Lithium-ion flow battery reactor

A battery reactor and liquid flow battery technology, which is applied in the direction of regenerative fuel cells, battery pack components, fuel cell components, etc., can solve problems such as insufficient air tightness, poor heat dissipation, and poor fluidity of electrode suspensions , to achieve the effects of improving fluidity, increasing effective volume, and improving rate characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with the accompanying drawings, the present invention will be further described through examples.

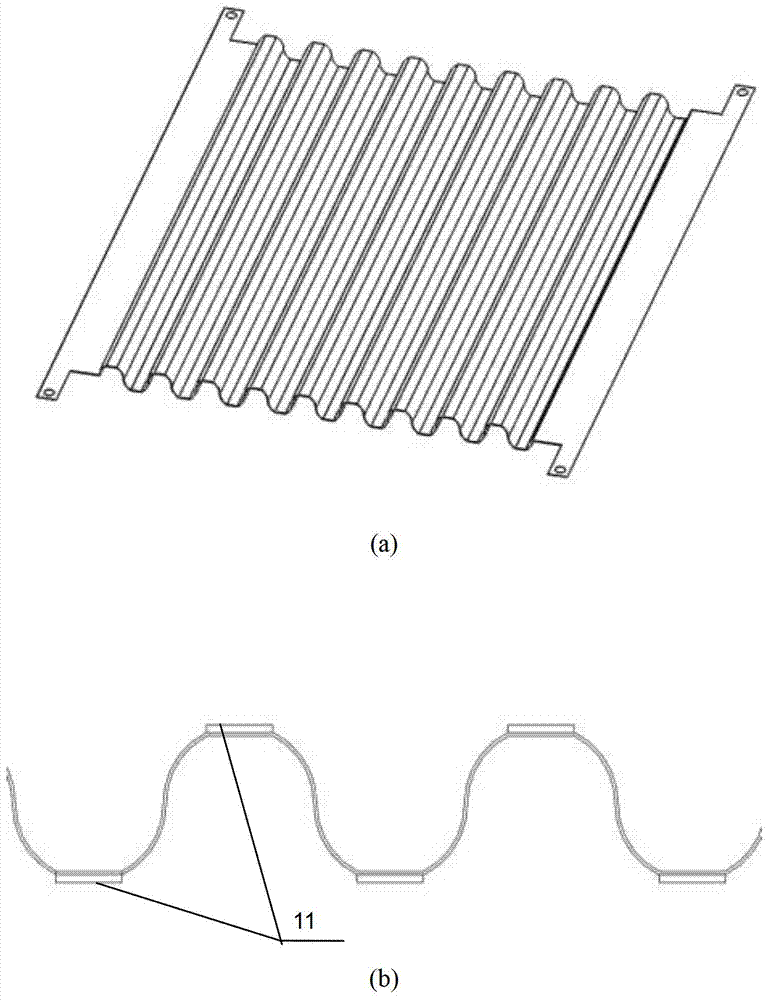

[0040] like figure 1 As shown, the current collecting plate of the present invention is a corrugated plate with straight grooves and is provided with tabs. An insulating layer 11 is coated on the outer side of the convex or concave points of the current collecting plate. In this embodiment, the cross-sectional waveform of the current collecting plate is a sine wave.

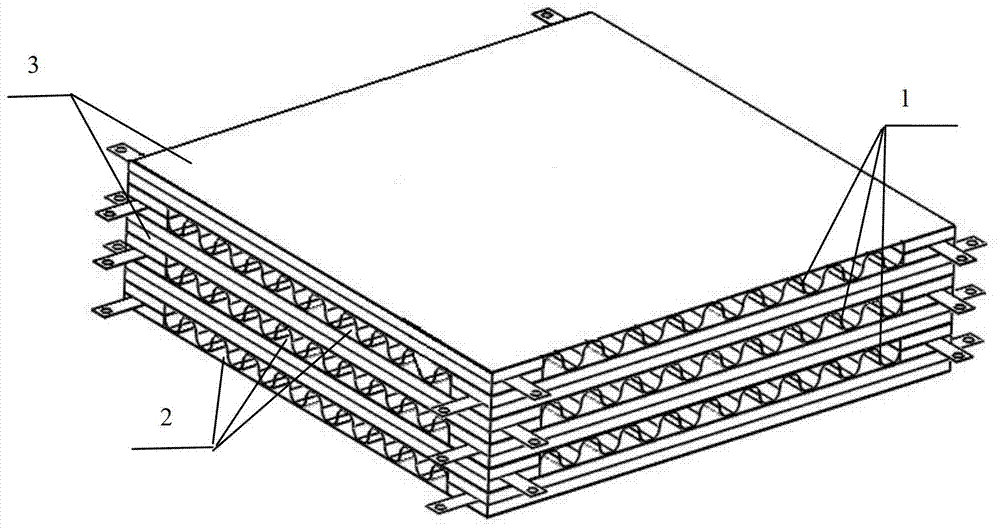

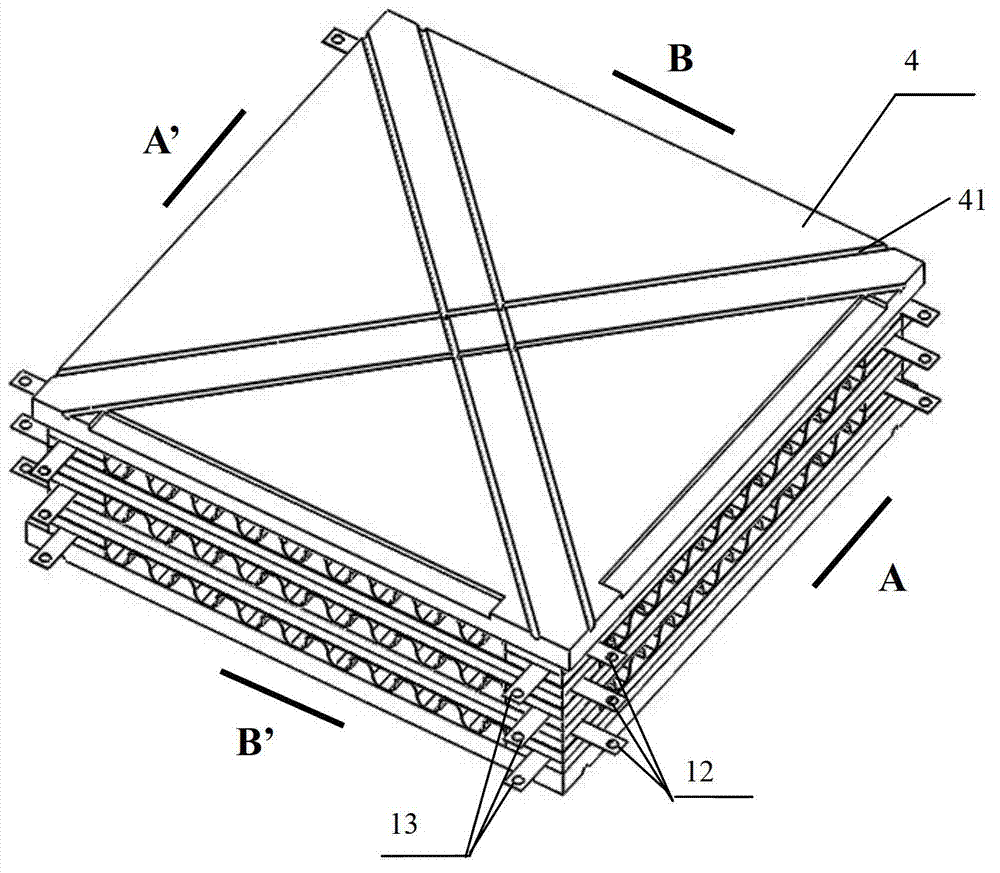

[0041] like figure 2 As shown, the lithium ion flow battery reactor of the present invention includes: a porous diaphragm 3, a positive current collector plate 1 and a negative electrode current collector plate 2, forming a structure in which the positive electrode current collector plate, the porous diaphragm, and the negative electrode current collector plate are superimposed on each other, wherein The positive electrode current collector plate 1 and the negative electrode current ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com