Modified spinel lithium manganate for secondary lithium ion battery and preparation method thereof

A technology of spinel lithium manganese oxide and lithium-ion batteries, which is applied in battery electrodes, circuits, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1: LiMn 2 o 4 Bulk - 5wt% SiO 2 Coating-2wt% carbon (glucose as carbon source) coating composites preparation and electrochemical performance testing.

[0042] Prepare LiMn by comparative example 1 method 2 o 4 Body material. Weigh LiMn 2 o 4 Body powder 100g, according to SiO after coating 2 Accounting for 5wt% of spinel lithium manganese oxide powder, weigh 17.3g of ethyl orthosilicate, measure ethyl orthosilicate: ethanol: single distilled water = 1:8:10 volume ratio, measure ethanol and deionized water, adjust with ammonia water pH=9, stir in 80°C water bath for 10min, after dissolving into a uniform and transparent tetraethosilicate sol, add the weighed LiMn 2 o 4 The bulk powder is stirred while heating at 100°C to make it fully and uniformly dispersed, and then baked in an oven at 60°C for 12 hours after forming a gel. The dried powder was treated in a muffle furnace at 500 °C for 4 h. After cooling, a spinel lithium manganese oxide material co...

Embodiment 2

[0043] Example 2: LiMn 2 o 4 Bulk-5wt%SiO 2 Coating-5wt% carbon (glucose as carbon source) coating composites preparation and electrochemical performance testing.

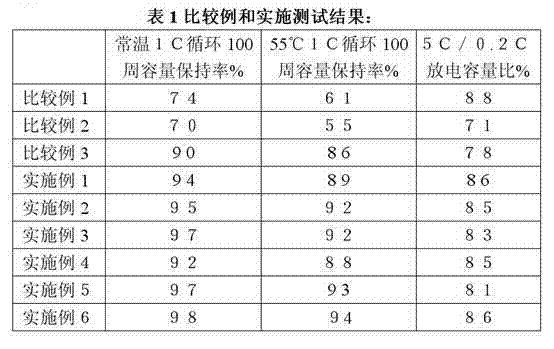

[0044] The final coated carbon accounts for the bulk material LiMn 2 o 4 5wt% of the others, as in Example 1 to prepare spinel lithium manganese oxide-silicon dioxide-carbon three-layer composite material. Compared with Comparative Examples 2 and 3, this material has better cycle performance and rate characteristics. The capacity retention rate after 100 cycles at room temperature is 95%, and the capacity retention rate at 55 °C is 92%. The cycle performance is better than that of the examples. 1 has been further improved, but the rate characteristic has declined slightly, and the discharge capacity ratio of 5C / 0.2C is 85%. The experimental results are shown in Table 1.

Embodiment 3

[0045] Example 3: LiMn 2 o 4 Bulk-5wt%SiO 2 Coating-10wt% carbon (glucose as the carbon source) coating composites preparation and electrochemical performance testing.

[0046] The final coated carbon accounts for the bulk material LiMn 2 o 4 The 10wt% of other preparations of spinel lithium manganate-silicon dioxide-carbon three-layer composite material as described in Example 1. A battery was fabricated according to Comparative Example 1 by using the above-mentioned modified spinel lithium manganese oxide material. Compared with Example 2, the cycle performance is further improved. The capacity retention rate after 100 cycles at room temperature is 97%, the capacity retention rate at 55 °C high temperature is 92%, the 5C / 0.2C discharge capacity ratio is 83%, and the rate performance is slightly reduced. . The experimental results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com