Heat pipe

A heat pipe and copper pipe technology, applied in the field of heat pipes, can solve the problems of high processing defect rate, large product scrap, and high finished product defect rate, and achieve the effects of high post-processing qualification rate, simple production process and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

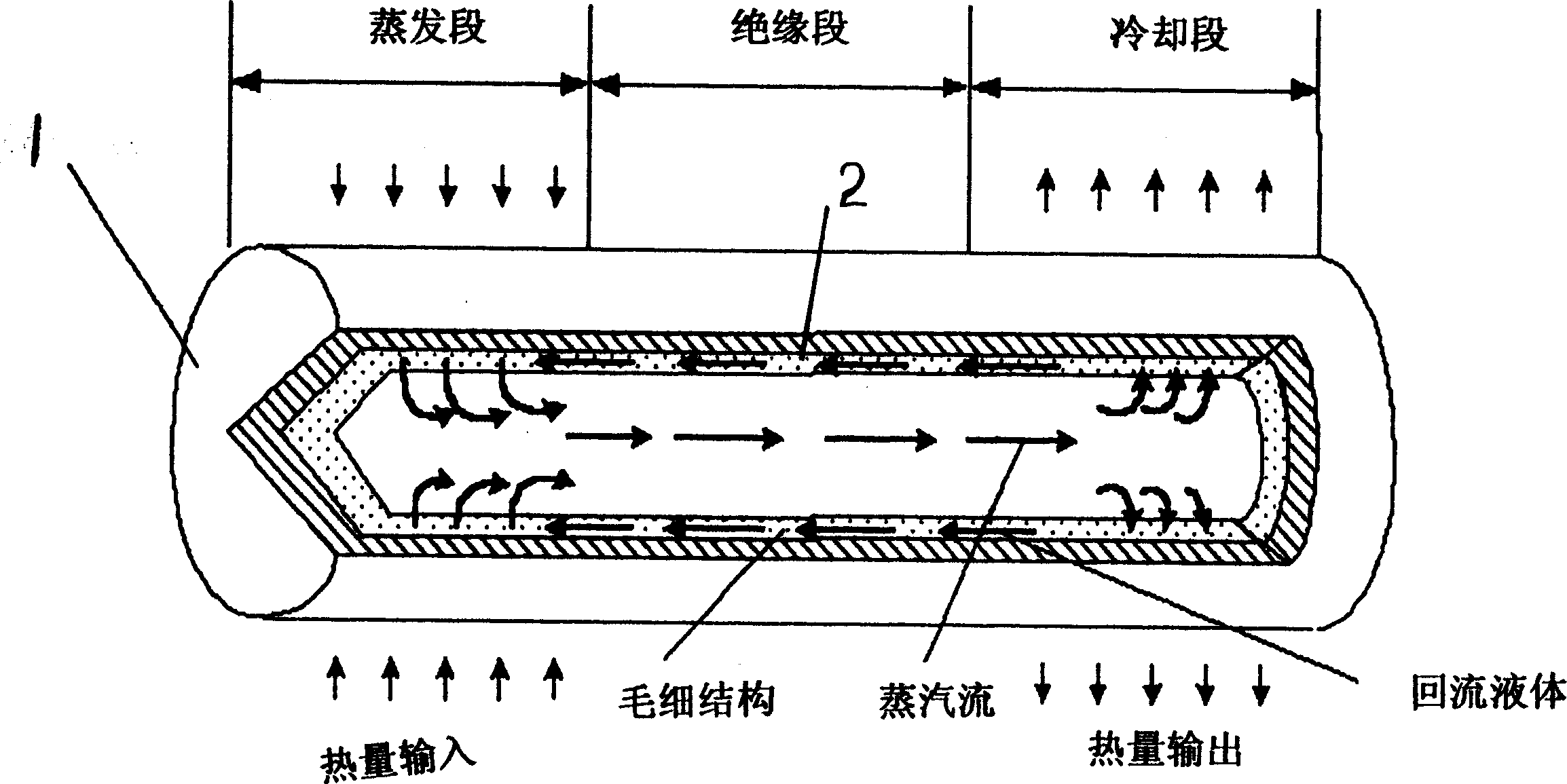

[0018] A heat pipe includes a sealed external container 1, and a heat-conducting material 2 made of foam metal and a working fluid injected into the external container 1 are arranged in the external container 1. After the working fluid is injected into the external container, it quickly seeps into the pores of the foam metal. The basic principle of heat transfer in the present invention is: the heat conduction of the heat pipe is the mechanism of using the latent heat of the working fluid in the tube to transport heat when the temperature changes. Because it can operate under a small temperature difference, it can have amazing heat transfer. Therefore, it has the reputation of thermal superconductor. In this way, when one end of the heat pipe is heated, the heated energy will vaporize the working fluid stored in the metal foam pipe wall, and at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com