Composite brightness enhancement film and preparation method thereof

A technology of brightness enhancement film and brightness enhancement layer, which is applied in optics, optical components, nonlinear optics, etc., can solve the problem of single brightness enhancement film, and achieve the effects of avoiding electrostatic adsorption, good peel strength and stiffness, and good shielding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

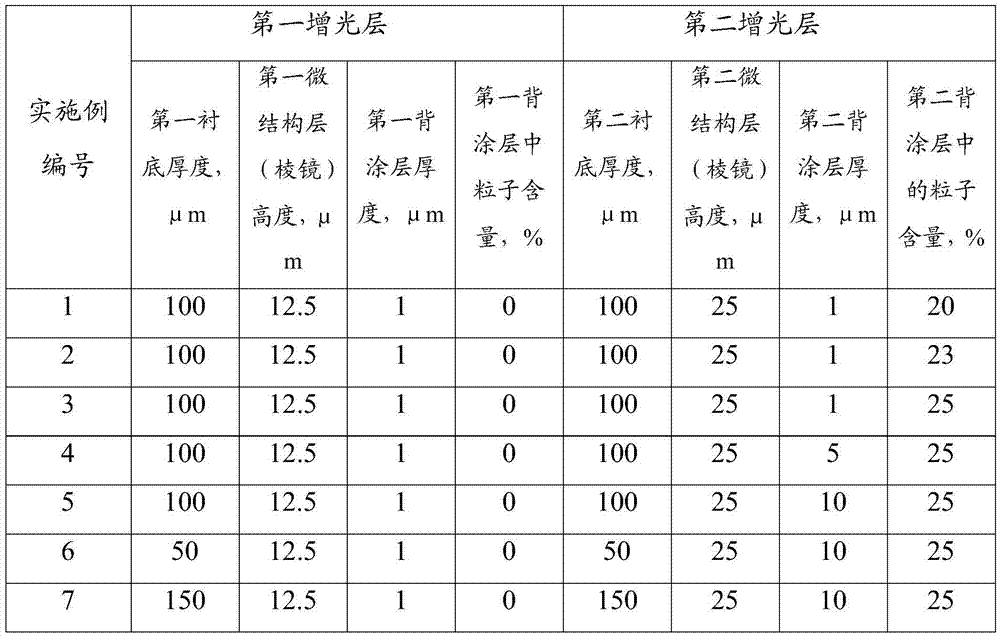

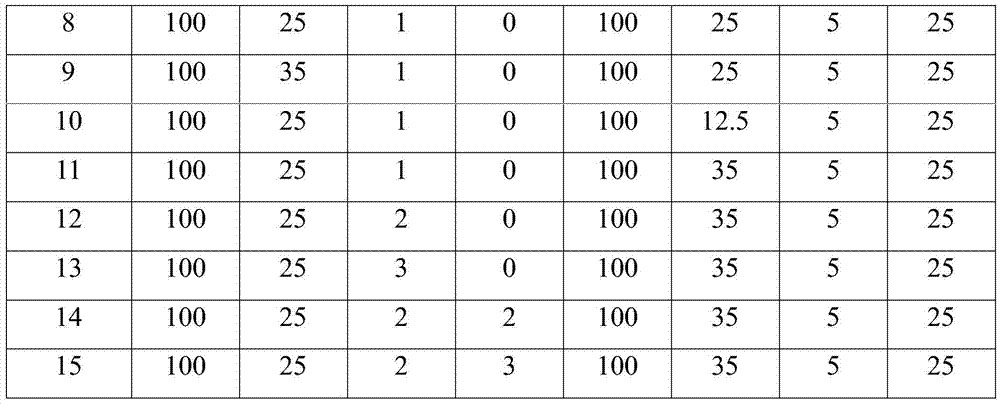

Embodiment 1

[0038] The invention provides a composite brightness enhancement film, wherein,

[0039] Preparation of the second light-enhancing layer: the second substrate is a biaxially stretched polyester film (thickness 100 μm, manufactured by Changyang Science and Technology Co., Ltd., trade name "OSQ2"). One side of the second substrate adopts the off-line coating method, and the coating includes PMMA diffusion particles (Soken Chemical (Suzhou) Co., Ltd., product model KSR-3) and polyurethane acrylate polymer binding resin (produced by DIC Corporation of Japan). ) coating liquid, through UV curing to form the second back coating, after film formation, the thickness of the second back coating is 1 μm, and the content of the diffusion particles is 20%. Then, on the other side of the second substrate, urethane acrylate glue (produced by Shinko Chemical Industry Co., Ltd., product model UB-3331) is passed through the forming roller and the back pressure roller, and UV curing is performed...

Embodiment 2

[0045] For the composite brightness enhancement film provided in Example 1, wherein the second back coating particle content is 23%, the optical properties and mechanical properties of the obtained composite brightness enhancement film are shown in Table 2.

Embodiment 3

[0047] For the composite brightness enhancement film provided in Example 2, wherein the particle content of the second back coating is 25%, the optical properties and mechanical properties of the obtained composite brightness enhancement film are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com