Composite film without base coat and method for preparing composite film

A composite film and primer-free technology, which is applied in chemical instruments and methods, synthetic resin layered products, flexible coverings, etc., can solve the problems of high cost and poor printing fastness, and achieve good anti-aging performance and bright Good whitening effect, high affinity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

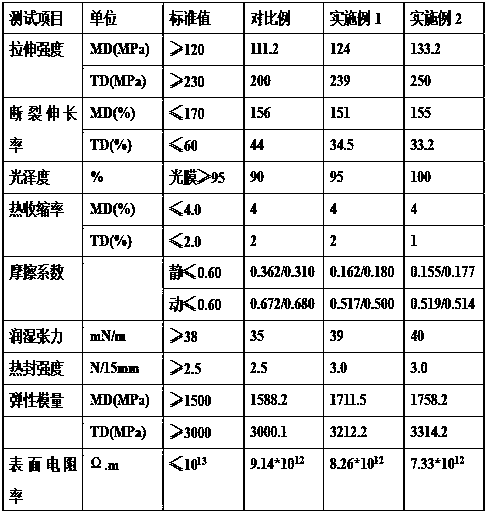

Examples

Embodiment 1

[0021] A kind of primerless composite film, is made up of surface 1 layer, surface 2 layer and core layer;

[0022] The material of the core layer includes by weight fraction: T30S 98.9%, additive AS2335PP 1.10%,

[0023] Table 1 layer includes by weight fraction: FT810 99%, AB6018PPR 1%.

[0024] Table 2 layer includes by weight fraction: H030SG 93.00%, AB6018PP 7.00%.

[0025] The thickness of the composite film is 12 μm, and the mass ratio of the surface 1 layer, the core layer and the surface 2 layer is 1:10:1.

[0026] A method for preparing a primer-free composite film, the steps of which include: adopting a three-layer structure for co-extrusion followed by biaxial stretching molding, and the process parameters are controlled as follows: the temperature of the main extruder is 245-250 °C; the auxiliary extruder I The temperature is 210~240℃, the temperature of the auxiliary extruder II is 210~245℃, the die head temperature is 243℃, the water tank temperature is 30℃, t...

Embodiment 2

[0028] A kind of primerless composite film, is made up of surface 1 layer, core layer and surface 2 layers;

[0029] Table 1 layer includes by weight fraction: FT810 80%, short oil alkyd resin 15%, BYK320 3%, AB6018PP 2%;

[0030] The material of the core layer includes by weight fraction: T30S 95.9%, polyethylene glycol acrylate 3%, additive AS2335PP 1.10%;

[0031] Table 2 layer includes by weight fraction: H030SG 93.00%, AB6018PP 7.00%.

[0032] The thickness of the composite film is 12 μm, and the mass ratio of the surface 1 layer, the core layer and the surface 2 layer is 1:10:1.

[0033] The preparation method is the same as in Example 1, using a three-layer co-extrusion process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com