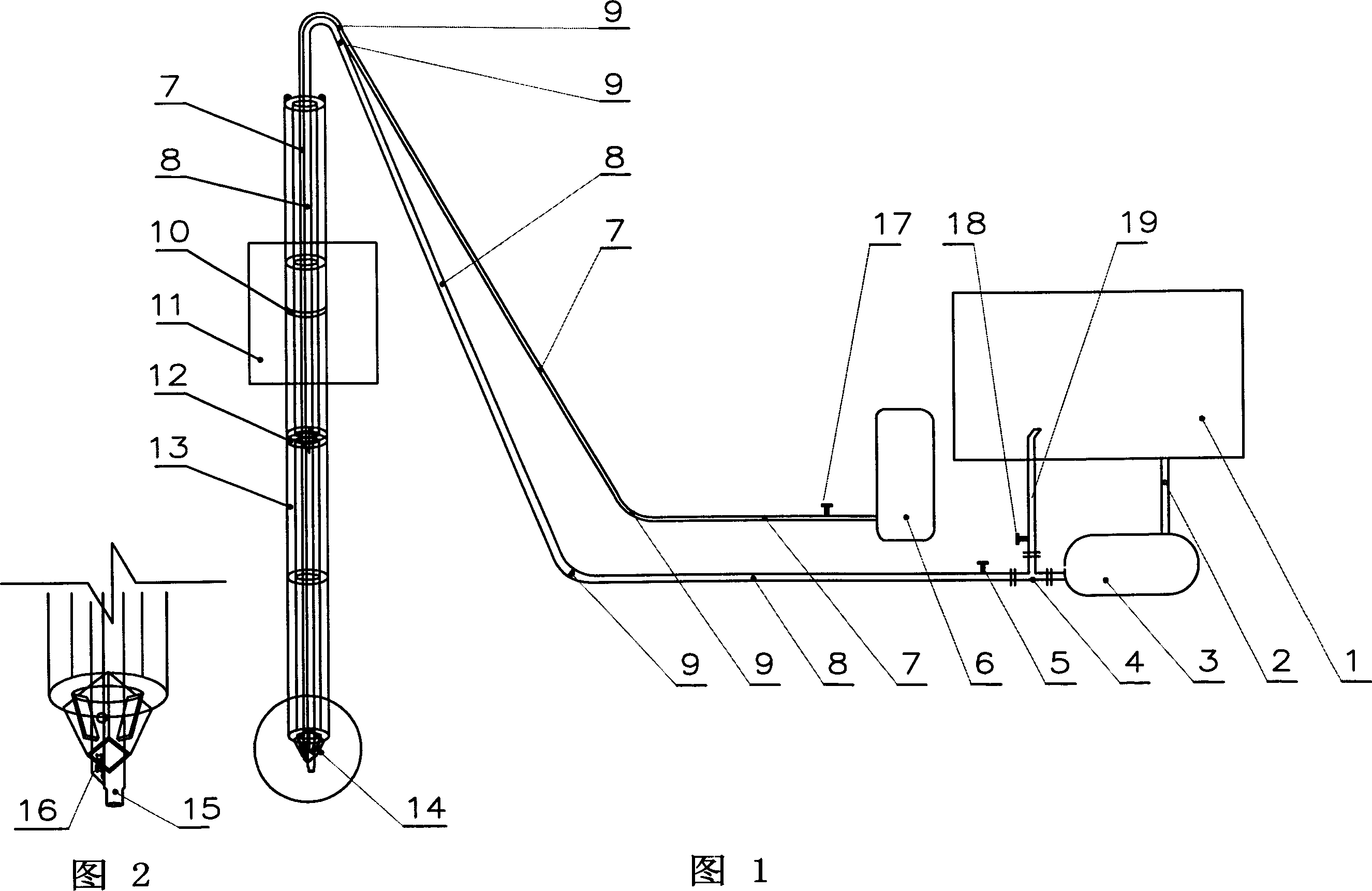

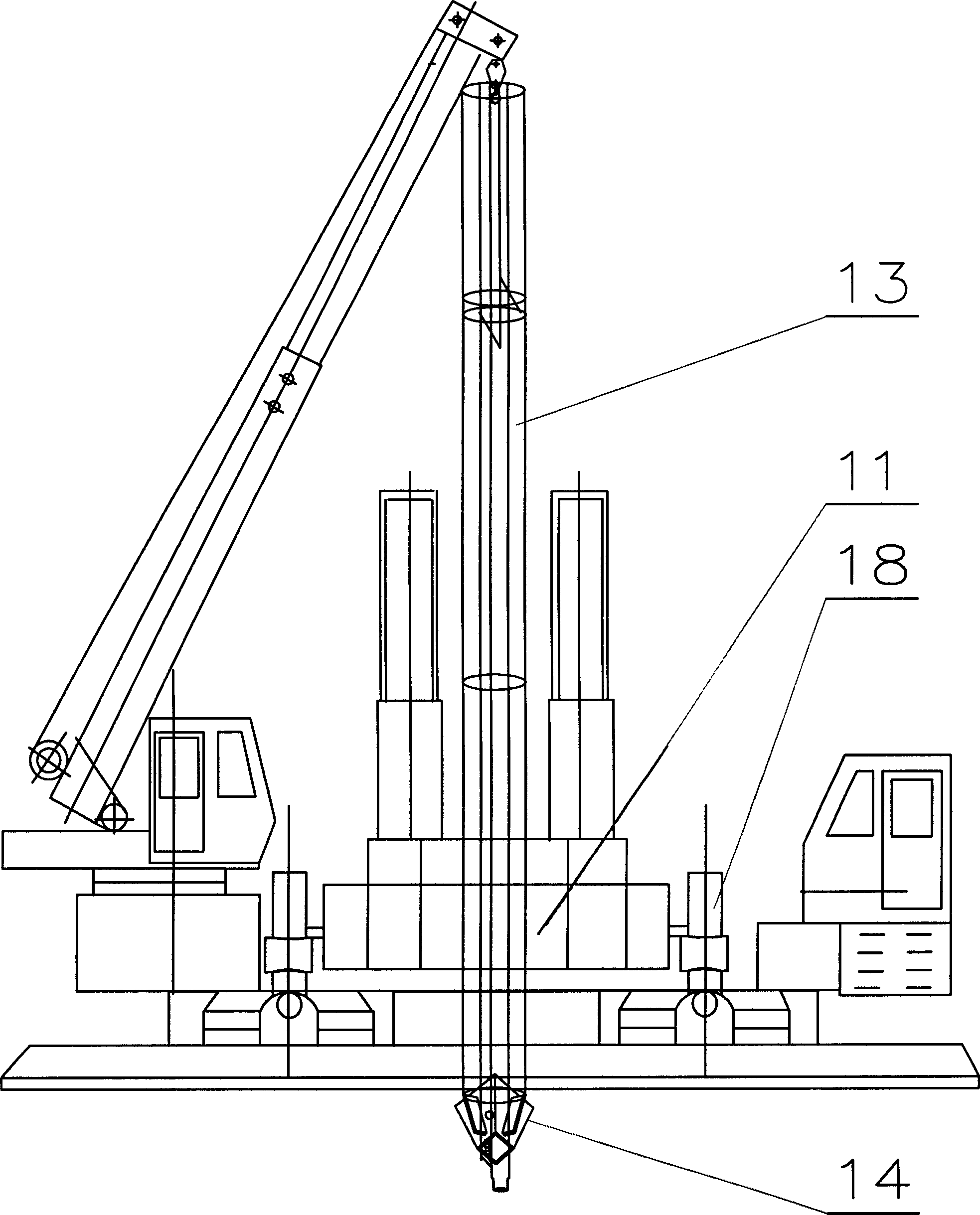

Construction technique for self-leading hole at pile tip of embrace press type PHC tubular pile to enter rock through static pressure

The present invention relates to a construction process capable of utilizing high pressure to make the pile tip of PHC pipe pile self-hole and enter into rock. It is characterized by that it utilizes high-pressure water flow and high pressure air flow to impact and pulverize solid gravel stratum positioned in the front end of pile tip. Said invention also provides the concrete method and steps for implementing said construction process.

Owner:刘小檀 +2

Preparation method of functional type engineered wood

ActiveCN105563586AWear-resistantWeather-resistantRadiation/waves wood treatmentWood treatment detailsStainingManufacturing technology

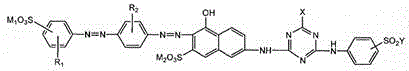

The invention relates to a furniture plate and in particular to a preparation method of a functional type engineered wood. The preparation method comprises the following steps: rotary cutting or slicing to prepare a blank veneer, and shearing the blank veneer into a needed size to obtain an A veneer; soaking the A veneer in a ternary compound solution prepared from a biomass nano cellulose solubilizer, a flame retardant and acid dyes, and carrying out treatments including toughening, flame retarding and dyeing to obtain a B veneer, wherein the ternary compound solution is prepared from the biomass nano cellulose solubilizer, the flame retardant and the acid dyes of a bis-azo compound according to the mass ratio to be 1:(25-40):(100-300) in a compounding manner; and adding a formaldehyde decomposition powder in a modified MUF adhesive, uniformly stirring, and carrying out dispensing, assembling, cold pressing and sawing on the B veneer to obtain a finished product. With the interface controlling design, the biomass nanotechnology and the synergistic compounding technology, the preparation method effectively solves the diversified matching problem of the flame retardant, a staining reagent and the adhesive, and realizes one material with multiple functions of the reconstituted decorative lumber manufacturing technology.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Treatment process for disinfection by-products of drinking water

ActiveCN106630321AGood penetrationProcessing speedWater/sewage treatment by irradiationTreatment involving filtrationChemistryChloramine B

The invention discloses a treatment process for disinfection by-products of drinking water. The treatment process comprises the following steps: extracting a water source to a water plant; coagulating, settling, filtering, sterilizing with ultraviolet rays, feeding into a clean water tank and adding chlorine dioxide and chloramines; adding polyferric sulfate and disinfecting; inputting to an air-blowing separation tank for aerating, blowing and separating; filtering with activated carbon; and inputting into a running water pipeline by a water pump under high pressure. According to the treatment process, the organic matters in water are treated before chlorination, the precursor of the disinfection by-products is removed, the generation of the chlorination by-products is controlled, and the disinfection by-products in water are cleaned again after the chlorination and the DBPs volume is effectively reduced.

Owner:麟州(巨野)孵化器有限公司

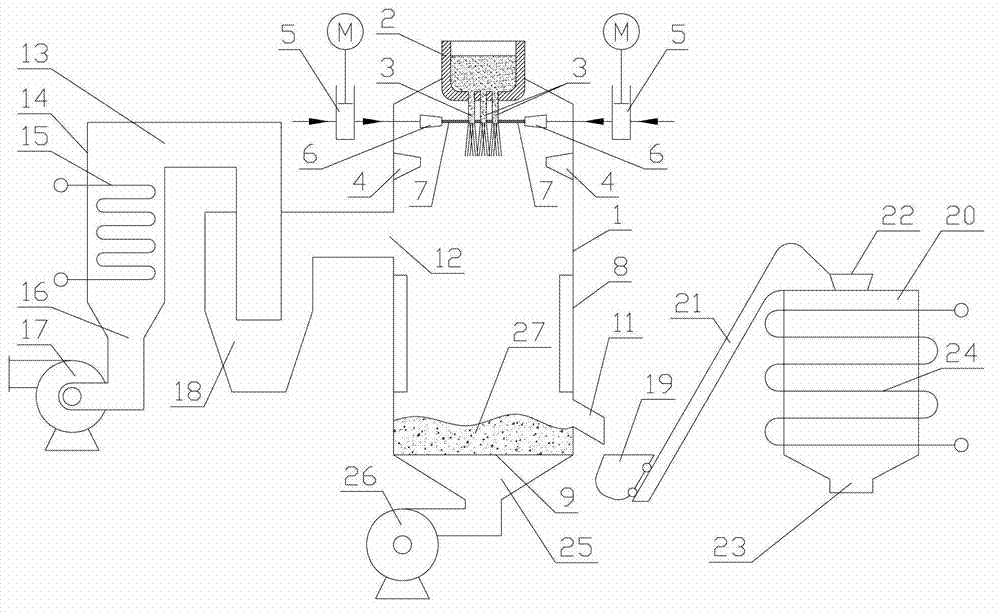

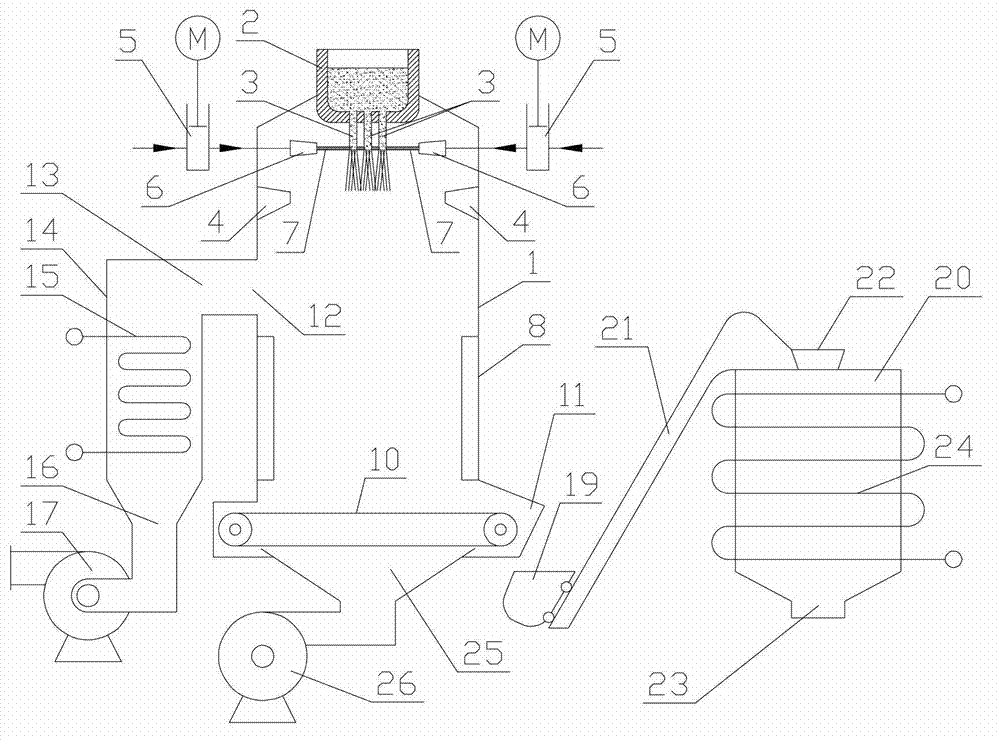

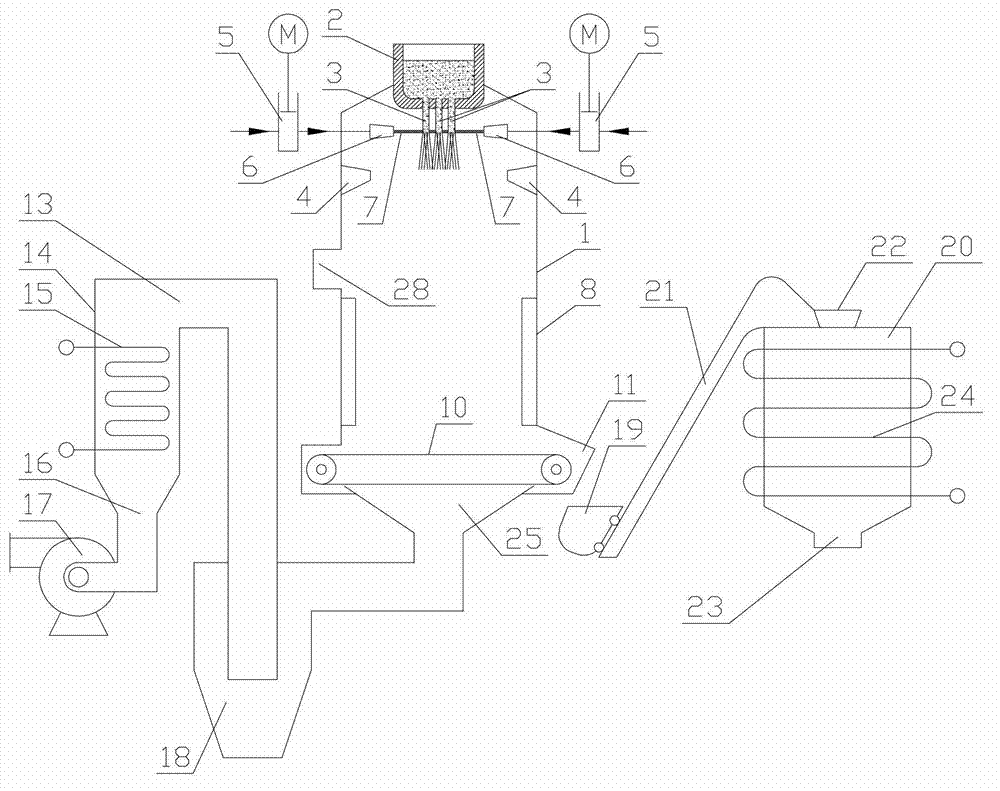

Method and system for molten slag granulation and sensible heat recovery

ActiveCN102864254AStrong impactGood penetrationProcess efficiency improvementIndustrial wasteWater jet

The invention discloses a method and a system for molten slag granulation and sensible heat recovery, and belongs to the technical field of industrial waste residue treatment and utilization. The method comprises the following steps of: pressurizing water, and injecting water from a nozzle to form a columnar high-speed water jet flow; impacting multiple strands of columnar molten slag flows on the same row in sequence; breaking the molten slag; in the falling process, cooing the broken molten slag by a water cooling wall; recovering parts of sensible heat; then, falling into the bed layer of a fluidized bed or a travelling grate to be cooled by air entering from outside, completely solidifying the molten slag to finish granulation and obtain hot air; sending hot air obtained on the fluidized bed or the travelling grate into a waste heat boiler to recover heat; and sending solidified molten slag particles output out of the fluidized bed or the travelling grate into a moving bed for further recovering the sensible heat. The molten slag can be broken by the high-speed water flow, the breaking and flying effect of the method is good, a slag wool generation amount is small, slag wool is easy to process because the slag wool contains water, the operation energy consumption and the water consumption of the slag wool are low, and therefore the sensible heat recovery of the molten slag can be favorably carried out.

Owner:TSINGHUA UNIV

Novel cell culture method, cell culture system and application of cell culture system

InactiveCN110272824AImprove compactnessImprove sintering performanceCompound screeningApoptosis detectionBiotechnology3D cell culture

The invention provides a novel cell culture method, a cell culture system and application of the cell culture system, and belongs to the field of biological materials and biotechnology. The three-dimensional cell culture system provided by the invention is used for in-vitro cell culture and comprises a packed bed cell reactor, wherein the reactor comprises a composite porous scaffold, and the composite porous scaffold comprises collagen, silk fibroin and hydroxyapatite. The method for three-dimensional cell culturing by using the system comprises the following steps of: setting the three-dimensional cell culture system; supplying the cell reactor with cells and a cell culture solution; and circularly filling the reactor with the cell culture solution, wherein the cell inoculation mode is dynamic inoculation. The porosity of the composite porous scaffold of the cell culture system and the uniformity and permeability of the pore structure are good so as to facilitate the transportation and transmission of moisture, ions and other nutrient substances, to have higher sensitivity to temperature, to respond to the change of ambient temperature, and to control the subsequent release of growth factors.

Owner:兰溪市立顺生物有限公司

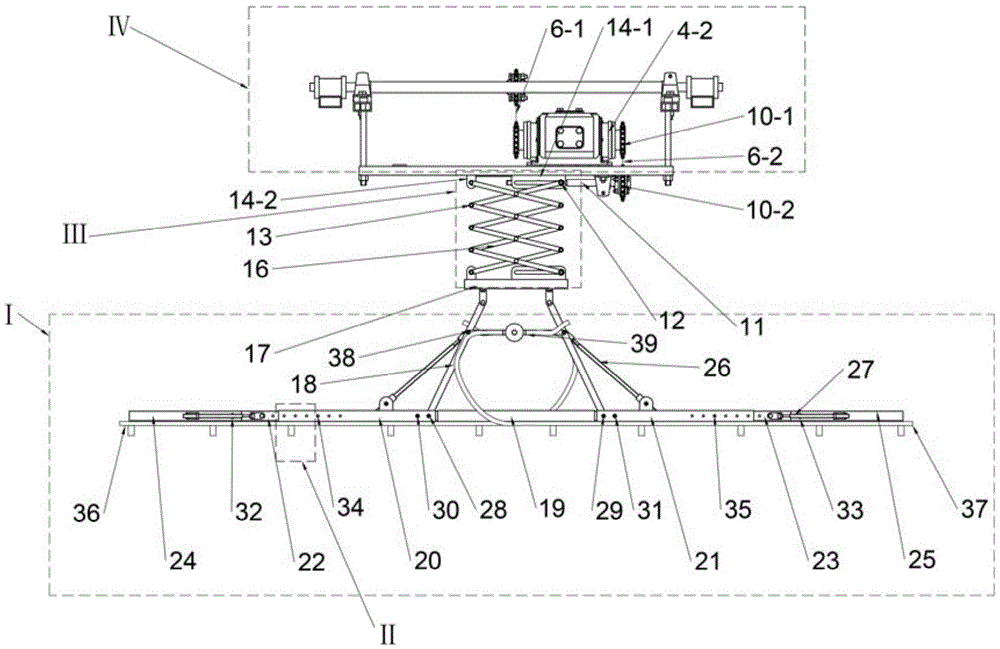

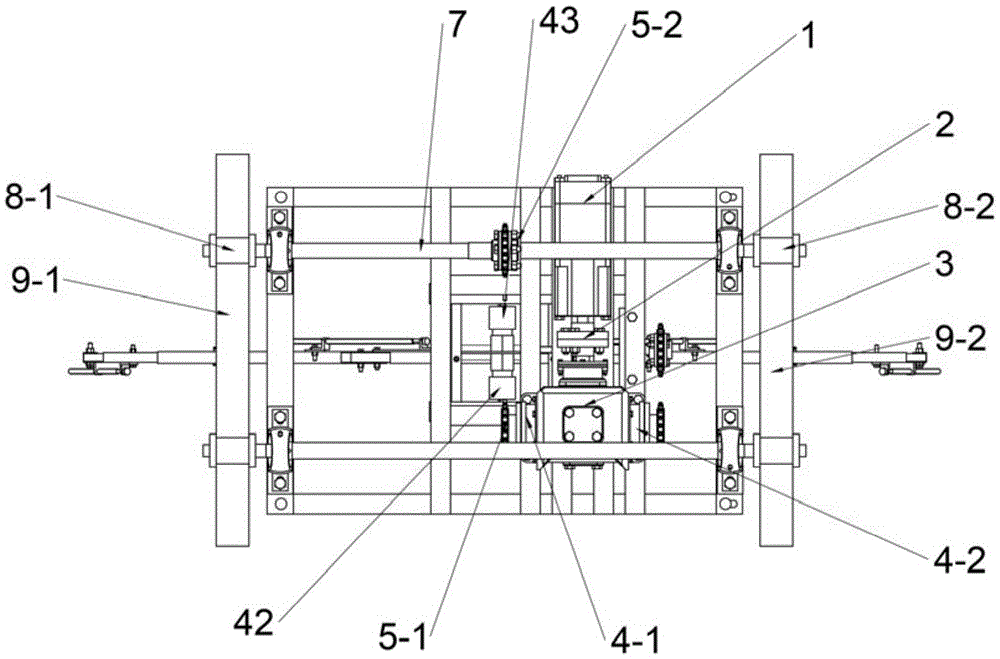

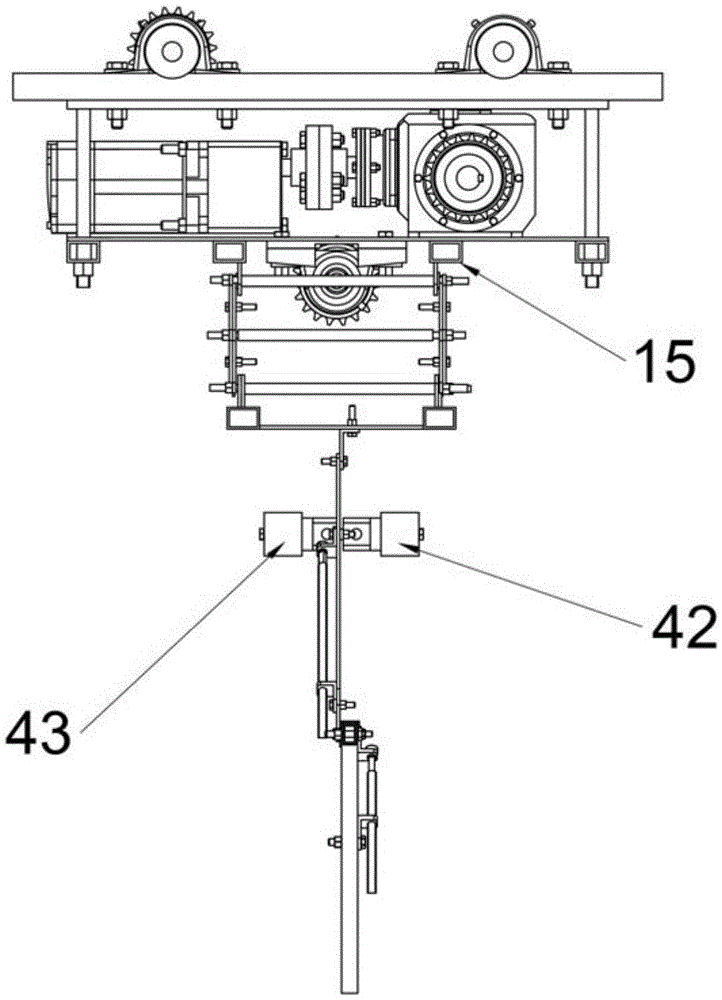

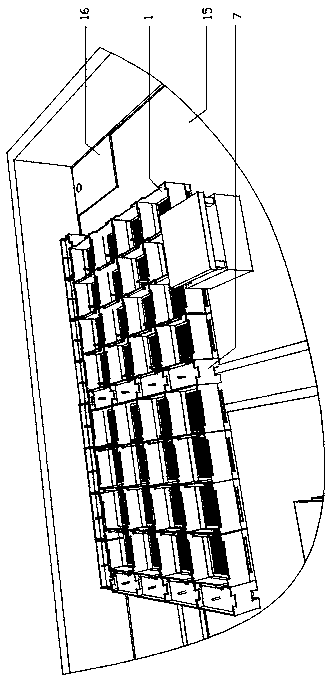

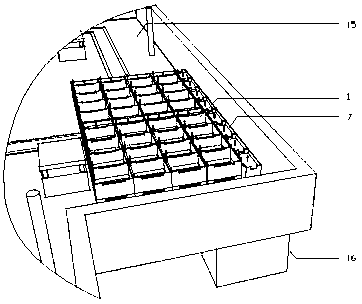

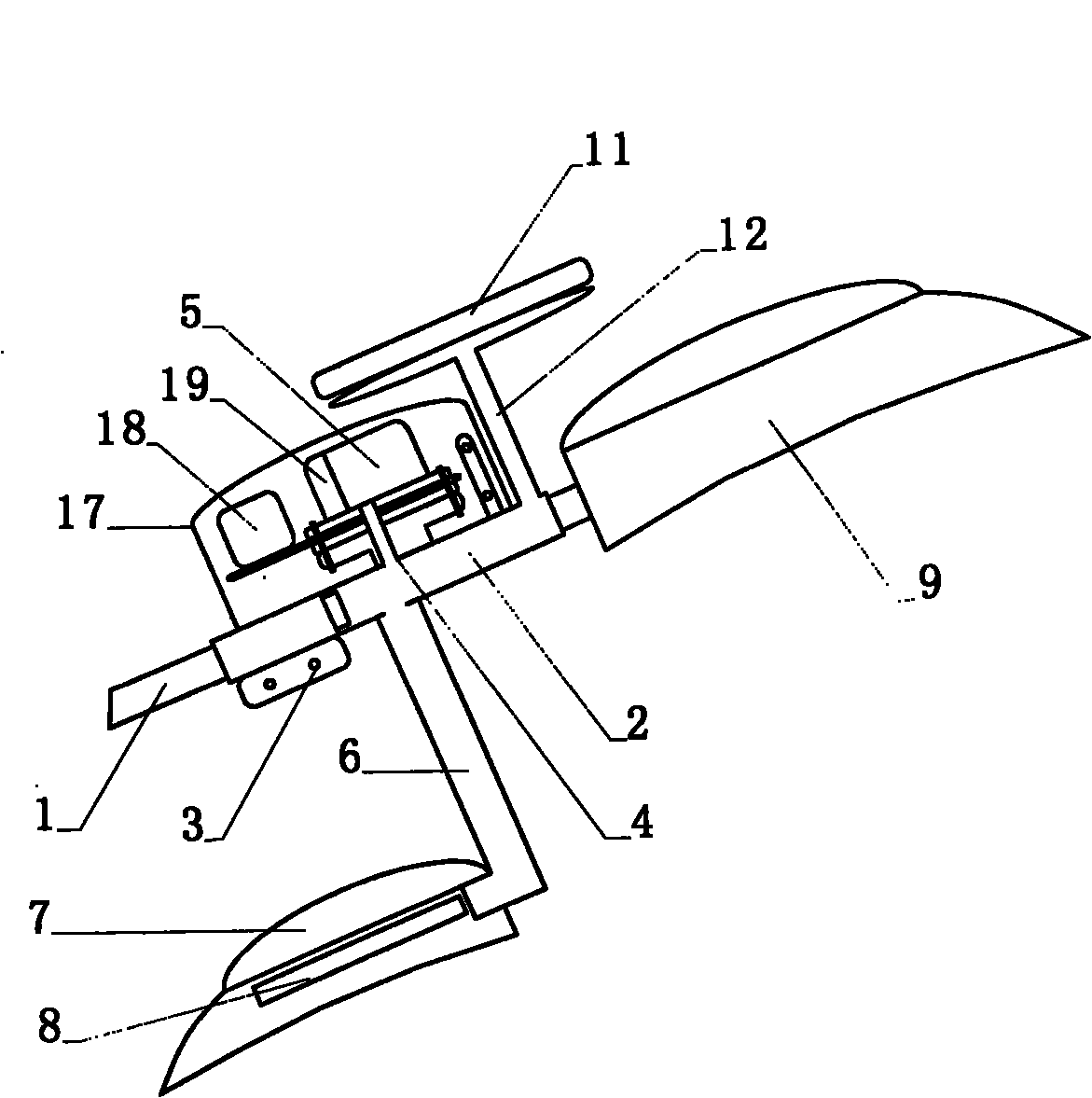

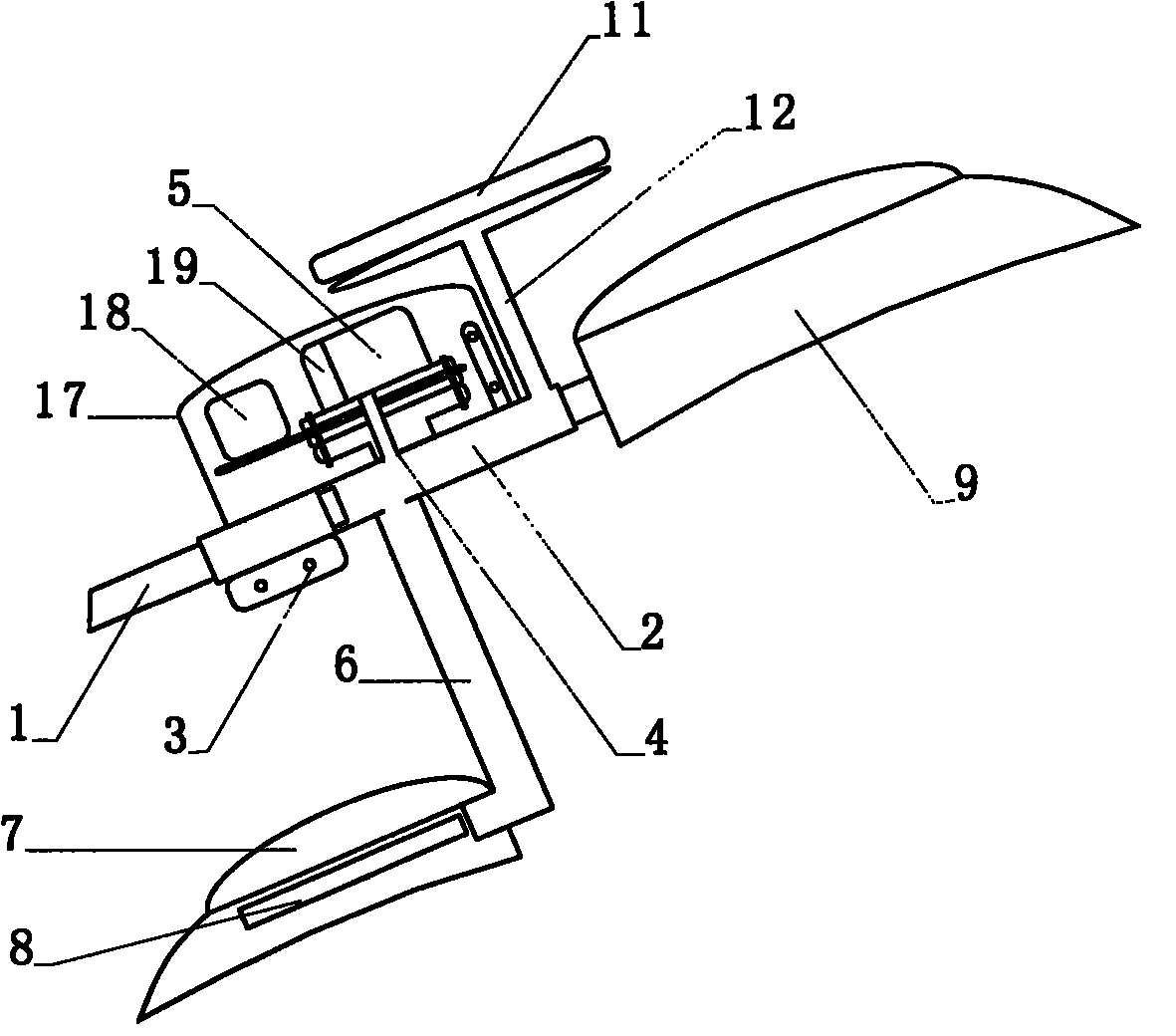

Spray boom system and suspension self-propelled type special multifunctional deformable spraying device for greenhouses

ActiveCN105613462AGood penetrationImprove application efficiencyInsect catchers and killersPesticide applicationFastener

The invention belongs to the field of agricultural machinery and discloses a spray boom system and a suspension self-propelled type special multifunctional deformable spraying device for greenhouses. The spray boom system is characterized in that suspension rods (18) above a fixed rod (19) is used for being connected with the fixed rod (19) to enable the fixed rod (19) to be in a horizontal position; a first rotating rod (20) and a second rotating rod (21) are fixed to two ends of the fixed rod (19) through fastening parts and first screw rod and screw sleeve devices (26) respectively; a third rotating rod (24) and a first telescopic rod (22) are connected through a fastening part and a second screw rod and screw sleeve devices (27); a fourth rotating rod (25) and a second telescopic rod (23) are connected through another fastening part and another second screw rod and screw sleeve devices (27). Adjustment according to different morphological structures of target crops can be realized, spraying penetrability and settleability are improved, three-dimensional spaces are effectively used, and occupancy of precious floor space resources is avoided. In addition, simple spray boom structure, convenience in adjustment and high efficiency in pesticide application aiming at different target crops are realized.

Owner:NANJING FORESTRY UNIV

Recombined decorative material technical wood

ActiveCN105461873AWear-resistantWeather-resistantLaminationLamination apparatusManufacturing technologyDecomposition

The invention relates to a furniture board, particularly a recombined decorative material technical wood. The recombined decorative material technical wood is prepared by the following steps: carrying out rotary cutting or shaving to prepare a blank veneer, and cutting the blank veneer into the required size to obtain a veneer A; carrying out immersion toughening flame-retardant dyeing treatment on the veneer A in a three-element compound solution composed of a biomass nano cellulose solubilizer, a flame retardant and an acidic dye to obtain a veneer B; adding formaldehyde decomposition powder into a modified MUF adhesive, stirring uniformly, and coating on the veneer B to obtain a veneer C; and carrying out cold pressing treatment on the veneer C assembly to obtain a batten D, and sawing into the required pattern and size to obtain the finished product. The interface regulation design, biomass nano technique and synergetic compound technique are utilized to effectively solve the problem of diversified matching among the flame retardant, staining agent and adhesive, thereby implementing multiple functions of the one material in the recombined decorative material manufacturing technique.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

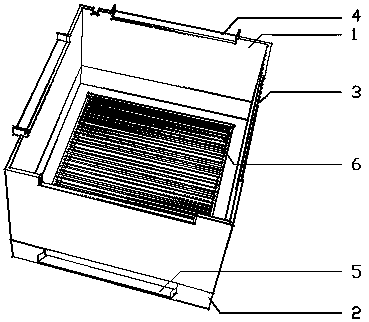

Polyurethane green island roof greening ecosystem

PendingCN109429792AImprove integrityReduce heat transferGeneral water supply conservationSelf-acting watering devicesHeat transmissionEngineering

The invention discloses a polyurethane green island roof greening ecosystem, which comprises a planting mechanism, a water well mechanism and a water collecting tank, wherein the planting mechanism iscommunicated with the water well mechanism and the water collecting tank (16), and features that: the planting mechanism comprises a plurality of planting units, each planting unit comprises a flowerpot (1), a water retention box (2) is arranged at the lower part of the flowerpot (1), a water seepage component is arranged at the bottom of the flowerpot (1), planting soil is paved on the water seepage component, an installation notch (3) is arranged at the opening of the edge part of the flowerpot (1), a first water guide strip (4) is arranged on the installation notch (3), a second water guide strip (5) is arranged at the opening of the edge part of the water retention box (2), the polyurethane green island roof greening ecosystem features good integrity and aesthetic appearance, and reduces the heat transmission on the roof, meanwhile, the rainwater can be collected and filtered, so that the filtered water is used for self-irrigation.

Owner:河南省海绵城市建设有限公司

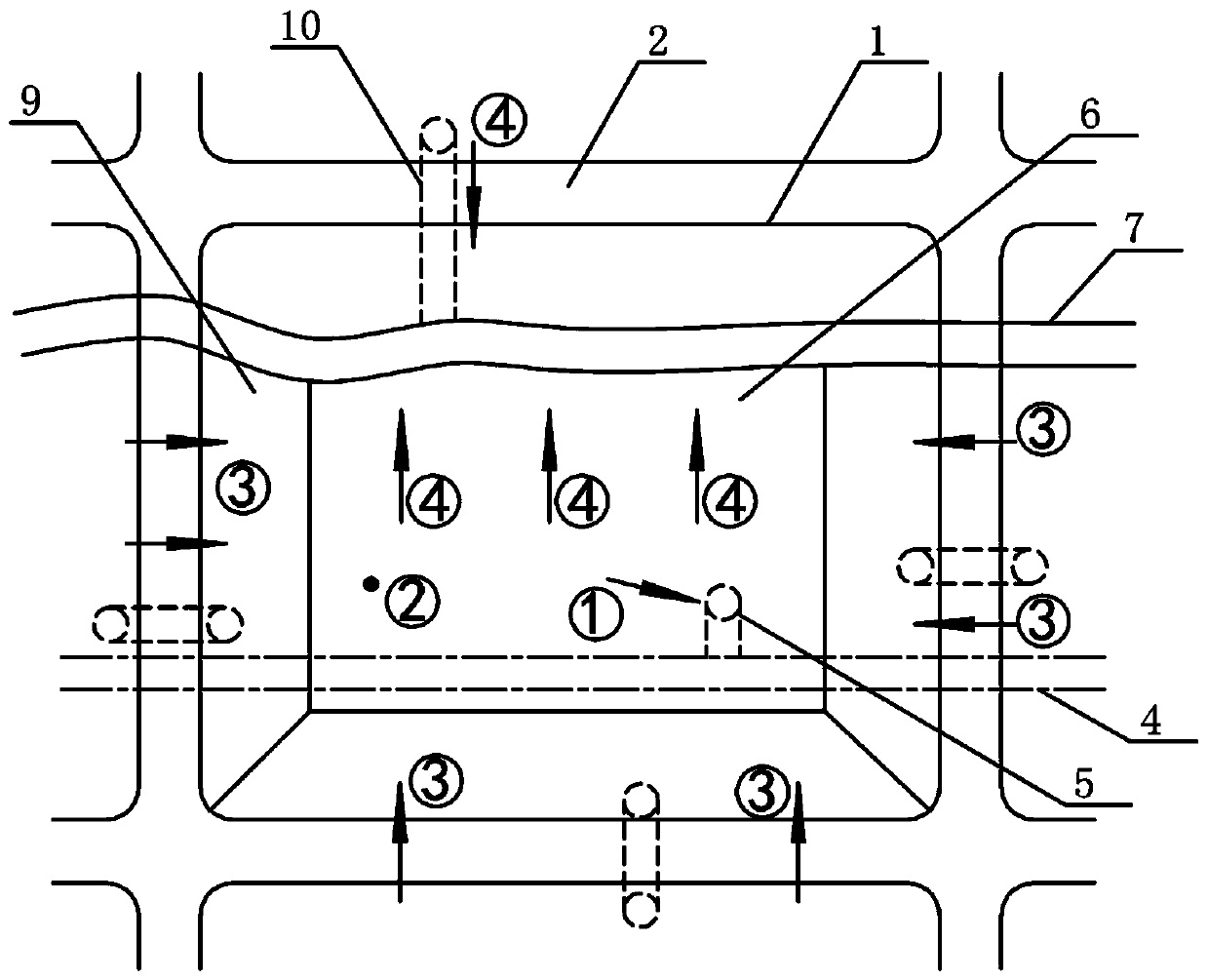

Rain flood resource utilization method and system

ActiveCN110485540AEfficient use ofImprove resource utilizationWater resource protectionSewerage structuresWater storageUrban region

The invention discloses a rain flood resource utilization method and system. An urban region is divided into a plurality of independent subregions, wherein the subregions suitable for modification areartificially modified into ecological water storage regions; and sedimentation reservoirs are established at the lower positions of the terrains of the subregions suitable for modification, and the regions not suitable for modification communicate with the adjacent ecological water storage regions until the regions communicate with the ecological water storage regions with the sedimentation reservoirs by arranging flow passages. Each flow passage is formed by establishing an artificial water flow dredging passage on the surface or underground between adjacent regions and draining the artificial water flow dredging passage to a corresponding sedimentation reservoir in a surface runoff or underground confluence concealed pipe confluence mode. The rain flood resource utilization method and system of the invention can be transformed by combining the current situation of each city, and can arrange the regions suitable for modification at present as the modification regions of the ecological water storage regions no matter how the modification degree of the city is; and multiple functions of the ecological water storage regions are matched, effective reconstruction and rainwater resource utilization are carried out, and the urban rainwater resource utilization rate is continuously improved.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

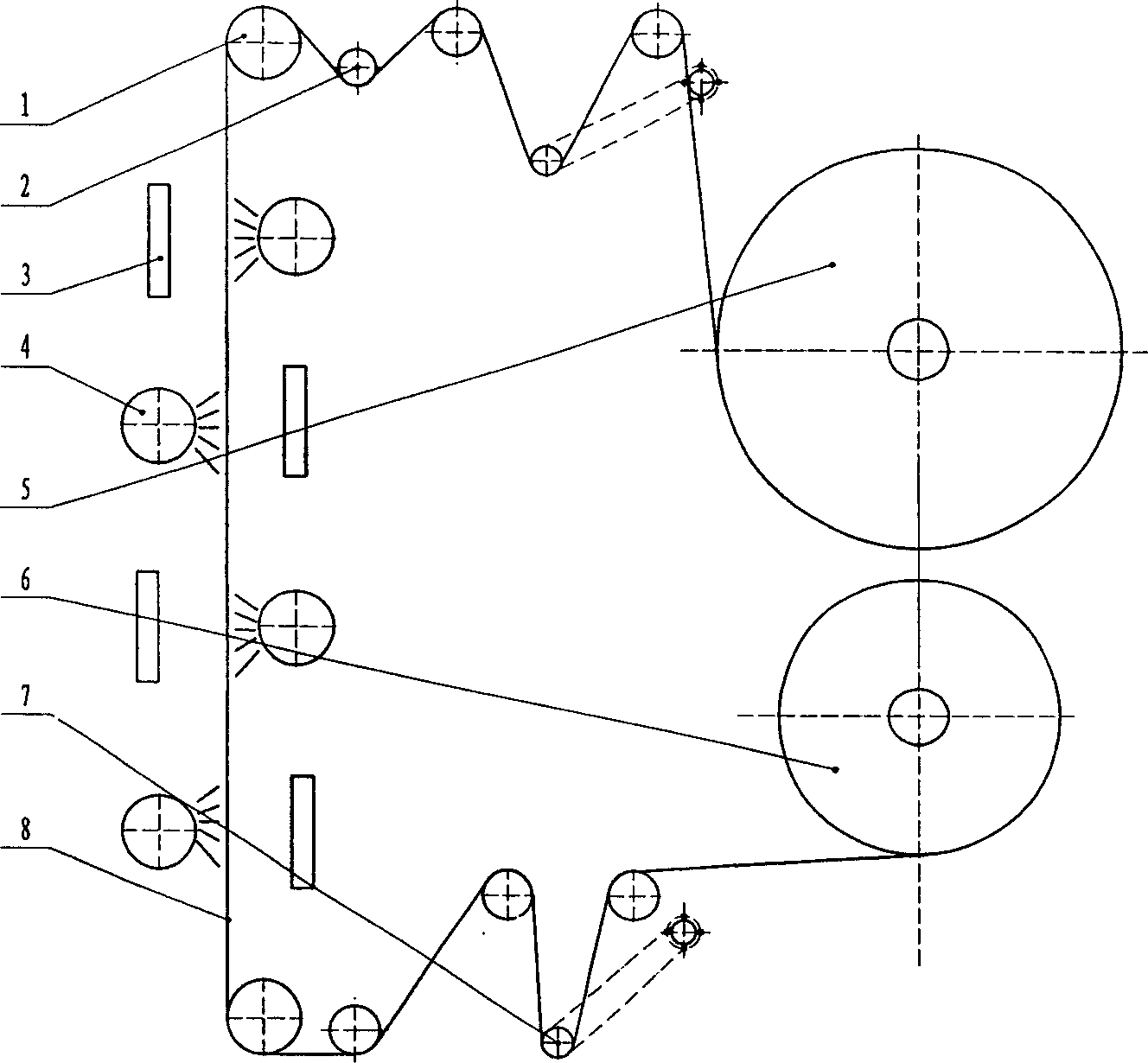

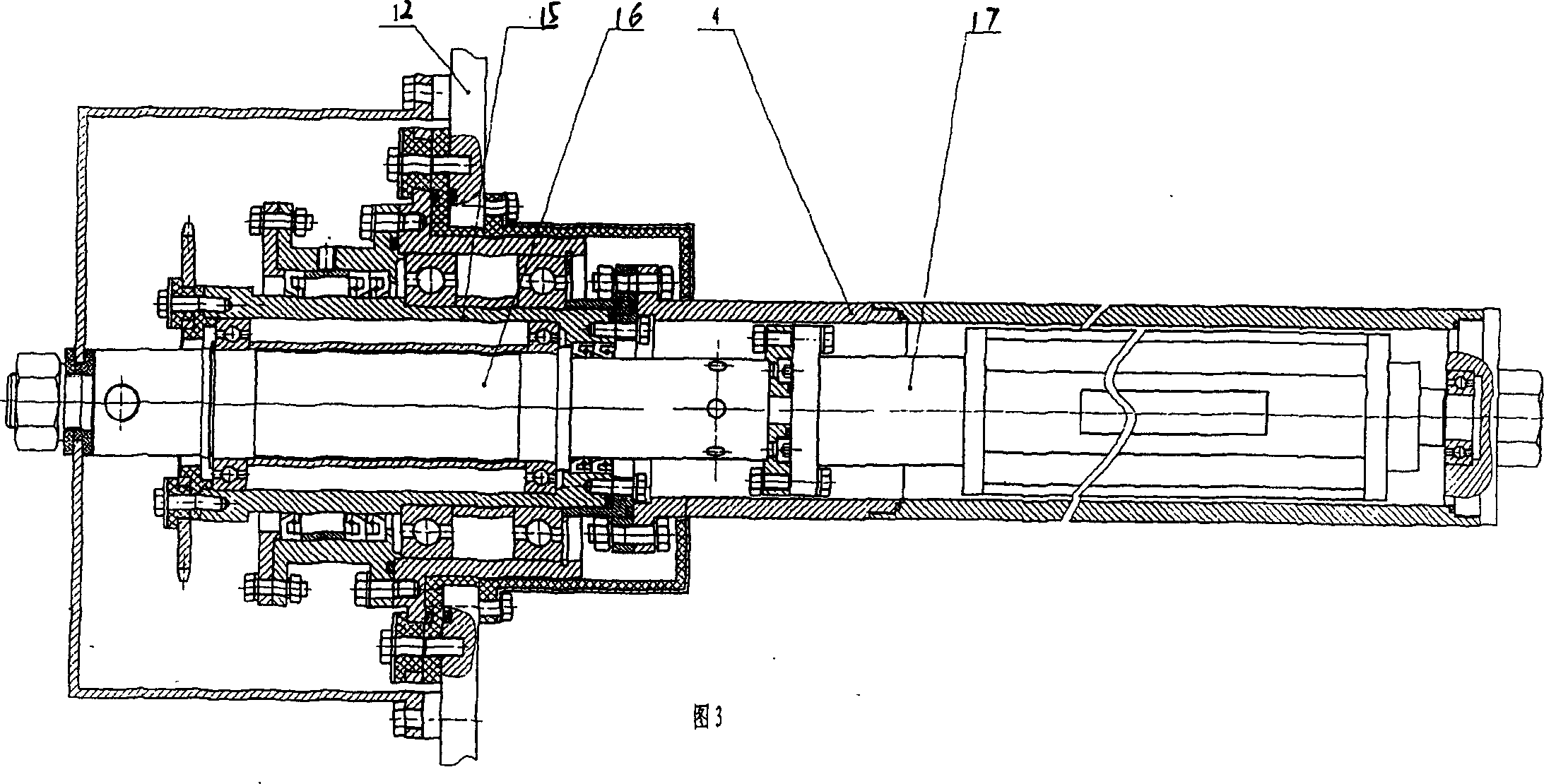

Method for surface metal coating of flexible strip-like articles and dedicated device therefor

InactiveCN1865492AEliminate the effect of temperature riseIncrease productivityVacuum evaporation coatingSputtering coatingVacuum chamberCoil structure

The invention discloses a flexible strip-typed surface metal deposition method and specific equipment, which is characterized by the following: the deposited material is started from scroll, which is coiled on the material received shaft through guide shaft and drawing shaft; the deposited material is sprayed and deposited on two surfaces by two target electrodes through target electrode spraying region; the specific equipment comprises vacuum chamber and vacuum system in connection with vacuum chamber; the target electrode moving door and driving moving door are set on the vacuum chamber; the magnetic control spraying target electrode is set on the target electrode moving door, which contains coiling structure for the deposited material.

Owner:HEZE TIANYU TECH DEV CO LTD

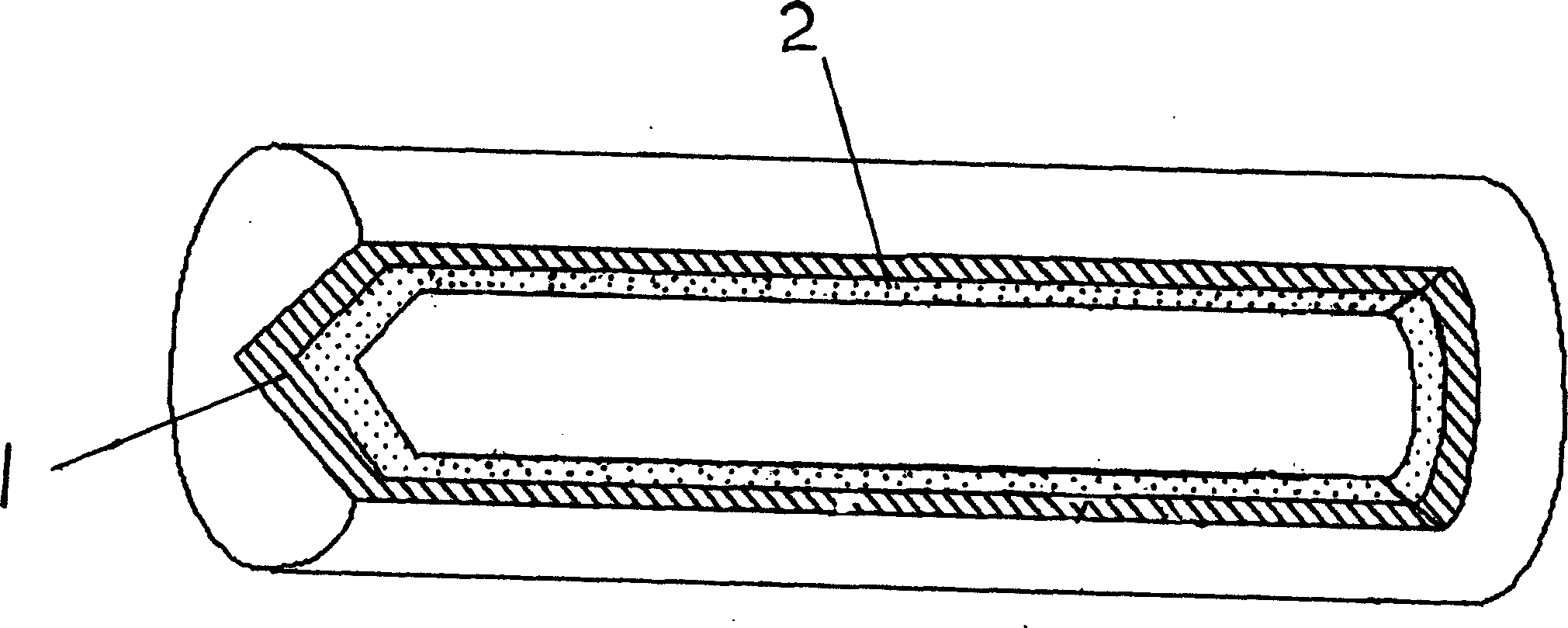

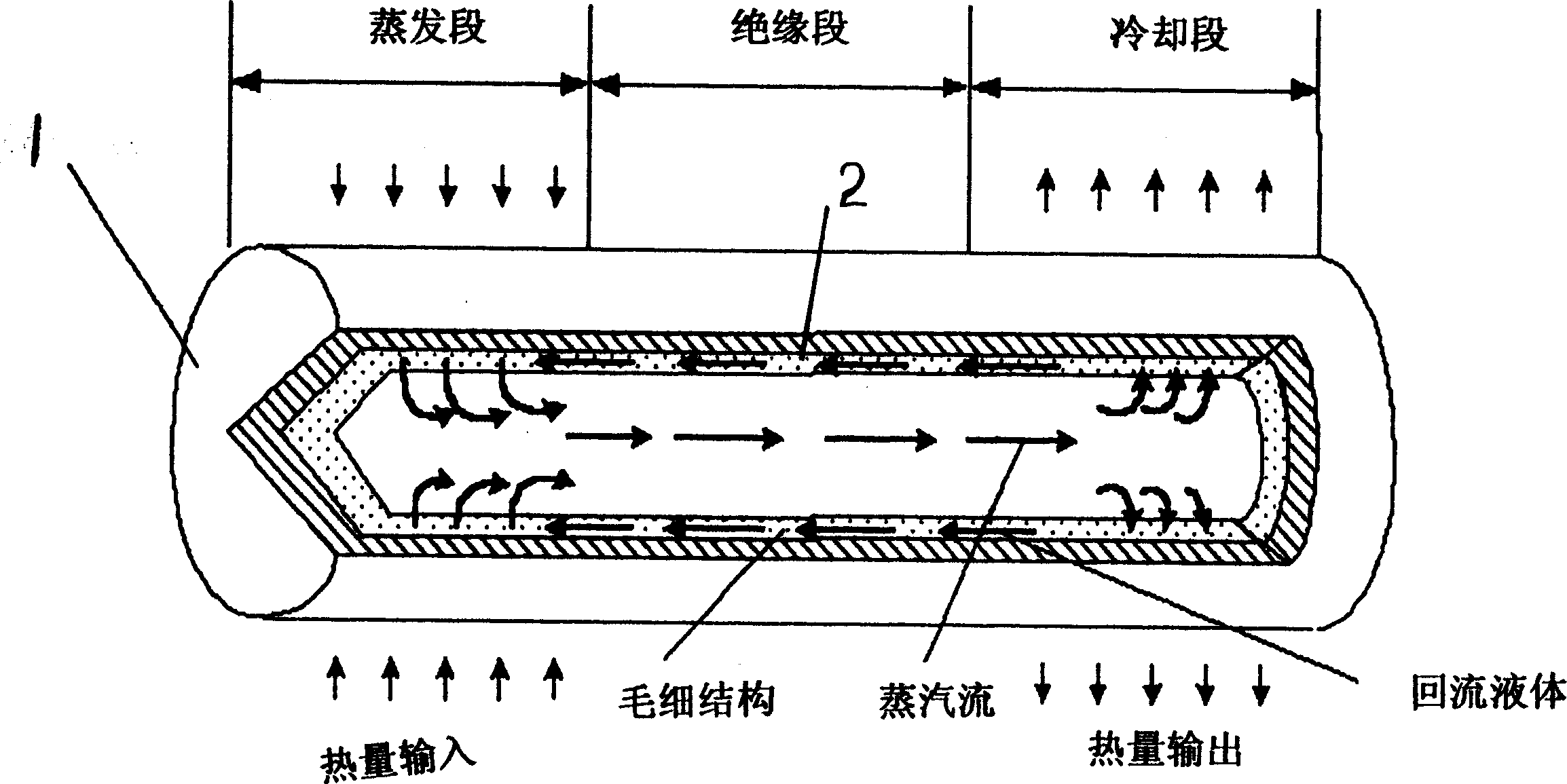

Heat pipe

Present invention discloses a thermal pipe. It contains sealed external use container with heat conductive material and filled operating fluid. It features said heat conductive material being foamed metal. Due to foam copper etc foamed metal having uniform pore with fine connectivity and simple process, the heat conductive material made from said foamed metal can absorb uniformly operating fluid like sponge and equalization dispersed over thermal pipe circumference, letting any point of thermal pipe heat radiation, said invention having fast heat transfer, high heat conduction quantity, less loss, yield quantity, low production costs, simple manufacturing process etc advantages.

Owner:李国辉

Preparation method for hydrotreatment catalyst

ActiveCN103801346AGood penetrationConducive to diffusionPhysical/chemical process catalystsRefining to eliminate hetero atomsChemistryEther

The invention discloses a preparation method for a hydrotreatment catalyst. The method comprises the following steps: in the process of gel formation by concurrent flow of an alkaline solution containing aluminum and an acidic solution containing aluminum, adding an additive and an organic template agent in the manner of concurrent flow at the same time, controlling proper reaction conditions and carrying out gel formation, wherein the organic template agent is cellulose ethers; then adding an alkaline solution to adjust a pH value; then carrying out filtering, washing and drying so as to obtain the alumina dry gel; carrying out molding, drying and calcining so as to obtain an alumina carrier; and loading active metal components. The catalyst prepared by using the method has the advantages of a large specific surface area, a great pore volume and a reasonable pore structure and is particularly applicable as a catalyst for hydrodesulfurization or hydro-conversion of residual oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Functional reconstituted lumber

ActiveCN105710939ALow formaldehyde and VOC emissionsGood penetrationOrganic chemistryWood treatment detailsIonChemistry

The invention relates to a furniture panel, particularly to functional reconstituted lumber. A manufacturing technology of the functional reconstituted lumber comprises the steps of preparing blank veneers through rotary cutting or slicing, and shearing the blank veneers into a required size, so as to obtain A veneers; soaking the A veneers in a ternary compound solution composed of a biomass nanocellulose solubilizer, a fire retardant and an acid dye for toughening, inflaming retarding and dyeing treatment, so as to obtain B veneers; adding a formaldehyde decomposition powder into a modified MUF adhesive, uniformly stirring, and dispensing on the B veneers, so as to obtain C veneers; assembling the C veneers, and carrying out cold pressing treatment, so as to obtain D square lumber; and carrying out compound hot pressing on the D square lumber with a transparent abrasion-resistant surface film adhesive paper layer, wherein the transparent abrasion-resistant surface film adhesive paper layer is a film adhesive paper layer formed through soaking transparent abrasion-resistant surface paper in an amino-formaldehyde resin adhesive solution containing tourmaline powder and Al2O3; the particle size of tourmaline negative ion powder is 500 meshes or above; and the count capacity of negative ions in the Giger. Miller zone is 3000 ions / cc or above. According to the functional reconstituted lumber, the effect that the lumber has multiple functions in a reconstituted decorative lumber manufacturing technology is achieved.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Antibacterial ultrafiltration membrane

InactiveCN105854643AGood penetrationExcellent stable membrane fluxMembranesSemi-permeable membranesSolventUltrafiltration

The invention discloses an antibacterial ultrafiltration membrane, the raw materials of which include by weight: 40-55 parts of polyacrylonitrile, 5-15 parts of polyvinylpyrrolidone, 1-2.5 parts of inorganic particles, 50-100 parts of solvent, composite antibacterial 2-3.5 parts of agent, 0.8-3 parts of antioxidant; the composite antibacterial agent consists of N-(4-hydroxy-3-methoxybenzyl) acrylamide, 2-hydroxyethyl methacrylate, N, Polymerized from N-dimethylaminoethyl methacrylate. The antibacterial ultrafiltration membrane proposed by the invention has good antibacterial performance, excellent antifouling performance and thermal stability, and long service life.

Owner:安庆市天虹新型材料科技有限公司

Novel low-foam mercerizing penetrating agent for cotton fabric

InactiveCN106087408AGood penetrationGood emulsifying effectVegetal fibresChemistryPolystyrenesulfonic acid

The invention discloses a novel low-foam mercerizing penetrating agent for cotton fabric. The penetrating agent is prepared from, by weight, 11-14 parts of dioctyl sebacate, 16-22 parts of sodium diethylhexyl sulfosuccinate, 1-8 parts of fatty alcohol-polyoxyethylene ether, 4-8 parts of sodium lauryl polyoxyethylene ether sulfate, 8-10 parts of alkylphenol ethoxylates, 40-50 parts of deionized water, 5-6 parts of sodium polystyrenesulfonate, 3-6 parts of sucrose ester, 10-14 parts of poly monooleate, 12-16 parts of trioctyl phosphate and 5-10 parts of sophorolipid. The penetrating agent has a good effect on promoting the mercerizing treatment of the cotton fabric, is quite suitable for large-scale industrial production, has a good penetration effect and a good emulsification effect, and has a low-foam function and a foam restraining function; the raw materials needed for preparing the mercerizing penetrating agent are low in cost and easy to obtain, the preparation process is simple, and the requirements for production devices are low.

Owner:刘慧宝

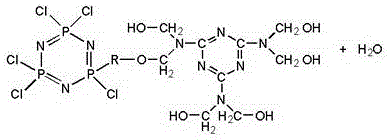

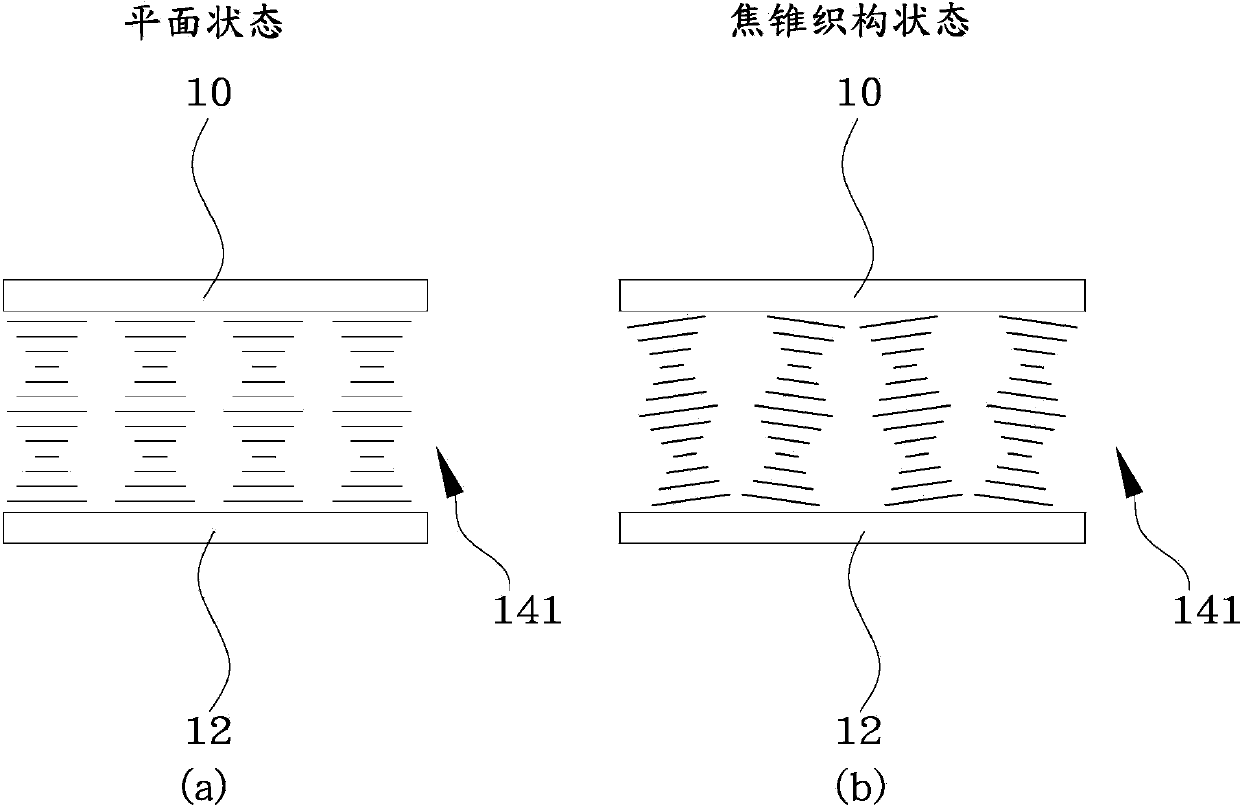

Cholesterol liquid crystal panel and manufacturing method thereof

InactiveCN103995398AGood penetrationGood masking effectNon-linear opticsCholesteric liquid crystalSurface processing

The invention provides a cholesterol liquid crystal panel and a manufacturing method of the cholesterol liquid crystal panel. The cholesterol liquid crystal panel comprises a first substrate, a second substrate and cholesterol liquid crystals, wherein the second substrate and the first substrate are opposite and parallel to each other, and the cholesterol liquid crystals are arranged between the first substrate and the second substrate. A corresponding alignment film is selected for the cholesterol liquid crystal panel according to the helical pitch of the cholesterol liquid crystals. Compared with the prior art, different surface processing modes can be utilized for the cholesterol liquid crystal panel so as to be matched with cholesterol liquid crystals with different reflection wavebands, and thus the cholesterol liquid crystal panel can have a good penetrating effect in the planar state, moreover, the cholesterol liquid crystal panel has a good fog state in focalconictexture so as to achieve the shading effect, and the optical performance of the cholesterol liquid crystals is promoted.

Owner:AU OPTRONICS CORP

Compound oil, skin care composition comprising same, and preparation method of skin care composition

InactiveCN108096070AMaintain skin moisture and elasticityGood penetrationCosmetic preparationsToilet preparationsProtective barrierCellular metabolism

The invention discloses compound oil. The compound oil is prepared from the following ingredients: olive fruit oil, rose flower oil, sweet orange oil, argania spinosa kernel oil and crambe abyssinicaseed oil. The invention further provides a skin care composition which comprises the compound oil, C12-C18 alkane and an emollient. The compound oil takes effect from multiple aspects including the nutritional ingredients, scavenging of free radicals and promotion of skin cellular metabolism, so that the moist and young state of the skin can be maintained. The skin care composition can form a protective barrier which is light and thin, is breathable, and is excellent in skin affinity on the skin.

Owner:广州皓雨投资有限公司

Acne-removing skin beautifying lotion and preparation method thereof

ActiveCN106038337AGood penetrationEffectively repair damaged skinCosmetic preparationsToilet preparationsPapuleMedicine

The invention belongs to functional cosmetics and discloses an acne-removing skin beautifying lotion which is prepared from, by weight, 30-70 parts of deionized water, 1-5 parts of polypylene glycol, 3-10 parts of arbutin, 2-10 parts of glycerin, 1-10 parts of aloe juice extract, 5-10 parts of small cucumber juice extract, 2-10 parts of dandelion extract, 5-10 parts of Crocus sativus extract, 2-10 parts of Witch hazel extract, 1-3 parts of palmitoyl oligopeptide, 2-10 parts of Sophora flavescens extract, 1-5 parts of nicotinamide, 0.1-0.5 part of hyaluronic acid, 0.1-1 part of Capo u20, 0.1-1 part of triethylanmine, 0.1-2 parts of sodium ascorbyl phosphate and 0.3-1 part of diazolidinyl urea. The acne-removing skin beautifying lotion aims at various types of acne skin, can remove whelks, blackheads, whiteheads and acnes on human skin and has good treatment, restoration and tranquilization effects on facial upper knobbing, cyst, pustule and papule.

Owner:大连苗谣青颜生物科技有限公司

Complementary type energy-saving lamp

InactiveCN102338296ASave electricityGood penetrationElectric circuit arrangementsElectric lightingPower gridHigh intensity

The invention discloses a complementary type energy-saving lamp, which can be used for achieving the purpose of saving energy through illumination advantage complementation. The complementary type energy-saving lamp is characterized in that a connecting pipe is arranged between a lamp post pipe and a lampshade, a solar cell panel is arranged above the connecting pipe, an LED (Light-Emitting Diode) lamp support is arranged below the connecting pipe, a left and a right reflectors are arranged on two sides of an HID (High Intensity Discharge) lamp, and a photoelectric conversion module and a thermoelectric conversion module are arranged on the inner side of the lampshade and are used for collecting and storing solar energy at daytime and recycling and storing energy on a non-illumination side of the HID lamp at night and supplying the stored energy to an LED lamp, so that the utilization efficiency of a power grid is greatly increased while the advantages of greatly saving electricity, reducing cost, prolonging the service life and enhancing a comprehensive illumination effect are achieved, and huge social and economic benefits are about to be generated.

Owner:孟晓静

Method for welding balancing air leakage pipe of medium-high pressure outer cylinder in turbine

A method for welding a balancing air leakage pipe of a medium-high pressure outer cylinder in a turbine relates to a method for welding and is used for solving the technical problems of more welding defects, coarse welding lines, uneven welding line widths and lowered welding quality due to the adoption of a method for manually arc-welding the balancing air leakage pipe of the medium-high pressure outer cylinder in the turbine. The method is ad follows: a beveled edge of the balancing air leakage pipe of the medium-high pressure outer cylinder in the turbine is preheated, is welded through adopting argon arc welding, is thermally insulated for 2 hours at 300 DEG C to 400 DEG C after the welding, is heated, is thermally insulated and is cooled so as to complete the welding of the balancing air leakage pipe of the medium-high pressure outer cylinder in the turbine. After the method is adopted, the defects of weld beading, lack of penetration and pits which are easily generated through adopting shielded metal arc welding do not exist, and the first pass yield of postwelding radiographic inspection is above 90%; and moreover, after the method is adopted, the welding line formation is good, i.e. weld ripples are fine, the welding line widths are consistent with each other, no splashing is generated, and the postwelding appearance quality is good.

Owner:HARBIN TURBINE

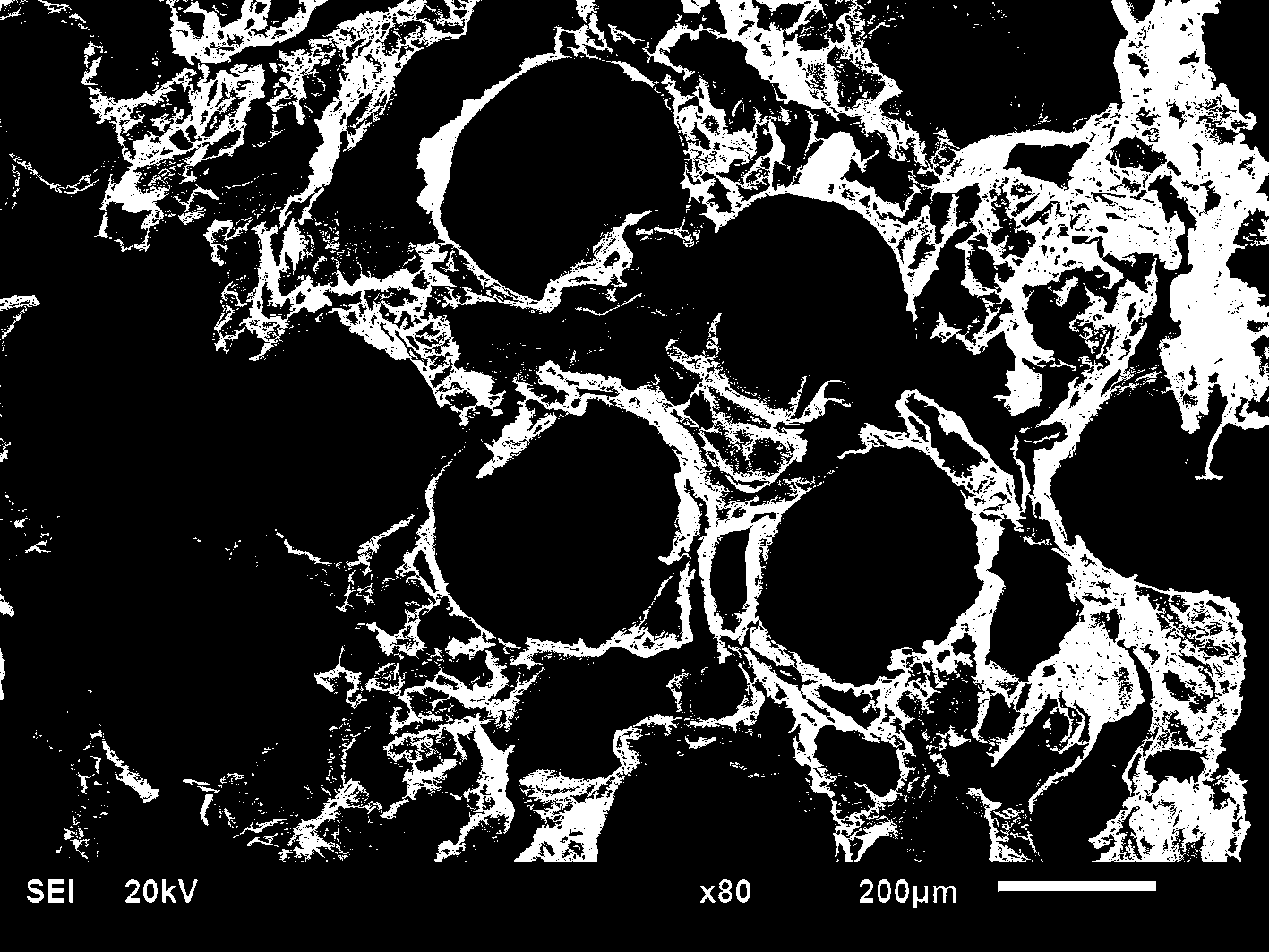

Preparation method of bone repair bracket with osteoid poriform regeneration channel structure

The invention discloses a preparation method of a bone repair bracket with an osteoid poriform regeneration channel structure. The method comprises the steps that a filament pore forming material with the diameter corresponding to the required pore diameter is embedded into nanometer apatite and polyamide composite pulp with the viscosity of 50-500Pa.s; a solvent is heated, volatilized and solidified at 80-200 DEG C, and then the filament pore forming material in the solvent is removed; and finally a bone repair bracket body product with orientation pores / channels in the structure is obtained. The method is simple and convenient; the bone repair bracket with the orientation pores / channels can be prepared; the pore size of the prepared osteoid orientation pores / channels and the porosity of the bracket can be adjusted and controlled as required; the mechanical properties in hole directions of the orientation pores / channels of the bracket can be significantly improved; the connectivity of the pores is good; rapid vascularization, cell growth and new bone tissue growth are facilitated; and regeneration and repair of a bone tissue are promoted.

Owner:SICHUAN UNIV

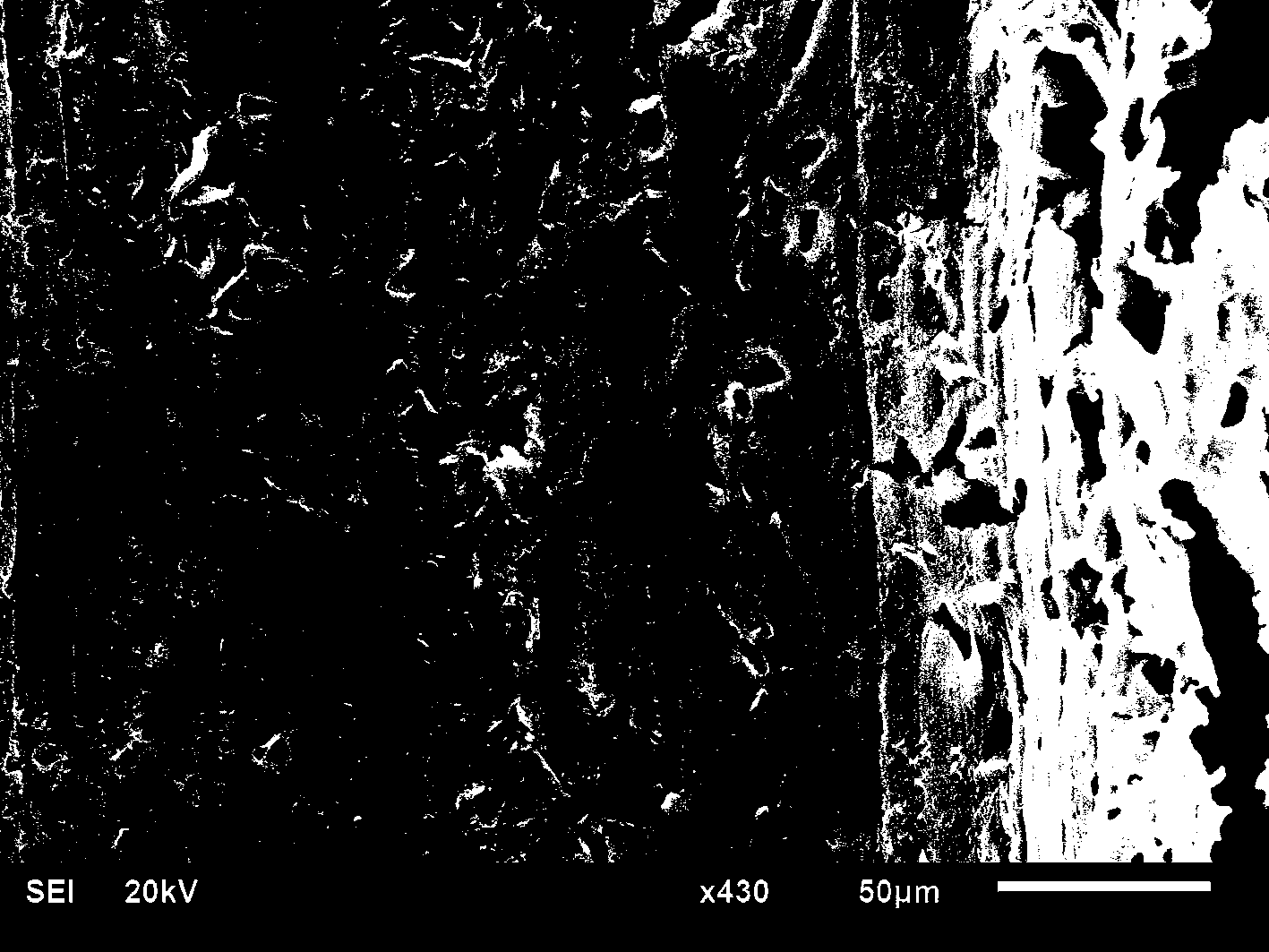

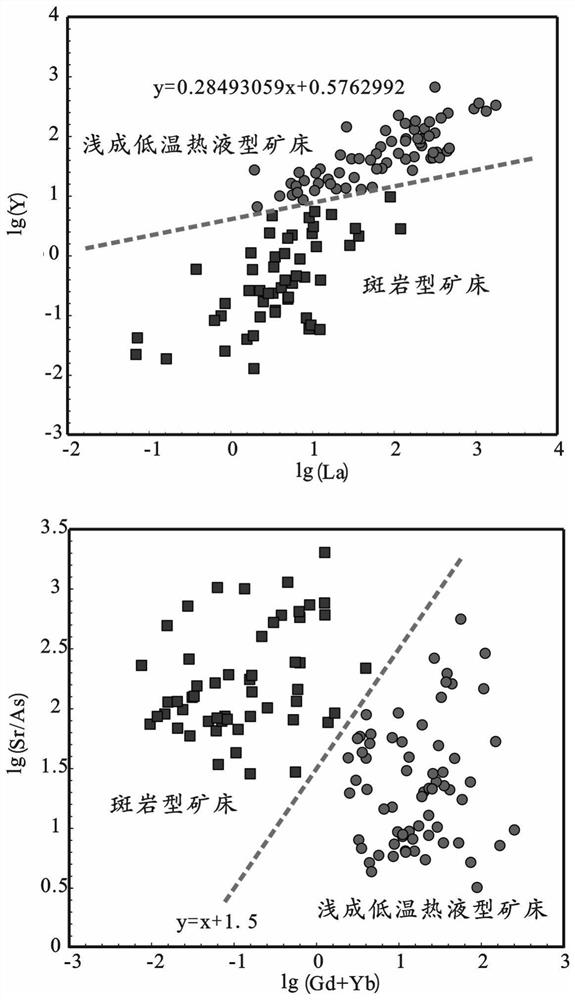

Ore prospecting method based on epidote microelements

PendingCN114646682AOvercoming inefficienciesGood penetrationMaterial analysis using wave/particle radiationWithdrawing sample devicesHydrothermal mineralizationSample collection

The invention discloses a prospecting method based on epidote microelements. The prospecting method specifically comprises the following steps that a metallogenic section is delineated; sample collection and analysis: collecting a bedrock sample containing epidote from the metallogenic section according to a certain sampling unit; analyzing and testing trace elements; data processing and interpretation: processing the obtained initial record data by using LADRlib software; and discriminating the prospecting action type. The method has the advantages that the LA-ICP-MS in-situ analysis technology is utilized, the description of the epidote altered minerals in the magma-hydrothermal mineralization system is improved from the macroscopic qualitative description to the microcosmic quantitative interpretation of the change of the trace elements, and the change of the trace elements is associated with the response of the scale prospecting type of an ore concentration area; the method overcomes the difficulties of low efficiency, long period and high cost of a traditional prospecting type discrimination method, can provide a theoretical basis for the optimization and selection of a prospecting exploration method for the ore deposit scale, and reduces the exploration risk.

Owner:西藏巨龙铜业有限公司 +1

Polytetrafluoroethylene hollow fiber membrane

ActiveCN106669465AEnsure uniformityGood penetrationSemi-permeable membranesPore distributionHollow fibre membrane

The invention provides a polytetrafluoroethylene hollow fiber membrane which comprises a polytetrafluoroethylene material body, wherein polytetrafluoroethylene takes the shape of fiber; the diameter of the fiber is greater than 200 nm and less than or equal to 2000 nm; the polytetrafluoroethylene material body is provided with pore cavities of which the apertures are 10-2000 nm and cavity walls formed by three-dimensional spaces surrounding the pore cavities; the pore cavities are in uniform distribution; the pore cavities are communicated in a three-dimensional manner; the pore cavities are in uniform distribution means that the pore cavities are in uniform distribution in a porous material by any unit-grade volume; and the porosity is greater than or equal to 65%. A specific and definite measurement mode is provided for pore cavity distribution uniformity of the polytetrafluoroethylene hollow fiber membrane, the pore distribution uniformity of the porous material and a multi-stage porous structure of the porous materials is measured by small-unit grade volume, the porous structure is high in uniformity, and thus uniformity consistency of different properties of the porous material can be ensured.

Owner:CHONGQING RUNZE PHARM CO LTD

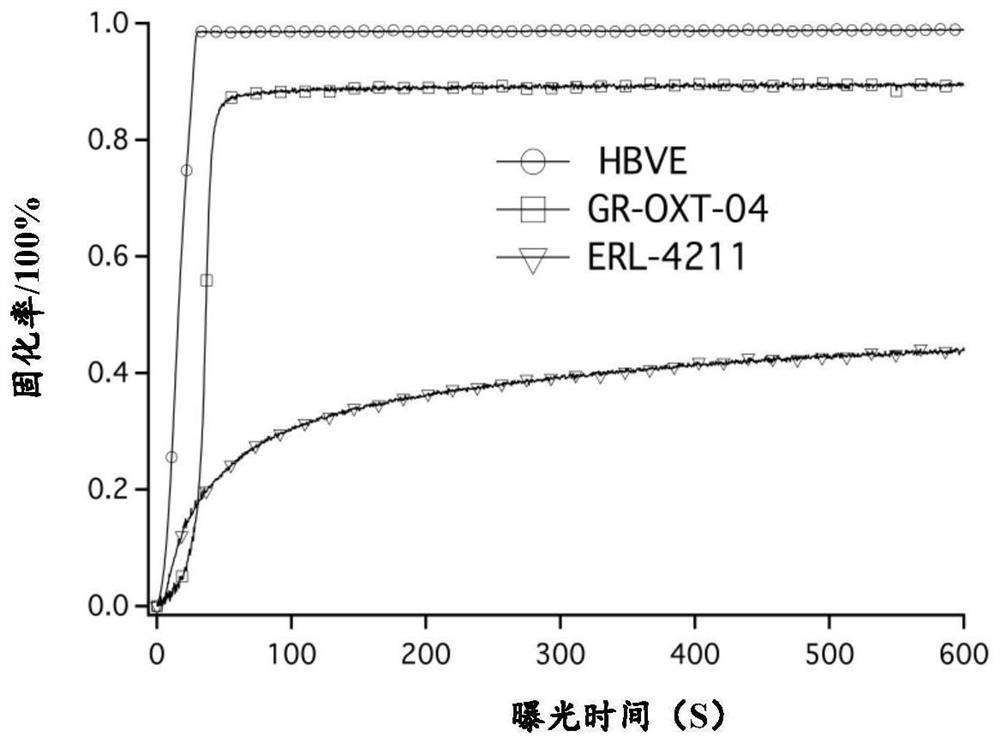

Photocurable composition for PCB containing alkenyl ether and/or oxetane compounds and free radical polymeric compounds

The invention discloses a photocurable composition for a printed circuit board, which contains the following components: (a) a photopolymerizable compound, (b) at least one infrared absorbing photosensitizer and (c) at least one photopolymerization initiator, wherein the photopolymerizable compound as the component (a) contains (a1) at least one free radical polymeric compound and (a2) at least one cationic polymeric compound, and is selected from alkenyl ether compounds and / or oxetane compounds, and the infrared absorbing photosensitizer as the component (b) comprises at least one polymethinecyanine compound.

Owner:BAODING LUCKY INNOVATIVE MATERIALS +1

Highly effective skin lotion and preparation method thereof

InactiveCN101284045AGood penetrationGood curative effectAntimycoticsPharmaceutical delivery mechanismPsoriasisMedicine

An efficient skin lotion is mainly prepared from the following raw materials of (by weight parts): Thymus vulgaris 20-40, Pseudolarix kaempferi bark 15-40, white alum 3-10, and bitter liquor 50-100. The preparation method of the skin lotion comprises the steps of: mixing raw materials except bitter liquor, pulverizing, charging into a bag, decocting in water (3-7 times the weight of raw materials) in a decocting container for 3-5 hours, filtering, taking out the medicinal bag, adding water, decocting again for 3-5 hours, filtering, mixing the two filtrates, and concentrating to obtain clear paste with relative density of 1.2; and slowly adding the clear paste into the bitter liquor, stirring, and bottling. The skin lotion has good therapeutic effect on dermatosis such as tinea manuum, tinea pedis, psoriasis and eczema, particularly tinea manuum and tinea pedis; and can completely kill fungi both on skin surface and in deep skin.

Owner:湖北百里香生物医药科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com