Polymerization emulsion, preparation method thereof, aqueous adhesive, and preparation method and application of aqueous adhesive

A technology of water-based adhesives and polymer emulsions, applied in non-aqueous electrolyte batteries, electrical components, circuits, etc., can solve problems such as technical obstacles, complex processes, and low oxidation resistance of adhesives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

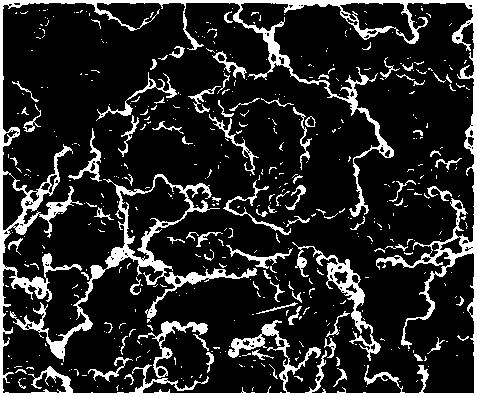

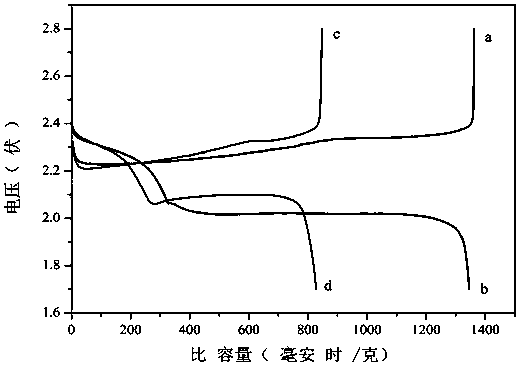

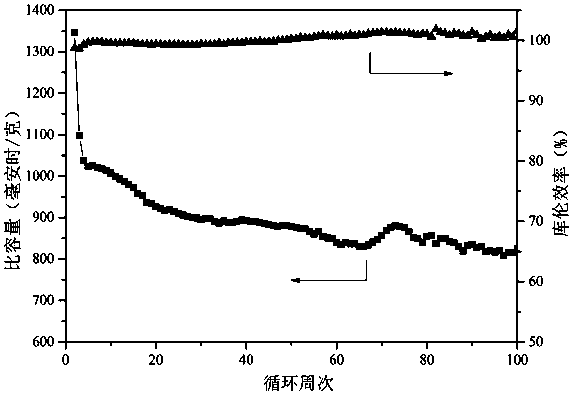

Image

Examples

Embodiment 1~9

[0072] Polymerized emulsion embodiment 1 molecular structure general formula:

[0073]

[0074] Wherein, m=1-100, n==1-100.

[0075] Polymerized emulsion embodiment 2 molecular structure general formula:

[0076]

[0077] Wherein, m=1-100, n==1-100.

[0078] Polymerized emulsion embodiment 3 molecular structure general formula:

[0079]

[0080] Wherein, m=1-100, n==1-100.

[0081] Polymerized emulsion embodiment 4 molecular structure general formula:

[0082]

[0083] Wherein, m=1-100, n==1-100.

[0084] Polymerized emulsion embodiment 5 general molecular structure formula:

[0085]

[0086] Wherein, m=1-100, n==1-100.

[0087] Polymerized emulsion embodiment 6 molecular structure general formula:

[0088]

[0089] Wherein, m=1-100, n==1-100.

[0090] Polymerized emulsion embodiment 7 molecular structure general formula:

[0091]

[0092] Wherein, m=1-100, n==1-100.

[0093] Polymerized emulsion embodiment 8 general molecular structure formula: ...

Embodiment 1~3

[0105] According to the parts by weight of the raw materials in Examples 1 to 3 described in Table 1, first add deionized water, chain transfer agent and sulfonic acid type reactive emulsifier to mix, and add acrylic acid dropwise at a speed of 25mL / min while stirring. The monomer was stirred and pre-emulsified at 800rpm at 20°C for 40min, and nitrogen gas (purity ≥ 99%) was introduced at a flow rate of 50mL / min for 20min to remove O in the pre-emulsion.2 Finally, add a cross-linking agent and an initiator, and conduct a polymerization reaction for 6 hours at 65°C to complete.

[0106] The preparation method embodiment 4 of polymerization emulsion

[0107] According to the parts by weight of the raw materials in Example 4 described in Table 1, first add deionized water, chain transfer agent and sulfonic acid type reactive emulsifier to mix, and add the acrylic monomer dropwise at a speed of 20mL / min while stirring , at 600rpm rotating speed, under 10 ℃, carry out agitation pre...

Embodiment 7

[0111] According to the parts by weight of the raw materials in Example 7 described in Table 1, first add deionized water, chain transfer agent and sulfonic acid type reactive emulsifier to mix, and add the acrylic monomer dropwise at a speed of 30mL / min while stirring , at 1000rpm rotating speed, under 10 ℃, carry out agitation pre-emulsification 50min, feed argon (purity ≥ 99%) 10min with flow rate 70mL / min, remove the O in the pre-emulsion 2 Finally, add a cross-linking agent and an initiator, and polymerize for 5 hours at 60°C to complete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com