Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

228results about How to "Good masking effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Yam fish ball and production method thereof

The invention discloses a yam fish ball and a production method thereof. The yam fish ball comprises the following components by weight part: 10 parts of fish mixture, 1-4 parts of Chinese yam rhizome, 0.2-0.4 part of egg white, 0.2-0.6 part of potato starch, 0.2-0.4 part of fat lining, 0.73-0.83 part of modifier and 0.5 part of seasoning. The method comprises the following steps: (1) selecting fresh water fish; (2) poaching, draining, rubbing and straining fish meat; (3) preparing yam mash; (4) mincing the fish meat and producing balls; (5) gelling the yam fish balls; and (6) packaging, quickfreezing and refrigerating. The yam fish ball produced by the method has low cost, full nutrition, delicious taste, white colour and good sense, is easy for digestive absorption and is favorable forhealth of human bodies.

Owner:高翔

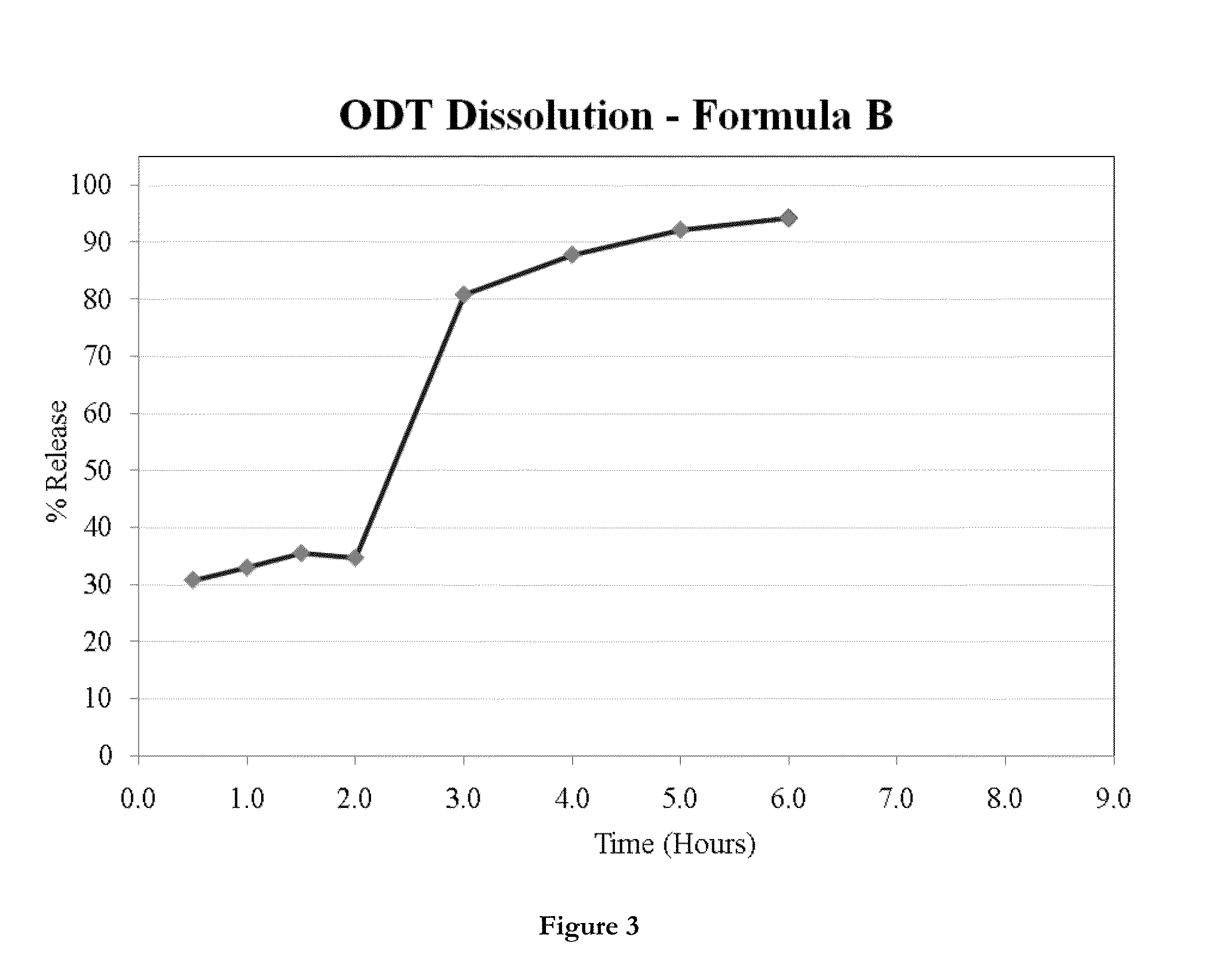

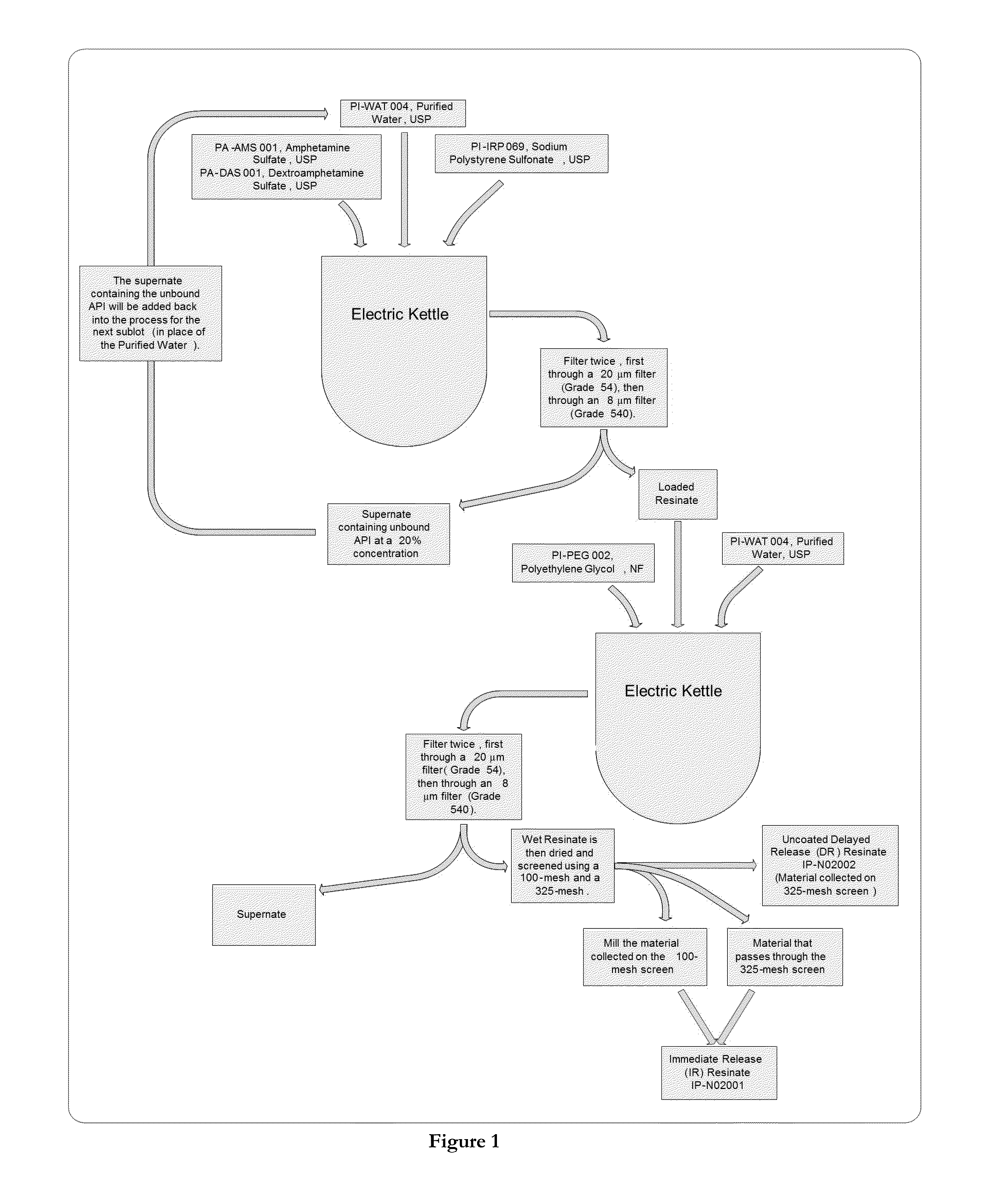

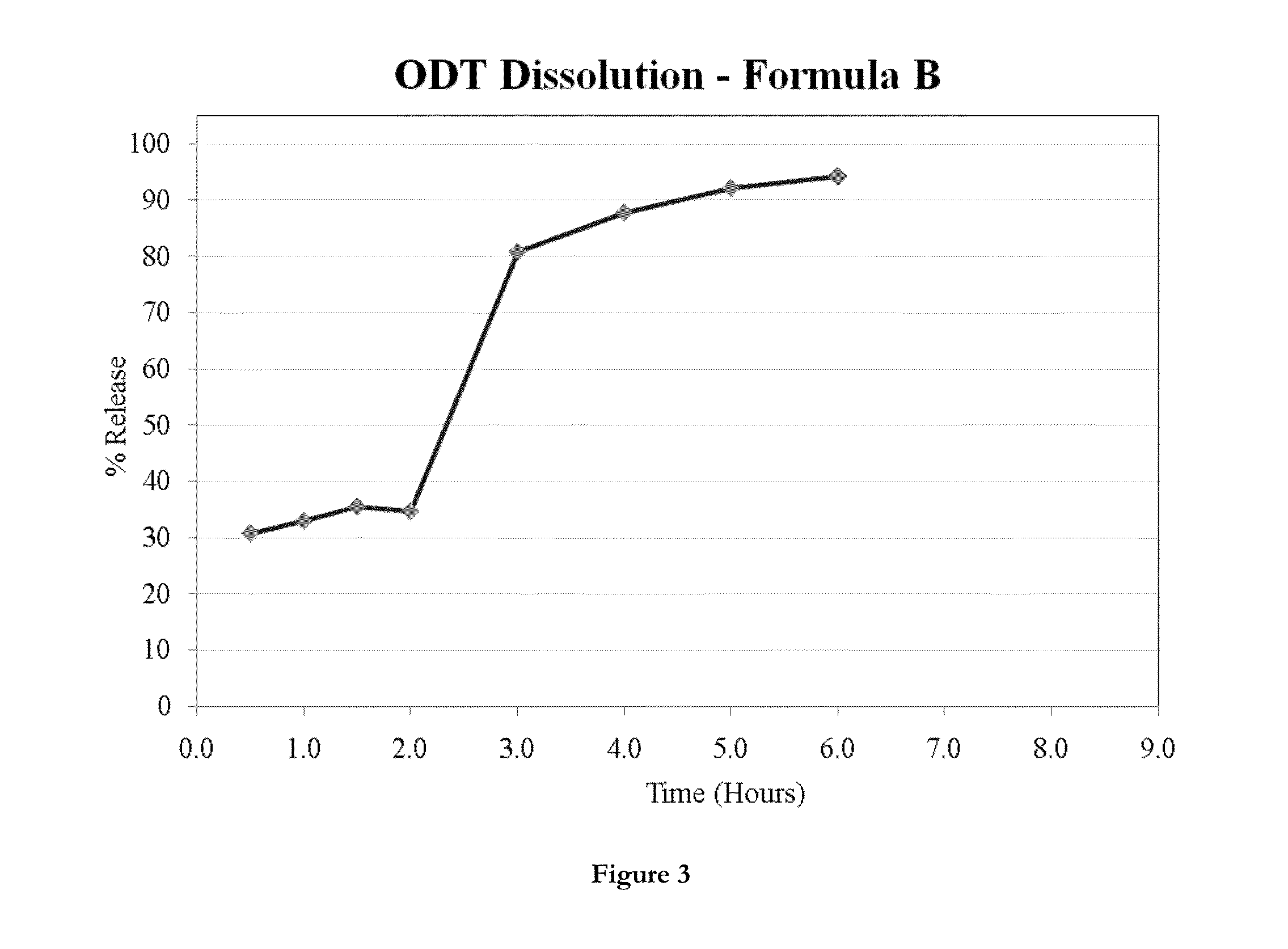

Dosage forms for oral administration and methods of treatment using the same

ActiveUS20130236554A1Increase intakeEffective and prolonged treatmentBiocideOrganic active ingredientsOral medicationIntrathecal

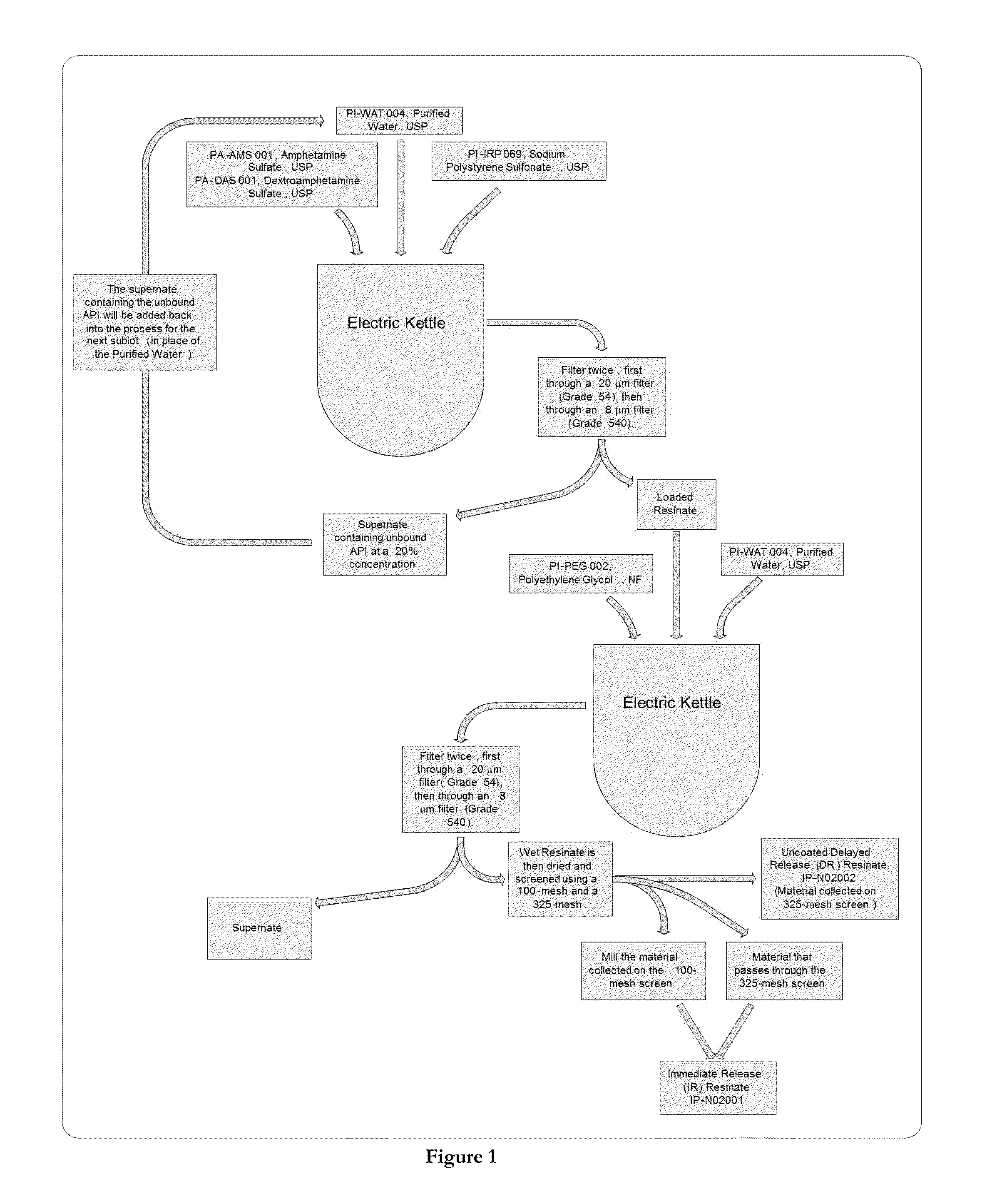

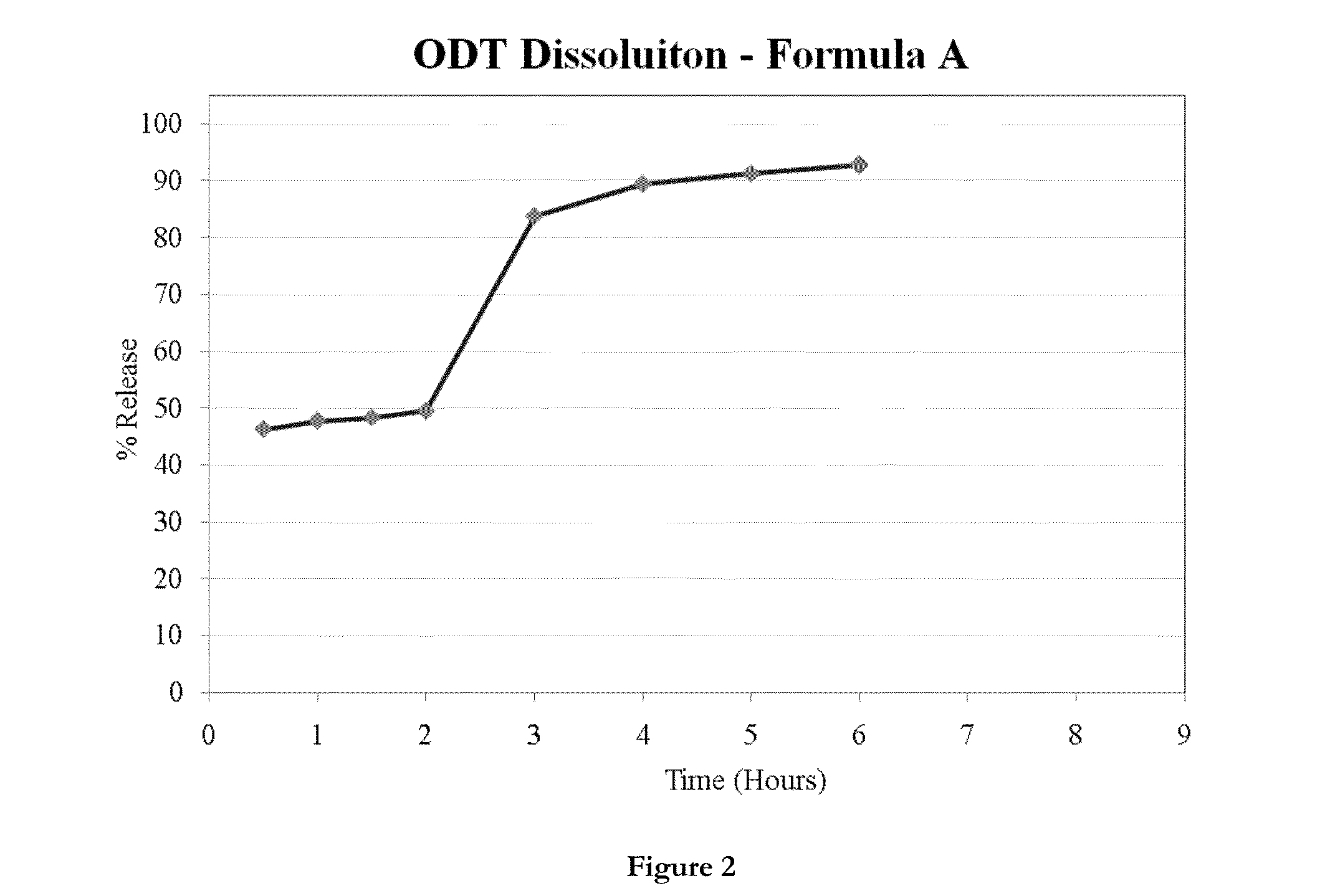

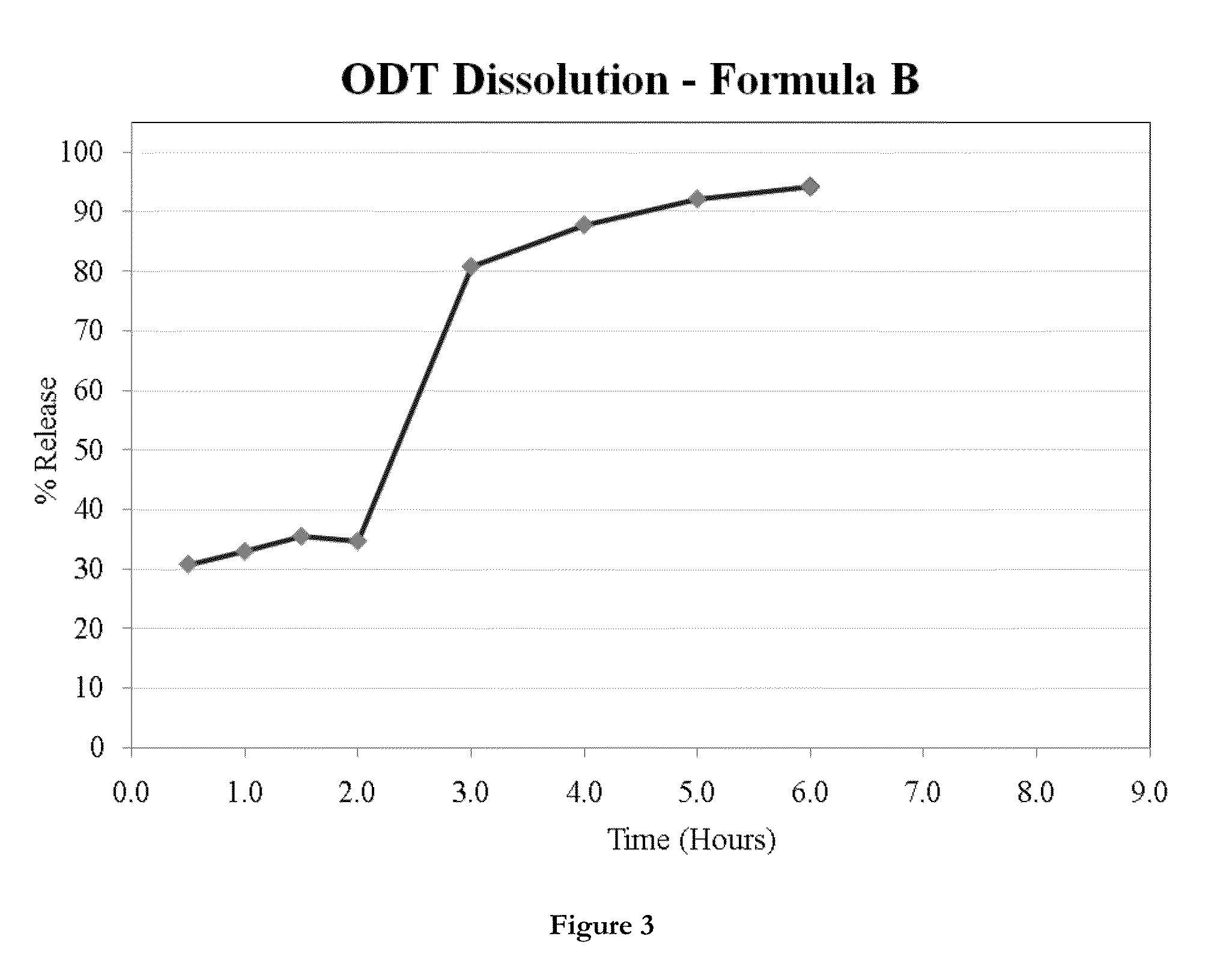

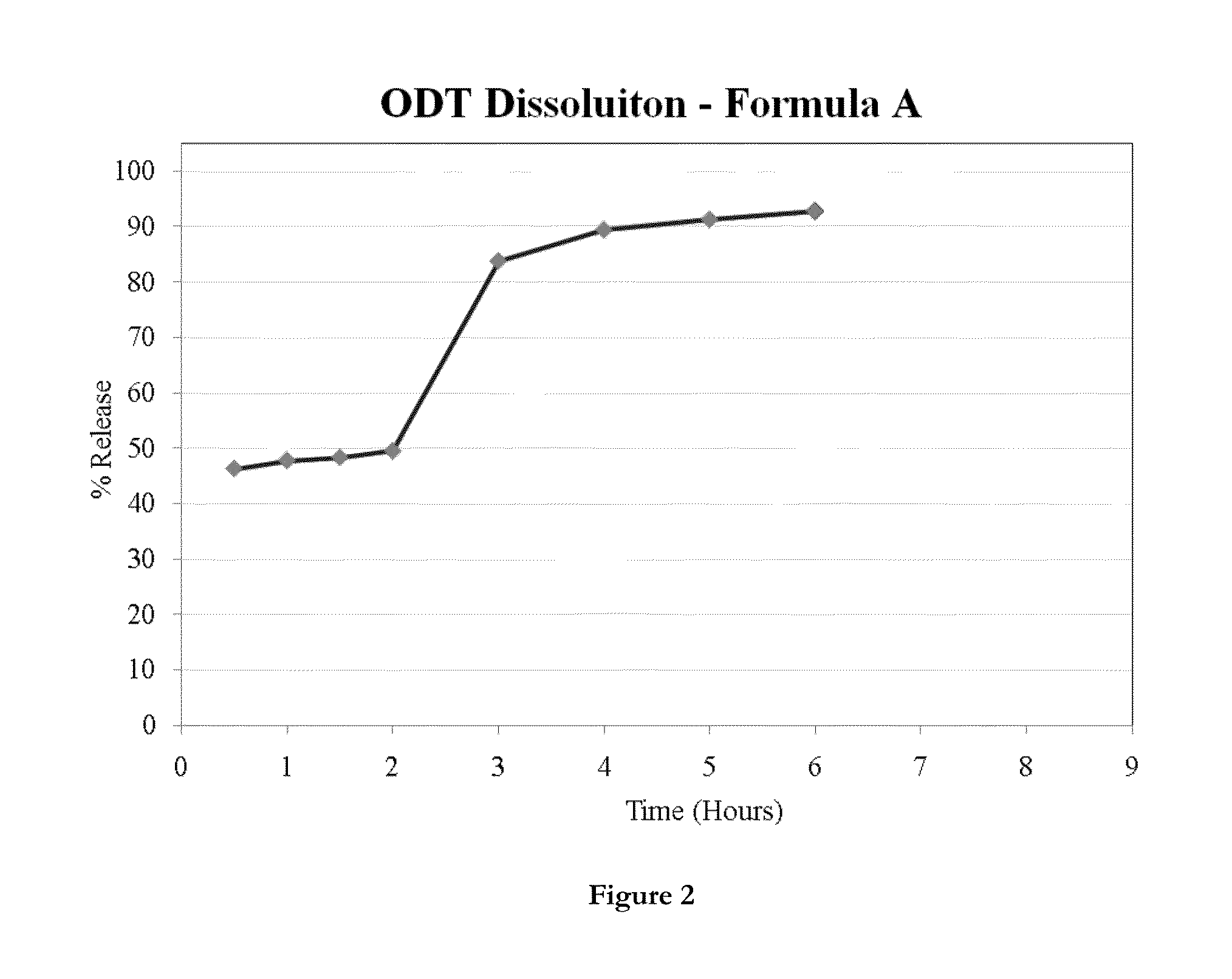

The invention relates to dosage forms that provide prolonged therapy. In particular, the invention relates to dosage forms including various pluralities of drug-containing resin particles. The invention also relates to methods of making these dosage forms and methods of treating using these dosage forms.

Owner:NEOS THERAPEUTICS LP

Dosage forms for oral administration and methods of treatment using the same

ActiveUS20130243869A1Increase intakeEffective and prolonged treatmentBiocideOrganic active ingredientsOral medicationIntrathecal

The invention relates to dosage forms that provide prolonged therapy. In particular, the invention relates to dosage forms including various pluralities of drug-containing resin particles. The invention also relates to methods of making these dosage forms and methods of treating using these dosage forms.

Owner:NEOS THERAPEUTICS LP

Transfer Sheets

InactiveUS20080302470A1Good masking effectImprove mechanical propertiesStampsDecorative surface effectsTitanium oxideMasking agent

In a transfer sheet which comprises a support and a transfer layer releasable from the support, the transfer layer comprises (i) an adhesive layer formed on one surface of the support and (ii) a masking layer formed on the adhesive layer and containing a masking agent and a binder resin which may have a crosslinking group, and the transfer layer is adjusted to have an elongation at break of not less than 30% (e.g., 30 to 200%). The masking layer may comprise a white pigment such as a titanium oxide and a urethane-series resin which may have an isocyanate group. The transfer sheet may comprise an image-receiving layer at least containing a urethane-series resin particle formed on the masking layer. Moreover, the transfer sheet may comprise an anchor layer between the masking layer and the image-receiving layer. The transfer layer is capable of recording an image thereon the image being transferred from a recording sheet. These transfer sheets may be used for forming the image on a colored object by transferring to the object.

Owner:DAICEL CHEM IND LTD

Dosage forms for oral administration and methods of treatment using the same

InactiveUS20130243871A1Increase intakeEffective and prolonged treatmentOrganic active ingredientsPowder deliveryEnteral administrationOral medication

Owner:NEOS THERAPEUTICS LP

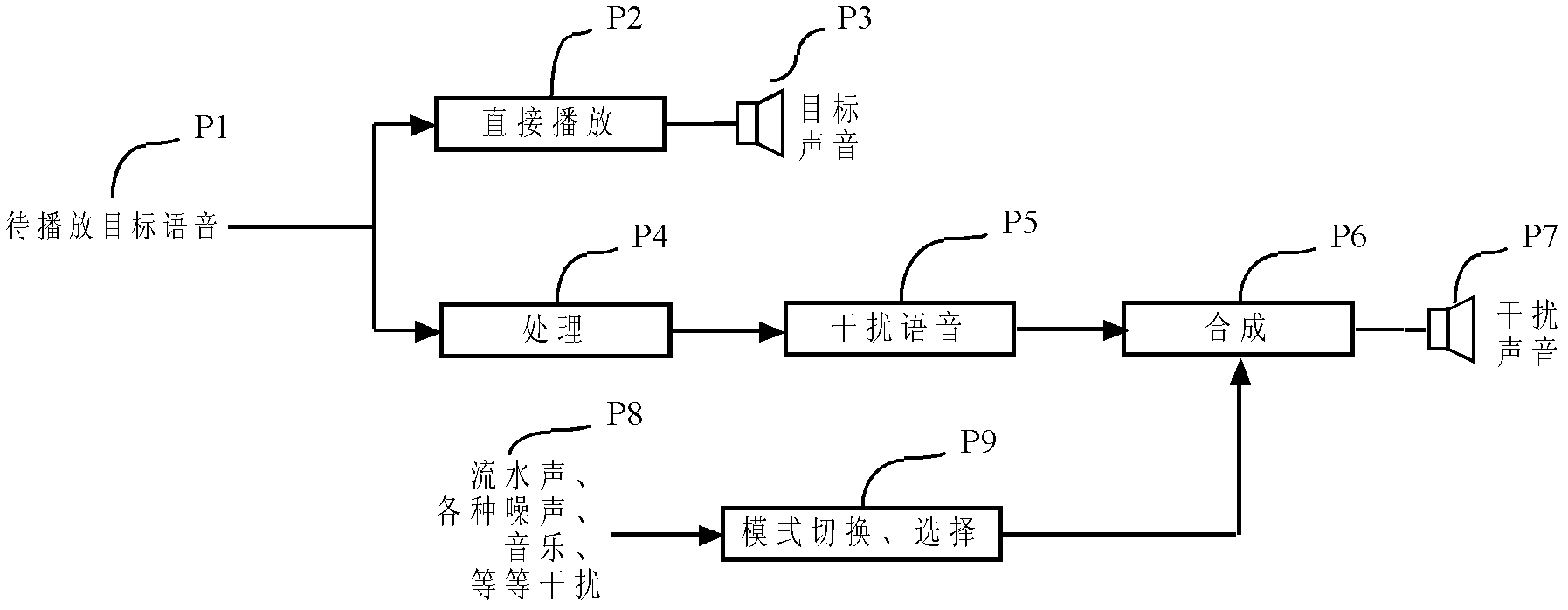

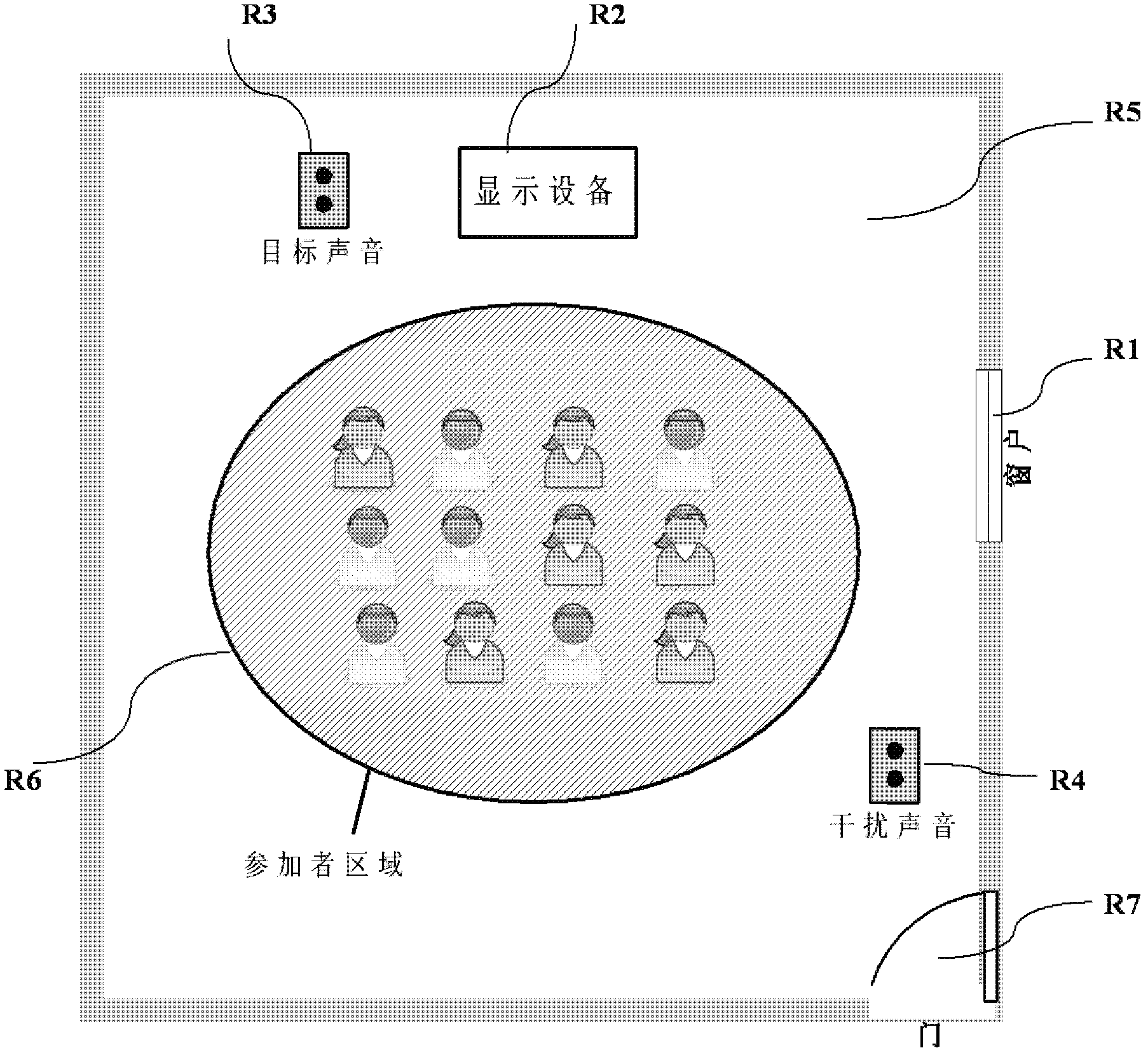

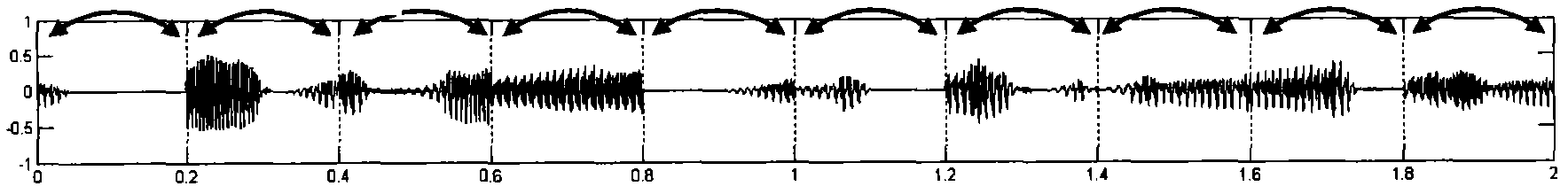

Target voice privacy protection method and system

ActiveCN102543066AHigh interference efficiencyLow annoyanceSound producing devicesSpeech synthesisPrivacy protectionLoudspeaker

The invention relates to a target voice privacy protection method and a target voice privacy protection system. The method comprises the following steps of: generating an interference voice signal based on a target voice signal, and combining the existing interference signals in an interference repository to synthesize composite interference sound, wherein the target sound and the composite interference sound are played by loudspeaker systems at different positions in a room. In the system, the interference voice signal is generated on the basis of the target voice signal, and the existing interference signals in the interference repository are combined to synthesize the composite interference sound, wherein the target sound and the composite interference sound are played by the loudspeaker systems at different positions in the room. The interference sound is a composite interference signal comprising a target voice signal-related part, wherein the related part is generated by processing the target voice signal, and the interference sound has the advantages of high interference efficiency and low annoyance. In addition, the interference sound and the target sound are played by the loudspeaker systems at different positions in the room, a sound signal is picked from interference voice recording equipment, and normal operation of a conference is not influenced basically.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

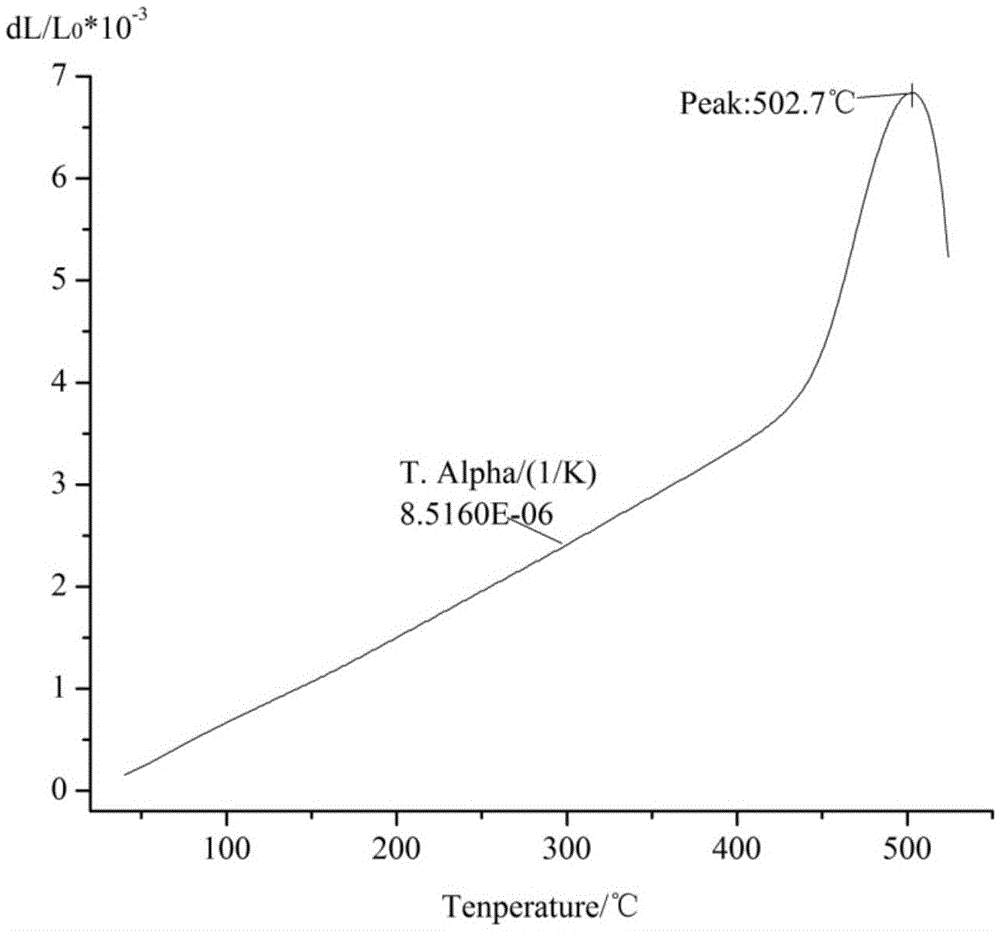

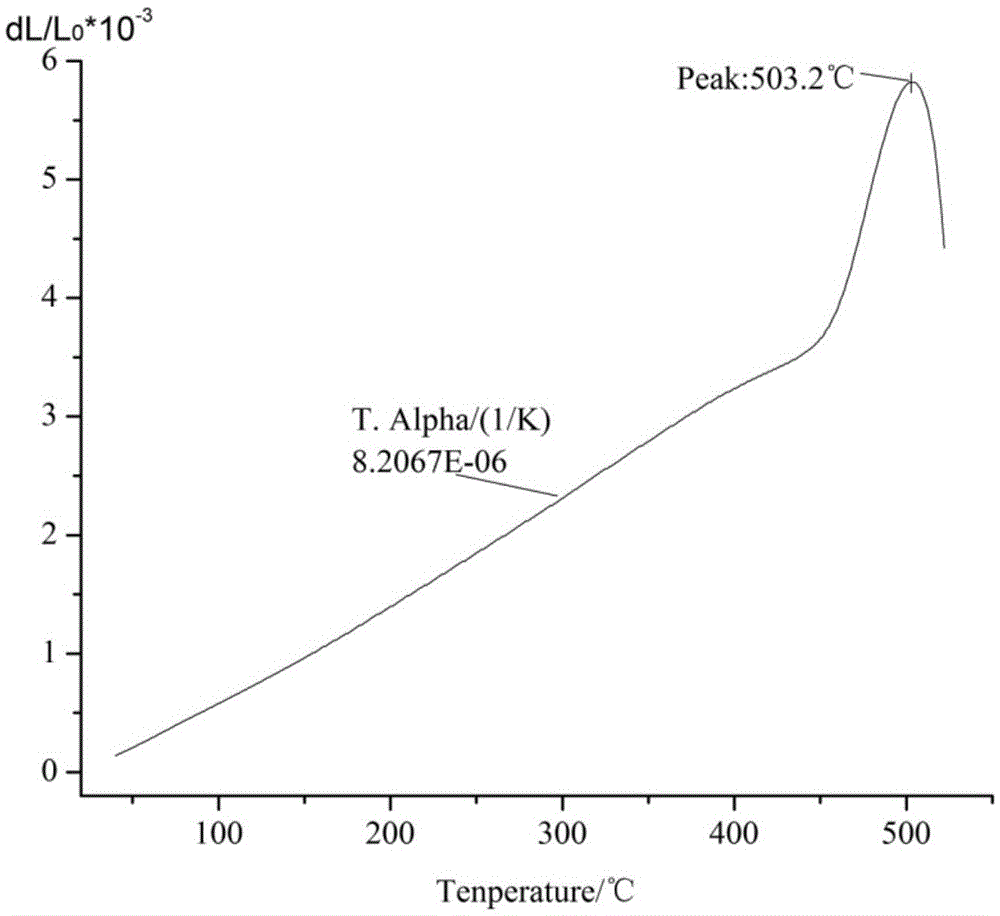

Acid-and-alkali-resistant environment-friendly ink for automotive windscreen and preparing method thereof

The invention relates to the technical field of ink, in particular to an acid-and-alkali-resistant environment-friendly ink for an automotive windscreen.The acid-and-alkali-resistant environment-friendly ink is characterized by being prepared from, by mass, 50%-70% of lead-and-cadmium-free composite glass powder, 8%-20% of inorganic pigment, 20%-40% of varnish, 0.6%-1% of dispersing agent, 0.6%-1% of flatting agent and 0.3%-0.6% of thixotropic agent.The acid-and-alkali-resistant environment-friendly ink for the automotive windscreen is efficient and environmentally friendly, has excellent acid and alkali resistance and suitable sintering temperature, is good in water resistance, high in adhesive force and good in ultraviolet resistance, and has the quite low light transmissivity, and foreign-automobile-windscreen ink products can be replaced with the ink.

Owner:湖南衡义材料科技有限公司

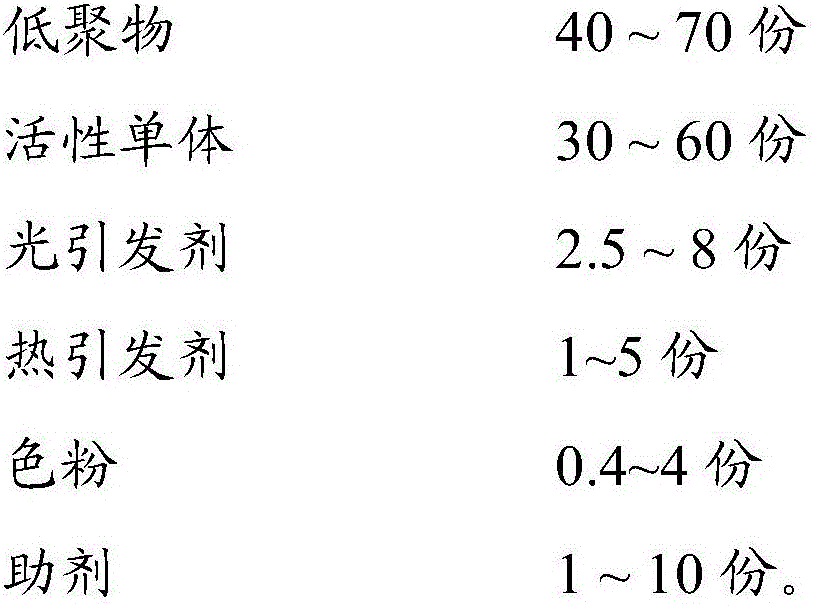

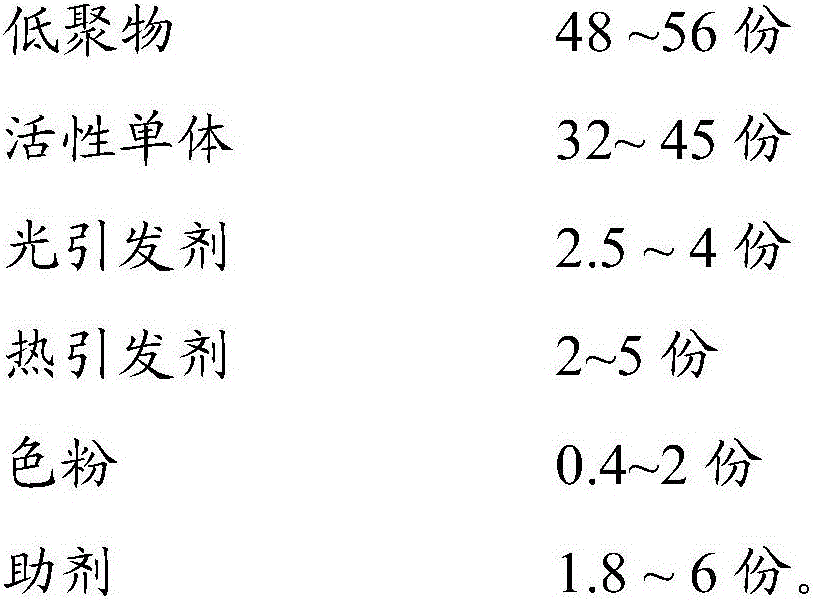

Photo-thermal dual-curing shielding glue and preparation method thereof

The invention relates to photo-thermal dual-curing shielding glue and a preparation method thereof, and belongs to the technical field of chemical materials. The photo-thermal dual-curing shielding glue is mainly prepared from, by weight, 40-70 parts of low polymer, 30-60 parts of activated monomer, 2-8 parts of photo-initiators, 1-5 parts of thermal initiators, 0.1-4 parts of toners and 0.1-10 parts of auxiliaries. The low polymer is at least one of epoxy acrylate, pure acrylic ester and polyester acrylate, and the activated monomer is at least one of mono-functional acrylic ester, bifunctional acrylic ester and poly-functional acrylic ester. The shielding glue can adopt a photo-thermal dual-curing mode, UV (ultraviolet) pre-curing shaping is performed, complete heating and curing are performed, and batch treatment is performed within a certain proper time. The shortcomings of serious excessive glue caused by only heating and curing or normal-temperature curing and incompleteness of only UV curing are overcome. The photo-thermal dual-curing shielding glue can be widely used for touch glass, LCD (liquid crystal display) modules and cover glass shading and enhancement.

Owner:广州惠利电子材料有限公司

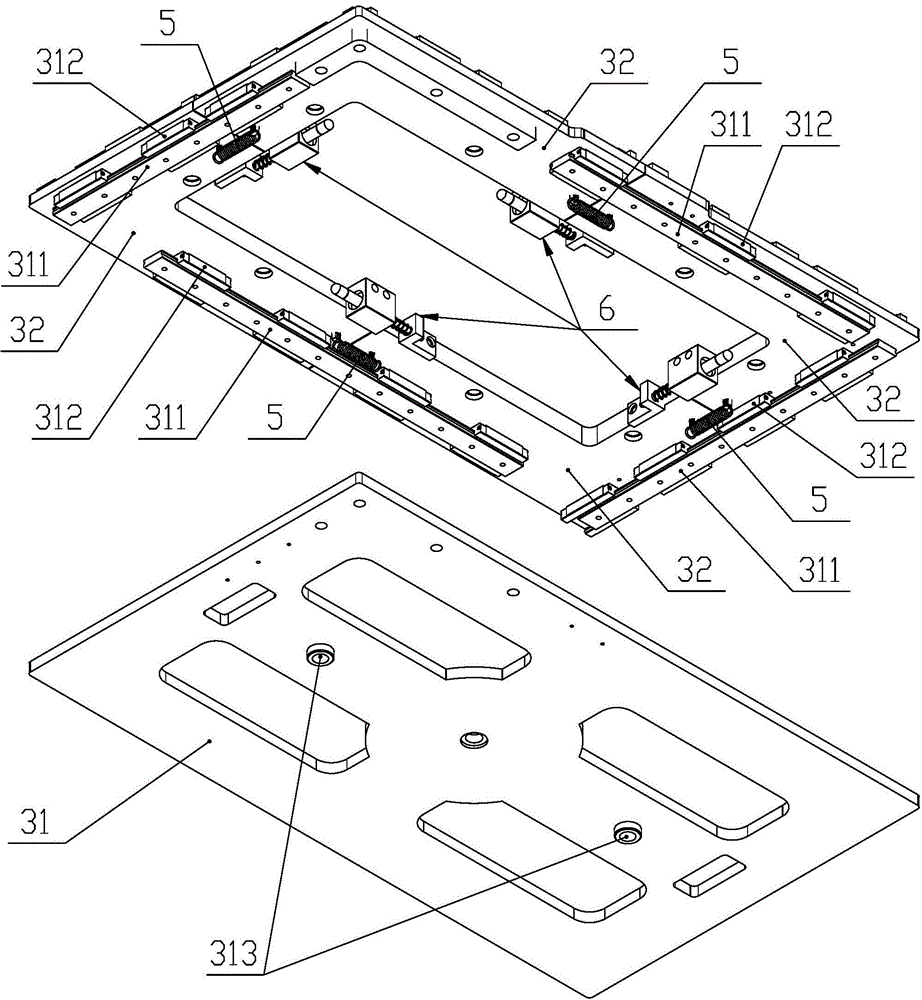

Flexible screen and foldable equipment

PendingCN113053238AImprove integrityImprove securityDigital data processing detailsSubstation equipmentFolded formEngineering

The invention provides a flexible screen and foldable equipment, relates to the technical field of electronic equipment, and aims to solve the technical problem of poor folding effect of the flexible screen. The flexible screen provided by the invention comprises a flexible display panel and a bearing plate, and the flexible display panel is provided with a back face and a display face used for displaying images. The bearing plate is arranged on the back face of the flexible display panel and used for providing a certain supporting effect on the flexible display panel. The bearing plate is provided with a first fixing part, a first bending part, a first connecting part, a main bending part, a second connecting part, a second bending part and a second fixing part which are sequentially arranged in the first direction, and the first direction is parallel to the plate surface of the bearing plate; after the flexible screen is folded, the main bending part can be bent towards the folding direction, and the first bending part and the second bending part can be bent away from the folding direction, so that the folding form of the flexible screen can be effectively controlled; and according to the flexible screen provided by the embodiment of the invention, the folding state can be effectively controlled, so that the folding effect is improved.

Owner:HUAWEI TECH CO LTD

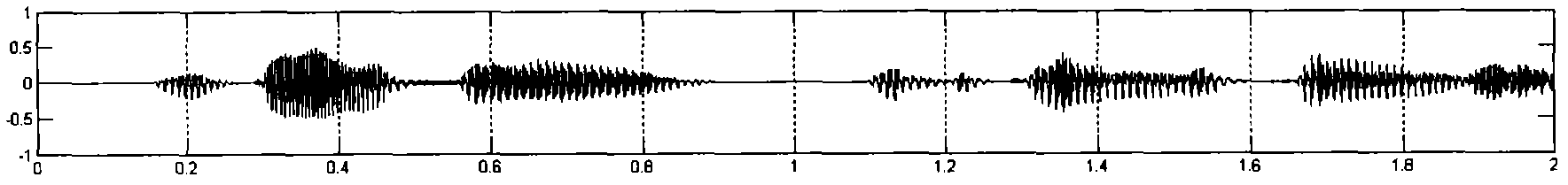

Method for generating sound masking signal based on time reversal

InactiveCN102110441AGood masking effectReduce intelligibilitySpeech analysisSound producing devicesTime domainSound sources

The invention relates to a method for generating a sound masking signal based on time reversal. In the method, a corresponding sound masking signal is acquired according to a target sound source signal and has a long-time amplitude spectrum similar to that of the target sound source signal and extremely low speech intelligibility. The method comprises the following steps of: picking up the target sound source signal by using a microphone or a microphone array and performing preprocessing to acquire a clean target sound source signal; performing framing based on a specific time window length according to the acquired target sound source signal; and performing time reversal on a time domain of each frame of signal according to y(t)=x(-t) to acquire the sound masking signal corresponding to a target sound source, wherein x(t) represents a frame of signal, and the y(t) represents an output signal of the frame. The time reversal sound masking signal has the long-time amplitude spectrum similar to that of the target sound source signal; the method has advantages in energy masking; and the time reversal sound masking signal is completely unintelligible or is partially intelligible and cannot become a new interference sound source.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

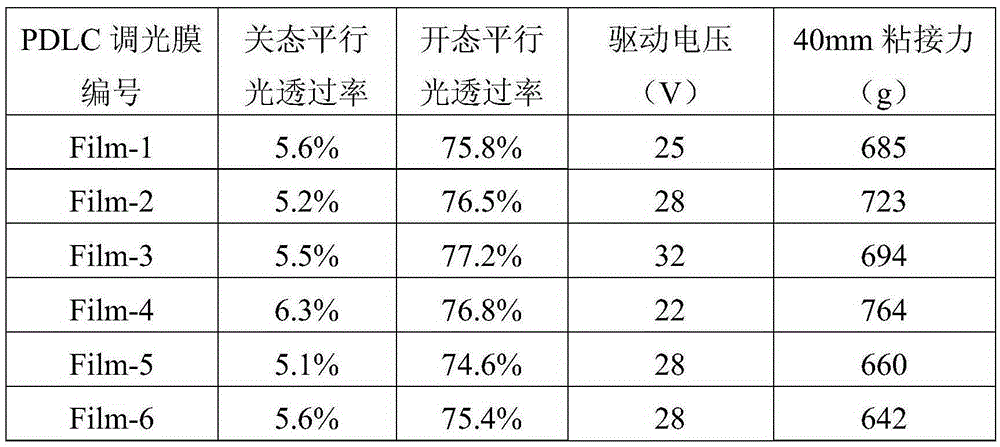

PDLC composition with high bonding force

InactiveCN105418854AHigh bonding strengthReduce the driving voltageLiquid crystal compositionsNon-linear opticsTransmittancePhotoinitiator

The invention discloses a PDLC composition with a high bonding force. The PDLC composition is prepared from the following raw materials: light-cured prepolymer monomers, a liquid crystal material, a photoinitiator, spacers and a phosphor element providing agent through a light curing reaction. The light adjusting material is applied in a light adjusting membrane or light adjusting glass, has excellent bonding intensity, excellent photoelectric performances and a good service life performance, the problem can be solved that the bonding force is not good when a light adjusting material is used on a PET base material, and different demands of users are met. Compared with the present conventional PDLC light adjusting membranes at market, the PDLC light adjusting membrane has a high membrane transmittance and an obviously low driving voltage, the bonding force performance is excellent, and the provided PDLC light adjusting membrane has obvious visual effects and applicability.

Owner:SHIJIAZHUANG CHENGZHI YONGHUA DISPLAY MATERIALS CO LTD

Light diffuser board integrated with high transmittance, high haze and high toughness in one body

InactiveCN103645525AGood light diffusion effectImprove uniformityDiffusing elementsPolystyreneStabilizing Agents

The invention discloses a light diffuser board integrated with high transmittance, high haze and high toughness in one body. A fiber-level GPPS such as transparent and blue-background polystyrene is taken as a main material, glass beads are taken as a silicon diffusion agent, and a high haze flexibilizer SCBS is innovatively added. Based on the diffuser board having functions of light collection, light diffusion and light reflection, a product formula is improved and added, auxiliary agents such as a diffusion agent, a light stabilizing agent and a high haze flexibilizer are added to a raw material, and thereby functions of light refraction, light reflection and light diffusion are realized in products, not only can quite high light diffusion and emergent light uniformity be realized, but also a utilization rate of the power source is high, anti-folding performance and shielding performance are good, a penetration rate of products can reach 93%+ / -5%, and the haze can reach 99%+ / -1%.

Owner:HUIZHOU YUETAIXIANG TECH

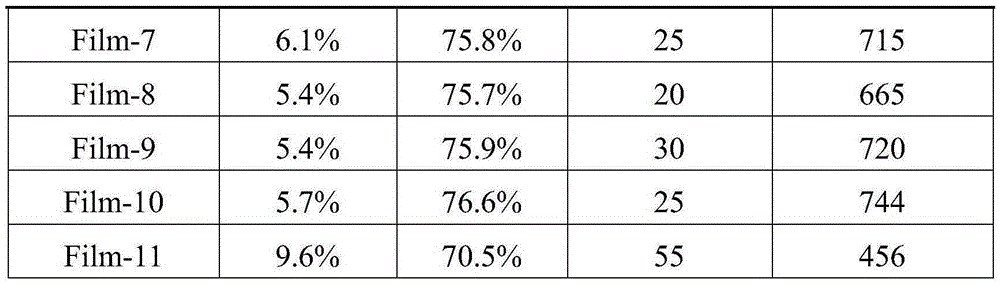

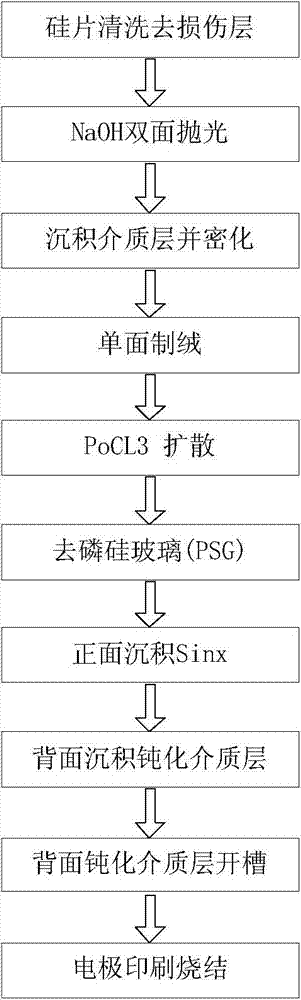

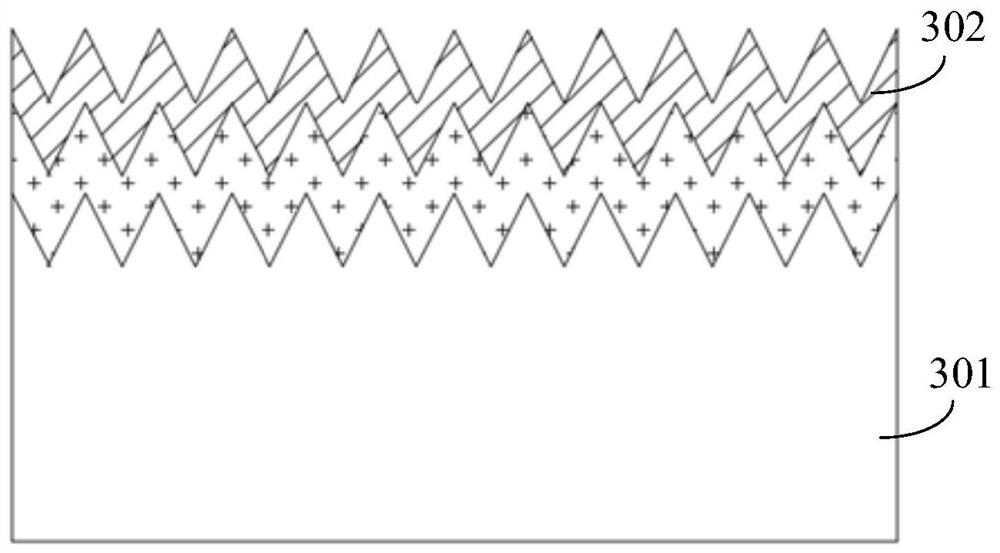

Back-passivation efficient PERL battery technology

InactiveCN104716224AReduce dosageSimple processFinal product manufactureSemiconductor devicesAluminium pasteEngineering

The invention relates to a back-passivation efficient PERL battery technology. The back-passivation efficient PERL battery technology comprises the steps that a silicon wafer is cleaned in a HF / HNO3 mixed solution, a surface damaged layer is removed, double-side polishing is carried out, a SiOx film layer is deposited on a single-side, a suede face is made, POCl3 single-side deposition and diffusion are carried out in a high-temperature furnace, surface phosphorosilicate glass is removed, SiNx with a thickness of 80 nm is deposited on the front side of the silicon wafer, SiOx with a thickness ranging from 10 nm to 20 nm is deposited on the back side of a polished surface of the silicon wafer, an SiNx layer with a thickness ranging from 100 nm to 200 nm is deposited in a pipe-type or a plate-type PECVD equipment, slots and holes are formed in a back-passivation layer, and silk-screen printing and sintering are carried out on back aluminium paste, a back electrode and a positive electrode. Compared with the prior art, the technology is simplified, and therefore the large-scale mass production is facilitated.

Owner:SHANGHAI SHENZHOU NEW ENERGY DEV

Production technology for preparing leather from pig split leather scytoblastema

ActiveCN104608431AImprove featuresImprove stabilityLamination ancillary operationsLaminationComposite materialPolymer chemistry

The invention relates to the technical field of leatherworking, and particularly relates to a production technology for preparing leather from pig split leather scytoblastema. The production technology comprises the following working steps: selecting materials, spraying and filling resin, scraping and repairing, drying, flattening, rubbing down, spraying a covering coating, and pressing by plates. According to the production technology disclosed by the invention, the loose side parts on the pig split leather scytoblastema is sprayed and filled with the resin, then the irregular parts on the surface of the scytoblastema are scraped in a scraping and repairing manner, then the surface of the scytoblastema of the pig split leather is smoothened and flattened by drying, flattening, rubbing down, spraying the covering coating and pressing by the plates, so that the quality of the prepared leather can reach the level of cowhide and the added value of the leather can be improved.

Owner:DONGGUAN TIANYI LEATHER TECH CO LTD

Composite brightness enhancement film and backlight module

The invention relates to the technical field of optical films, and especially relates to a composite brightness enhancement film and a backlight module to solve problems that a conventional backlight module is high in thickness and assembling procedures are complicated. The composite film sequentially comprises a first prism film, a first bonding layer, a second prism film, a second bonding layer and a third prism film. The third prism film comprises a third prism layer, a third PET substrate layer and a back coating layer. The third prism layer is formed by a plurality of third prism strips and a plurality of diffusion regions, the third prism strips and the diffusion regions being arranged alternately. The composite brightness enhancement film has brightness enhancement and diffusion effects. If the composite brightness enhancement film is assembled into the backlight module without mounting of a diffusion film, the thickness of the backlight module is reduced. The composite brightness enhancement film exhibits good luminance, uniformity and covering properties.

Owner:NINGBO CHANGYANG TECH

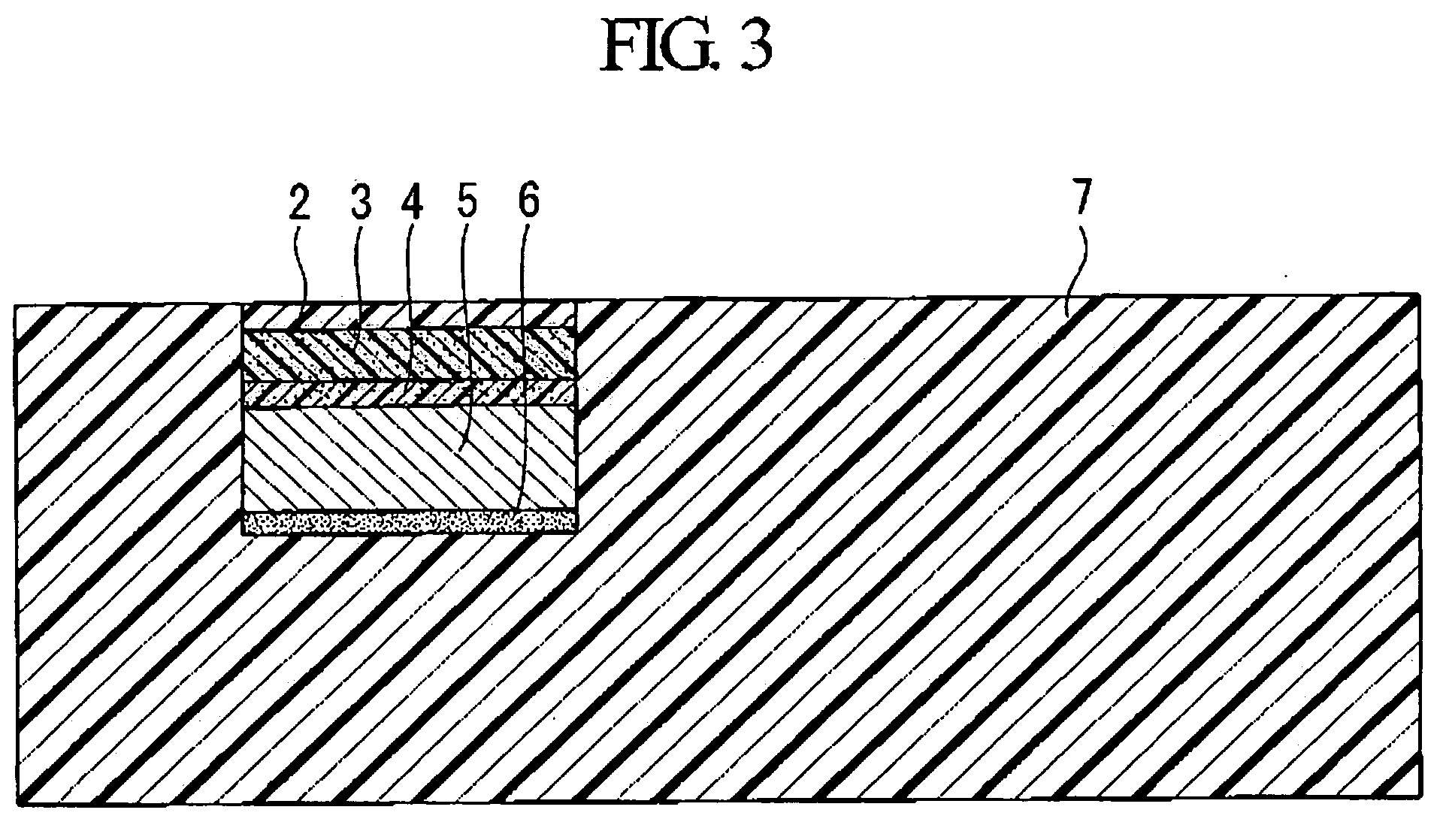

Magnetic Recording Medium and Manufacturing Method Therefor

InactiveUS20080305365A1Easy to produceSimple designProtective coatings for layersRecord information storageLight reflectionDiffuse reflection

A card-like magnetic recording medium comprising a non-magnetic substrate and a laminate containing a magnetic recording layer wherein the laminate is placed in at least a portion of the non-magnetic substrate; wherein the laminate comprises a light reflection quantity controlling layer, which includes a binder resin and at least one of a scale-like metal powder and fine flakes obtained from a metallic thin film and is formed on the magnetic recording layer, and further comprises a glistening coating layer which includes glistening particles and is formed on the light reflection quantity controlling layer; and the maximum reflectance of diffuse reflection light with respect to incident lights having a wavelength from 400 to 700 nm is 20 to 70% on a portion where the glistening coating layer is provided.

Owner:DAINIPPON INK & CHEM INC

Self-adaptive shielding device

The invention discloses a self-adaptive shielding device which is high in working efficiency and convenient for fixing of plastic frame products. The self-adaptive shielding device comprises a rack, a lifting mechanism, a fixing mechanism and a shielding mechanism, the lifting mechanism is arranged on the rack, the shielding mechanism is arranged on the lifting mechanism and can move along the vertical direction, the fixing mechanism is arranged on the rack and positioned below the shielding mechanism, the fixing mechanism comprises a mounting bottom plate and self-adaptive fixing plates, the shielding mechanism comprises a mounting top plate, shielding strip mounting plates and push rods, positioning pins are arranged on the lower surface of the shielding strip mounting plates, guide holes corresponding to the positioning pins are formed in one of the self-adaptive fixing plates corresponding to the shielding strip mounting plates, and the lower end of each positioning pin is a guide end. Compared with existing shielding modes, the self-adaptive shielding device has the advantages that the shielding device is convenient to fix, good in effect, quick and accurate in shielding and high in working efficiency, and manpower resources and consumable cost are saved.

Owner:四川长虹模塑科技有限公司

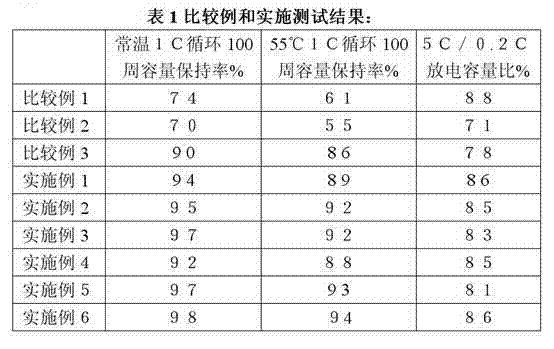

Modified spinel lithium manganate for secondary lithium ion battery and preparation method thereof

InactiveCN102412395AHigh rate characteristicsGood rate characteristicsCell electrodesCarbon coatingCarbon film

The invention is modification of spinel lithium manganate for secondary lithium ion batteries and its preparation method, and is characterized in that the spinel lithium manganate is orderly coated with a silica film and an outer carbon film, which forms a composite material with a spinel lithium manganate-silica-carbon three-layer core-shell structure. The coating is performed by a sol-gel method and a solid phase coating method respectively. The composite material with the three-layer core-shell structure has excellent rate capability, and has a 5C / 0.2C discharge capacity ratio of up to 86%. The normal-temperature and high-temperature cycle performance are greatly improved; the capacity retention rate for 100 cycles of normal-temperature 1C is up to 98%; the capacity retention rate for 100 cycles of 55 DEG C 1C is up to 94%, such as a modified spinel lithium manganate material coated with Li1.04Al0.05Mn1.95O4 body-5 wt% silica coating-5 wt% carbon coating. The problems of unstable cycle performance and poor rate capability of the spinel lithium manganate for secondary lithium ion batteries are effectively solved. The preparation method of the invention is simple and practical, low in cost, and is applicable to large-scale production.

Owner:WUXI LITAI ENERGY TECH

Aqueous marking ink composition

InactiveUS20120316276A1Suitable and good wetting propertyLow viscosityMaterial nanotechnologyInksMarking InkAlcohol

An aqueous marking ink composition that contains at least 1 to 20% by mass of a resin which is water-soluble and has a hydrophobic part in a molecule thereof, a colorant containing at least 5 to 30% by mass of titanium oxide, 0.05 to 2% by mass of at least one selected from acetylene glycols, acetylene alcohols or derivatives thereof, 1 to 20% by mass of a water-soluble solvent having a vapor pressure of 5 mmHg or less at 25° C. and water. The composition can provide good wetting property to a non-absorbing surface of metals, resins and the like stained with oils, can write smoothly thereon at a low viscosity without being repelled to make it possible to obtain drawn lines having a high masking property and a high fixing property, and is readily redispersed by a simple stirring operation.

Owner:MITSUBISHI PENCIL CO LTD

Double-face isomeric novel curtain textile and production process

InactiveCN101724973AIncrease the proportionStrong reflexesWarp knittingCurtainsOptical propertyUser privacy

The invention discloses a functional home textile product and a spinning process thereof, in particular a double-face isomeric single-layer curtain textile capable of transmitting light, resisting ultraviolet rays and preventing snooping. A special organization structure and parameters are designed by utilizing the good optical properties of profiled cross sections and extinction polyester filament yarns, and different raw materials are covered on the front face and the back face of the textile respectively in the forms of coils and drawn tows so as to ensure that the front face and the back face of the curtain obtain optical property differences; and then different structural characteristics are combined so as to finally have the effects of achieve the functions of indoor normal lighting, ultraviolet rays resistance and user privacy protection.

Owner:陈慰来 +1

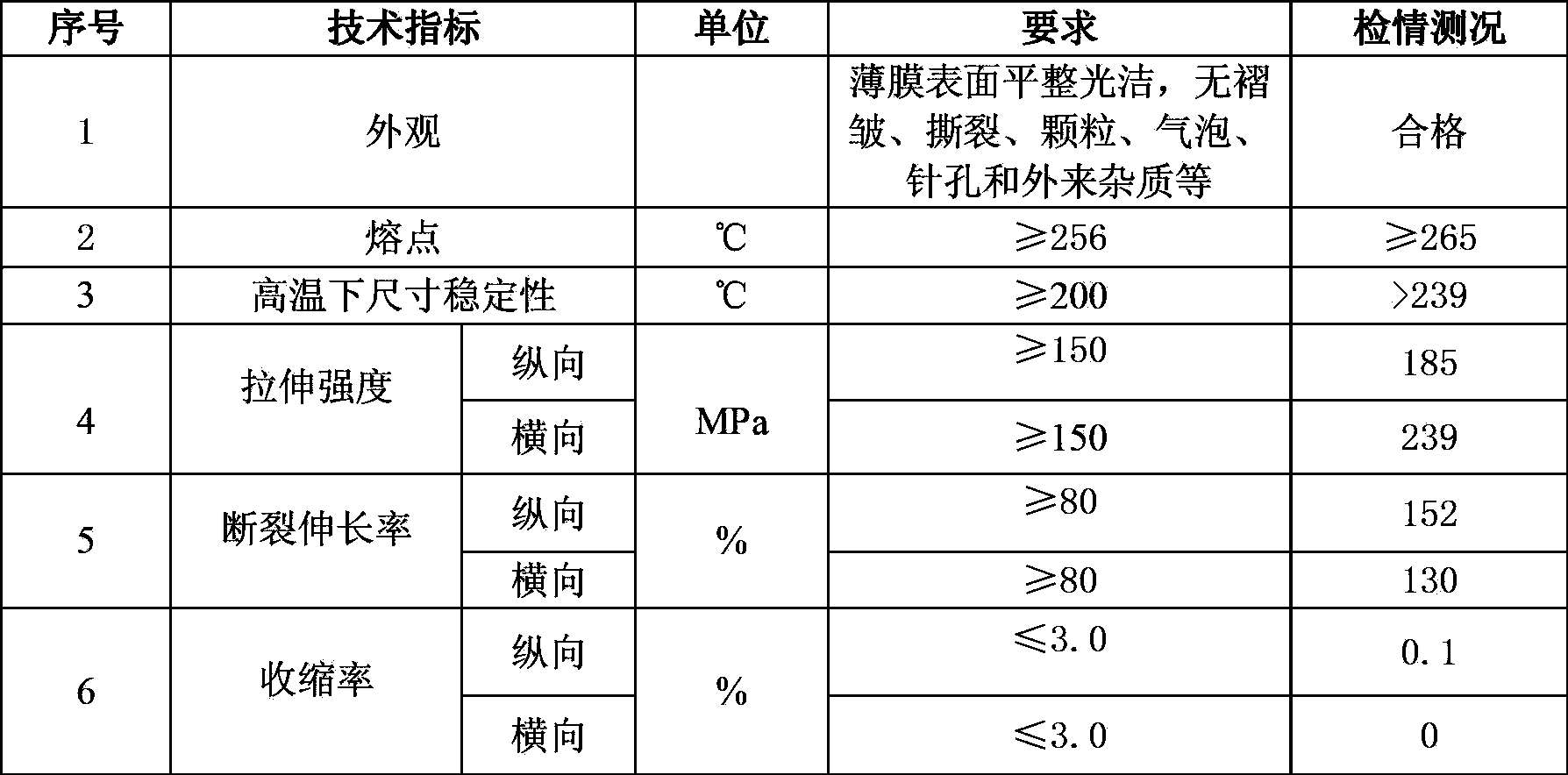

Ultrathin polyester film and manufacturing method thereof

An ultrathin polyester film is composed of a membrane-grade polyester slice and a polyester master batch slice, wherein the membrane-grade polyester slice accounts for 60% to 80% of the total weight of the ultrathin polyester film, and the polyester master batch slice accounts for 20% to 40% of the total weight of the ultrathin polyester film. The manufacturing method of the ultrathin polyester film is provided with corresponding special technological parameters in the processes of melt extrusion, roller cooling, longitudinal stretching, and horizontal stretching. The raw materials of the ultrathin polyester film contain a titanium homogeneous catalyst, so the ultrathin polyester film can be applied to the field of food package such as cooked food package, candy package, package for various kinds of foods, and the like, and is environment-friendly and nontoxic. Corresponding technological conditions are set in the production process of the polyester film product so as to achieve the product characteristics of high transparency, non-toxicity, no odor, high chemically-resistant performance, high temperature resistant performance, high corrosion resistant performance, good shielding performance on ultraviolet lights, and good oxygen gas obstructing performance.

Owner:TIANJIN SHIQI TECH DEV

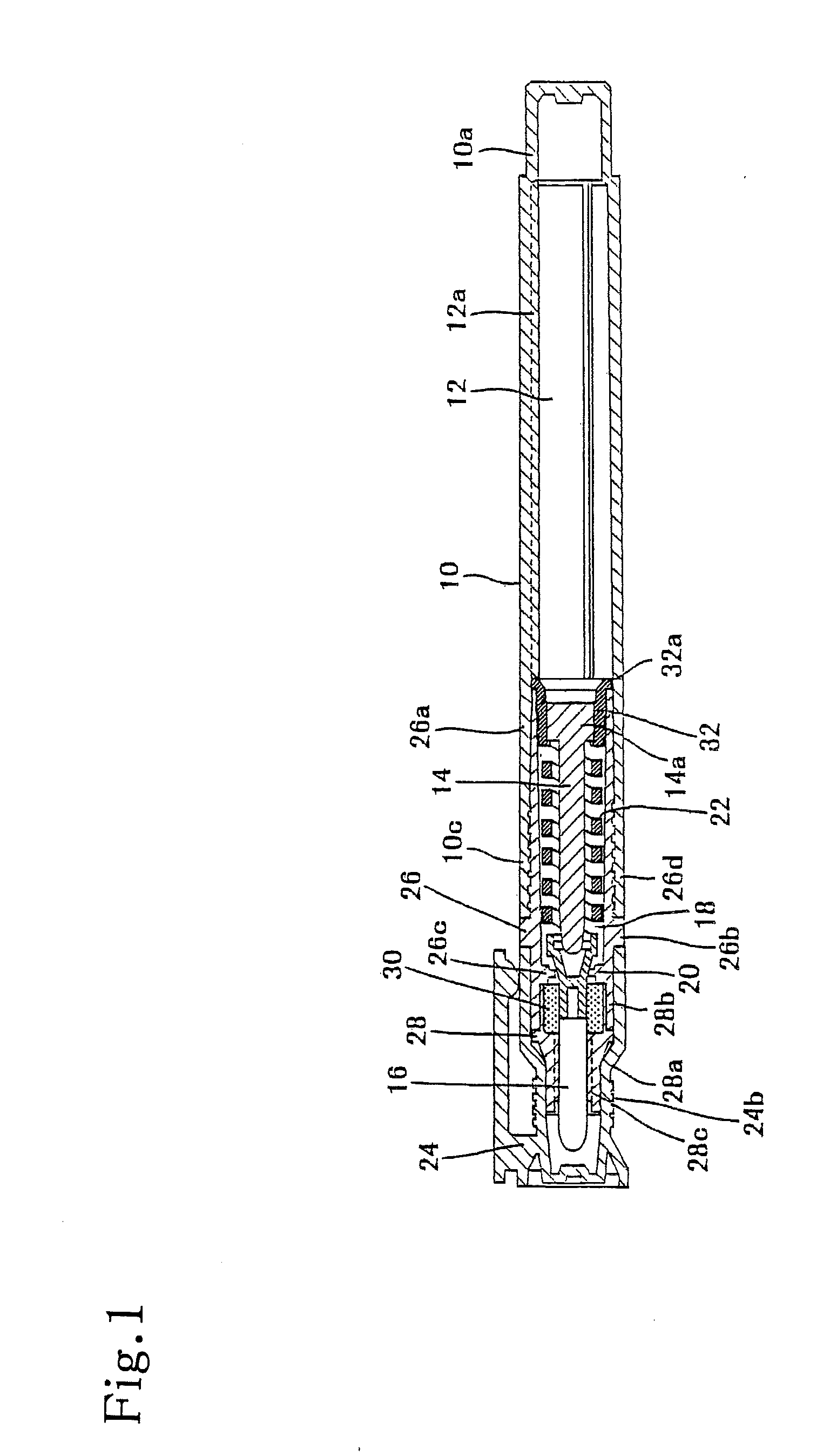

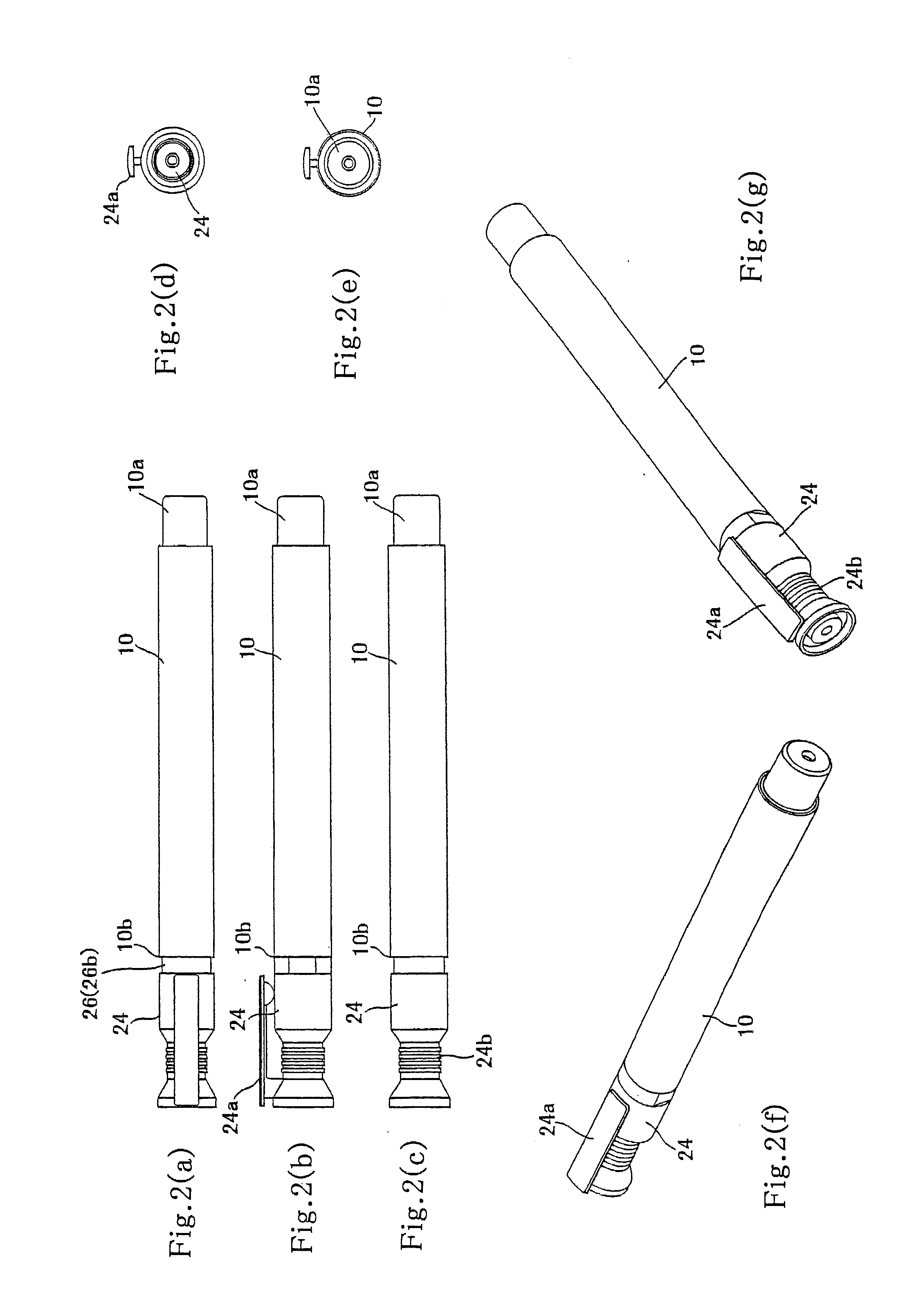

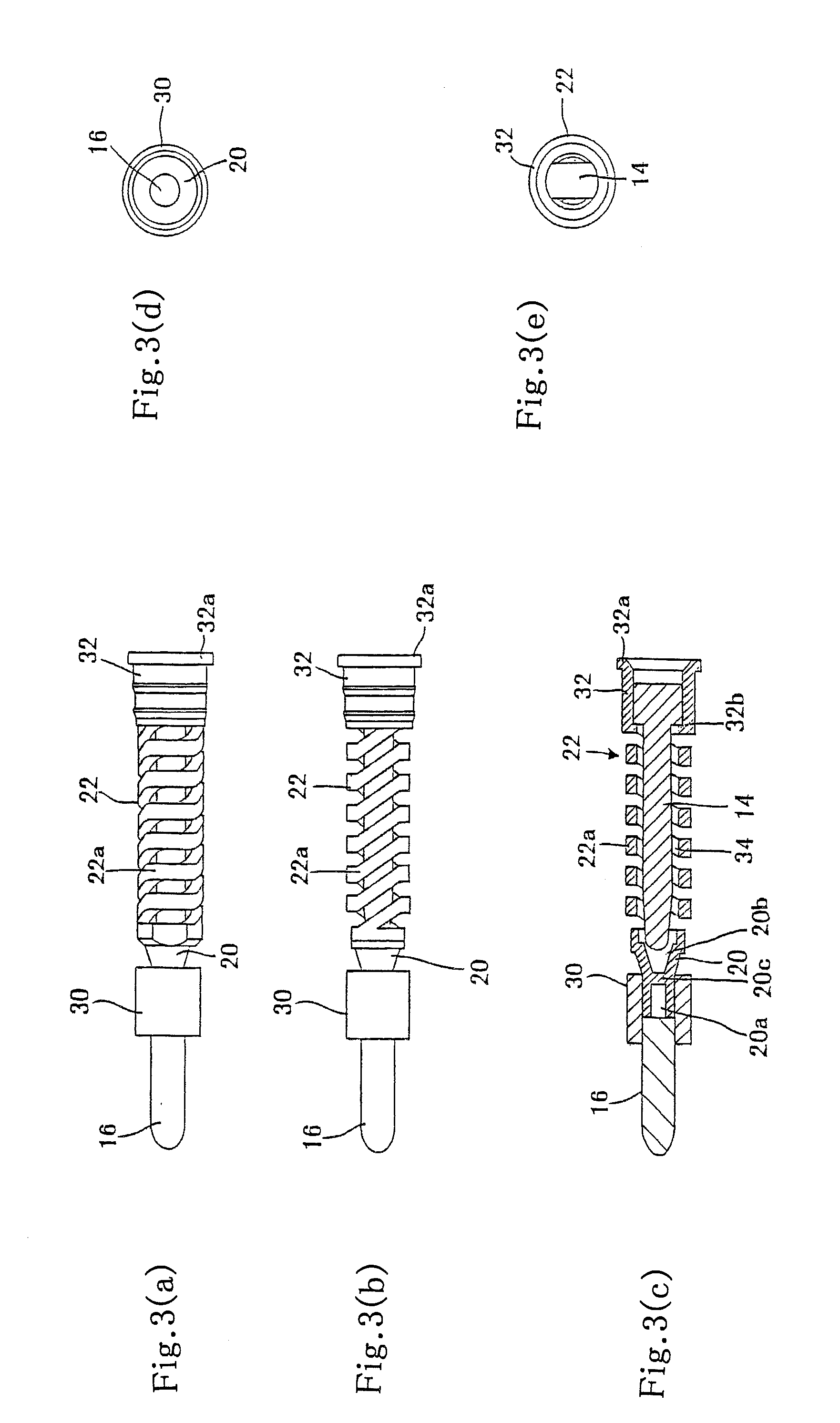

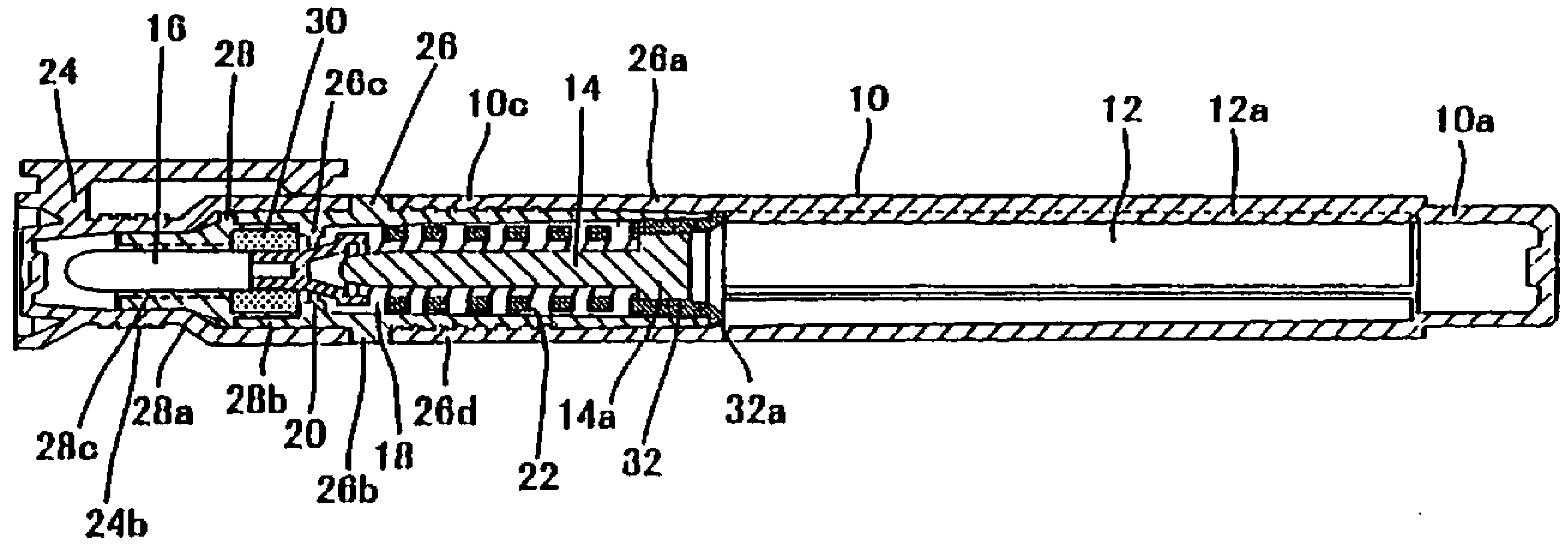

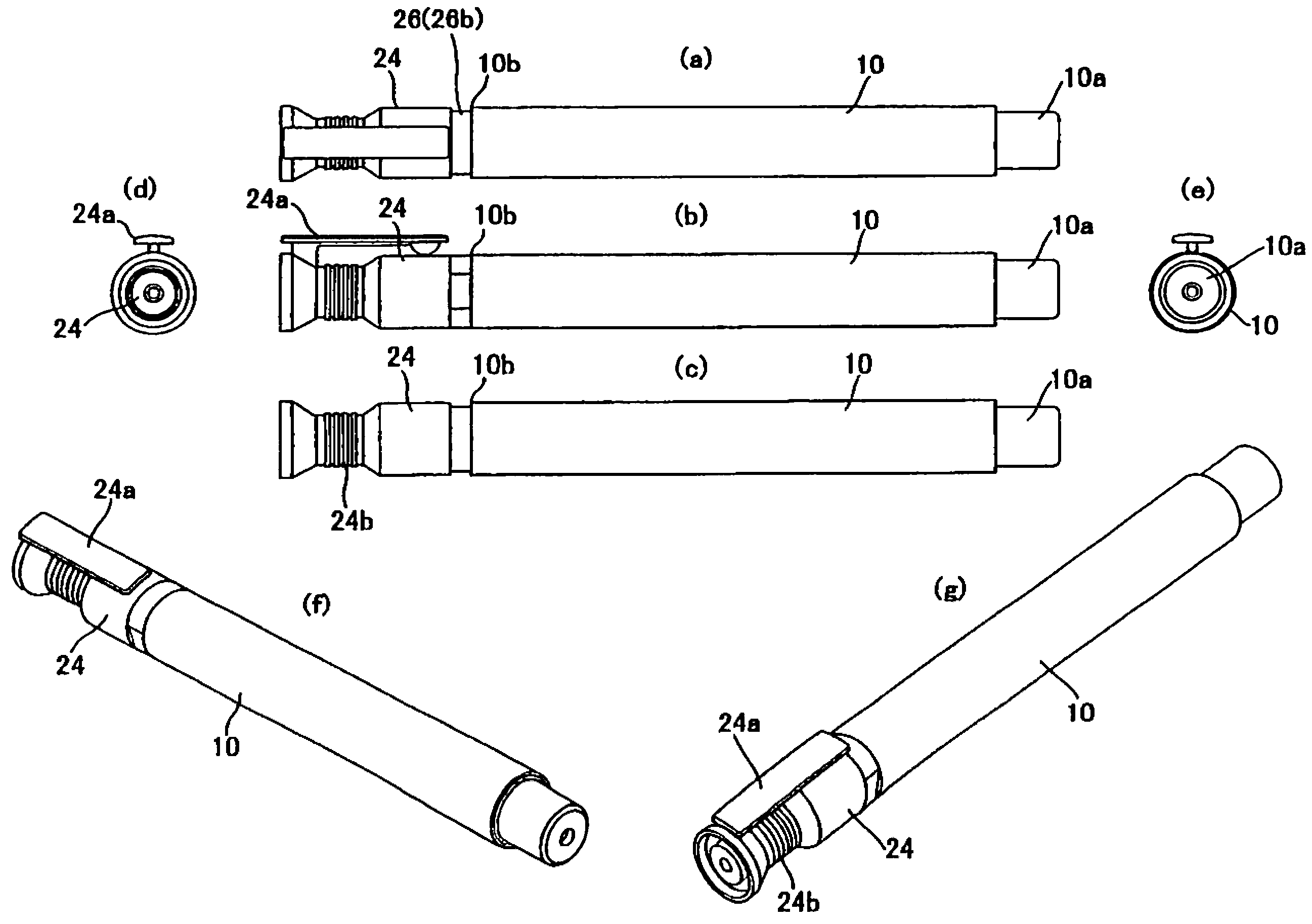

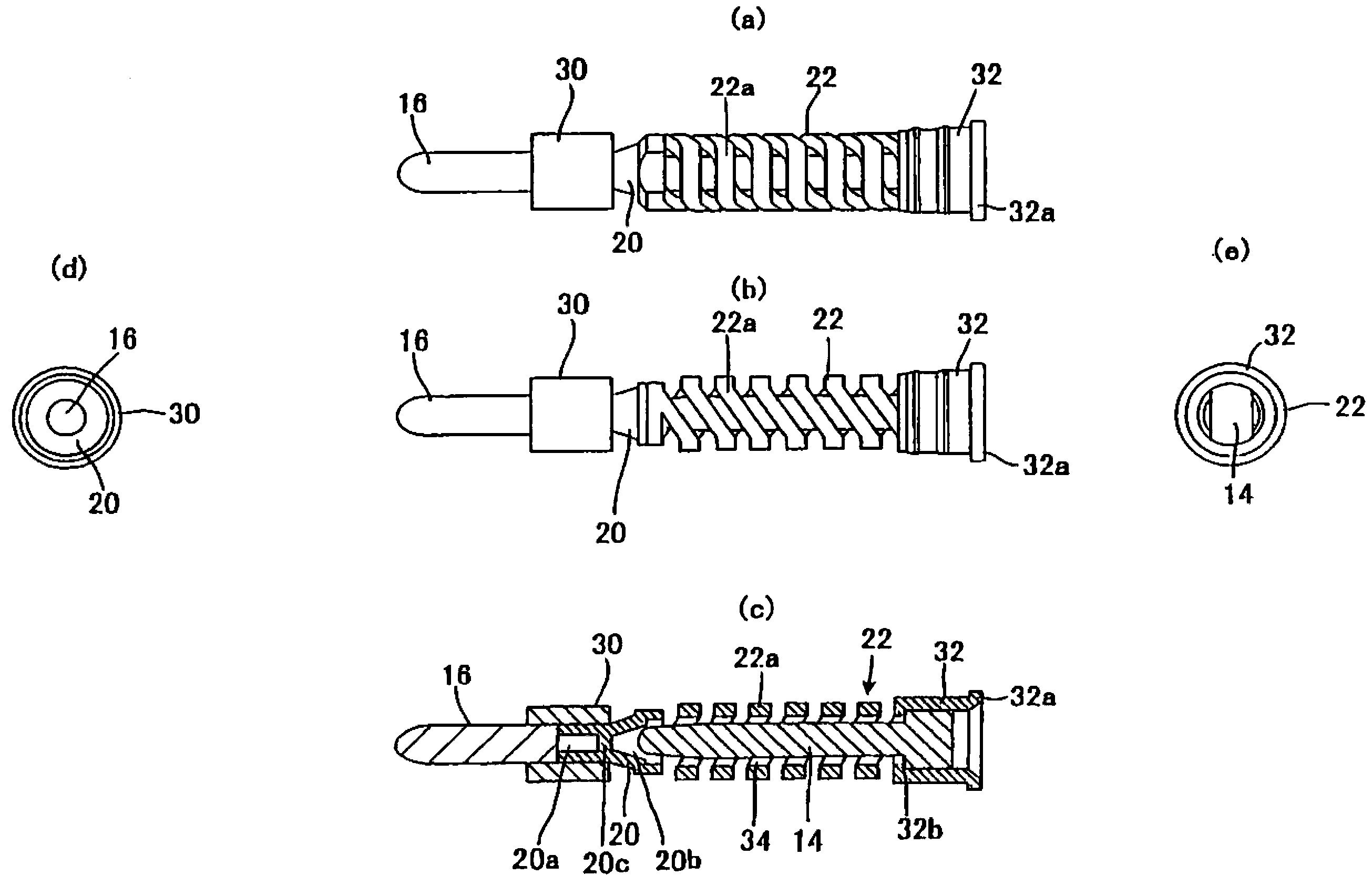

Masking tool for evaporation of electrodes of micro-mechanical quartz sensor

ActiveCN103668054ASimple structureReduce alignment fixationVacuum evaporation coatingSputtering coatingEvaporationEngineering

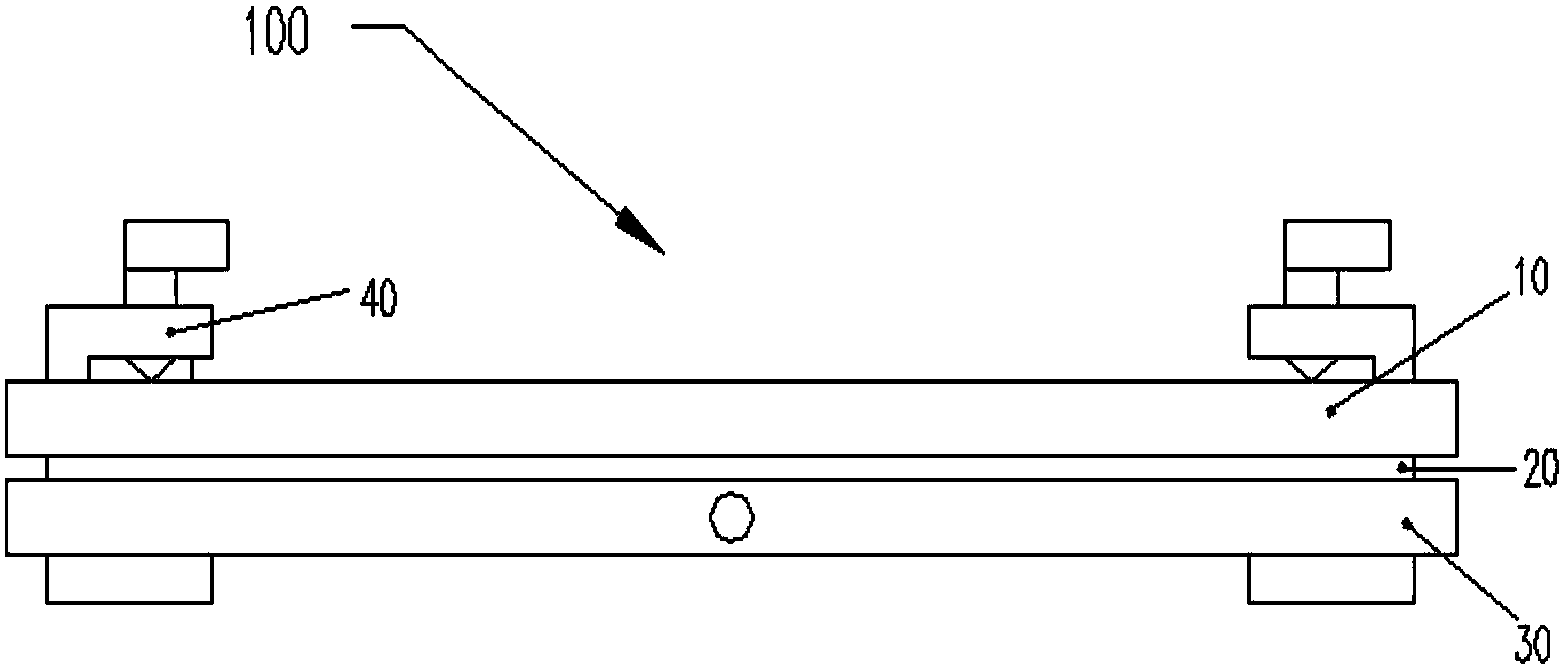

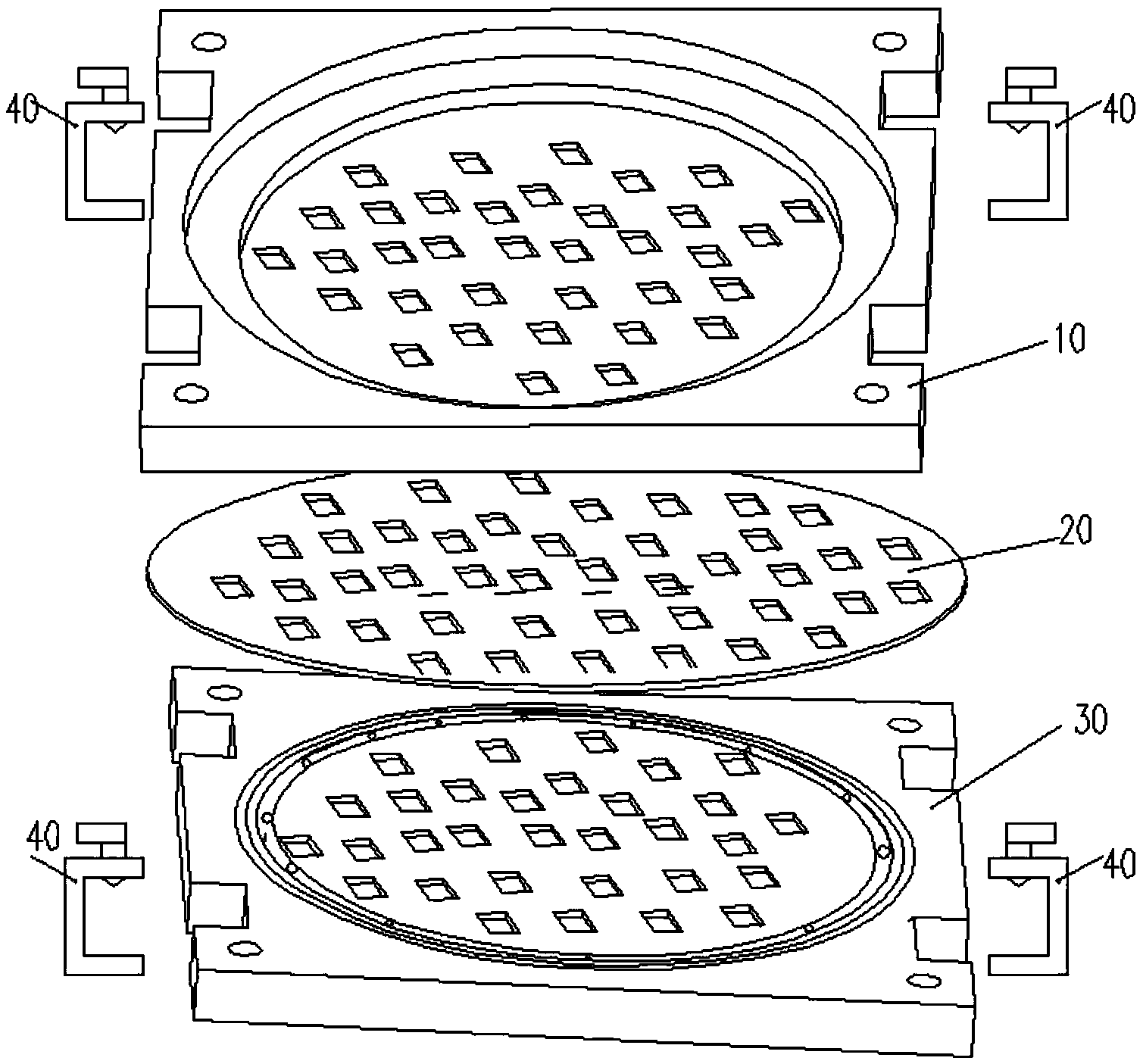

The invention discloses a masking tool for evaporation of electrodes of a micro-mechanical quartz sensor. The masking tool comprises an upper masking plate (10), a lower masking plate (30) and fixing fixtures (40), wherein the upper masking plate (10) comprises a first frame (1) and a first sheet (3); the lower masking plate (30) comprises a second frame (5) and a second sheet (8); the second sheet (8) is fixed on the upper surface of the second frame (5) through laser welding; air suction holes (4) are transversely formed in the second frame (5); air suction grooves (7) are formed in positions, which are close to the outer edge of the second sheet (8), of the second frame (5) circumferentially and communicated with the air suction holes (4); and the upper masking plate (10), a to-be-machined substrate (20) and the lower masking plate (30) are sequentially fixed through the fixing fixtures (40). The masking tool is simple in structure, convenient to machine and capable of well realizing two-sided masking evaporation of the electrodes.

Owner:BEIJING RES INST OF TELEMETRY +1

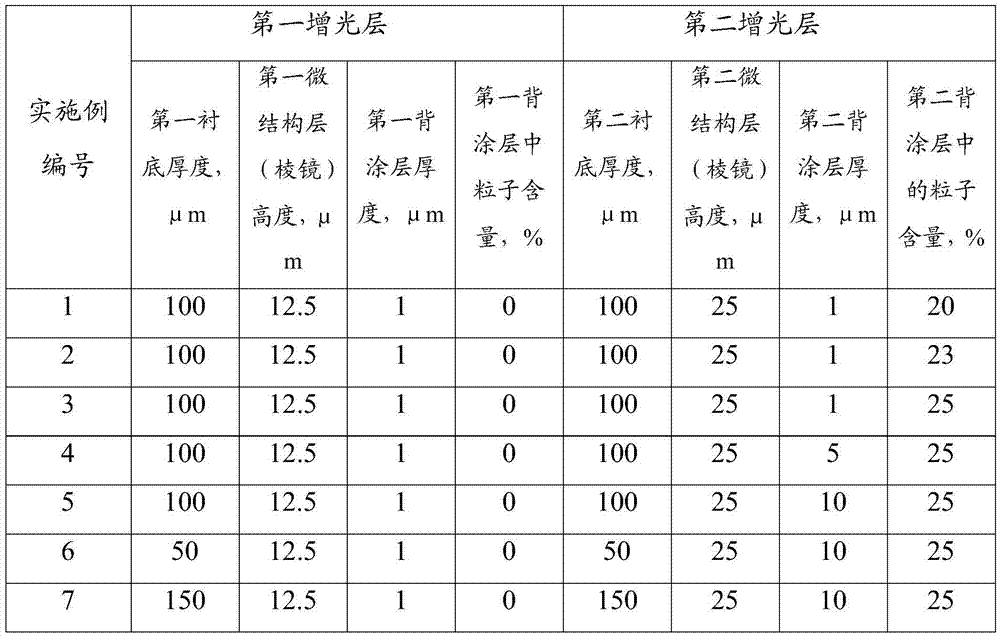

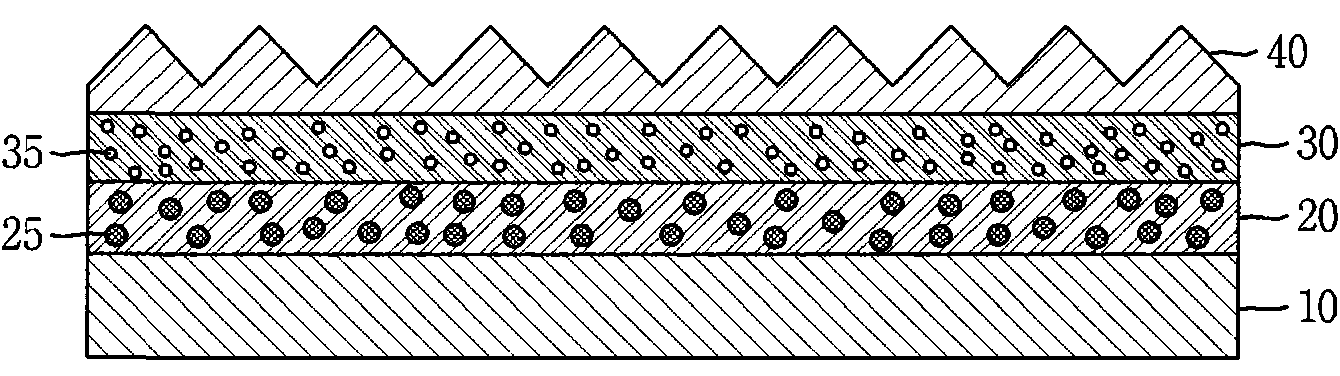

Composite brightness enhancement film and preparation method thereof

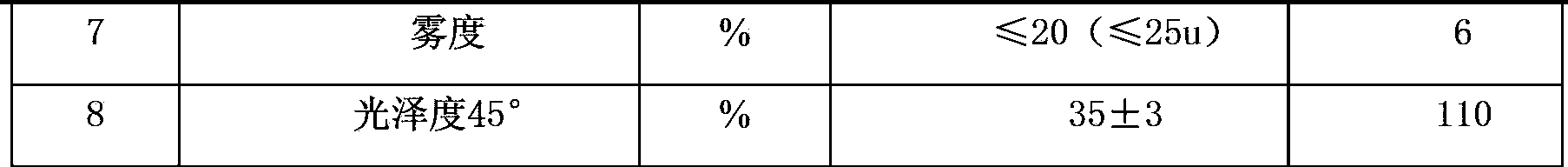

ActiveCN106908865AImprove brightening effectGood masking effectDiffusing elementsNon-linear opticsOptoelectronicsUltimate tensile strength

The invention relates to a film for optics, and especially relates to a composite brightness enhancement film and a preparation method thereof to solve the problem that a conventional brightness enhancement film can only gather light in a single direction. The composite brightness enhancement film comprises a first brightness enhancement layer and a second brightness enhancement layer. The first brightness enhancement layer comprises a first substrate, a first microstructure layer and a first back coating layer, wherein the first microstructure layer is arranged on the first substrate, and the first back coating layer is arranged under the first substrate. The second brightness enhancement layer comprises a second substrate, a second microstructure layer and a second back coating layer, wherein the second microstructure layer is arranged on the second substrate, and the second back coating layer is arranged under the second substrate. The first back coating layer is adhered to the second microstructure layer, so that the first brightness enhancement layer and the second brightness enhancement layer are compounded together. The composite brightness enhancement film exhibits a good brightness enhancement effect and a good shielding effect, and exhibits great peeling intensity and rigidness.

Owner:NINGBO CHANGYANG TECH

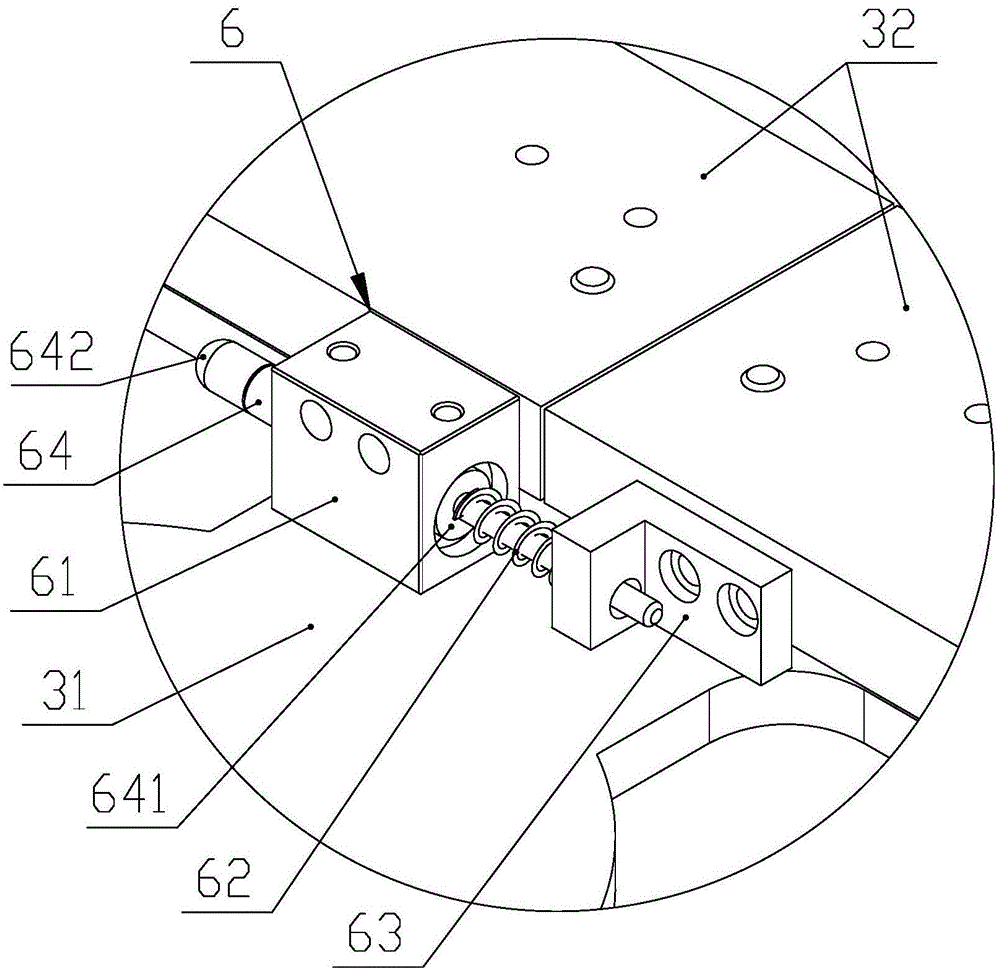

Double-station laser cutting workbench

InactiveCN106392345APossess self-displacement repair abilityGuaranteed flexibility and agilityLaser beam welding apparatusEngineeringLaser cutting

The invention discloses a double-station laser cutting workbench comprising a base, a working platform, a locating mechanism, a driving cylinder and a safety door mechanism; the bottom of one end of the working platform is fixedly provided with at least two slide blocks, the bottom of the other end of the working platform is provided with a V-shaped guide wheel, and a linear guide rail and a V-shaped guide rail are respectively fixed at two ends of the upper surface of the base; a central mounting seat is fixed at the outer side of the end, provided with the slide block, of the working platform, and the middle part of the driving cylinder is mounted in the central mounting seat; the locating mechanism further comprises a locating cylinder and a locating plate, and the front end of the working platform is fixedly provided with at least two regulating seats arranged in parallel; and the safety door mechanism further comprises an overhead door, a connecting stack and a lift cylinder, two ends of the working platform are provided with shielding plates connected with a safety door, and a viewing window is formed in the overhead door. According to the double-station laser cutting workbench, a way that the linear guide rail and the V-shaped guide rail are combined is adopted, and a power cylinder of the double-station laser cutting workbench adopts a way of connecting the center of the central mounting seat, so that the working platform has the self-compensation repair capacity in the reciprocating motion process, and the clamping phenomenon is avoided.

Owner:SUZHOU LEAD LASER TECH

Photosensitive resin composition, photosensitive resin laminate, method for forming resist pattern, conductive pattern, and method for manufacturing printed wiring board

ActiveCN102144189BExcellent peelabilityHigh definition printingSolid-state devicesPhotosensitive material processingArylResist

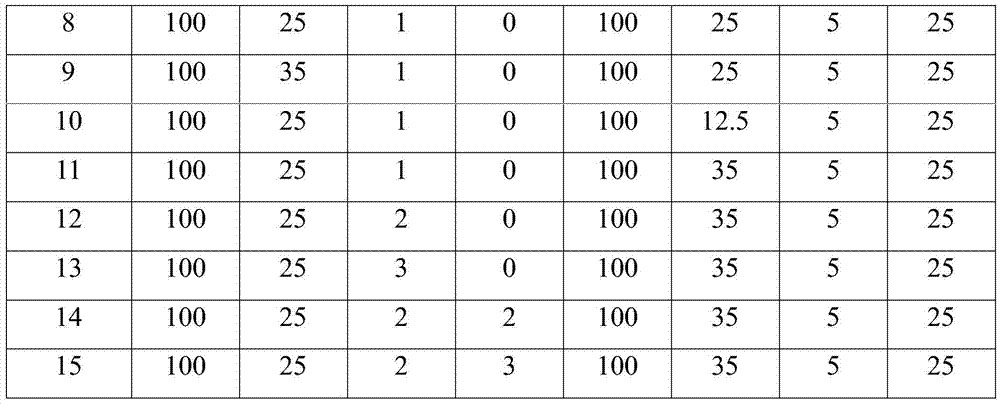

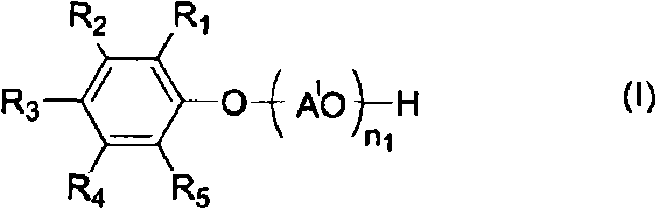

A photosensitive resin composition providing excellent resolution, adhesion, tinting properties and releasability. The photosensitive resin composition contains (a) a thermoplastic polymer obtained by polymerizing, as a polymerization component, at least a,ß-unsaturated carboxyl group-containing monomer, and having an acid equivalent weight of 100-600 and a weight average molecular weight of 5,000-500,000, (b) an addition-polymerizable monomer having at least one polymerizable ethylenically unsaturated bond in each molecule, (c) a photopolymerization initiator and (d) a compound represented by general formula (I). (In the formula, R1-R5 independently represent an H, an aryl group or an arylalkyl group, and at least one of R1-R5 represents an aryl group or an arylalkyl group; A1 represents C2H4 or C3H6, and when n1 is not less than 2, the plurality of A1's may be the same as or different from each other; and n1 represents an integer of 1-50.)

Owner:ASAHI KASEI KK

Preparing method of digital printing shading fabric

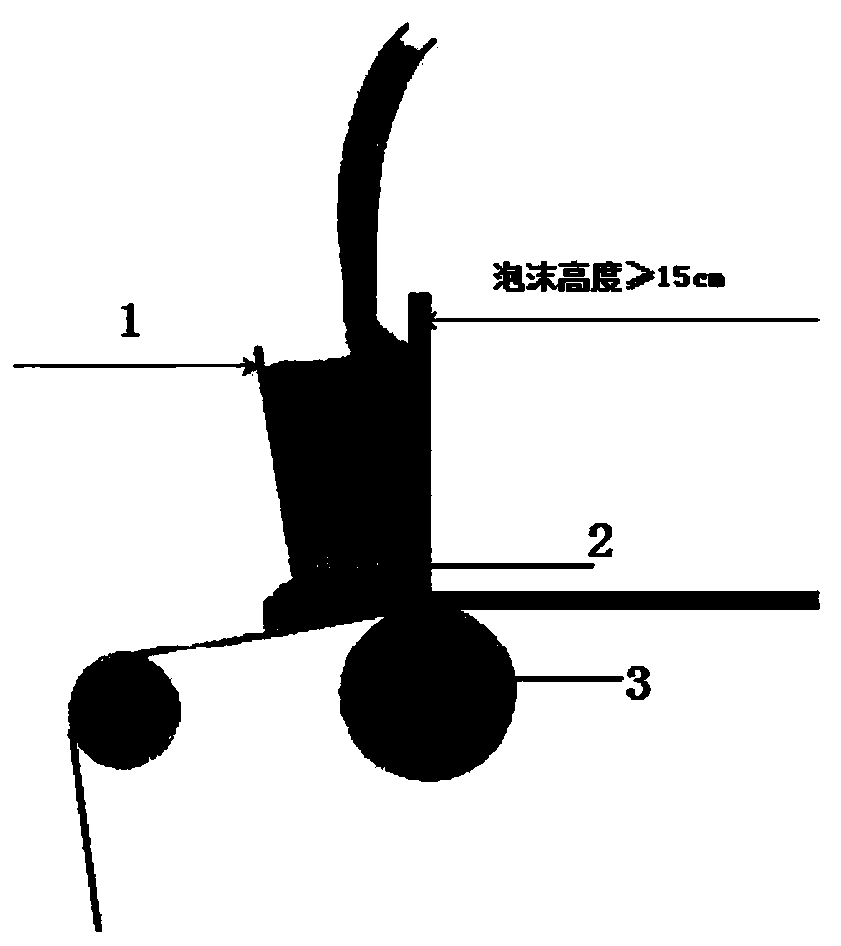

InactiveCN110592964AGuaranteed stabilityHigh occlusion rateCoatingsTextiles and paperWater basedSlurry

The invention belongs to the field of advertising materials, and relates to a preparing method of a digital printing shading fabric, in particular to water-based acrylate resin and a modified polymer-based high-flame-retardance full-shading advertising material thereof. The method includes the step of preprocessing a warp knitting fabric, scrape-coating one side of the warp knitting fabric with alayer of white slurry foamed through a foaming process, then a layer of black slurry foamed through the foaming process and finally a layer of qualified foam foamed through the foaming process or directly coating one side of the warp knitting fabric with transparent slurry through a direct-coating process, wherein the parameters of a foaming machine include the foam density of 250-400 g / L and themachine speed of 20-30 m / min. The prepared digital printing shading fabric has the advantages of being slightly elastic, high in softness and firmness and 100% high in shading; the most importantly, apattern to be digitally printed or printed is stable in image size and not prone to deformation, and images are of more textural quality due to the clear fabric surface.

Owner:浙江亦阳新材料有限公司

Transfer sheet

InactiveCN1929992AImprove stabilityGood masking effectStampsDuplicating/marking methodsImage formationTitanium oxide

A transfer sheet comprising a base material and, detachable therefrom, a transfer layer, wherein the transfer layer is composed of an adhesive layer provided on one major surface of the base material and, superimposed on the adhesive layer, a hiding layer containing a hiding agent and a binder resin optionally having a crosslinking group, and wherein the transfer layer has an elongation at breaking point regulated for >=30% (for example, 30 to 200%). The hiding layer may be composed of a white pigment, such as titanium oxide, and a urethane resin optionally having an isocyanate group. This transfer sheet may have an image receiving layer containing at least urethane resin particles superimposed on the hiding layer. Further, an anchor layer may be disposed between the hiding layer and the image receiving layer. This transfer sheet may be one wherein images can be formed by transfer from a recording sheet having images recorded in advance. The provided transfer sheets may be used in image formation through transfer onto a colored transfer subject.

Owner:DAICEL CHEM IND LTD

Multi-functional optic sheet

InactiveCN101883995ASpread evenlyIncrease brightnessPrismsDiffusing elementsLiquid-crystal displayPrism

Disclosed is a multifunctional optical sheet for use in liquid crystal displays, which can exhibit appropriate hiding performance while realizing luminance equivalent to that of a conventional case in which a prism sheet is layered on a light diffusion member, thus reducing the number of sheets to be mounted in a backlight unit.

Owner:KOLON IND INC

Aqueous marking ink composition

ActiveCN102762675AHigh shieldingImprove fixation effectInksOriginals for photomechanical treatmentAcetylenic alcoholSolvent

Provided is an aqueous marking ink composition with which it is possible to write smoothly with low viscosity on non-absorbent surfaces, such as metals and resins, that are greased with oil, such as cutting oil and lubricating oil, while having suitable and favorable wettability and without being repelled; with which it is possible to draw lines having excellent masking characteristics and excellent adherence; in which the masking agent can be re-dispersed easily by a simple stirring operation even if the masking agent settles out over time; which has excellent masking characteristics and stability; and especially which can be stirred easily even with a stirring element having a low specific gravity. The disclosed aqueous marking ink composition contains at least: 1-20% by mass of a water-soluble resin having a hydrophobic moiety in a molecule thereof; a coloring agent containing at least 5-30% by mass of titanium oxide; 0.05-2% by mass of at least one compound selected from acetylenic glycols, acetylenic alcohols, and derivatives thereof; 1-20% by mass of a water-soluble solvent having a vapor pressure of at most 5 mmHg at 25 DEG C; and water.

Owner:MITSUBISHI PENCIL CO LTD

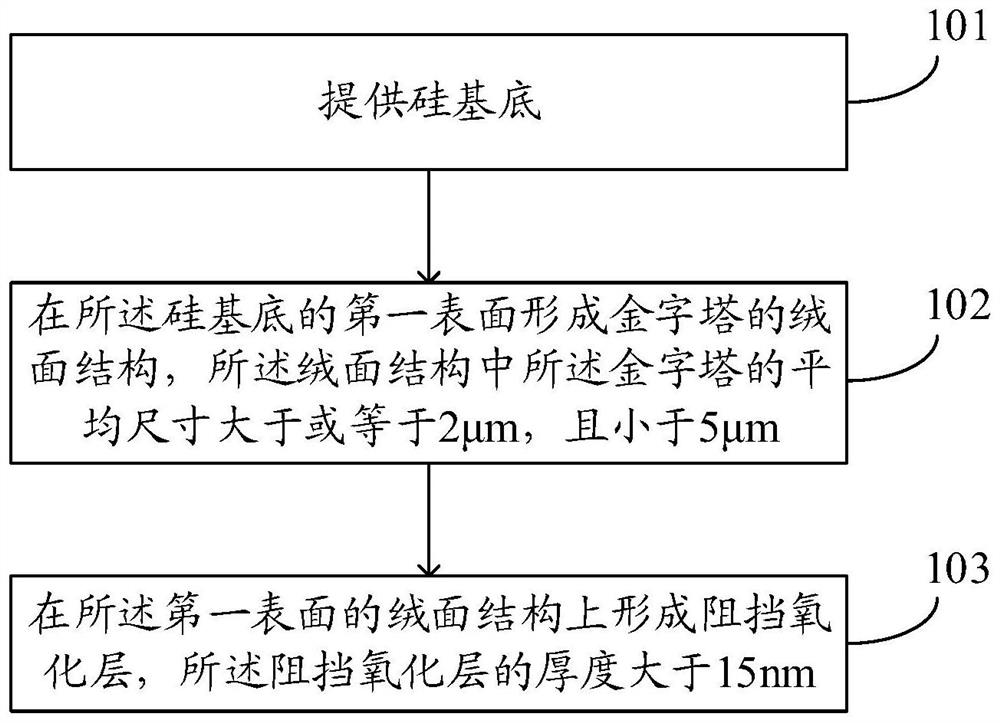

Production method of solar cell and solar cell

InactiveCN112635591APerformance impactImprove efficiencyFinal product manufacturePhotovoltaic energy generationSolar cellBattery cell

The invention provides a production method of a solar cell, and relates to the technical field of solar photovoltaics. In the process of producing the solar cell, an average size of pyramids in a textured structure of a first surface of a silicon substrate is controlled to be larger than or equal to 2 microns and smaller than 5 microns, and due to the fact that the average size of the pyramids is large and the pyramids are distributed dispersedly, the reflectivity of the silicon substrate is ensured to be low and light absorption is good through a pyramid structure. Damage to the textured structure in the process of forming a barrier oxide layer with a thickness greater than 15nm on the textured structure can be avoided, at the moment, the thickness of the barrier oxide layer can achieve a good mask effect, the influence of the thick oxide layer on the performance of the solar cell is also avoided, and the efficiency of the solar cell is significantly improved.

Owner:LONGI SOLAR TECH (TAIZHOU) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com